Professional Documents

Culture Documents

Indicatoare Circulatie Ulei 12CCL2CATR04-E

Uploaded by

maggamOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Indicatoare Circulatie Ulei 12CCL2CATR04-E

Uploaded by

maggamCopyright:

Available Formats

Flow Indicators

Series CCL2

Cat: 12CCL2CATR04-E Rev: 04 – 05/2010

Catalogue N° 12CCL2CATR03-E

Rev. N° 03 – 19.05.2010

12 – Oil and Water Flow Indicators Series CCL2 Page N° 1 of 3

1 General Features

1.1 Characteristics

The liquid circulation indicators Series CCL2 are designed to detect the operation of circulation

pumps in cooling installations, in particular those of electric transformers, and are therefore particu-

larly suited for detecting the flow of oil or water in piping, respectively by types CCL2-O, for oil, and

CCL2-A, for water. The possibility of using them with other fluids and/or in other installations depends

on the fluid and its compatibility with the materials used in the construction of the device and must

therefore be looked into in every case.

The presence of circulation is displayed optically by white and red indicators visible through two sight

glasses and electrically by one or two electrical switches. The devices Series CCL2 only show that

the liquid velocity inside the piping has the required value; therefore the optical display may not be

proportional to the velocity.

The way the devices Series CCL2 work is based on the dynamic pressure applied by the moving fluid

on detection disc paddle placed inside the pipe, whose dimensions depend on the diameter of the

pipe itself and the flow rate that it will have to detect. An adjustment screw allows the triggering point

to be altered, within certain limits, in order to adapt it to the effective local flow conditions.

1.2 Field of Use

The circulation indicators Series CCL2 may be used with the following characteristic values:

• pipeline diameter from 50 to 400 mm

• flow velocity from 0,3 to 5,0 m/sec

• pressure in the pipe from 0,0 to 2,0 bar

• working temperature from -20°C to +120°C

• resistance to vibrations up to 3 g on all axes

• resistance to shock up to 10 g on all axes

2 Special Features

Based on the experience of previous series, the design includes the following features, aimed at sim-

plifying the choice of the device and its interchangeability, and allowing the user to modify the setting

to a certain degree to allow for local flow conditions:

• two sight glasses placed perpendicularly to the direction of flow allow the optical display to be

seen from both sides of the pipe and two cable entries, allow the electrical connection to be

made from whichever side is most convenient; therefore the same device may be fitted indiffer-

ently with the flow from the left or from the right, provided the arrow engraved laterally on the

flange points in the direction of the flow;

• the tension in the return spring is adjustable after removing the top cover, even with the device

mounted in the pipe; this allows the indicator to be adjusted to the real working conditions.

• the devices made for mounting in vertical piping are provided with a counterweight fitted to the

lever activating the optical and electrical displays in order to counterbalance the weight of the

paddle; all of the devices may be fitted with this counterweight, which may be added as needed.

It is necessary to point out that the devices are supplied ready to be mounted according to the infor-

mation given in the order and that any successive modification must be understood as exceptional.

Furthermore it is also necessary to inform us of these modifications, quoting the serial number of the

article, so that we can update our records as regard any future supply of spare-parts.

3 Construction Features, Finish and Accessories

3.1 Construction Features

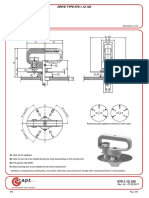

With reference to drawings N° 12.202.00 and N° 12.202.000 and the relative part description, which

also indicates the materials, the device is constructed as follows:

D:\ETI\Docs Rev 2009 NT\Testi\English\12\12CCL2CATR03_E.doc

Catalogue N° 12CCL2CATR03-E

Rev. N° 03 – 19.05.2010

12 – Oil and Water Flow Indicators Series CCL2 Page N° 2 of 3

• on one side of the body 1.0 there is the flange 1.0.1 for assembly to the pipe with the gasket

seat; on the other side body 1.0 is connected to casing 2.0; in order to avoid errors during as-

sembly two arrows engraved on the body 1.0 indicate the direction of flow;

