Professional Documents

Culture Documents

Construction of Cast In-Situ Segmental Box Girder (Road, Land Bridge) Rev 05

Uploaded by

Fateh Aliya100%(1)100% found this document useful (1 vote)

637 views126 pagesConstruction of Cast In-situ Segmental Box Girder (Road, Land Bridge) Rev 05

Original Title

Construction of Cast In-situ Segmental Box Girder (Road, Land Bridge) Rev 05

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentConstruction of Cast In-situ Segmental Box Girder (Road, Land Bridge) Rev 05

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

100%(1)100% found this document useful (1 vote)

637 views126 pagesConstruction of Cast In-Situ Segmental Box Girder (Road, Land Bridge) Rev 05

Uploaded by

Fateh AliyaConstruction of Cast In-situ Segmental Box Girder (Road, Land Bridge) Rev 05

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 126

CDBsez

CHINA COMMUNICTIONS CONSTRUCTION

COMPANY

EAST COAST RAIL LINK PROJECT

METHOD STATEMENT

FOR

ACTIVITY : CONSTRUCTION OF CAST IN-SITU

SEGMENTAL BOX GIRDER

(ROAD AND LAND BRIDGE)

: SECTION 4

LOCATION

Document No |: ECRL-S4-BR-MS-0009

Revision No | : 05

Date Issued |: 8 JULY 2021

SC Signature |: Date: (Code:

PREPARED BY | REVIEWED | REVIEWED BY | REVIEWED | APPROVED BY |

BY BY

ANG) tol aw?

AFI On

Puvaneswaran | Liang Jianyuan Liu Bo Liu Liang Feng Rongxian |

‘Senior Engineer | Section QAQC HSE Chief Infrastructure

Manager Manager Engineer Deputy General

Manager

‘CONSTRUCTION OF CAST IN-SITU SEGMENTAL BOX GIRDER

Dee (ROAD AND LAND BRIDGE)

Document No. TECRL-S4-BR-MS-0008

Revision No. 05 Rev. Date [8 JULY 2021

REVISION HISTORY

No.

00 ‘| First Issue 06 AUGUST 2020

01 | Second Issue as Per DRS (ECRL-HSSI-S1-BR- | 04 SEPTEMBER

DRS-0065, 23/8/2020, Rev 00) 2020

02 | Third Issue as Per DRS (ECRL-HSSI-S1-BR- 11 OCTOBER 2020

DRS-0065, 01/10/2020, Rev 01)

03 | Fourth Issue as Per DRS (ECRL-HSSI-S1-BR- | 02 JANUARY 2021

DRS-0065, 23/12/2020, Rev 02)

04 | Fifth Issue as Per DRS (ECRL-HSSI-S1-BR- 28 APRIL 2021

DRS-0065, 23/12/2020, Rev 03)

05 ‘| Fifth Issue as Per DRS (ECRL-HSSI-S1-BR- B JULY 2021

DRS-0065, 27/6/2021, Rev 03)

Construction of Cast in-Situ Segmental Box Girder

(Road And Land Bridge)

ECRL-S4-BR-MS-0008 & Rev. 05

Page 2 of 60

‘CONSTRUCTION OF CAST IN-SITU SEGMENTAL BOX GIRDER

OBR (ROAD AND LAND BRIDGE)

Document No. ECRL-S4-BR-MS-0008

Revision No. 05 Rev. Dato JULY 2024

Table of Contents

1.0 SCOPE OF WORK.

4.4 General Description

1.2 Reference

1.3. Materials...

1.4 Plant and Equipment...

1.5 Manpower.

1.6 Construction Procedures.

2.0 SAFETY AND HEALTH......

2.1 Hazard Identification, Risk Assessment and Risk Control (HIRARC)...39

2.2 Information to Personnel... 40

2.3. Emergency Arrangements. 41

2.4 Permit Requirements. - AS

2.5 Permit to Work.

3.0 ENVIRONMENTAL ISSUES.

3.1 Environmental Aspects, Impacts & Control Measures.

4.0 QUALITY ASSURANCE & QUALITY CONTROL

41° Contractual Requirements

4.2 _ Inspection & Testing

4.3 Follow up & Evaluation. 52

5.0 APPENDICES 53

5.1 Construction Sequence Flow eee 54

5.2 Hazard Identification, Risk Assessment and Risk Control (HIRARC)...56

5.3 Environmental Aspect Impact Register (EAIR)...

5.4 Inspection Test Plan (ITP)..

5.5 Quality Control Site Inspection Checklist .

5.6 Work and Activity Commencement Notification. sens 60

ATTACHMENT! Formwork Design & Static Calculation

ATTACHMENT II Drawing for Continuous Segmental Box

ATTACHMENT Ill

1e Frame for work sequence.

Construction of Gast In-Situ Segmental Box Girder

(Road And Land Bridge)

ECRL-S4-BR-MS-0009 & Rev. 05,

Page 3 of 60

Ee (ROAD AND LAND BRIDGE)

CONSTRUCTION OF CAST IN-SITU SEGMENTAL BOX GIRDER

Document No. ECRL-S4-BR-MS-0009

Revision No. 05. Rev. Date. SJULY 2021

1.0

SCOPE OF WORK

1

General Description

‘The purpose of this Method Statement is to briefly describe the works

sequence for the construction of Cast-In-Situ Segmental Box Girder

(Form Traveller) Road bridges in Section 4 ECRL Project. Describe the

specific area of works and reference document, drawing and scope of

work under Section 4 ECRL project line. This method statement is also

to be implement for all Road Bridges where the methodology of cast-in

situ balance cantilever bridge constructed using from traveller method.

This Method Statement describe the installation of Form Traveller (FT)

operation and sequence, balance cantilever construction of Typical

Segments, Side Span, Closure Segment work for the completion of Two

(FT) moulds will be used to cast number of segmental box girder, with

type for span (Refer to Deck erection sequence drawing) for the SBG

bridges. The Top slab width is 12.8m and bottom with 6m and 5.763m

(refer to Drawings for Bridges). The works shall be complying as per

General Specification, Material & Approved Construction Drawings

referring to Table of Contents 1.2 (Reference). RFI shall issue for

Survey work, PE Inspection, Safety Inspection and SC & QAQC

inspection.

The nominated specialist contractor will erect & operate the Form

Traveller system. RFI should raise for machinery inspection, access to

the hammerhead pier for form travellers installation to obtain the P.T.W

Utilities detection and piloting works will be carried out well in advance

to investigate. And prepare shop drawings. The construction of this

work should commence with Approved Construction Drawing. All the

related document will be submitted to the client and Supervising

Consultant (SC) for approval concurrent with submission to local

authority for approval.

This statement describes the method for 3 span Segmental Box

Girder where the hammerhead installed in pier 1 and pier 2 for

bridges where more than 3 spans, the method of casting and

sequence will same with hammer head shall installed at piers as

refer to Construction Drawing for individual bridge design.

Construction of Cast In-Situ Segmental Box Girder

(Road And Land Bridge)

ECRL-S4-BR-MS-0009 & Rev. 05,

Page 4 of 60

CONSTRUCTION OF CAST IN-SITU SEGMENTAL BOX GIRDER

cage (ROAD AND LAND BRIDGE)

Document No. ECRL-S4-BR-MS-0009_

Revision No. 5 Rev.Date | 8 JULY2021

Note: Details of the procedures contained herein may be reviewed periodically and

modified based on the actual site requirements.

BRIDGE 2 ALIGNMENT (3 SPAN)

Yo ess f Ah UE,

B

#0)

¢

Construction of Cast In-Situ Segmental Box Gieder

(Road And Land Bridge)

ECRL-S4-BR-MS.0009 & Rev. 05,

Page 5 of 60

‘CONSTRUCTION OF CAST IN-SITU SEGMENTAL BOX GIRDER

(ROAD AND LAND BRIDGE)

Document No.

