Professional Documents

Culture Documents

Paint and LP Gas

Uploaded by

Sky engineering consultancyOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Paint and LP Gas

Uploaded by

Sky engineering consultancyCopyright:

Available Formats

Section 11—Standards for Material

Handling, Storage, and Disposal

11.14.6 Safety Relief Valves. Equip each container with one or more

approved safety relief valves. These valves must allow free venting to the

outer air. The discharge must be 5 feet away from any building opening.

Place container safety relief devices and regulator relief vents at least 5 feet

from air openings into sealed combustion system appliances or mechanical

ventilation air intakes.

11.14.7 Dispensing

a. Portable Containers. Fill portable containers from storage containers

outside and at least 50 feet away from the nearest building.

b. Motor Vehicles. Fill fuel containers on motor vehicles from bulk

storage containers at least 10 feet away from a masonry-walled building

and at least 25 feet away from any other building or structure.

c. Refueling. Shut down equipment using LPG during refueling.

11.14.8 Storage of Cylinders and Containers. Store LPG containers and

cylinders not in use outside of buildings or structures, at not less than the

following distances away from the nearest building or combustible material

storage.

Minimum distance

Quantity of LP-gas stored (a) and (b) (c) and (d) (e)

(pounds) (feet) (feet) (feet)

720 or less 0 0 5

721 to 2,500 0 10 10

2,501 to 6,000 10 10 10

6,001 to 10,000 20 20 20

Over 10,000 25 25 25

(a) nearest building or storage area; (b) line of adjoining property;

(c) thoroughfares or sidewalks; (d) line of adjoining property used for public

gathering; (e) dispensing station.

11.14.9 Fire Protection. Provide storage locations with at least one

accessible portable fire extinguisher rated not less than 2-A:40-B:C, between

25 feet and 75 feet away from the container.

11.15 Requirements for Storing and Handling Paints, Varnishes, and

Thinners

Storing and handling paints, varnishes, or thinners requires special attention to

flammability characteristics.

11.15.1 Storage. Store and dispense paints, varnishes, lacquers, thinners, and

other volatile paints or coatings according to their flammability

October 2009 11-11

Reclamation Safety and

Health Standards

characteristics. Tightly close containers when not in use; store no more than a

1-day supply in buildings under construction.

11.15.2 Ventilation. Provide sufficient ventilation to prevent hazardous

concentrations of flammable vapors from accumulating where employees

dispense or apply paints or coatings.

11.15.3 Spray Painting. Do not allow smoking, open flame, exposed

heating elements, or other sources of ignition where employees spray

flammable or combustible paints or coating. Spray painting booths and

equipment must be in accordance with NFPA 33, “Standard for Spray

Application Using Flammable and Combustible Materials.”

11.15.4 Personal Protective Equipment. Make exposure determinations for

employees who have been exposed to paints or coatings potentially hazardous

to their health to document exposure and, when appropriate, provide

appropriate protective equipment and hazard training.

11.15.5 Electrostatic Paint Spraying

a. Electrical. Locate transformers, power packs, control apparatus, and

other electrical portions of the equipment, with exception of the gun and

its connection to the power supply, outside the spraying area.

b. Grounding. Ground the handle of the spray gun with a conductive

device to ensure the gun and the operator are at the same ground potential.

11.16 Housekeeping

Keep work and storage areas clean and orderly and in a sanitary condition. Keep

stairways, access ways, and exits free from scrap, supplies, materials, or

equipment.

11.16.1 Waste Disposal. Collect, store, and remove combustible waste

products at the end of each workday or at the end of each work shift. Use

only noncombustible containers to dispose of waste and rubbish and equip

them with fitted or self-closing covers. Promptly remove and dispose of

spills of flammable or combustible liquids. Place scrap lumber in containers

and do not allow it to accumulate in work areas. Remove or bend over

protruding nails unless the scrap lumber is placed directly in containers for

removal.

11.16.2 Segregation of Materials and Waste. Consider storage segregation

precautions for all materials. Use MSDS to determine appropriate storage

segregation. Identify and label segregated material containers. Following are

some examples of materials that must be segregated:

a. Ordinary combustibles such as paper, wood, and natural fiber fabrics.

11-12 October 2009

Section 11—Standards for Material

Handling, Storage, and Disposal

b. Oily or flammable materials, such as saturated oily or solvent rags.

c. Corrosive and caustic materials, such as batteries.

d. Infectious materials that may cause infection, disease, or death.

e. Reactive materials that may self-decompose or self-ignite because of

heat, chemical reaction, friction, or impact.

f. Radioactive materials.

g. Toxic materials that may be fatal if inhaled, swallowed, or absorbed

through the skin.