• on the side facing the pipe, the flow detector paddle 3.1, which can rotate by about 22° around

the shaft 3.1.1, is fitted to the body 1.0; through the pin 3.2.1 the paddle 3.1 causes the transmis-

sion shaft 3.2 to rotate; the rotation of shaft 3.2 and of the paddle 3.1 is limited by the stops 3.2.2;

the protection 1.1 protects these parts from damage during transportation and mounting;

• shaft 3.2 passes through the body 1.0 and activates the optical and electrical display by means of

lever 3.3, fitted to the shaft itself; the sealing along the shaft 3.2 is assured by gaskets;

• the optical display consists of two red and white dials 3.3.1 fitted to lever 3.3 and visible through

the sight glasses 2.2; the electric signal takes place through 1 or 2 microswitches 3.4 fixed to the

body 1.0 and triggered by the lever 3.3;

• the electrical connection with the microswitches and the earth screw 3.8 can be made through

the terminal 3.7 and the cable entries 2.0.1 by removing the casing cover 2.1; on the inside of

cover 2.1 plate 2.4 shows the wiring diagram and the serial number; cable 2.5 ties the cover 2.1

to the casing 2.0, preventing it from getting lost or swapped;

• spring 3.5 returns the lever 3.3 and therefore also the paddle 3.1 to their rest position; through

device 3.6 it is possible to adjust the tension of the spring 3.5 to adapt the detection to the local

flow conditions.

As a special execution the liquid circulation indicators Series CCL2 can be supplied with the mounting

dimensions according to drawing N° 12.202.70

3.2 Finish

In standard execution, all cast parts are protected by one coat of two-pack epoxy primer and one coat

of two-pack polyurethane paint, final colour RAL 7031 and screws and washer are in stainless steel;

the protection level of the device is IP 55 and of the contacts IP 67. Therefore the device is suitable

for fitting in the open even in tropical climate and with high industrial pollution.

3.3 Accessories

The device is supplied with its assembly gasket and with one cable entry fitted with a metallic plug.

4 Wiring Diagrams and Contact Performance

As mentioned above, the circulation indicators Series CCL2 can be supplied with one or two electric

contacts, set out according to one of the wiring diagrams shown in the specification N° 12SCHRxx,

which indicates also the numbering of the terminals and the performance of the contacts.

As shown in specification contacts suitable for electronic circuits having low current (1 to 100 mA) and

voltage (4 to 10 V) can also be supplied.

5 Operation

The circulation indicators Series CCL2 operate as follows:

• the fluid moving in the pipe hits the paddle 3.1, which has dimensions chosen according to pipe

diameter and nominal fluid velocity, and causes it to rotate around its axis 3.1.1 by about 22°; the

movement of the paddle is limited by the stops 3.2.2, which act on the pin 3.2.1;

• the movement of the paddle provokes the rotation of the shaft 3.2 by means of the pin 3.2.1, win-

ning over the force of the return spring 3.5;

• lever 3.3 triggers the electric signal through microswitches 3.7 while the two red and white dis-

plays 3.3.1, fitted to the lever itself, move in front of the sight glasses 2.2, showing either the red

or white sector, respectively when the flow rate is lower or higher than the pre-set value; as al-

ready mentioned, the optical display may not be proportional to the flow rate;

• when the fluid velocity falls below the pre-set value, the return spring 3.5 brings the mechanism

into its rest position.

D:\ETI\Docs Rev 2009 NT\Testi\English\12\12CCL2CATR03_E.doc

Catalogue N° 12CCL2CATR03-E

Rev. N° 03 – 19.05.2010

12 – Oil and Water Flow Indicators Series CCL2 Page N° 3 of 3

6 Mounting, Adjustment and Maintenance

6.1 Mounting

The circulation indicators Series CCL2 may be used when the working conditions are within the val-

ues indicated in chapter 1.2.