ECRL-S4-BR-MS-0009,

Revision No. 05

Rev. Date

‘SIULY 2024

1.2 Reference

124

‘The relevant references are as follows:

No. Description

Document Ref. No.

1 | Construction Drawings Bridge 2

Abutment Layout and Details

CD/ECRL/C/MLIBR/SEC2.4/VD002

(24sheet Rev-1, 2, & 3)

2 | List of Drawings (Reference

Drawing) RFD

CD/ECRLIC/MLBR/RFD/48BE 201/00000

to 00028 (Rev 01)

3 | List of Drawings (Reference

Drawing) RFD

CD/ECRLIC/MLIBR/RFD/P1002/00001 to

00032 (Rev 02)

4 | Construction Drawings Bridges

CD/ECRL/C/ML/BR/RFD/48BE 201(rev 2)

(Continuous Box Girder)(32+48+32)

5 | Approved Formwork Design

with PE endorsement

MA 2002/C&S/ECRL-S4/LP-01 (Attachment

i)

6 | Stressing Sequence Drwg

‘Sequence stage casting,

Stressing Tendon. Jacking

CD/ECRLIC/MUBRIRFD/48BE201/0008,9,1

O,Rev3)

7 | Technical Specification

(Reinforced Concrete Works)

CD-ECRL-AW-GEN-SPC-0006-3 (SEC 18)

8 | Technical Specification(Testing

of Materials and Workmanship)

CD-ECRL-AW-GEN-SPC-0006-3 (SEC 16)

9 | Technical Specification (Earth

Works)

CD-ECRL-AW-GEN-SPC-0006-3 (SEC 03)

10 | Technical Specification

(Pressurising for Structures)

CD-ECRL-AW-GEN-SPC-0003 (SEC 11)

11 | Technical Specification (Site

Clearing)

CD-ECRL-AW-GEN-SPC-0006-3 (SEC 02)

12 | Method Statement for Bulk

excavation and Filling works

ECRL-S4-SR-MS-0001

Construction of Cast n-Situ Segmental Box Girder

(Road And Land Bridge)

ECRL-S4-BR-MS-0000 & Rev. 05

Page 6 of 60

oom

‘CONSTRUCTION OF CAST IN-SITU SEGMENTAL BOX GIRDER

(ROAD AND LAND BRIDGE)

Document No- TEGRL-S4-BR-MS-0009

Revision No. 5 Rev. Date ‘S JULY 2021,

13 | Method Statement for Surface ECRL-S4-AW-MS-0013

Drainage works

14 | Method Statement for ECRL-S4-AW-MS-0008

Reinforcement Concrete Works

15 | Method Statement for Bridge ECRL-S4-BR-MS-0006

Abutment, Pier and Crosshead

16 | Project Quality Plan ECRL-CCCC-QA-PQP-0001

17 | Survey Quality Plan ECRL-S4-AW-PLN-0001

18 | MSA Procedure ECRL-CCCC-AW-PRO-0005

19 | RFI Procedure ECRL-CCCC-QA-PRO-0003

20 | Occupational Safety and Health Act 514 OSHA 1994

‘Act (OSHA 1994)

21 | Factory & Machinery Act (FMA. Act 319 FMA 1967

1967)

22 | Project Safety and Health Plan ECRL-S4-AW-PLN-0002

23 | SOP Permit to Works ECRL-CCCC-HSE-SOP-0006

24 | SOP for Scaffolding ECRL-CCCC-HSE-SOP-0007

25 | SOP for Working at Height ECRL-CCCC-HSE-SOP-0014

26 | Traffic Management Plan (TMP) Proposed Draft Atached

27 | Environmental Management AS (B) T: 50/013/601/004 Jld.4(3)

Plan (EMP)

28 | Emergency Response Plan ECRL-S4-AW-PLN-0003,

29 | SOP Mobile Construction ECRL-CCCC-HSE-SOP-0003

Equipment

30 | SOP for Site Sanitation and ECRL-CCCC-HSE-SOP-0008

Vector Diseases Control

Construction of Cast In-Situ Segmental Box Grder

(Road And Land Bridge)

ECRL-S4-BR-MS-0009 & Rev. 05,

Page 7 of 60

CONSTRUCTION OF CAST IN-SITU SEGMENTAL BOX GIRDER

EER (ROAD AND LAND BRIDGE)

Document No. TECRL-S4-BR-MS-0008

Revision No. os Rev. Date SwULY 202%

31 | SOP for Housekeeping ECRL-CCCC-HSE-SOP-0010

32 | SOP for Hand and Power Tools ECRL-CCCC-HSE-SOP-0016

33

Construction Industry Standard

(Guidelines on Construction

Works at Night) CIS 14:2019

34

Industry Code of Practice for

Safe Working in A Confined

Space 2010

41.3

Materials

1.3.1 List of materials requires shall be as follows:

No Type of Material

Material

(Mould)

1 | System Formwork Traveller 30-0005508-B001_aSC

(VARIO Formwork and CB

Platform)

2_ | Post Tensioning Strands

(7 wire strand @ 15.24mm)

ECRL-CCCC-BR-MSA-0008

ECRL-CCCC-BR-MSA-0009

ECRL-CCCC-BR-MSA-0010

3_ | Post Tension Corrugated ECRL-CCCC-BR-MSA-0012

Duct

4 | Mould Oil ECRL-S4-AW-MSA-0061

5 | Bonding Agent TBA

6 | Reinforcement T 12

7 | Reinforcement T 16

ECRL-CCCC-AW-MSA-0013

8 | Reinforcement T 20

9 | Concrete G55/20

TBA

‘Construction of Cast In-Situ Segmental Box Girder

(Road And Land Bridge)

ECRL-S4-BR-MS-0000 & Rev. 05,

Page 8 of 60

CONSTRUCTION OF CAST IN-SITU SEGMENTAL BOX GIRDER

(ROAD AND LAND BRIDGE)

‘Document No. TECRL-S4-BR-MS-0009

Revision No. i Rov. Date SJULY 2021

10 | Concrete G50/20 ECRL-S4-BR-MSA-0014

11 | Concrete G40/20 ECRL-S4-AW-MSA-0047

12 | Grout Mix G50 TBA

13 | Non-shrink grout-Moment TBA

NS grout

14 | Pot Bearing (Fixed) CD/ECRLAWIGEN SPC-0015

SECTION 14

15 | MEQZ-Pot Bearing (Fixed) | | CD/ECRLAWIGEN SPC-0015

‘SECTION 14,

(CDIECRLIC/MLIBR/RFD/BAD/

00301(Rev1)

ECRL-CCCC-BR-MSA-0013,

16 | MEQZ-Pot Bearing CD/ECRLIAWIGEN SPC-0015

(Longitudinally Guide) SECTION 14,

CD/ECRL/ICIMUBR/RFD/BAD/

(00302(Rev1)

ECRL-CCCC-BR-MSA-0013,

17 | MEQZ-Pot Bearing (CDIECRUAWIGEN SPC-0015

(Transversely Guide) SECTION 14.

CD/ECRLICIMUBRIRFD/BAD/

00303(Rev1)

ECRL-CCCC-BR-MSA-0013,

18 | MEQZ-Pot Bearing (Free) | CD/ECRUAWIGEN SPC-0015

SECTION 14.

DC/ECRLICIMLIBRIRFD/BAD/

00304(Rev1)

ECRL-CCCC-BR-MSA-0013

19 | PVC Drainage Pipe 125mm TBA

CCCC will submit MSA for approval before commence the work.

All work should be carried out with approved MSA.