11.16.3 Outdoor Housekeeping. Keep the areas adjacent to facilities free

from rubbish, waste, and tall, dry vegetation. Place combustible waste

materials stored outdoors to await subsequent disposal at least 20 feet away

from facilities.

11.16.4 Tools and Equipment. To prevent tripping or injury, keep floors

clear of tools and portable equipment. Adequately secure tools, materials, and

equipment where a tripping hazard exists.

11.16.5 Wind. Store loose or light materials on roofs or unenclosed height

only if they are safely tied down or secured.

11.16.6 Sacks and Bags. Remove empty bags that contained cement, lime,

or other dust-producing material from the work area at least daily.

11.16.7 Working Aloft. Provide containers to store or carry rivets, bolts,

drift pins, and similar items. Secure containers against accidental

displacement.

11.16.8 Excavated Materials. Keep roads and walkways clear of excavated

materials wherever possible. Where this is not possible, adequately post or

barricade these areas and provide other access.

11.16.9 Dropping Material. Drop or throw waste material and debris more

than 6 feet only if you:

a. Completely enclose the area into which the material is dropped with

barricades at least 6 feet back from the projected edge of the opening or

level above. Post signs warning of the hazard at each level.

b. Install safely designed chutes providing protection for persons below.

Fully enclose chutes for debris and scrap for their entire run except for

openings for inserting materials. Equip such openings with covers or

enclosures.

October 2009 11-13

You might also like

- Bombers' Training, and Application of Same in Trench WarfareFrom EverandBombers' Training, and Application of Same in Trench WarfareNo ratings yet

- Fire Section 10Document10 pagesFire Section 10appcisdNo ratings yet

- Bunding of Storage Tanks and Transfer FacilitiesDocument4 pagesBunding of Storage Tanks and Transfer FacilitiesAjiri IvoviNo ratings yet

- Es 132 ReportDocument23 pagesEs 132 Reporttevesearljade82No ratings yet

- Explosives & Materials Handling and StorageDocument31 pagesExplosives & Materials Handling and StorageNelgine GepuitNo ratings yet

- The Philippines, Occupational Safety and Health Standards: RULE 1140 ExplosivesDocument15 pagesThe Philippines, Occupational Safety and Health Standards: RULE 1140 ExplosivesRuby Arnz PagaranNo ratings yet

- GL 06 Storage of Flammable LiquidsDocument1 pageGL 06 Storage of Flammable Liquidstp101267No ratings yet

- Firecode SheetDocument153 pagesFirecode SheetAleck Gabrielle BragaNo ratings yet

- H960 Experimental and Operating ManualDocument52 pagesH960 Experimental and Operating Manualnes1b0No ratings yet

- Safety PolicyDocument10 pagesSafety Policykenneth molinaNo ratings yet

- DM-Envrt TG - 30 Paint Spray BoothsDocument6 pagesDM-Envrt TG - 30 Paint Spray Boothsaspire79No ratings yet

- Fire Risk Reduction Rules 2007Document14 pagesFire Risk Reduction Rules 2007Cyprian CypuNo ratings yet

- Sec 10Document10 pagesSec 10SuadNo ratings yet

- Orca Share Media1591859827449 6676744041710261722Document14 pagesOrca Share Media1591859827449 6676744041710261722Jesse Jones SeraspeNo ratings yet

- Part I - 12 Material HandlingDocument7 pagesPart I - 12 Material Handlingsalah abddayemNo ratings yet

- 11 Specific OccupanciesDocument5 pages11 Specific OccupanciesVijay PatelNo ratings yet

- 19 Hazardous Waste ManagementDocument3 pages19 Hazardous Waste ManagementMohammed MinhajNo ratings yet

- S-849 - December 2018 Page - 6Document1 pageS-849 - December 2018 Page - 6paniyaNo ratings yet

- Control of Hazardous Energies: Occupational Safety and Health Standards RULE 1090Document9 pagesControl of Hazardous Energies: Occupational Safety and Health Standards RULE 1090gkaty28No ratings yet

- B. Protective Enclosure of ExitsDocument3 pagesB. Protective Enclosure of ExitsNiña Joy T. MacaranasNo ratings yet

- Codes of Practice For BMDDocument8 pagesCodes of Practice For BMDKuldeep SinghNo ratings yet

- Dunlop Vinyl Adhesive MSDSDocument8 pagesDunlop Vinyl Adhesive MSDSSN NazihahNo ratings yet

- Demolition & Excavation EnglishDocument64 pagesDemolition & Excavation EnglishRamon FrillesNo ratings yet

- Safety Management PlanDocument71 pagesSafety Management PlanSamuel Maclean ArthurNo ratings yet

