Professional Documents

Culture Documents

Alloy Spec Sheet

Uploaded by

Ali AhmadOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Alloy Spec Sheet

Uploaded by

Ali AhmadCopyright:

Available Formats

ALLOY SPECIFICATIONS

Magnesium

ASTM AMS European Major Min. Tensile Properties Typical Tensile Properties

Designation Reference Reference Elements From Casting – Ksi (Mpa) From Casting – Ksi (Mpa)

AZ91C-T6 4437 AZ-91 Al 9.0, Zn 0.6, Mn 0.2 25.5(175)/14.5(100)/0.75% 33.0(227)/21.0(145)/3.0%

General-purpose alloy. Primarily for parts operating in service up to 149°C (300°F).

AZ91E-T6 4446 Al 9.0, Zn 0.6, Mn 0.2, .005 Fe Max. 25.5(175)/14.5(100)/0.75% 36.0(248)/23.0(158)/4.0%

General-purpose alloy. Primarily for parts operating in service up to 149°C (300°F).

Excellent corrosion resistance properties (.050 inch per year max.).

AZ92A-T6 4434 Al 9.0, Zn 1.8, Mn 0.2 25.5(175)/16.0(110)/0.75% 38.0(262)/24.0(165)/3.0%

Excellent strength at room temperature. Primarily for parts in service up to 149°C (300°F).

EZ33A-T5 4442E ZRE1 RE 3.0, Zn 2.5, Zr 0.6 13.0(90)/11.0(76)/1.5% 22.0(152)/15.0(103)/3.5%

Excellent castability, pressure tight and weldable. Creep resistance up to 260°C (500°F).

QE22A-T6 4418F MSR(A) Ag 2.5, RE 2.0, Zr 0.6 32.0(220)/23.0(158)/2.0% 40.0(276)/28.0(193)/6.0%

High long-term yield strength at elevated temperatures up to 204°C (400°F). Pressure tight and weldable.

EQ21A-T6 4417 Ag 1.5, Re 2.1, Cu .08, Zr 0.7 32.0(220)/23.0(158)/2.0% 40.0(276)/28.0(193)/6.0%

High long-term yield strength at elevated temperatures up to 204°C (400°F). Pressure tight and weldable.

WE43A-T6 4427 Y 4.0, Nd 2.3, Zr 0.7 31.5(217)/22.0(151)/2.0% 38.0(262)/26.0(179)/5.0%

High long-term yield strength at temperatures up to 250°C (480°F). Excellent corrosion resistance properties.

ZE41A-T5 4439D RZ5 Zn 4.2, RE 1.3, Zr 0.7 26.0(179)/17.5(120)/2.0% 30.0(207)/21.0(145)/4.0%

Excellent castability and pressure tightness with useful strength at elevated temperatures up to 160°C (320°F).

Aluminum

ASTM AMS European Major Min. Tensile Properties Typical Tensile Properties

Designation Reference Reference Elements From Casting – Ksi (Mpa) From Casting – Ksi (Mpa)

203-T6 225B RR350 Cu 5.0, Ni 1.5, Mn 0.3 32.0(220)/24.0(165)/1.5% 39.0(269)/29.0(200)/2.5%

High strength and good stability up to 316°C (600°F), with resistance to stress corrosion cracking.

A242-T75 4220D Cu 4.0, Ni 2.0, Mg 1.5, Cr 0.2 20(138)/----/---- 30.0(207)/26.0(179)/1.5%

Good high temperature strength up to 204°C (400°F).

C355-T6 4215F LM16 Si 5.0, Cu 1.2, Mg 0.5 35.0(241)/28.0(193)/2.0% 45.0(310)/35.0(241)/5.0%

Good room and elevated temperature yield up to 177°C (350°F).

354-T6 Cu 1.8, Si 9.0, Mg 0.5 43.0(296)/33.0(227)/2.0% 50.0(349)/40.0(277)/3.5%

Excellent room and elevated temperature properties up to 148°C (300°F).

A356-T6 4218G LM25 Si 7.0, Mg 0.5 32.0(220)/22.0(152)/2.0% 40.0(276)/30.0(207)/4.0%

Good general-purpose alloy. Good strength up to 150°C (300°F).