Construction of Cast In-Situ Segmental Box Girder

(Road And Land Bridge)

ECRL-S4-BR-MS.0009 & Rev. 05

Page 9 of 60

‘CONSTRUCTION OF CAST IN-SITU SEGMENTAL BOX GIRDER

oBre (ROAD AND LAND BRIDGE)

Document No. ECRL-S4-BR-MS-0009

Revision No. 8 Rov. Dato ‘SJULY 2021

4.4 Plant and Equipment

1.4.1. List of plant and machineries requires for the execution of

activi

No | Plant and Machinery Purpose

1. | System Formwork | For casting in situ works

Traveller (Mould) | 39 9905508-8001_aSC

(VARIO Formwork and CB Platform)

2 | Lifting equipment for | For holding and iting the formwork

form traveller

formworks

3 | Excavator For excavation works/Site Works

4. | Bar Cutting Machine | For Cut the Rebar

5 | Bar Bending For Bending Rebar

Machine

6 | Crane Lifting works

7 | Water pump To Use for Cleaning and Curing Purpose

8 | Survey Equipment _ | Used for surveying work purposes

9. | Vibrator For Internal concrete compaction

10 | Genset For power supply

11 | Pump car and For Conereting works

Hoppers

12 | 500 Tonne Capacity | For stressing works

Multi Jack

13 | Twin Bow! Grout | To mix cement grout and pump the grout

Mixer & Pump mixture

14 | Air Compressor __| To check for leakages before grouting

16 | Strand Dispenser _| To dispense strand for threading works.

Construction of Cast n-Situ Segmental Box Grder

(Road And Land Bridge)

ECRL-S4-BR-MS-0009 & Rev. 05,

Page 10 of 60

‘CONSTRUCTION OF CAST IN-SITU SEGMENTAL BOX GIRDER

pera (ROAD AND LAND BRIDGE)

Document No- ECRL-S4-BR-MS-0009

Revision No, 05 Rev. Date BJULY 2021

1.5 Manpower

1.5.1. Responsibility / duty assigned are as follows:

No. | Description Type of Brief Roles and Responsibilities

Manpower

1. | Operations —_| Site Manager

Responsible for the proper execution of the

work under the scope of this work Method.

‘Surveyor and

Chainman

To do survey, measure and marking at site,

assuring all works are performed in the

appropriate manners.

Site

Supervisor

Foreman

Responsible for the daily coordination of the

work and the work of subcontractors in the

work site. And responsible for quality, safety

and maintaining schedules.

Site Engineers

Responsible for the daily coordination of

design information, including quality control,

safely, environmental items, and all

subcontractors’ quantities.

Profession | To endorse all the MTW formworks and

Engineers _ | verified the MTW.

Plants and | To handle the plants and machineries at site

Machinery

Operators,

System Form | To operate the Formwork system

Traveller

Operators,

Riggers _| Responsible for execution of launching and

stressing work

General __| To do the general works at site

Worker

2. | Safety, Health | Safetyand |To ensure the implementation by the

& Health Officer /| operation team on Safety and Health

Environment | Supervisor | procedure were adhere all the time and

responsible for promoting compliance with

sound safety and health practices and to

encourage full_partici ion in the project

Construction of Cast In-Situ Segmental Box Girder

(Road And Land Bridge)

ECRL-S4+-BR-MS-0009 & Rev. 05,

Page 11 of 60

CONSTRUCTION OF CAST IN-SITU SEGMENTAL BOX GIRDER

pare (ROAD AND LAND BRIDGE)

Document No. TECRL-S4-BR-MS-0009.

Revision No. 05 Rev. Dale SIULY 0H

initiatives and implementing safe work

practices and job procedures.

Environmental |To ensure the implementation by the

Officer | operation team on environment procedures

and requirements were adhere at all ime.

Quality Quality | To ensure the procedures carried out as per

Inspector | approved Methodology

@aac. | Assist to plan and coordinate the works

Engineer _ | Which to

be carried out at site and to monitor work

progress/quality and liaise with SC for any

arising matter

Supervising | Checking quality of materials and work in

Consultant | progress.

1.6 Construction Procedures

1.6.1. Installation Hammerhead

a. Alignment control for the construction of permanent works shall use

values as shown in bridge drawings

CD/ECRLCIMLBR/SEC2.4/VD002/20101 (Rev 1)

b. After construction pier completed, Hammerhead formwork will be

installed for the casting of hammerhead.

c. Casting will be done in two stages where first stage will be tll bottom

‘slab and second stage till top level of segment, or base on site

condition in one casting,

d. For Hammerhead Pre-embedded anchorage bar, need to conduct

pull-out test before commence with parts installation

Page 12 of 60

CONSTRUCTION OF CAST IN-SITU SEGMENTAL BOX GIRDER

(ROAD AND LAND BRIDGE)

Document No. ECRL-S4-BR-MS-0009

Revision No. 05 Rev. Date ‘8 JULY 2021

CROSS SECTION VIEW OF CASTING HAMMERHEAD

e.

i"

9.

Scaffolds shall be erected along the Interior Piers example (Pier 1),

stalled these shall be

used to support the construction of Interior Pier Segment

construction. Minimum bearing capacity required for ground for

scaffold. The scaffold design will be submitted separately for

approval. Heavy Duty Double Safety net will be installed along the

construction site during the construction. The working sequence for

In-Situ segmental casting shall refer to Drawing No

CD/ECRLIC/MUBR/RFD/48BE201/00035 (Rev 2)

The temporary works exceeding 2.5 m high shall have PE

‘endorsement and the Traffic Management Plan shall be approved

by local Authority and submitted to SC for review prior to

and for Pier 2 hammerhead bracket wil

commencement of physical work at site

Assembly of Form Traveller, the form traveller shall be delivered to

site in modular components whereby it would be assembled into the

key components on the ground prior to it being lifted and fixed on

the top of the hammerhead.

Construction of Cast In-Situ Segmental Box Girder

(Road And Land Bridge)

ECRL-S4-BR-MS-0009 & Rev. 05,

Page 13 of 60

‘CONSTRUCTION OF CAST IN-SITU SEGMENTAL BOX GIRDER

pee (ROAD AND LAND BRIDGE)

Document No, TEGRL-S4-BR-MS-0009

Revision No. 0 Rev. Date SIULY 2024

MAIN FRAME

1.6.2 FORM TRAVELLER

1.6.2.1 Bottom Slab Soffit and External Formwork

Installation of Mechanical bearing pad at interior pier and

abutment, (Permanent Bearing) bearing pad or after the

Mid Span casted Permanent bearing shall installed.

Installation of Bearing shall refer to construction drawing,

surveyor shall marked to bearing position. (Both method

of installation bearing pad is allowed refer to site

condition) Refer to Drawing no

(CDIECRLIC/MLIBRIRFD/48BE201/00044)

Each Pier consolidated with 2 Bearing Pad (Refer to

drawing no

(CD/ECRLIC/MUBR/RFD/48BE201/00035(Rev2))

Formwork to be used as soffit shall be installed on the

scaffoldings. Outer web formwork which is pre-

fabricated steel_mould shall be installing on soffit

formwork and braced. Safety net shall be installed

around the soffit formwork as protection.

) After assemble Bottom Slab, lower working platform

and rear working platform on ground, lift up the whole

unit using Lifting crane to hang the formwork as its.

b) Slowly move the Bottom Slab toward the hammer

head. When it is close to Front Beam & Rear Frame,

install chain tackles at the front and rear transverse

beams.

©) Atthis moment, the Bottom Slab is stil supported by

chain tackles

‘Construction of Cast niu Segmental Box Girder

(Road And Land Bridge)

ECRL-S4BRIMS-0008 & Rev. 05

Page 14 of 60

\D AND LAND BRIDGE)

‘Document No. ECRL-S4-BR-MS-0009

Revision No. 05 [ Rev. Date [8 JULY 2021

CONSTRUCTION OF CAST IN-SITU SEGMENTAL BOX GIRDER

rs (ROA 3

Construction of Cast In-Situ Segmental Box Girder

(Road And Land Bridge)

ECRL-S4BR-MS-0009 & Rev. 05,

Page 15 of 60

‘CONSTRUCTION OF CAST IN-SITU SEGMENTAL BOX GIRDER

CES (ROAD AND LAND BRIDGE)

Document No. TECRL-S4-BR-MS-0008

Revision No. 5 Rev. Dato JULY 2021

EXTERNAL FORMWORK

1.6.2.2 Setting out Alignment

Prior to commencement of rebar installation, the

alignment of pier segment shall be set-out by surveyor.

