Professional Documents

Culture Documents

Compressors For Gas Applications Tmic00020120

Uploaded by

La Juan Raul0 ratings0% found this document useful (0 votes)

10 views21 pagesOriginal Title

compressors_for_gas_applications_tmic00020120

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

10 views21 pagesCompressors For Gas Applications Tmic00020120

Uploaded by

La Juan RaulCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 21

OAL ce leec MLA L ce Lkl) uk sceai

Seu etcens

SCREW COMPRESSORS

for gas & special applications

Termomeccanica Industrial Compressors

ll gruppo Termomeccanica Tradizione,

tecnologia e innovazione

Termomeccanica fu fondata in La Spezia nel 1912 corne "So-

cieta Cerpall’ & C", divenendo successivamente negli anni 30

“Termomeccanica Italiana S.p.A." Nel gennaio 1995, le ativita

dla societé Termemeccanica Italiana Sp.A., anpartenente al

Gruppo di Stato EFIM in iquidazione, sono state cedute a Ter-

momeccanica &.p.A. affnché, con management privato, fosse-

ro porsoguite le storiche tracizioni dolla sociota nei campi mani-

fatturiore © impiantisico.

‘Termomeccanica ® oggi un gruppo industrial italiano trai princi-

pal operatori ne’ sertor! del Ecologia @ della Meccanica. Leader

nazionale nella produzione di grandi pompe industrial nel in-

Piantistica ecologica, il gruppo progetta, realizza e gestisce so-

luzioni tecnolagiche d avanguarca,

‘Termomeccanica svolge le sue attivta in Italia ed al'estero at-

traverso le sequent societ& operative, specializate neirispetiv

rmercati di rferimento:

TMB. SpA Termomeccanica Pompe sviluppa, costruisoe &

commercialzza pompe centifughe ingognerizzate per applica

oni nei setior dela Produzione di Energia, Dissalazione, Movi-

rmentazione dole Acque, dell & Gas ed Industria,

‘TMLC. Sil Termomeccanica Industrial Compressors @ loa-

{or italiano nala progettazione, costruzione © commercializza-

Zione di compressor rotath lubrificat! ad olio per applicazioni

ara e gas.

‘TME. SpA Termomeccanica Ecologia si ocoupa della proget-

tazione e costruzione di opere di ingegnenia ambientale ed indu-

striae per la Produzione di Energia (da rll soldi urbani e da

Fonti Rinnovabii quali biomasse, biogas, eolco ¢ solare) & per

il trattamento tecnologico dete aque ad uso cvle ed industrile

(potebilzzazione, dssalazione e depurazione).

Termomeccanica Group

Traaition, technology & innovation

Termomeccanica was established in 1912 in La Spezia as “Car

pall & C." and later became a stock company in the 1930s,

{taking the name of "Fermomeccanica ltalana $.p.A."

In January 1985, further to the dissolution of EFIM, the state-ow-

‘ned group it belonged to, the activities and shares of Termomec-

canica ttalana S.p.A. were transferred to privately-owned and

‘managed Termomeccanica S.p.A. with the aim to continue the

company’s strong heritage in the manufacturing and turn-key

plants sectors.

Today, Tommomeccanica is an italian industial group which is

amongst the main players of both the Environmental and Ma-

‘chanical sectors. The group, national leader in the manufactu:

‘ing of large industrial pumps and in environmental turn-key

‘plant projects, designs, develops and manages cutting edge

technological solutions.

Termomeccanica carries out ts various business activites in taly

and abroad through its operational companias, each specialized

In one of the group’ key market:

TM.P. SpA Termomeccanica Pompe designs, manufactures

and commercialzes engineered centritugal pumps for the fields

of Power Generation, Desalination, Water Transmission, Oil &

Gas and Heavy industry.

TM.LC. Srl Termomeccanica Industrial Compressors is tho

Italan leader in developing, manufacturing and commercializing

ail injocted screw compressors for air and gas applications.

TM.E. SpA Termomeccanica Ecologia isa turn-key EPC con-

tractor for Environmental & Industrial plant for the Production of

Energy (Waste to Energy and Renewable Energy) and Techno-

logical Water Treatments (potabilzatio, desalination and waste

water punifcation for cil and industria uses)

Screw compressor fo gas

and special applications

TMIC's worldwide presence

Our headquarters

‘TMIC: the leading ltaian compressor supplier

NG and SCG gas compressors series -

main characteristics

NG and SCG gas compressors series -

porformance rango

NG and SCG gas compressors sexios ~

products overview

TMIC's special features for gas applications

il fooded gas screw compressors technology

‘TMIC’s compressor technology - twin screw

{gas ends vs piston gas compressors,

TMIC's compressors - fields of application

& typical projects

TMIC's product overview for air applications

P

pag. ¢

pag. 6

pag. 8

ag,

pag.

ag.

pag.

ag.

pag.

ag,

pag,

12

14

16

7

18

20

TMIC’s world

More than 100 customer:

ide presence

3 in 30 different countries

no

2

o

<

io)

ro]

son

TMIC: the leading Italian

compressor supplier

boasts more than 40 years of experience in

the development and

compressors

supplier.