The device is either mounted on a flange with stub pipe, welded directly to the pipe following the di-

mensions indicated in the table of the assembly example of drawing N° 12.300.00, or by mounting a

flanged stub pipe onto the pipeline, sectioned off by valves, and attaching the device to it as indicated

in the assembly drawing N° 12.300.00. It is best to choose this second method if the device will need

to be removed for maintenance, as may be necessary if it is used with water.

The device is mounted using 4 bolts, with the insertion of the assembly gasket supplied with the de-

vice. After attaching it to the pipe, carry out the electrical connection according to the chosen wiring

diagram through the terminal board 3.7, accessible after removing the cover 2.1. After mounting, ver-

ify that the optical and electric indicators are working correctly by starting up and stopping the pump.

In order to make sure the signal paddle 3.1 is hit by the most uniform possible flow, avoid mounting

the device immediately down stream of bends, necks or other parts which could cause turbulence in

the flow; if this is impossible, the adjustment of the tension in the return spring 3.5, allows the indica-

tor to be set to the real flow conditions

6.2 Adjustment

The device is always supplied set according to the information given at ordering and with the adjust-

ment spring 3.5 loaded to about half the maximum load, so that it is possible to both increase the

load, so the device is triggered at a higher flow rate, or decrease the load, with the opposite effect. To

make adjustments of spring 3.5 proceed as follows:

• remove cover 2.1;

• insert a hollow barrel spanner inside on the hexagonal adjuster 3.6;

• insert a screwdriver in the barrel spanner and unscrew the adjustment locking screw one turn;

• turn the hexagonal adjuster in anticlockwise direction to increase the operational flow rate and in

clockwise direction to decrease it; the maximum angle the hexagonal adjuster can be rotated is

about 90°; two lockpins prevent it from being turned beyond this angle;

• lock the hexagon 3.6 in the new position by tightening the locking screw;

• verify that the device is working correctly by starting up and stopping the circulation pump.

• replace cover 2.1.

6.3 Maintenance

The circulation indicators Series CCL2 do not need regular maintenance, however it is advisable to

check that they are working correctly at regular intervals by starting up and stopping the circulation

pump and verifying that the optical and electrical display takes place as normal.

As mentioned above, it is possible that if used with water deposits and encrustation's may form which

prevent the device from working correctly. In this case remove the device from the pipe - closing any

shutoff valves present or emptying the installation - and carry out cleaning by removing protection 1.1

and eliminate the encrustation's mechanically until the paddle moves freely once again.

7 Order Specifications

When ordering it is necessary to indicate the following data:

• type of device:

◊ CCL2-O for use with transformer oil;

◊ CCL2-A for use with water;

• pipeline diameter;

• mounting position according to one of the diagrams in drawing N° 12.202.00;

• flow rate at which the indicator should be triggered;

• wiring diagram according to specification N° 12SCHxx;

• thread of cable entry.

D:\ETI\Docs Rev 2009 NT\Testi\English\12\12CCL2CATR03_E.doc

Specification N° Product: Page N°

12SCHR02-E Flow Indicators Series CCL2 and SCFR2 1 of 2

Title: Revision N°

Performance of contacts and description of wiring diagrams 02 – 12.06.06

1 Performance of the contacts and description of the wiring diagrams

The specification has a complete description of the contacts and of performance and function of the

wiring diagrams.

2 Wiring diagrams

2.1 Identification by numbering of the wiring diagrams

The identification numbering of the wiring diagrams follows criteria that allow to identify type of

contacts and operation of the wiring diagram from it's number.

2.1.1 Key to numbering of wiring diagrams

The following numbering system applies to wiring diagrams with standard contacts; wiring

diagrams with low current contacts are considered special and have a separate numbering.