Survey Control point will establish on Hammer Head

location (Pier’s and Abutment) Surveyor will control the

ignment, super elevation & Curve as work program ie

when the formwork travel to next segment

1.6.2.3 Steel Reinforcement and Tendon for Bottom Slab

and Web

Installation of steel reinforcement shall be carried out as

per bar bending schedule. Tendon of pre-stressing shall

install accordingly. Embedded items shall be installed

during this stage. Rebar erection shall refer to approved

drawing. Spacer block must be securely fixed to prevent

movement during the placing in the mould and

concreting

1.6.2.4 Concreting Bottom Slab

Upon formwork inspection approval by the represented,

concrete shall be placed in horizontal layers of not more

than 300mm thick.by concrete bucket Compaction of

fresh concrete by mean poker vibrator shall be carried

‘out. Prior of concreting, on ground testing for concrete

shall conduct such as slump test, and concrete cube

samples. Web kickers shall be installed to act as haunch.

Surface of concrete will be roughening mechanically for

every casted segment .Construction joint (C.J) have to

prepare by combination of Hi-rib and timber

‘Construction of Cast In-Situ Segmental Box Gieer

(Road And Land Bridge)

ECRL-S4BR-MS-0009 & Rev. 05

Page 16 of 60

CONSTRUCTION OF CAST IN-SITU SEGMENTAL BOX GIRDER

DEBS (ROAD AND LAND BRIDGE)

Document No. TECRL-S4-BR-MS-0009

Revision No. 05 Rev. Date SIULY 2021

1.6.2.5 Closing of Inner Web formwork.

After concreting of bottom slab, proceed to closing inner

Web formwork of side span segment. Any remaining

provision tie hole and RWDP shall be installed. Web

formwork shall be timber form. The inner Web formwork

shall tight to outer steel form with tie rod.

1.6.2.6 Top Slab Soffit Formwork

Formwork and scaffolding for top slab shall be erected.

The scaffolding will place on the concrete surface of

bottom deck

1.6.2.7 Steel Reinforcement and Tendon for Top Slab

Installation of stee! reinforcement shall be carried out as

per bar bending schedule. Tendon of pre-stressing shall

be installed accordingly. Installation of "steel

reinforcement shall be carried out as per bar bending

schedule. Tendon of pre-stressing shall install

accordingly. Embedded items shall be installed during

this stage. Rebar erection shall refer to approved

drawing. Spacer block must be securely fixed to prevent

movement during the placing in the mould and

concreting. Embedded item shall be installed during this

stage

1.6.2.8 Concreting of Web and Top Slab

Concreting shall be carried out for Web first and

following by top slab in one cast. The concrete pump

shall discharge through the hopper which be ready for

concrete to flow through until bottom web. The clearance

between concrete surface and end of hopper shall not

more than 1 meter to avoid Segregation and spillage.

Construction of Cast n-Sit Segmental Box Girder

(Road And Land Bridge)

ECRL-S4-BR-MS-0008 & Rev. 05

Page 17 of 60

ae (ROAD AND LAND BRIDGE)

Dosument No TECRL-S4-BR-MS-0008

Revision No. os Rev. Date ewULY 2024

CONSTRUCTION OF CAST IN-SITU SEGMENTAL BOX GIRDER

1.6.2.9 Striping of Formwork

1.6.3

1.6.4

1.6.4.1

Scaffolding will be dismantled first and follow with side

formwork. The web formwork of side span segment will

be strip after concreting the exposed surface shall be

cured by spraying approved curing compound or

Watering for minimum 3 days for each segment. The

formwork shall strip off after the stressing work complete

(Conerete strength shall achieve 95% of design strength

for stressing work) contractor to provide extra cube

sample prior to achieve the early strength of concrete or

95% of design strength.

Stressing tendons for pier segment, (Method Statement

for Stressing will submit separately)

Sequence of Post Tensioning (Stressing Work)

‘Stressing will be carried out as soon as the strength of

the concrete reaches the desire strength as per design

requirement. After each pair of segment casted, tendon

will be winched and stressed. Once the entire cantilever

is connected then there will be continuity tendon to be

stress. (Refer to MS ECRL-S4-BR-MS-0017)

Balance Cantilever Segment Construction Pier 1 to

2.

1 to Abutment 0 and Pier 2 to Abutment 4

a) Dismantle formwork and propping for pier Segment

for Pier 1 and Pier 2.

b) Set up Form Travellers for segment 0 at Pier 1 and

Pier 2 (Interior Pier) the casting sequence for FT

setting up may refer to Deck Erection Sequence.

(attachment 1)

¢) Alignment control for construction of balance

cantilever segments shall use the values as shown

in the drawings CD/ECRL/C/MLIBR/SEC2.4/

0002/2021 and 1(Rev 1)

Construction of Cast In-Situ Segmental Box Girder

(Road And Land Bridge)

ECRL S4-BR-MS.0009 & Rev. 05,

Page 18 of 60

‘CONSTRUCTION OF CAST IN-SITU SEGMENTAL BOX GIRDER

oer (ROAD AND LAND BRIDGE)

Document No. ECRL-S4-BR-MS-0008

Revision No. 05 Rev. Date JULY 2027

d) Installed Mechanical bearing Pad at Abutment AO

and Abutment A1 follow the sequence describe in

1.6 from 1.6.1 to 1.6.10.

€) Casting segment no 7 for abutment A1 and abutment

AO, and set up Form travellers at Abutment A1 and

Abutment AO.

) Cast segment as a balance cantilever concurrently

for segment 0 from Pier 1 towards Pier 2 and from

segment 0 Pier 2 towards segment 1*.by using FT.

4g) Install and stress cantilever tendon:

each pair of

segments as cantilever progress

h) The form traveller shall move to next casting after all

the stressing works complete and approved by SC.

1.6.4.2 Balance Cantilever Segment 6 Pier 1 to Pier 2, Abut

A0 to Pier 1 and Abut A1 to Pier 2(Mid-Span Stitch).

a) As per Design Construction sequence, upon

completion of cantilever segment no 5 and 5* the

middle span is to be stitched with segment no 6.

b) For Abutment AO and Abutment A1 segment no 7

and 5, 7* and 5* is to be stitched with end span

segment no 6.

1.6.4.3 Mid Span Stitching

a) Remove the bracket for the last casted span and the

form traveller for mid segment installed the form

traveller for closure segment (Mid Span).

b) Installed the temporary rigid connection to closure

segment (mid span).

©) Do the formwork reinforcement placement, and

prestressed duct setting for mid span and casting the

concrete.

d) Remove the temporary rigid connection, remove the

temporary consolidation connection at the top of the

‘Construction of Cast In-Situ Segmental Box Girder

(Road And Land Bridge)

ECRL-S4+-BR-MS-0009 & Rev. 05

Page 19 of 60

‘CONSTRUCTION OF CAST IN-SITU SEGMENTAL BOX GIRDER

oSre (ROAD AND LAND BRIDGE)

Document No. ECRL-S4-BR-MS-0000

Revision No. 05] Rev. Dato BIULY 2024

terior pier and first cast segment, installed the

permanent bearings.

€) Tension longitudinal prestressed tendons in top and

bottom slabs for mid span simultaneously and

symmetrically, and the timely grouting and sealing

the anchor.

f) Tension the vertical pre-stressed rebar and timely

grouting and sealing the anchor.