‘TMIC offers an all-encompassing service, ranging

from the identification of market needs to the

tudy of

teams grant the

most. qué pport throughout the enti

supply chain:

TMIC's gas compressor line has been developed

based on the experience gained from the existing

SCA series, renowned for its reliability for air

applications: the company customized its SCA

series to make it suitable for gas applications.

Each compressor is designed and manufactured

according to the highest technology standards.

Indeed, our entire production is fully tested before

reaching our customers facilites.

Our workshop is also equipped to perform

hydrostatic, mechanical and performance tests

according to customer specifications.

TMIC supports its worldwide customer base

through its dedicated Service Division, which

offers a broad range of services not only for

its own rolating machines but also for other

original equipment manufacturers’ machines.

‘Such services include training courses, warranty

services and engineering support for every stage

of a compressor’s maintenance, thus allowing to

extend product lf.

Termomeccanica Industrial Compressors

NG and\SCG compressors series

Na13

Stat Power ergo or 1 6

‘Shatt Power range (CV): rom 18 1050

(Capacity (Neh from B7 to 760

Gear ato. trom 102% 218

Weight (xa): 100

.

Neg

Shalt Bower range (kW): rom 6 to $0

Shaft Power range (CV): fom 80 41

Eaoaciy ine tom 70 380

Sear fho fom 1 281005

Beste) 2

.

.

NG8&

‘Shaft Power range (kW): from 5 to 24

Shak Powe ag 6 (CV) rom 710 33 °

spac un Hom

Getrake om 18b10 3 7 O14 a covany gam saw vi

font aft Power ange (rom 1410

. eo Shan Dover ange (Uy fom 1818 168

Capacity (Nein): tom 12010 1,400

Gear Ratio trom 1 14 10222

Weight (xa) 140

les overview

.

NG30

Shaft Power range (AW): rom 45 to 420,

Shaft Power range (Cv). rom 61 10.571

Capacity (Nain from 430 10 5400 .

Gear Ratio from 0.49 10 1.94 NG3oT

Seana) tons Shalt Bower range (from 101 0 860

Shalt Powe range (CV): fom 137 10 1156

Gapaciy (Nm rom 800 0 11/000

Gear ato From 11D to 2.28

Weign (egy 2755

NG and SCG compressors seri

N@2o

‘Shatt Power range (ki): or 20 to 169,

$Shatt Power range (CV). trom 27 © 230,

Capacity (Neh from 200 to 2,100

Gear ato: from oso to 2 14

‘Weight (xg): 820

.

NG22

Sra or range (fom 280 28

Shall Pawar range (CV; rom 35 1@ 362

Gapscity (Nein fom 250 0 8.450

Gear ati From 0.61 t0 2.10

Wieignt (kg) 490

SCG10

‘Shatt Power range (kt): or 9 to 50.

‘Shatt Powet range (Cv): rom 120 68

Capacity (Nin from 680 720

‘Gear Rate: from 1 26 10.3.0

wright (kg) 68

.

scat4

Sta Power ang a fom 14 110

Shall Power range (CVE: tom 19 8 180

Capacity (Nein: trom 12010 1,570

Gear ato. rom 1.14 t0 2.21

Weigne (xg) 140

Termomeccanica Industrial Compressors

TMIC’s special features for gas applications

NGSOSL (separate lubrication system)

Acompressor particularly suitable for aggressive gases

‘The NG3OSL's main features are:

‘+ Two separate oil lines

Internal and external mechanical seals

» Drainage system

* Thermowell connections

Termomeccanica Industrial Compr

Special integrations for gas applications

‘TMIC offers special features to answer its customers’ specific needs related

to gas applications such as:

'» More compact design solutions

= Personalized filters

'* Single mechanical seal

15

TMIC screw compressors are twin rotary screw

machines (positive displacement design) capable

The oil injected in the compression chamber fulfils

many functions:

of handling a wide range of gases thanks to the

accuracy and the control of the small clearance

between rotors and their casings. Infact, during the

rotation of rotors, the volume of the compression

chamber decreases with the increasing discharge

pressure. This way, gas is compressed from the

suction port ((ocated at

the too of the machine) to the discharge port

placed at the bottom (or at the front) of the

machine,

sealing during the compression allowing to

reach high volumetric efficiency;

lubrication of the rotation elements (rotors,

bearings, mechanical

heat removing and discharge temperature

control, allowing to keep the gas in the right

condition in terms of liquids condensation.