A357-T6 4219C Si 7.0, Mg 0.5 38.0(262)/30.0(207)/2.0% 46.0(317)/38.0(262)/4.0%

High strength alloy for structural and gearbox applications. Good elevated temperature strength up to 150°C (300°F).

D357 4241 Si 7.0, Mg 0.58 45.0(310)/36.0(260)/2.0% 51.0(352)/41.0(282)/5.0%

Premium, high strength, structural alloy with tight chemistry control. Maintains strength at elevated temperatures.

Notes: 1. Usage of all alloys is not limited to the application detailed above.

2. Aluminum alloy properties made to meet customer needs.

3. Only AMS specifications are listed above. Other specifications are used and available (Military, ASTM and Customer).

4. Tensile properties are specified as Ultimate Strength (UTS), Yield Strength (YS) and Elongation (El).

5. Heat treatment conditions are: T4-Solution, T5-Stabilized, T6-Solution treated and aged, T7-Solution treated and over-aged.

Haley Industries Limited Presto Casting Company

634 Magnesuim Road, Haley, Ontario, Canada K0J 1Y0 54401 W. Luke Avenue, Glendale, Arizona, USA 85301

Telephone: 613-432-8841 Telephone: (623) 939-9441

You might also like

- Material Cross Reference TableDocument3 pagesMaterial Cross Reference TableLuis Pol SistiNo ratings yet

- Aisi 200 SeriesDocument19 pagesAisi 200 Seriessgupta_192494No ratings yet

- Material enDocument2 pagesMaterial enjoshiShripad31No ratings yet

- WELDING SPREADER Electrode KALMAR PDFDocument1 pageWELDING SPREADER Electrode KALMAR PDFArtin HykoNo ratings yet

- 301 Stainless SteelDocument7 pages301 Stainless Steeldilnair99No ratings yet

- AISI Type 403 Stainless Steel Properties and ApplicationsDocument7 pagesAISI Type 403 Stainless Steel Properties and ApplicationsMiguelPacheecoAgamezNo ratings yet

- The Role Stainless Steel in Industrial Heat ExchangersDocument46 pagesThe Role Stainless Steel in Industrial Heat ExchangerswholenumberNo ratings yet

- S.No Materials Specification DescriptionDocument4 pagesS.No Materials Specification DescriptioniyamNo ratings yet

- 303 Spec SheetDocument2 pages303 Spec SheetYankMulya MusaNo ratings yet

- AUTROD 316LSiDocument2 pagesAUTROD 316LSijoao guilhermeNo ratings yet

- Properties of Ss410Document5 pagesProperties of Ss410gregkilatonNo ratings yet

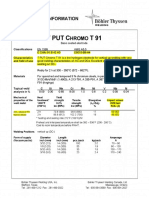

- T PUT Chromo T91Document1 pageT PUT Chromo T91Ahmed GamalNo ratings yet

- Stainless AISI 3XXDocument3 pagesStainless AISI 3XXThitaphol HuyananNo ratings yet

- Wire Mesh Steel Reinforcement BarsDocument6 pagesWire Mesh Steel Reinforcement Barssattar12345No ratings yet

- 1414 Ev 50 PDFDocument1 page1414 Ev 50 PDFbabaaromeNo ratings yet

- Bohler Fox DMV 83 KB - SmawDocument1 pageBohler Fox DMV 83 KB - Smawsoft4gsmNo ratings yet

- Custom Welding Lines for Non-Machinable Cast IronDocument2 pagesCustom Welding Lines for Non-Machinable Cast IronAlvaro Fernando Reyes CastañedaNo ratings yet

- Grade Data SheetDocument2 pagesGrade Data Sheetamitkharb111195No ratings yet

- MIP Bohler Welding Austria 63Document1 pageMIP Bohler Welding Austria 63thod3rNo ratings yet

- Grade Data Sheet for 304, 304L and 304H Stainless SteelsDocument2 pagesGrade Data Sheet for 304, 304L and 304H Stainless Steelss swamiNo ratings yet

- Supranox Rs 309L: MMA Electrodes Stainless and Heat Resistant SteelsDocument1 pageSupranox Rs 309L: MMA Electrodes Stainless and Heat Resistant SteelsbrunizzaNo ratings yet