- FPS Lab Worker JSA Updated 6-2016Document6 pagesFPS Lab Worker JSA Updated 6-2016Khadija AsgharNo ratings yet

- 15 Materials Handling and Storage: Answers-Quiz 1Document2 pages15 Materials Handling and Storage: Answers-Quiz 1KiliNo ratings yet

- Rule 1090 Hazardous MaterialsDocument45 pagesRule 1090 Hazardous MaterialsJustice ArjonaNo ratings yet

- Fire Protection and PreventionDocument38 pagesFire Protection and PreventioncixaxaNo ratings yet

- Workplan:: Heavy Equipment Hazards and ControlsDocument3 pagesWorkplan:: Heavy Equipment Hazards and ControlsRenauld WilsonNo ratings yet

- Caperts InstallationDocument3 pagesCaperts InstallationMunaku TafadzwaNo ratings yet

- MSDS - Monopropylene Glycol - Industrial - EngDocument11 pagesMSDS - Monopropylene Glycol - Industrial - Engamiller1987No ratings yet

- Tamil Nadu Factories Rules 1950Document18 pagesTamil Nadu Factories Rules 1950Sindarth RaveendrakrishnanNo ratings yet

- Scan 14-16Document3 pagesScan 14-16ᜇᜒᜌᜓᜈᜎ᜔ᜇ᜔ ᜊᜒᜇᜓᜌ᜔No ratings yet

- Course H-4002Document32 pagesCourse H-4002newnse2008No ratings yet

- Safety Standard For Material Storage and Handling Final 03 10 16Document11 pagesSafety Standard For Material Storage and Handling Final 03 10 16Shrikant Mishra RaipurNo ratings yet

- Toolbox Talk: No1 Spill ControlDocument24 pagesToolbox Talk: No1 Spill ControlArun100% (1)

- Emergencies and SpillsDocument5 pagesEmergencies and SpillsClement KipyegonNo ratings yet

- Div 3 FDocument22 pagesDiv 3 FSalman KhanNo ratings yet

- Project Fire Risk AssessmentDocument72 pagesProject Fire Risk AssessmentIshmael TettehNo ratings yet

- Radiation Safety AssistanceDocument1 pageRadiation Safety Assistancemyco samNo ratings yet

- Lesson 7 Control of Hazardous MaterialsDocument6 pagesLesson 7 Control of Hazardous MaterialsSheena Ann StonehillNo ratings yet

- Unit Test 2 P-7 H & E Legislation 23114Document11 pagesUnit Test 2 P-7 H & E Legislation 23114pankajsharma130No ratings yet

- Section 5 - FIRE PROTECTION FACILITIESDocument135 pagesSection 5 - FIRE PROTECTION FACILITIESAnoop PrajapatiNo ratings yet

- 01 - Aramco Exam & Interview QuestionsDocument4 pages01 - Aramco Exam & Interview QuestionsChen XinNo ratings yet

- Selection and Use of Specialized Chemical Protective EnsemblesDocument3 pagesSelection and Use of Specialized Chemical Protective EnsemblesAlvaro Rojas AnzolaNo ratings yet

- NIRB Screening Decision Report, Nanisivik Naval FacilityDocument20 pagesNIRB Screening Decision Report, Nanisivik Naval FacilityNunatsiaqNewsNo ratings yet

- For-2009-06-08-602 7Document1 pageFor-2009-06-08-602 7amin mohNo ratings yet

- Section 01545 SafetyDocument4 pagesSection 01545 SafetyAnonymous NR3qZ30No ratings yet

- Safety: Linhas Aéreas InteligentesDocument30 pagesSafety: Linhas Aéreas InteligentesChristian OliveiraNo ratings yet

- Safety Precautions For Civil Construction ActivitiesDocument14 pagesSafety Precautions For Civil Construction ActivitiesMohit AgarwalNo ratings yet

- Alexander County Government Housekeeping PolicyDocument3 pagesAlexander County Government Housekeeping PolicySol AbonNo ratings yet

- Chapter 12 - Storage Transportation Handling of Explosive 30 Jun 07Document12 pagesChapter 12 - Storage Transportation Handling of Explosive 30 Jun 07Raj Lilhare0% (1)

- SDS3 PDFDocument1 pageSDS3 PDFjohnNo ratings yet

- 18 HousekeepingDocument3 pages18 HousekeepingMohammed MinhajNo ratings yet

- Fire PreventionDocument3 pagesFire PreventionflorelmagNo ratings yet

- Aluminium Ferrosilicon PowderDocument2 pagesAluminium Ferrosilicon PowderkemalaaNo ratings yet