12-xxx = Wiring diagram for flow indicators;

12-Xxx = Total number of contacts:

1, 2, 3 and 4 = 1, 2, 3 or 4 contacts

12-xXx = Contact Type

0 = Normally open; 1 = Normally closed; 3 or 9 = Changeover

12-xxX = Contacts position:

1 = Contact/s for minimum flow; 2 = Contact/s for maximum flow;

3 = One contact for minimum + one contact for maximum flow

4 to 9 = Other positions

2.2 Table of Contact's Performance

2.2.1 Standard Contact (ST)

Changeover microswitch contact worked mechanically

Degree of protection IP 67

Casing Poliester

Gasket Fluorosilicon rubber

Lever and push button Stainless steel

Contact's material Silver, nickel coated

7

Mechanical endurance of contact 1x10 cycles

Temperature range -40°C to +125°C

Standard power of interruption (1x105 cycles) AC 250V/5A - DC 125V/1A

Maximum power of interruption (1.000 cycles) DC 125V/1,5A

Isolation to mass at 20°C 2.500 V

Isolation of open contact at 20°C 1.500 V

Minimum and maximum current 0,1 - 10A

2.2.2 Low Current Contact (BC)

Same performance as standard contact except:

Contact's material Gold

Operation range 1 to 100 mA - 4 to 30 V

2.2.3 Electric circuitry

Degree of protection of instrument casing:

• Type CCL2 IP 65

• Type SCFR2 IP 55

Insulation to mass 2.500 V

Material of terminal board tin coated brass

D:\ETI\Docs Rev 2009 NT\Testi\English\12\12SCHR02-E.doc

Specification N° Product: Page N°

12SCHR02-E Flow Indicators Series CCL2 and SCFR2 2 of 2

Title: Revision N°

Performance of contacts and description of wiring diagrams 02 – 12.06.06

3 Tables of function and performance o wiring diagrams

The most commonly used wiring diagrams are described in detail in the following tables; the

following notes describe the acronyms.

3.1 Notes on tables of function and performance of wiring diagrams

The following tables showing the performance of the wiring diagrams make use of some acronyms;

for a full understanding they are explained in the following:

NE = Normal exercise = corresponds to maximum flow

N° Term. = Numbers that identify the terminals

N° WD = Wiring diagram number

Pos. in NE = State of the contact in normal exercise.