1.6.5 Completion

a) Final stage stressing for top blister and bottom

tendons accordingly to the sequence and

requirement as indicate in the approved Drawings.

b) Conduct the checking for alignment control.

¢) Final grouting and touch up.

d) Checking for grout leakage

1.6.6 Reinforcement works.

1.6.6.1 Rebar Bending

a) The rebar shall be bent according to the approved

Construction drawing (Bar Bending Schedule). The

bar bending operations shall be conducted at the

designated bar bending yard.

b) The cut bar shall be distributed to the bar bending

areas as per the approved segment casting schedule

and /or as instructed by the Supervisor.

©) The bending works shall be carried-out in

accordance with approved construction drawing /BS

8666, using Bar Bending Machine at each bending

area. All bars for each segment shall be distributed

from bending areas, using forklift and /or other

suitable motor vehicle.

4) All the bent rebar then be stockpiled in accordance

with shapes and diameters at bending area before

distributed to site for installation/assemble. Timber

Construction of Cast In-Situ Segmental Box Grder

(Road And Land Briége)

ECRL-S4-BR-MS-0009 & Rev. 05,

Page 20 of 60

CONSTRUCTION OF CAST IN-SITU SEGMENTAL BOX GIRDER

(ROAD AND LAND BRIDGE)

Document No.

ECRL-S4-BR-MS-0009,

Revision No.

5

Rev. Date:

SJULY 2024

1.6.6.2 Rebar Assembly

pallet shall be used, if necessary, to hand out the

bent rebar to the formwork/mould the distribution of

rebar shall be carried out as per the approved

schedule or as requested by the Site engineer.

a) The surveyor shall be carried out the inspection of

rebar mould dimension, prior to the commencement

of the rebar installation works, fixing works. The

b)

4)

°)

\spection is necessary, to ensure the stability as

well as the dimensional accuracy of rebar and

formwork,

The making of rebar shall be carried out in the rebar

formworkimould, which fabricated to match the

internal mould dimensions precisely based on the

approved drawings to attain the correct concrete

cover. The circular or rectangular mild steel pipe

shall be fixed at the rebar mould soffit longitudinally

as to the required level.

Corrugated pipe for intemal stressing must be

included during the rebar tying to ensure that the

rebar is tied to the correct position as required in the

mould /formwork.

i, Placement of duct (Tendon Ducting) shall be

placed after/during rebar installation. Once

installation done and final inspection shall be

carried out inside the mould. Duct shall be

laid according with the approved construction

CD/ECRUC/MUBR/RFD/48BE

201/00006 (Rev 1)

‘Any necessary cast-in item wil

drawing.

| be installed

according to the approved Construction drawing,

Final inspection is to carried out by Site Engineer

jointly with Supervising Consultant /QAQC and

‘Construction of Cast In-Situ Segmental Box Gieder

(Road And Land Bridge)

ECRL-S4-BR-MS-0009 & Rev. 05

Page 24 of 60

CONSTRUCTION OF CAST IN-SITU SEGMENTAL BOX GIRDER

Dee (ROAD AND LAND BRIDGE)

Document No. TECRL-S4-BR-MS-0008

Revision No. 08 Rev. Date SIULY 2021

approval is to be obtained prior to placing the

concrete, The Pre-Concreting Inspection checklist

must be signed off by all parties before any

concreting commence.

1.6.7 Concrete Placing

a) Commencement of the concreting works shall be

carried after design mixed and trail mix has been

b)

d)

)

approved. Upon obtaining the approval from the

consultant, the operation/QAQC, Engineering side

must check the final

rebar cage inside the

mould/formwork against casting procedure and

segmental span approved drawings.

The supervisor always has to sure his crew members

are ready for the work. Experienced vibrator

operators and concrete finisher must be present

during concreting.

The concrete team has to make sure all their

equipment and tools are clean and ready for use,

namely bucket, external vibrator, inverter, hand tools

and test cube moulds are in place.

Internal Vibrators shall have a maximum vibrations

ratio and sufficient amplitude to consolidate the

concrete mass properly. External vibrator shall have

of maximum vibrations ratio. Additionally, as a

backup, itis advisable to stand by at least 2 units of

vibrators in working con

\n for emergency use.

The project engineer and supervisor are responsible

to place order for the concrete according to the

required quantity of the segment to cast.

Prior to discharging into the mould/Formwork, the

conorete slump test must be done to check for

concrete workability and concrete temperature shall

be confirmed not to exceed 36°C. If in any case the

‘Construction of Cast In-Situ Segmental Box Girder

‘Road And Land Bridge)

ECRL-S4-BR-MS-0000 & Rev. 05,

Page 22 of 60

CONSTRUCTION OF CAST IN-SITU SEGMENTAL BOX GIRDER

(ROAD AND LAND BRIDGE)

Document No. ECRL-S4-BR-MS-0009

Revision No. 5 Rev. Date: SJULY 2024

concrete workability fails out the range (design

workability/Slump), the concrete shall be rejected.

) Cube sampling shall take from conorete truck base

on Technical Specification Section 16, (Table 16-3-

2) and additional cube shall be done for earlier

striking/dismantle of formwork.as agreed by

Supervising Consultant.

h) Concrete shall be placed using bucket/pump or other

method agreed by Supervising Consultant, in the

mould/Formwork where the discharge point is less

than 300mm height from the top of reinforcement

layer.

i) The concrete shall be discharged into the

mould/formwork by loads the concrete shall be

placed in the mould as per recommended sequence

of concrete placement, section by section and /or

layers nor exceeding 300mm thick.

j) Due care is required during concreting works to

ensure the post tensioning anchor head, duets, and

other cast in items are in their original position and

also to avoid unnecessary damages andlor

dislocation. The concrete shall be thoroughly

compacted using both the external and internal

vibrator. Compaction by intemal vibrators is by

working around the reinforcement, tendon duct,

anchor head, cast-in items and into corners of

formwork.

Deck Casting Sequence

a) The length of each segments shall refer to the

Approved Details Drawings for Box Girder and

uncovered issues shall refer to related code and

guidance

b) The construction site shall be prepared for three

supplies and one levelling. Construction of Pier, Pier

Construction of Cast In-Situ Segmental Box Girder

(Road And Land Bridge)

ECRL-S4-BR-MS-0009 & Rev. 05,

Page 23 of 60

‘CONSTRUCTION OF CAST IN-SITU SEGMENTAL BOX GIRDER

Bee {ROAD AND LAND BRIDGE)

Document No. TECRL-S4-BR-MS-0008

Revision No. 05 Rev. Date SSULY 2021

Refer to Drawing no:

Foundation and Pier Cap for the Interior and Exterior

Piers. Set the temporary bracket of segment no 0 on

the Interior Pier, the bracket shall take measures to

eliminate inelastic deformation

(CD/ECRL/C/ML/BR/48BE201/00026)

i—-

Form Travelers

Exterior Pier

Interior Per Interior ier

rT

I]

©) The Formwork of segment no 0 is assembled on the

interior pier bracket, the reinforcement and

pressurised duct are arranged. Simultaneously cast

segment No 0 symmetrically and make reliably

consolidated with the pier cap by temporary

consolidation measures.

d) Tension longitudinal prestressed tendons in the top

slab and web of segment No 0 and timely grouting.

Tension the vertical pressurised rebar and timely

grouting and sealing the anchor.

> Bxterior Pier

z

T

|

|

i

]

|

Construction of Cast In-Situ Segmental Box Gider

(Road And Land Bridge)

ECRL-S4-8R-MS-0009 & Rev. 05

Page 24 of 60

CONSTRUCTION OF CAST IN-SITU SEGMENTAL BOX GIRDER

(ROAD AND LAND BRIDGE)

Document No.

ECRL-S4-BR-MS-0009

Revision No. 05

Rev. Date

SJULY 2021

e) Remove the interior pier temporary bracket and

install Form Traveller at the segment No 0 and do the

formwork, reinforcement placement and pressurised

duct setting for segment No 1 and No 1%,

simultaneously cast segment No 1 and 1*.