- Chemical Spill Cleanup SWPDocument5 pagesChemical Spill Cleanup SWPSalman ShahzadNo ratings yet

- Fire Protection Prevention AutosavedDocument32 pagesFire Protection Prevention AutosavedChaskieNo ratings yet

- Viking RaidDocument31 pagesViking RaidAnonymous 61kSe1MNo ratings yet

- Deck Cranes PDFDocument7 pagesDeck Cranes PDFIndra Ranu KusumaNo ratings yet

- How To Avoid Wastage of EnergyDocument1 pageHow To Avoid Wastage of EnergyNazrawi IJobsNo ratings yet

- Aakas Aiats 2020 Test1 29-07-2019Document119 pagesAakas Aiats 2020 Test1 29-07-2019gyandatt100% (3)

- Solar Panel Thesis PhilippinesDocument6 pagesSolar Panel Thesis Philippinesmelanierussellvirginiabeach100% (2)

- Class 9 Science Study Material Chapter 12Document16 pagesClass 9 Science Study Material Chapter 12rajman1990No ratings yet

- Cleaning of Pipes by Gas Discharge Back PuffingDocument1 pageCleaning of Pipes by Gas Discharge Back PuffingVamsi MahantiNo ratings yet

- AEH Company Profile-1Document14 pagesAEH Company Profile-1Hrishikesh RaiNo ratings yet

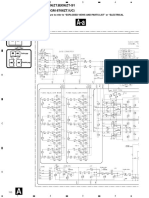

- 3.3 Schematic Diagram (Gm-8706Zt/Uc)Document12 pages3.3 Schematic Diagram (Gm-8706Zt/Uc)qmarcelNo ratings yet

- UHDE - Nitrate Fertilizers PDFDocument24 pagesUHDE - Nitrate Fertilizers PDFvzgscribdNo ratings yet

- SMK0765FJ: Switching Regulator ApplicationsDocument8 pagesSMK0765FJ: Switching Regulator ApplicationsranaateeqNo ratings yet

- Rig Mechanic PDFDocument3 pagesRig Mechanic PDFUpendra ChoudharyNo ratings yet

- Bruce E. Depalma: N-Machine: Extraction of Electrical Energy Directly From Space: The N-MachineDocument7 pagesBruce E. Depalma: N-Machine: Extraction of Electrical Energy Directly From Space: The N-MachinebanzailoicNo ratings yet

- 2014 Aprilia SR MAX 300 (Service Manual)Document335 pages2014 Aprilia SR MAX 300 (Service Manual)alexander ortizNo ratings yet

- Puma Energy - JPM Bond ConferenceDocument30 pagesPuma Energy - JPM Bond ConferenceKA-11 Єфіменко ІванNo ratings yet

- Phase Diagram (Compatibility Mode)Document29 pagesPhase Diagram (Compatibility Mode)soonvy100% (7)

- NACHI Full Catalog Small RevDocument468 pagesNACHI Full Catalog Small RevSombat MahamadNo ratings yet

- Product Catalogue 2017: AquathermDocument183 pagesProduct Catalogue 2017: AquathermZeeshanNo ratings yet

- TALAT Lecture 1253: CreepDocument26 pagesTALAT Lecture 1253: CreepCORE Materials100% (1)

- DatasheetDocument13 pagesDatasheetkishore kumarNo ratings yet

- EFuel ReportDocument52 pagesEFuel ReportMassimiliano ZocchiNo ratings yet

- UOP Merox Chapter PDFDocument12 pagesUOP Merox Chapter PDFrohl55No ratings yet

- OzoneDocument1 pageOzonebolsjhevikNo ratings yet

- Portal Frame ConstructionDocument2 pagesPortal Frame Constructionriz2010No ratings yet

- 5 Feeder Protection & Relay CoordinationDocument51 pages5 Feeder Protection & Relay CoordinationSatya VasuNo ratings yet

- Generator Relay Protection Setting Calculation REV 1.0Document18 pagesGenerator Relay Protection Setting Calculation REV 1.0SreekanthMylavarapuNo ratings yet

- Annexure-3 Calculation of Safe Bearing Pressure Based On N Value Settlement CriteriaDocument4 pagesAnnexure-3 Calculation of Safe Bearing Pressure Based On N Value Settlement CriteriaAnkitaNo ratings yet

- Ultra Cote 401 HsDocument3 pagesUltra Cote 401 HsGilbert Dela Serna IINo ratings yet

- Eat That Frog!: A Book Summary OnDocument17 pagesEat That Frog!: A Book Summary OnramranganNo ratings yet

- Dipen Baroda Follo-Up SheetDocument92 pagesDipen Baroda Follo-Up Sheetanon-272209100% (1)