3.2 Tabella

N° Pos. in

N° WD Functional description of wiring diagram Operates at

Term. NE

12-000 Without contacts, only optical indication

1-2 Open

12-131 1 changeover contact for minimum flow minimum

1-3 Closed

1-2 Open

12-132 1 changeover contact for maximum flow maximum

1-3 Closed

1-2/4-5 Open

12-291 2 changeover contacts for minimum flow minimum

1-3/4-6 Closed

1-2/4-5 Open

12-292 2 changeover contacts for maximum flow maximum

1-3/4-6 Closed

1-2 Open

1 changeover contact for minimum flow minimum

1-3 Closed

12-293

4-5 Open

1 changeover contact for maximum flow maximum

4-6 Closed

D:\ETI\Docs Rev 2009 NT\Testi\English\12\12SCHR02-E.doc

Nomenclature N° Reference drawing N° Page N°

12CCL2NomR01-E 12.202.00 - 12.202.70 - 12.202.000 1 of 1

Product: Revision N°

Oil and Water Flow Indicators Series CCL2 01 of 04.06.06

Pos. Part Denomination N° Material

CCL2-O - Aluminum

1.0 Body with flow direction indication 1

CCL2-A - Brass

Mounting flange

Types CCL2-O and CCL2-A with O-Ring gasket seat for

1.0.1 OR 6262 1

Types CCL2-OS and CCL2-AS without gasket seat

1.1 Protection 1 Brass

2.0 Casing 1 Aluminium

2.0.1 Cable entry - Max 1" or PG21 2

2.1 Casing cover 1 Aluminium

2.2 Window of optical indication 2 Acrylic

2.3 Window frame 2 Nylon 30% glass fibre

2.4 Wiring diagram and serial number plate 1 Aluminium

2.5 Cover fixing string 1 Nylon

3.0 Optical and electrical indication unit

CCL2-O - Aluminium

3.1 Flow measuring disk paddle 1

CCL2-A - Brass

3.1.1 Paddle shaft 1 Stainless steel

3.2 Transmission shaft 1 Stainless steel

3.2.1 Transmission shaft 3.2 driving pin 1 Stainless steel

3.2.2 Transmission shaft 3.2 stop pins 2 Stainless steel

3.3 Lever of optical and electrical indication 1 Brass

3.3.1 Dials of optical indication 2 Aluminium serigraph

3.4 Microswitches 1/2

3.5 Reset spring 1 Spring steel

3.6 Regulation knob 1 Brass

3.7 Terminal board for electrical connection 1

3.8 Earthing screw 1 Stainless steel

D:\ETI\Docs Rev 2009 NT\Testi\English\12\12CCL2NomR01-E.doc

You might also like

- Incicatoare Circulatie Ulei 12SCFR2CATR04-EDocument9 pagesIncicatoare Circulatie Ulei 12SCFR2CATR04-EmaggamNo ratings yet

- Voltage Regulators G225-10-30: Functional Specification GuideDocument17 pagesVoltage Regulators G225-10-30: Functional Specification Guideمصطفى علىNo ratings yet

- C0302CDocument4 pagesC0302CFredy MurilloNo ratings yet

- Instruction Manual of Capacitor Voltage TransformersDocument22 pagesInstruction Manual of Capacitor Voltage Transformerst.o.i.n.gNo ratings yet

- 3.3KV VCB SpecDocument9 pages3.3KV VCB SpecVishnuraj RNo ratings yet

- Edwards CP25K Cold Cathode Gauge Sensor ManualDocument18 pagesEdwards CP25K Cold Cathode Gauge Sensor Manualঅর্ণব কোলেNo ratings yet

- Wapda P 46 2008Document81 pagesWapda P 46 2008Engr Awais Khan100% (7)

- Instrumentation - Liquid Level: MAY 1994 Page 1 of 8Document8 pagesInstrumentation - Liquid Level: MAY 1994 Page 1 of 8Jhonny Rafael Blanco CauraNo ratings yet

- Proportional Reducing ValveDocument8 pagesProportional Reducing ValvediabalziabNo ratings yet

- P-90-82 F - CT's 33 To 132 KVDocument13 pagesP-90-82 F - CT's 33 To 132 KVHasnain AwanNo ratings yet

- KOBOLD KAL-A (KAL-7000 Series) Thermal Flow Transmitter User InstructionsDocument17 pagesKOBOLD KAL-A (KAL-7000 Series) Thermal Flow Transmitter User InstructionsMariana SerbanNo ratings yet

- Buchholz RelayDocument23 pagesBuchholz RelayMukesh KumarNo ratings yet

- UniGear ZS3.2Document40 pagesUniGear ZS3.2saturasatuNo ratings yet

- Technical Specification For 20 MVA Transformer PDFDocument21 pagesTechnical Specification For 20 MVA Transformer PDFamulya00428100% (10)

- 25pt4622Philips+L7 3A+AADocument48 pages25pt4622Philips+L7 3A+AAWall BrysonNo ratings yet

- Transductor FLOWSERVE NT3000Document20 pagesTransductor FLOWSERVE NT3000Xavier EspinozaNo ratings yet

- Line Troll 3100Document26 pagesLine Troll 3100tunghtdNo ratings yet

- 15-2-3 - Protn Details - 33-13.8kV TrafoDocument8 pages15-2-3 - Protn Details - 33-13.8kV Trafodaniel.cabasa2577No ratings yet

- WT 200 Water Transducer: Component DescriptionDocument16 pagesWT 200 Water Transducer: Component Descriptionmilad100% (1)

- SECTION 22 05 19 Meters and Gages For Plumbing PipingDocument7 pagesSECTION 22 05 19 Meters and Gages For Plumbing PipingMiguel Angel Pacahuala CristobalNo ratings yet

- SpecificationsDocument7 pagesSpecificationspvenkyNo ratings yet

- Cathodic ProtectionDocument13 pagesCathodic Protectionnamanvyas21No ratings yet

- Trafo RTCCDocument363 pagesTrafo RTCCKrishna Chandavar0% (1)

- Control Ad or Neumatico de Nivel Fisher 2502Document16 pagesControl Ad or Neumatico de Nivel Fisher 2502mizor82No ratings yet

