Professional Documents

Culture Documents

RT Report Format

RT Report Format

Uploaded by

rokan1230 ratings0% found this document useful (0 votes)

34 views1 pageOriginal Title

RT report format

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

34 views1 pageRT Report Format

RT Report Format

Uploaded by

rokan123Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 1

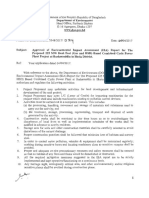

at Radiant Engineering Training

Seeteeaecn RADIOGRAPHIC TESTING REPORT

Limited.(RETSIL) RAPHY ING Rl

[Job No: N/A Project :Boiler tube changing project. Reet

Customer: 1V¥ Trading International Procedure No: RETSILRT [01/2015 Rev. 00 ae pesiiied

[Makers Number: N/A [Drawing Ref: N/A

(Code / Specification: ASMEBSIL Extent of test: Spot Radiography as

[Test Condition: As Welded _ Material: Carbon Steel Seu

[Source Type: X-ray [Source foca Size +2 [Activity N7A [Density : 2-3 [Sensitivity (9%): [rechnique : DWDI

exposure Time: 36 Sec [OL Type: DIN10-16 ql Placement: Film Side

[Screen type :Lead __[Front:0.125 [Back 0.125 _ |Welding process : GTAW Film: AGFA D7 Trype: Roll ral

Weld] Mati | Pipe | 80D] OFD | Welder Ret Result

Weld identification interpretation Remarks] Abbreviation

reference |Thk(mm)|Dia (in)| (in)_| (mm) [Root | cap |'™**"™ Tee | Re

wyswrevensscwrspaieror| 4 | 267 | 38a | 12 | 267 | n/a] nval NSD A NSD=No Significant Defect

‘weae

B | 267 | 381] a2 | 267 | nal nal nso | a ‘SD=t ign Deo

BLANK

Noo Approved Fins0o | Radiograph Taken by. [Ein Tnrproead Cent Representative Rapid

INo of Repair Films: 0 Md Haider Ali

/Md.Masudur Rahman. Md.Masudur | an

LrotatNo.of Films:02___[Date: 27-11-2017 Date: 27-11-2017 Date: Date: ]

rm Md. Masudur Rahman

Mv ASNTLaeelt REUTMTPT

ASNT Levelt REUTMTET Radiant Engineering Training

SLiemcinet tates

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Fork Lift Inspection FormDocument1 pageFork Lift Inspection Formrokan123No ratings yet

- Cable ReelDocument2 pagesCable Reelrokan123No ratings yet

- Levelgauges SightglassesDocument72 pagesLevelgauges Sightglassesrokan123No ratings yet

- Eot Crane Inspection FormDocument1 pageEot Crane Inspection Formrokan123No ratings yet

- ESIA SummaryDocument6 pagesESIA Summaryrokan123No ratings yet

- EIA ApprovalDocument2 pagesEIA Approvalrokan123No ratings yet

- Environmental Monitoring ProgramDocument7 pagesEnvironmental Monitoring Programrokan123No ratings yet

- G SM PPLT Pip 805Document12 pagesG SM PPLT Pip 805rokan123No ratings yet

- Fuel Gas Compressor SystemDocument64 pagesFuel Gas Compressor Systemrokan123No ratings yet