Interior Pier

Exterior Pier

[> interior Pier

f) Tension Longitudinal prestressed tendons in the top

slab and web of segment No 1 and No 1* and timely

grouting and sealing the anchor. Tension the vertical

pressurised rebar and timely grouting the ducting

and sealing the anchor.

9) Cantered on the interior pier, Form Traveller shall

move forward symmetrically to the next cantilever

segment, and do the formwork, reinforcement

placement and pressurised, duct setting for that

segment. And tension longitudinal prestressed

tendons in the top slab and web of each cantilever

segment successively and symmetrically at the

same time and timely grouting and sealing the

anchor.

h) Tension the vertical pressurised rebar and timely

grouting and sealing the anchor of each cantilever

segment successively and timely grouting and

sealing the anchor, at the exterior pier do the

formwork and cast segment No 7 in-situ as for the

cast.

measures to eliminate inela

‘Construction of Cas n-Situ Segmental Box Girder

(Road And Land Bridge)

ECRL-S4-BR-MS-0009 & Rev. 05,

-situ segment the bracket shall take

deformation.

Page 25 of 60

‘CONSTRUCTION OF CAST IN-SITU SEGMENTAL BOX GIRDER

Dae (ROAD AND LAND BRIDGE)

Document No- ECRL-S4-BR-MS-0008

Revision No. 5 Rev. Date SIULY 2021

Exterior Pier Exterior Per

Interior Pier Interior ier

i)

i)

Remove form Travellers for segment No Sand No 5*

and installed travellers for closure segment No 6.

Installed the temporary rigid connection to closure

segment No 6 for end span. Do the formwork,

teinforcement placement and pressurised duct

setting for segment No 6.

Remove from temporary rigid connection, tension

longitudinal prestressed tendons in the top and

bottom slabs of the closure segment simultaneously

and symmetrically,

anchor. Tension the vertical pressurised rebar and

fimely grouting and sealing the

grouting and sealing the anchor

B

Exterior Pier

[Interior ier F Interior ier

Exterior Pier

I

Construction of Cast In-Situ Segmental Box Girder

(Road And Land Bridge)

ECRL-S4-BR-MS-0009 & Rev. 05,

Page 26 of 60

CONSTRUCTION OF CAST IN-SITU SEGMENTAL BOX GIRDER

(ROAD AND LAND BRIDGE)

Document No. TECRL-S4-BR-MS-0009

Revision No. 05 Rev. Date ‘S JULY 2024

k) Remove the bracket for end span ad the form

traveller for segment No 6. Install the form traveller

for closure No 6* in mid span. Install the temporary

rigid connection to closure segment No 6* for mid

span, installed formwork, reinforcement, and

pressurised duct setting for segment No 6* and

concrete.

1) Remove the temporary rigid connection, and

temporary consolidation connection at the top of

interior pier and segment No 0. Install the permanent

bearings. Tension longitudinal prestressed tendons

in the top and bottom stabs for mid span

simultaneously and symmetrically and grouting and

sealing the anchor. Tension the vertical pressurised

rebar and timely grouting and sealing the anchor.

L Exterior Per

[THETA TE

a a

Interior Pier Interior Pier

|

i T

l

m) Remove the form Traveller for the closure segment

‘No 6* in mid span. Finish the construction of the main

structure and site cleaning have be done 4) End

span segment casting shall be temporary rigid

connection to closure segment. (There is no scaffold

for probing) the formwork system already calculated

all the safety factor)

Construction of Cast In-Situ Segmental Box Girder

(Road And Land Bridge)

ECRL-S4-BR-MS.0009 & Rev. 05

Page 27 of 60

Exterior Pier

OAD AND LAND BRIDGE)

Document No. ECRL-S4-BR-MS-0009

Revision No. 8 Rev. Dato | 8 JULY 2021

‘CONSTRUCTION OF CAST IN-SITU SEGMENTAL BOX GIRDER:

& Dee & )

1) Construct the bridge deck and conduct Dynamic and

‘static load experiment test.

I Exterior Pier Exterior Pier

Interior Pier Interior Pier

i f

—

Refer to Drawing no: (CD/ECRL/C/MLIBR/48BE201/00026)

SEQUENCE FOR CAST IN SITU SEGMENTAL BOX GIRDER

41) ELEVATION VIEW OF CANTILEVER

‘Construction of Cast In-Situ Segmental Box Girder

(Road And Land Bridge)

ECRL-S4-BR-MS-0009 & Rev. 05,

Page 28 of 60

(ROAD AND LAND BRIDGE)

Document No. ECRL-S4-BR-MS-0009

Revision No. 08 Rev. Date ‘JULY 202%

& |azig | CONSTRUCTION OF CAST IN-SITU SEGMENTAL BOX GIRDER

2) CROSS SECTION VIEW OF CASTING HAMMERHEAD

3) MAIN FRAME

‘Construction of Cast In-Situ Segmental Box Girder

(Road And Land Bridge)

ECRL-S4-BR-MS-0000 & Rev. 05

Page 29 of 60

‘CONSTRUCTION OF CAST IN-SITU SEGMENTAL BOX GIRDER

OSS (ROAD AND LAND BRIDGE)

Document No. ECRL-S4-BR-MS-0008

Revision No. 05 Rev. Date JULY 2021

4) FRONT BEAM & CROSS ARMS

‘UROHL BLAM CROSS ARMS

suet

Construction of Cast In-Situ Segmental Box Girder

(Road And Land Bridge)

ECRL-S4-BR-MS.0000 & Rev. 05

Page 30 of 60

‘CONSTRUCTION OF CAST IN-SITU SEGMENTAL BOX GIRDER

Be (ROAD AND LAND BRIDGE)

Document No. ECRL-S4-BR-MS-0008

Revision No. 05 Rev. Date [8 JULY 2021

6) TROLLEYS IN MAIN FRAME

7) EXPRESS ROLLER

8) UPPER WORKING PLATFORM

Construction of Cast In-Situ Segmental Box Girder

(Road And Land Bridge)

ECRL-S4-BR-MS-0009 & Rev. 05,

Page 31 of 60

‘CONSTRUCTION OF CAST IN-SITU SEGMENTAL BOX GIRDER

Ere (ROAD AND LAND BRIDGE)

Document No. ECRL-S4-BR-MS-0009

Revision No. 05 [_Rev.Date [8 JULY 2021

9) FRONT BOGI

Construction of Cast In-Situ Segmental Box Girder

(Road And Land Bridge)

ECRL-S4-BR-MS-0009 & Rev. 05,

Page 32 of 60

CONSTRUCTION OF CAST IN-SITU SEGMENTAL BOX GIRDER

(ROAD AND LAND BRIDGE)

412) EXTERNAL FORMWORK

Document No. TECRL-S4-BR-MS-0009

Revision No. 8 Rev. Date ‘JULY 2024

11) REAR FRAME

Construction of Cast In-Situ Segmental Box Girder

(Road And Land Bridge)

ECRL-S4-BR-MS-0009 & Rev. 05,

Page 33 of 60

ves

‘CONSTRUCTION OF CAST IN-SITU SEGMENTAL BOX GIRDER

‘Document No.

(ROAD AND LAND BRIDGE)

ECI 9-0

Revision No.

8

Rev. Dato.