- Carbo 4370 Mpr-E307Document1 pageCarbo 4370 Mpr-E307ali torabiNo ratings yet

- KST 309LDocument1 pageKST 309LTharman SupramaniamNo ratings yet

- AISI 430 Ferritic Stainless Steel Grade for AppliancesDocument3 pagesAISI 430 Ferritic Stainless Steel Grade for AppliancesAgus MulyadiNo ratings yet

- Supply Range of AISI M42 Tool Steel High SpeedDocument4 pagesSupply Range of AISI M42 Tool Steel High SpeedSama UmateNo ratings yet

- Böhler Fox CM 2 KB: Classifi CationsDocument1 pageBöhler Fox CM 2 KB: Classifi CationsBranko FerenčakNo ratings yet

- Metrode ER110S-G FillerDocument6 pagesMetrode ER110S-G FillerBernie SimcsNo ratings yet

- P 36 Material 15NiCuMoNb5-6-4Document13 pagesP 36 Material 15NiCuMoNb5-6-4Mudassar Iqbal100% (1)

- Böhler CM 5-Ig: TIG Rod, High-Alloyed, Creep ResistantDocument1 pageBöhler CM 5-Ig: TIG Rod, High-Alloyed, Creep Resistantwesley59No ratings yet

- Classification - 316,316L Application and Properties - AK SteelDocument7 pagesClassification - 316,316L Application and Properties - AK SteelAditya Krisna HutomoNo ratings yet

- Applications: TYPE: RutileDocument1 pageApplications: TYPE: Rutilesattar12345No ratings yet

- 304 Grade SteelDocument6 pages304 Grade SteelShashank SaxenaNo ratings yet

- DS482Document3 pagesDS482mariomatoNo ratings yet

- 25CR20NIDocument2 pages25CR20NIShariq KhanNo ratings yet

- Die Casting Heat Treatment Process To Increase Strength Part 1Document4 pagesDie Casting Heat Treatment Process To Increase Strength Part 1itslowNo ratings yet

- Atlas 304 - 304L: Colour Code: Lilac/TurquoiseDocument3 pagesAtlas 304 - 304L: Colour Code: Lilac/TurquoiseOthoniel MunizNo ratings yet

- datasheet-saf-2205-en-v2021-10-07 13_05 version 1Document8 pagesdatasheet-saf-2205-en-v2021-10-07 13_05 version 1simone.mauriNo ratings yet

- Aluminium Alloy 6061 - Composition, Properties, Temper and ApplicationsDocument4 pagesAluminium Alloy 6061 - Composition, Properties, Temper and ApplicationsMadhu SudanNo ratings yet

- Duplex SSDocument2 pagesDuplex SSsjk_akolNo ratings yet

- CHS29 9Document1 pageCHS29 9sulis setiawanNo ratings yet

- Alloy Data Sheet: Heat Resistant Alloy REVISION: 03/91Document2 pagesAlloy Data Sheet: Heat Resistant Alloy REVISION: 03/91tetirichieNo ratings yet

- 316/316L Stainless Steel Spec SheetDocument3 pages316/316L Stainless Steel Spec SheetLinnie McleodNo ratings yet

- Engineering Data Chapter Provides Valve Material SpecificationsDocument93 pagesEngineering Data Chapter Provides Valve Material SpecificationsBhuidhar VermaNo ratings yet

- Engineering Data Chapter Provides Specifications for Valve MaterialsDocument9 pagesEngineering Data Chapter Provides Specifications for Valve MaterialsVu Tung LinhNo ratings yet

- CF10MC (1.4571)Document3 pagesCF10MC (1.4571)Gilcimar Cavalcante GilcimarNo ratings yet

- Fe-Base Superalloy A286 (EAF+ESR) A286 (EAF+VAR) : Z Equivalent SpecificationDocument1 pageFe-Base Superalloy A286 (EAF+ESR) A286 (EAF+VAR) : Z Equivalent SpecificationpvdangNo ratings yet

- Inconel 82 (Austral-Wright)Document1 pageInconel 82 (Austral-Wright)Claudia MmsNo ratings yet

