Professional Documents

Culture Documents

General Principles of Presentation Pag 60 - Pag 61

General Principles of Presentation Pag 60 - Pag 61

Uploaded by

Birlan Adrian0 ratings0% found this document useful (0 votes)

14 views1 pageCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

14 views1 pageGeneral Principles of Presentation Pag 60 - Pag 61

General Principles of Presentation Pag 60 - Pag 61

Uploaded by

Birlan AdrianCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 1

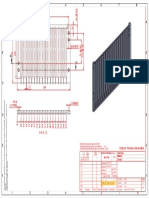

26 Tolerancing (ISO 406)

2.61 Tolerances for linear dimensions

can be indicated a follows:

he basic size and the ISO tolerance symbol (and, ifnec-

essary the vals ofthe deviations in parentheses

(Fig. 60/1 and 602)

the basic size and the deviations (Fig. 60/3). Where the

deviation is 0 (zero) must also be shown, without pre

fix (Fig, 60/4 and 6005).

= If the tolerance is symmetrical. in relation to the basic

size, the value of the deviations is indicated once only,

preceded by the sign = (Fig, 60/6).

‘The upper deviation isto be weitten in the upper pos

tion and the lower deviation in the lower position, ime-

spective of whether a hole (internal dimension) or shaft

(external dimension) is toleranced (Fig, 60/7... 60/9),

Deviations are to be expressed in the same units as the

basic size

26.2 Tolerances in drawings of assembled parts

‘can be indicated as fallow:

“by the basic size followed by the 1SO tolerance

symbols for hole and shalt separated by a forward

slash (Fig. 60/10),

= itis necessary to specify the numerical values of the

deviations, the values for the hole are placed above the

dimension line and those for the shaft below it

(Fig. 60/11).

by placing the basic size and the numerical value of

the deviations afte the par designation or part number,

also with the values for the hole are placed above the

dimension line and those for the shaft below it

(Fig. 60/12)

263 Tolerances for angular dimensions

fare indicated in the same manner as for linear dimensions

(Fig, 60/14) or by angular deviation expressed in degrees

(©) minutes () and seconds (") (Fig, 60/13).

02

ssomn_| porous

ig con Fis.

+0,1

43 -0,4

recon

° 10,05

woo] 200

rato as

19.08

soon | |_awiaite

1

acon recon

02 0.02

2033 | |_ancales

recon acon

|

mom — [eBHInS

0.008

soot.)

po

soal.4.00)|

Faso

|

20.3

41.630 20:1,

-O.1

Fie.owa 2.030012

epee vx

oa

g.6ora Fg 604

27180 SYSTEM OF LIMITS AND FITS, 8

2.7150 system of limits ang fits (EN 20286-1)

271 General

The ISO system of limits and fits provides dimensional tolerances for workpieces and for fits

between such workpieces.

For simplicity only eylindrical workpieces of circular section are referred to in the following. How-

ever, everything mentioned also applies to workpiece of other than circular sections. The general

terms “hole” and “shaft” can be taken to refer to the space contained by or containing the two paral-

lel faces ofa workpiece of any form, e.g the width of a slot or the thickness ofa key.

212 Reference temperature

“The reference temperature is +20

this temperate.

«gauges and workpieces have their designated dimensions at

273 Tolerances for workpieces

2234 nacuracy of manufacturing nthods

Deamoe ofthe inhernt naar of annfachring methods, a workpice can never be made

precy to an exact se, However ti slice for the function of the workpiece when

Teno ae hin what costed a perme upper and lower mers the

difference between which is a tolerance. me .

a

2.73.2 _ Relationship of deviation to nominal size

For simplicity a dimension is designated as nominal size, and the two limiting dimensions re deter-

‘mined by their deviations from the nominal size

274 Definitions

2741 Size

‘Annumber expressing, in a particular unit, the numerical value of a linear dimension,

2.44.2 Nominal size (basic size)

‘The size from which the limits of size are derived by application of the upper and lower deviations,

‘The nominal sy canbe a hol umber or dana mabe 0. 32875 05 ete

2743 Actual size

‘The size ofa feature, obtained by measurement

(di, di diy és

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Fizica Distractiva ZamfirescuDocument7 pagesFizica Distractiva ZamfirescuBirlan AdrianNo ratings yet

- General Principles of Presentation Pag 78 - Pag 79Document1 pageGeneral Principles of Presentation Pag 78 - Pag 79Birlan AdrianNo ratings yet

- Designed Sgd. PS Drawing Verified Aproved Sgd. PS: 1st Angle Projection Dimensions in Mm. 6/18/2019 11/19/2018Document1 pageDesigned Sgd. PS Drawing Verified Aproved Sgd. PS: 1st Angle Projection Dimensions in Mm. 6/18/2019 11/19/2018Birlan AdrianNo ratings yet

- Designed Sgd. PS Drawing Verified Aproved Sgd. PS: 1st Angle Projection Dimensions in Mm. 6/18/2019 6/18/2019Document1 pageDesigned Sgd. PS Drawing Verified Aproved Sgd. PS: 1st Angle Projection Dimensions in Mm. 6/18/2019 6/18/2019Birlan AdrianNo ratings yet

- Designed Sgd. PS Drawing Verified Aproved Sgd. PS: 1st Angle Projection Dimensions in Mm. 6/24/2019 11/19/2018Document1 pageDesigned Sgd. PS Drawing Verified Aproved Sgd. PS: 1st Angle Projection Dimensions in Mm. 6/24/2019 11/19/2018Birlan AdrianNo ratings yet