JULY 202%

13) BOTTOM SLAB

Construction of Cast In-Situ Segmental Box Girder

Road And Land Bridge)

i

ECRL-S4-BR-MS.0009 & Rev. 05,

Page 34 of 60

‘CONSTRUCTION OF CAST IN-SITU SEGMENTAL BOX GIRDER

Deze (ROAD AND LAND BRIDGE)

Document No- TECRL-S4-BR-MS-0009

Revision No. 5 Rev. Date ‘SJULY 2021

15) MAIN RAILS ONTO HAMMERHEAD

16) MAIN RAILS & HYDRAULIC JACKS ONTO HAMMERHEAD

th th

‘Construction of Cast In-Situ Segmental Box Girdor

(Road And Land Bridge)

ECRLS4-BR-MS-0009 & Rev. 05,

Page 36 of 60

‘CONSTRUCTION OF CAST IN-SITU SEGMENTAL BOX GIRDER

DEE (ROAD AND LAND BRIDGE)

Document No. ECRL-S4-BR-MS-0009

Revision No. 05 ]_ Rev. Date [8 JULY 2024

47) PERSPECTIVE VIEW AFTER MAIN RAILS AND MAINS JACK INSTALL

ON HAMMERHEAD

PULL DOWN LAUNCHING

CYLINDERS CYLINDERS

~.

MAIN

CYLINDERS

18) INSTALLATION OF MAIN FRAME

Tenn Te i ome

(Garten By

Tigo La Baig

etapa dt

Construction of Cast In-Situ Segmental Box Gider

(Road And Land Bridge)

ECRL-S4-BR-MS-0009 & Rev. 05

Page 36 of 60

‘CONSTRUCTION OF CAST IN-SITU SEGMENTAL BOX GIRDER

e DB (ROAD AND LAND BRIDGE)

‘Document No. ECRL-S4-BR-MS-0000

Revision No. 05: Rev. Date ‘JULY 2021

19) INTERNAL FORMWORK INSTALLATION

20) EXTERNAL FORMWORK INSTALLATION

Construction of Cast In-Situ Segmental Box Girder

(Read And Land Bridge)

ECRL-S4-BR-MS-0009 & Rev. 05

Page 37 of 60

Document No.

CONSTRUCTION OF CAST IN-SITU SEGMENTAL BOX GIRDER

4p veze

(ROAD AND LAND BRIDGE)

Et

ECRL-S4-BR-MS-0009

Revision No.

5

Rev Date | SJULY 2021

21) PERSPECTIVE VIEW AFTER CROSS ARMS, BOTTOM FRAMEWORK,

INTERNAL FRAMEWORK,

HAMMERHEAD

BOTTOM

SLAB INSTALLED ON

Var te pe ee

22) PERSPECTIVE VIEW OF FORM TRAVELLER AFTER COMPLETE

INSTALLATION

‘CONSTRUCTION OF CAST IN-SITU SEGMENTAL BOX GIRDER

(ROAD AND LAND BRIDGE)

Document No. ECRL-S4-BR-MS-0009

Revision No. 08 Rev. Date S JULY 2024

2.0 SAFETY AND HEALTH

2.1 Hazard Identification, Risk Assessment and Risk Control

(HIRARC)

a.

All personal shall receive CCCC ECRL Section 4 HSE

Induction Program.

All personal shall have valid CIDB green card.

All HSE issues in every work location will be coordinated by

the Safety Officer/Site Safety Supervisor.

All personal shall be provided with and shall use appropriate

personal protective equipment (PPE) (e.g. safety helmet,

safety goggle, face shields, dust masks, safety shoes, hand

gloves, etc.)

All tools and equipment shall be checked daily by qualified

person prior to use.

‘Any damaged equipment or tools shall not to used. They shall

be tagged, removed from site and replaced by equipment and

tools in proper condition.

‘Any work must follow closely with approved HIRARC.

Obtain CCCC ECRL Section 4 approval prior to execute work.

Due to Covid-19, control measure must be done to ensuring

safe and health working environment at workplace

i. Allworkers to go through Covid-19 screening (implement

until further notice or information by CIDB).

ii, To inform KKM if found positive workers on the Covid-19

‘screening. To inform KKM on the workers which have

symptoms of Covid-19.

fi. Use face mask and hand sanitizer prior start of work.

iv. Brief workers on the safe method of work during toolbox (1+

meter gap).

v. Do health monitoring by temperature screening before start

work.

vi. Safe social distance more then 1-meter before work, during

work, during rest hour and after work.

Construction of Cast In-Situ Segmental Box Gieder

(Road And Land Bridge)

ECRL-S4-BR-MS.0009 & Rev. 05,

Page 39 of 60

CONSTRUCTION OF CAST IN-SITU SEGMENTAL BOX GIRDER

(ROAD AND LAND BRIDGE)

Document No, ECRL-S4-BR-MS-0008

Revision No. co Rev. Date SJULY 2021

Disinfection work execute at all vehicle, toilet and

frequently used facility

vil, All screening and disinfection work must be recorded and

keep.

2.2 Information to Personnel

Construction Industry Development Board (CIDB)

CCCC ECRL Section 4 shall ensure all employees and it's to have a

valid CIDB card when working in the CCC ECRL Section 4 project site.

This CIDB training is conducted by competent trainer.

CCC ECRL Section 4 HSE Induction Program

Upon receipt of valid CIDB card and prior to start WORK in the CCC

ECRL Section 4 project site, all employees including SUB

CONTRACTOR employees shall attend a HSE Induction program to be

conducted by the CCC ECRL Section 4. This HSE induction program

shall be done at site in CCC ECRL Main Office/ site. Each employee

‘and who has attended and passed the HSE Induction program will be

issued with a sticker to indicate that he has completed the HSE

Induction Program. Only then, WORK is allowed to commence at site.

A briefing based on the control measures detailed in the job safety and

health analysis is required for all work activity and all personnel involved

in the work have been given a pre-task briefing in a language that can

be understood by all persons involved. Detail the person responsible for

providing this briefing and the way in which records will be maintained

Confined Space

All personnel involve in confine space activity must require Authorize

Entrant Standby Person (AESP) certification from recognized training

provider. Authorize Gas Tester and Entry Supervisor (AGTES) must

evaluate and make reading for the confine space before any personnel

proceed for any work. All activity in Confine Space must comply to

Industry Code of Practice for Safe Working in A Confined Space 2010.

Construction of Cast n-Situ Segmental Box Grder

(Road And Land Bridge)

ECRL-S4-BR-MS.0000 & Rev. 05

Page 40 of 60

‘CONSTRUCTION OF CAST IN-SITU SEGMENTAL BOX GIRDER

Eze (ROAD AND LAND BRIDGE)

Document No. ECRL-S4-BR-MS-0000

Revision No. 08 Rev. Date ‘SJULY 2021

2.3 Emergency Arrangements

In order to minimize casualties, property losses and social impacts

caused by safety accidents, the project department worked out

contingency plans. After the accident, emergency deployment should

be started immediately, and accidents should be dealt with in time so

as to prevent the loss of accidents from expanding.

1) Emergency on Covid-19

If workers or staff found with Covid-19 symptoms, send to the

nearest Klinik Kesihatan for screening and immediate treatment,

depending on Doctor Advice.

Report to the Project Manager and SHO.

Preventive measures: Before sending the personal to Klinik

Kesihatan, the vehicle must be disinfecting and all personal use

hand sanitizer. Safe social distancing must be applied inside vehicle.

All people inside vehicle must wear face mask. Avoid close contact

to each other. After finished al the procedure, all personal must

wash hands and take bath. The vehicle must be disinfecting.

Report to the HQ CCC ECRL as soon as possible.

If someone in the project is found positive Covid-19, other members

who to be in closed contact should be observed and receive medical

observation for at least 14 days.

2) Construction in Thunderstorm

Local rainfall, rainy season construction more prone to lightning,

heavy rain, wind weather, construction equipment, personnel

damage.

Preventive measures: before hoisting operation, to know the

weather in advance, not suitable for operation of the weather

(thunderstorm weather, wind speed up to 6) to carry out lifting

operations and piling work is strictly prohibited. In the construction

process such as sudden strong wind or heavy rain, steel pipe piles

or stee! should be immediately put back, and fixed, until the weather

conditions improved, check the spreader may continue to work.