- 5 - Duplex Stainless Steels and Nickel AlloysDocument44 pages5 - Duplex Stainless Steels and Nickel AlloysdennykvgNo ratings yet

- Columbus Stainless Pocket GuideDocument29 pagesColumbus Stainless Pocket Guidebruteforce2000No ratings yet

- Sus904l 158Document1 pageSus904l 158rinthusNo ratings yet

- Specification Sheet: Alloy 309/309S/309H: (UNS S30900, S30908, S30909) W. Nr. 1.4833Document2 pagesSpecification Sheet: Alloy 309/309S/309H: (UNS S30900, S30908, S30909) W. Nr. 1.4833Felipe A. Gutiérrez M.No ratings yet

- Alloy 410s Spec SheetDocument2 pagesAlloy 410s Spec SheetALONSO GOMEZNo ratings yet

- AISI Type 302 Stainless Steel (UNS S30200) : Chemical CompositionDocument4 pagesAISI Type 302 Stainless Steel (UNS S30200) : Chemical CompositionnagboccaNo ratings yet

- 304 304L Data BulletinDocument8 pages304 304L Data Bulletinmayur2708No ratings yet

- 316l Austenitic Stainless Steel BarDocument3 pages316l Austenitic Stainless Steel Barதமிழன் இராமசாமிNo ratings yet

- Spec 4140 & 4130Document7 pagesSpec 4140 & 4130Nisa_nisheNo ratings yet

- Stainless Steel PlateDocument19 pagesStainless Steel PlateHarsh AdvaniNo ratings yet

- Materials Data for Cyclic Loading: Low-Alloy SteelsFrom EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsRating: 5 out of 5 stars5/5 (2)

- Fuel Processing TechnologyDocument7 pagesFuel Processing TechnologyAli AhmadNo ratings yet

- Hasannuddin 2016Document12 pagesHasannuddin 2016Ali AhmadNo ratings yet

- Basic Lost Wax Kilncasting: What This Tipsheet CoversDocument8 pagesBasic Lost Wax Kilncasting: What This Tipsheet CoversAli AhmadNo ratings yet

- Optimization of Diesel Fuel and Corn Oil Mixtures CompositionDocument10 pagesOptimization of Diesel Fuel and Corn Oil Mixtures CompositionAli AhmadNo ratings yet

- Tech - Note 5Document2 pagesTech - Note 5Ali AhmadNo ratings yet

- CastingProcessesLecture7 PDFDocument37 pagesCastingProcessesLecture7 PDFmel118No ratings yet

- Arrow 125cc Shifter/Gearbox Kart HighlightsDocument2 pagesArrow 125cc Shifter/Gearbox Kart HighlightsAli AhmadNo ratings yet

- Life Enhancement of Hot-Forging Dies by Plasma-NitridingDocument7 pagesLife Enhancement of Hot-Forging Dies by Plasma-NitridingAli AhmadNo ratings yet

- Structural Changes in 12-2.25% CR Weldments - An Experimental and Theoretical ApproachDocument8 pagesStructural Changes in 12-2.25% CR Weldments - An Experimental and Theoretical ApproachAli AhmadNo ratings yet

- Jenny C. Overeynder, ACSW Kathleen Bishop, Ph.D. Strong Center For Developmental Disabilities University of RochesterDocument9 pagesJenny C. Overeynder, ACSW Kathleen Bishop, Ph.D. Strong Center For Developmental Disabilities University of RochesterAli AhmadNo ratings yet

- @nitdgpDocument10 pages@nitdgphussainamir786No ratings yet

- @nitdgpDocument10 pages@nitdgphussainamir786No ratings yet

- @nitdgpDocument10 pages@nitdgphussainamir786No ratings yet

- Preventive Maintenance Service Concept For SPACOM Product FamilyDocument27 pagesPreventive Maintenance Service Concept For SPACOM Product FamilyMiguel MarquesNo ratings yet

- CFD Answer KeyDocument12 pagesCFD Answer KeyRaahini IzanaNo ratings yet

- Marketing 5 0Document23 pagesMarketing 5 0gmusicestudioNo ratings yet

- Heliflex Hose CatalogueDocument119 pagesHeliflex Hose CatalogueAugustine DharmarajNo ratings yet