After the gas end mixes the compressed gas

and the oll, the mixture then passes

through an cil separator system and the oil

is cooled, filtered and sent back into the

gas end once again:

protection of components from corrosion

and gas materials aggression,

The advantages offered by twin screw gas ends

are:

better/more compatible behavior with

aggressive gases;

lower noise level

higher efficiency in the range below 40 bar

(the instalation of vaive ports reduces losses

of energy);

longer MTBF;

lower maintenance costs and simpler

operation;

lower cost of plant construction as no foundations

are required to prevent vibration

higher reliability therefore lower complete life

cycle costs.

Fields of application & typical projects

Oil & Gas Power Generation

* Well head gas * Turbine and gas engine boosting

* Vapour recovery units * Biomethanization plant and biogas

* Natural gas gathering / gas boosting compression system

and trasmission

* Shale gas, tight gas and coal bed

methane system

Refining and Petrochemical General utilities

‘Ammonia vapour system CNG dispenser

Termomeccanica Industrial Compressors

TMIC’s product overview

for air applications

Capacity range: 0.8 - 96 m/min Capacity range: 7-31 m/min

Max. power: 950 KW Max. power: 250 kW

Max. cischarge pressure: 20 bar Max. discharge pressure: 16 bar

SCISERIES

Capacity range: 0.3 - 5.5 m/min

Max. powor: 55 KW

Max. discharge pressure: 20 bar

Oil Free

Capacity range: 6 - 18 m/min

Max. power: 70 KW

Max. discharge pressure: 2.6 bar

20

ORR a ea eciny

Pete eee re)

coe ar eae

eee eee uot)

cee

Senne Auk

You might also like

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Guia Rapida DMD DenairControlador AirmasterDocument5 pagesGuia Rapida DMD DenairControlador AirmasterLa Juan RaulNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5806)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

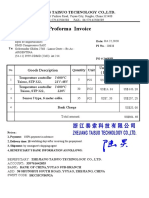

- Proforma Invoice: Zhejiang Taisuo Technology Co.,LtdDocument1 pageProforma Invoice: Zhejiang Taisuo Technology Co.,LtdLa Juan RaulNo ratings yet

- Compressors For Air Applications Tmic00010319Document48 pagesCompressors For Air Applications Tmic00010319La Juan RaulNo ratings yet

- Conceptosbasicos 191027230213Document53 pagesConceptosbasicos 191027230213La Juan RaulNo ratings yet

- Efecto PelicularDocument12 pagesEfecto PelicularLa Juan RaulNo ratings yet

- S C T 0 1 3 G - D: Ф16Mmaperture Split Core Current TransformerDocument5 pagesS C T 0 1 3 G - D: Ф16Mmaperture Split Core Current TransformerLa Juan RaulNo ratings yet

- RSLF 120 PD PDFDocument1 pageRSLF 120 PD PDFLa Juan RaulNo ratings yet

- Brochure y Verticales Zennon BI - Nov 2020Document17 pagesBrochure y Verticales Zennon BI - Nov 2020La Juan RaulNo ratings yet

- CO Radial Piston Compressor (Transcritical)Document9 pagesCO Radial Piston Compressor (Transcritical)La Juan RaulNo ratings yet

- Catalog Modicon M262 Logic-Motion Controller - IIoT Ready For Performance Machines PDFDocument23 pagesCatalog Modicon M262 Logic-Motion Controller - IIoT Ready For Performance Machines PDFLa Juan RaulNo ratings yet

- Acti9 iEM3000 - A9MEM3155Document3 pagesActi9 iEM3000 - A9MEM3155La Juan RaulNo ratings yet

- How To Set Up Q1 For Isc (Master/Slave) : ST NDDocument3 pagesHow To Set Up Q1 For Isc (Master/Slave) : ST NDLa Juan RaulNo ratings yet

- Many1405a.en - Airmaster™ - Addendum - Q1 Software Manual - en - E25Document86 pagesMany1405a.en - Airmaster™ - Addendum - Q1 Software Manual - en - E25La Juan RaulNo ratings yet

- Airmaster Q Series Q1 Controller Software For Positive Displacement Compressor FactsheetDocument8 pagesAirmaster Q Series Q1 Controller Software For Positive Displacement Compressor FactsheetLa Juan RaulNo ratings yet

- Addendum Q1 Positive Displacement Rotary Compressor Software Manual, E09 - E23Document80 pagesAddendum Q1 Positive Displacement Rotary Compressor Software Manual, E09 - E23La Juan Raul100% (1)