Construction of Cast In-Situ Segmental Box Girder

(Road And Land Bridge)

ECRL-S4+BR-MS-0009 & Rev. 05

Page 41 of 60

CONSTRUCTION OF CAST IN-SITU SEGMENTAL BOX GIRDER

Dae (ROAD AND LAND BRIDGE)

Document No. ECRL-S4-BR-MS-0009

Revision No. 05 Rev. Date ‘B JULY 2021

3) Matters needing attentions under the influence of tide

In the waters of the construction range, a proper distance vertical

draft, observe the tidal changes. Through local JPS and water

conservancy irrigation Bureau, the river management department

issued the water construction announcement ahead of time,

reminding the passing vessels safe passage.

4) Operations nearby sea or river

‘The personnel fell into the water and drowned.

Water construction personnel life jacket, traffic and other lifesaving

boat facilities shall be complete and effective. Steel pipe piles,

operations platform erection process must be designated in

dangerous zone, danger zone strictly prohibited.

5) Accident

occurs an accident on construction site, employees shall:

~ Assess the situation: do not put yourself in danger;

- Make the area safe, and do not try to move the casualty;

- Look for a first aid responder;

~ First aid responder should;

= Assess the victim: Check for consciousness, bleeding,

breathing, heart;

~ Call- or send somebody to call - the site nurse.

= Explain the location, cause of accident, number and state of

victims.

= Look for a first aid box and material that first aid responder /

rescuer will need;

~ First aid responder should provide first aid care;

- Send someone near road / access to guide the ambulance /

paramedic staff;

- Report to immediate supervisor and Safety Head.

Construction of Cast In-Situ Segmental Box Girder

(Road And Land Bridge)

ECRL-S4-BR-MS-0009 & Rev. 05,

Page 42 of 60

‘CONSTRUCTION OF CAST IN-SITU SEGMENTAL BOX GIRDER

DISS (ROAD AND LAND BRIDGE)

Document No- ECRL-S4-BR-MS-0009

Revision No. 0 Rev. Dato BULY 202%

6) Fire

Ifa fire occurs, employees shall:

- Alert personnel in the immediate area;

- If no personal risk is involved remove injured person from

immediate danger,

- Call Supervisor or Safety Head who will assess if Fire

Department must be called;

+ If no personal risk is involved and fire is still small, try to

‘extinguish it with a fire blanket, fire extinguisher or other

available means;

~ If in doubt, or if fire is not controllable evacuate quickly and

calmly;

= Proceed to designated Assembly Point following evacuation

routes;

~ Report to immediate supervisor and Safety Head

7) Pollution spillage or leakage

In the event of pollutant spillage or leakage no matter what size,

‘employees shall:

- Tryto stop the spill source, e.g. close the valve, if possible;

~ Notify personnel in the immediate area of the spill;

- Attend to any persons that may have been contaminated.

Contaminated clothing must be removed immediately and

appropriate first aid applied;

~ If a volatile flammable material is spilled, control any

possible sources of ignition and ventilate the area;

- Wear appropriate PPE (Safety goggles, chemical suits or

approved coveralls, rubber, vinyl gloves, rubber boots) for

the material spilled and avoid breathing any vapor from the

spill;

- Use appropriate spill control material to first contain and

absorb the spill according to procedures previously obtained

from the SDS;

‘Construction of Cast In-Situ Segmental Box Girer

(Road And Land Bridge)

ECRL-S4-BR-MS-0000 & Rev. 05

Page 43 of 60

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- ENG ICOP CHC (Amendment) Part 1 2019Document66 pagesENG ICOP CHC (Amendment) Part 1 2019Fateh AliyaNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- LAWS OF MALAYSIA ACT 520Document73 pagesLAWS OF MALAYSIA ACT 520May OngNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Industy Code of Practice For Safe Working in A Confined Space 2010Document80 pagesIndusty Code of Practice For Safe Working in A Confined Space 2010Abd Rahim100% (2)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- 1) MRL-ICT-IMSP-01.01 (S) (04) Asset ManagementDocument16 pages1) MRL-ICT-IMSP-01.01 (S) (04) Asset ManagementFateh AliyaNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Industry Code of Practice For Management of Occupational Noise Exposure PDFDocument75 pagesIndustry Code of Practice For Management of Occupational Noise Exposure PDFMohd AbidNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- ECRL-S4-BR-MS-0014 Casting of T-Beam Rev 00Document74 pagesECRL-S4-BR-MS-0014 Casting of T-Beam Rev 00Fateh Aliya0% (1)

- Acf-Mra-068 - UcDocument1 pageAcf-Mra-068 - UcFateh AliyaNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Acf-Mra-069 - UcDocument1 pageAcf-Mra-069 - UcFateh AliyaNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

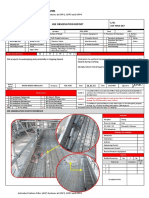

- Description of NCR at Bridge 3Document7 pagesDescription of NCR at Bridge 3Fateh AliyaNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Acf-Mra-066 - SCDocument1 pageAcf-Mra-066 - SCFateh AliyaNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- MRL-HRM-IMSF-03.01C (01) Training Seminar Conference RequestDocument1 pageMRL-HRM-IMSF-03.01C (01) Training Seminar Conference RequestFateh AliyaNo ratings yet

- Acf-Mra-065 - SCDocument1 pageAcf-Mra-065 - SCFateh AliyaNo ratings yet

- Acf-Mra-067 - UcDocument1 pageAcf-Mra-067 - UcFateh AliyaNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Acf-Mra-065 - SCDocument1 pageAcf-Mra-065 - SCFateh AliyaNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Acf-Mra-063 - UaDocument1 pageAcf-Mra-063 - UaFateh AliyaNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- MMSB Consult SDN BHD / China Railway Design Corporation East Coast Rail Link Project (Ecrl)Document1 pageMMSB Consult SDN BHD / China Railway Design Corporation East Coast Rail Link Project (Ecrl)Fateh AliyaNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Acf-Mra-064 - SCDocument1 pageAcf-Mra-064 - SCFateh AliyaNo ratings yet

- Acf-Mra-062 - SCDocument1 pageAcf-Mra-062 - SCFateh AliyaNo ratings yet

- Fire Extinguisher Layout For Acf System: List of Drawings / Documents For ApprovalDocument2 pagesFire Extinguisher Layout For Acf System: List of Drawings / Documents For ApprovalFateh AliyaNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Acf-Mra-064 - SCDocument1 pageAcf-Mra-064 - SCFateh AliyaNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Hirard - DrivingDocument2 pagesHirard - DrivingFateh AliyaNo ratings yet

- Fire Extinguisher Layout For Acf System: List of Drawings / Documents For ApprovalDocument2 pagesFire Extinguisher Layout For Acf System: List of Drawings / Documents For ApprovalFateh AliyaNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Fire Extinguisher Layout For Acf System: List of Drawings / Documents For ApprovalDocument2 pagesFire Extinguisher Layout For Acf System: List of Drawings / Documents For ApprovalFateh AliyaNo ratings yet

- PTS - 18.03.01 HSE Committee PDFDocument16 pagesPTS - 18.03.01 HSE Committee PDFFateh AliyaNo ratings yet

- PTS - 18.03.01 HSE Committee PDFDocument16 pagesPTS - 18.03.01 HSE Committee PDFFateh AliyaNo ratings yet

- Fire Extinguisher Layout For Acf System: List of Drawings / Documents For ApprovalDocument2 pagesFire Extinguisher Layout For Acf System: List of Drawings / Documents For ApprovalFateh AliyaNo ratings yet

- PTS - 18.03.01 HSE Committee PDFDocument16 pagesPTS - 18.03.01 HSE Committee PDFFateh AliyaNo ratings yet

- AsdsadassadsadfwqwqwqweDocument1 pageAsdsadassadsadfwqwqwqweFateh AliyaNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)