- Iodine Summaryupdate 2016Document26 pagesIodine Summaryupdate 2016FrankNo ratings yet

- Entry-Exit Arrangement With Service RoadDocument1 pageEntry-Exit Arrangement With Service RoadRamBhuvan SonkarNo ratings yet

- Miniaturized 90 Degree Hybrid Coupler Using High Dielectric Substrate For QPSK Modulator PDFDocument4 pagesMiniaturized 90 Degree Hybrid Coupler Using High Dielectric Substrate For QPSK Modulator PDFDenis CarlosNo ratings yet

- Beneficiation of Cassiterite From Primary Tin OresDocument11 pagesBeneficiation of Cassiterite From Primary Tin OresSULMAGNo ratings yet

- MIND - BODY RelationshipDocument18 pagesMIND - BODY RelationshipvishwabhashaNo ratings yet

- Wemco Depurator 2003Document2 pagesWemco Depurator 20031mmahoneyNo ratings yet

- LEEA-036 (B) - Academy ITS Practical Training Courses Jan - June 2020 Version 1 October 2019Document18 pagesLEEA-036 (B) - Academy ITS Practical Training Courses Jan - June 2020 Version 1 October 2019kaito kurabaNo ratings yet

- Factors to Consider in Reactor Design for Industrial ProcessesDocument3 pagesFactors to Consider in Reactor Design for Industrial Processesuma villashini100% (2)

- Belazo Elastomeric Roof PaintDocument2 pagesBelazo Elastomeric Roof PaintrumahsketchNo ratings yet

- MODULE-2-VETTECH325 (2)Document31 pagesMODULE-2-VETTECH325 (2)cejproiloNo ratings yet

- SilverDocument16 pagesSilversharma_shruti0% (1)

- DM3xxx Accessory List LeafletDocument2 pagesDM3xxx Accessory List LeafletAdvantec SrlNo ratings yet

- Discover Over 70 Player Classes and RacesDocument1 pageDiscover Over 70 Player Classes and RacesFred FrançaNo ratings yet

- A Study On Renewable Energy Resources in IndiaDocument39 pagesA Study On Renewable Energy Resources in IndiaDevendra SharmaNo ratings yet

- Quarter 1-Module 2 Modern ArtDocument20 pagesQuarter 1-Module 2 Modern ArtKimberly Trocio Kim100% (1)

- Final Nasir GlassDocument57 pagesFinal Nasir GlassShuvo Taufiq Ahmed100% (2)

- DST Sketch S.E Alhamd 2Document3 pagesDST Sketch S.E Alhamd 2GPCNo ratings yet

- Air Sentry - Energy Statement App 3 Dessicant and Filters PDFDocument20 pagesAir Sentry - Energy Statement App 3 Dessicant and Filters PDFEsteban Fernando Meza IbacetaNo ratings yet

- HymssheetDocument4 pagesHymssheettoby_wardmanNo ratings yet

- Airway Management in The Critically Ill: ReviewDocument9 pagesAirway Management in The Critically Ill: ReviewQuarmina HesseNo ratings yet

- Phychem Chapter 3 Part 1Document14 pagesPhychem Chapter 3 Part 1Skye DiazNo ratings yet

- We Are Intechopen, The World'S Leading Publisher of Open Access Books Built by Scientists, For ScientistsDocument21 pagesWe Are Intechopen, The World'S Leading Publisher of Open Access Books Built by Scientists, For Scientistsnonzero15No ratings yet

- Material Safety Data Sheet: Chemtherm 550Document6 pagesMaterial Safety Data Sheet: Chemtherm 550Javier vaca villalbaNo ratings yet

- The Cactus and the SnowsDocument22 pagesThe Cactus and the SnowsCrisNo ratings yet

- A Feminist Analysis of Habba Khatoon'S Poetry: Dr. Mir Rifat NabiDocument7 pagesA Feminist Analysis of Habba Khatoon'S Poetry: Dr. Mir Rifat NabiShabir AhmadNo ratings yet

- SE 276B Syllabus Winter 2018Document2 pagesSE 276B Syllabus Winter 2018Manu VegaNo ratings yet