- Voleti de Desfumare SEDS - Specificatii Tehnice (EN)Document28 pagesVoleti de Desfumare SEDS - Specificatii Tehnice (EN)Mihai STANNo ratings yet

- Pressure Transmitter: FeaturesDocument4 pagesPressure Transmitter: FeaturesIrvin Gnivry RodríguezNo ratings yet

- F003 AtosDocument4 pagesF003 Atoschandushar1604No ratings yet

- Sony Klv-26t400a-G 32t400a Service ManualDocument117 pagesSony Klv-26t400a-G 32t400a Service ManualLê Đức63% (8)

- Sharp Lc-32m43u Lc-37m43u SMDocument88 pagesSharp Lc-32m43u Lc-37m43u SMmosavlaNo ratings yet

- Flow Meter ManualDocument70 pagesFlow Meter Manualrommel duranNo ratings yet

- Bul 36115 Servo Valve OperationDocument12 pagesBul 36115 Servo Valve Operationrikkitech100% (1)

- 11 KV 6 3 KV Trans - EpcDocument16 pages11 KV 6 3 KV Trans - EpcTarek FawzyNo ratings yet

- Bus Bar Selection 20338744 - 0606073419Document40 pagesBus Bar Selection 20338744 - 0606073419yac128No ratings yet

- Westinghouse Type CODocument24 pagesWestinghouse Type CORicardo Hernandez100% (1)

- 33KV GTP WbsebDocument13 pages33KV GTP Wbsebmaniking1No ratings yet

- Electromotoric Actuators For Air Dampers and Control Valves of Oil or Gas Burners of Small To Medium CapacityDocument11 pagesElectromotoric Actuators For Air Dampers and Control Valves of Oil or Gas Burners of Small To Medium CapacityalexjoelNo ratings yet

- SCR Unit Chapter 3Document48 pagesSCR Unit Chapter 3stashkinvalriy100% (2)

- LV Bulk Metering Sri LankaDocument15 pagesLV Bulk Metering Sri Lankaxeroix7039No ratings yet

- Il 41 100 1BDocument20 pagesIl 41 100 1Brajat_nandy5297No ratings yet

- Types CR, CRC, CRP and CRD Directional Overcurrent Relays: CautionDocument32 pagesTypes CR, CRC, CRP and CRD Directional Overcurrent Relays: CautionRida JavidNo ratings yet

- K-Tek Ms50 Level SensorDocument8 pagesK-Tek Ms50 Level SensorjlrestrepoNo ratings yet

- Duplo MaticDocument8 pagesDuplo MaticHENRYGALLEGOSNo ratings yet

- AutoTransformers P-169:09 WAPDADocument58 pagesAutoTransformers P-169:09 WAPDArzor100% (3)

- Dil AngolDocument19 pagesDil AngolCybossNo ratings yet

- Meter Manual Final PDFDocument12 pagesMeter Manual Final PDFAnonymous TAKRGCkb100% (2)

- Globe Valve Type Flow Switch: DescriptionDocument4 pagesGlobe Valve Type Flow Switch: DescriptiongoparsucoNo ratings yet

- ABB High Speed Directional Relays PDFDocument28 pagesABB High Speed Directional Relays PDFking_electricalNo ratings yet

- RMU Technical SpecificationDocument15 pagesRMU Technical SpecificationGAGANNo ratings yet

- MMR ServiceManual K Line e 22007240Document96 pagesMMR ServiceManual K Line e 22007240Eliana CristinaNo ratings yet

- Tech Spec - 6.3&10MVA With OLTC &SCADA-compatible-RTCCDocument34 pagesTech Spec - 6.3&10MVA With OLTC &SCADA-compatible-RTCCkushal BNo ratings yet

- Power Supply Projects: A Collection of Innovative and Practical Design ProjectsFrom EverandPower Supply Projects: A Collection of Innovative and Practical Design ProjectsRating: 3 out of 5 stars3/5 (2)

- Sony Klv-26s550a 32s530a 32s550a-L-T 37s550a Chassis Ex2t SMDocument72 pagesSony Klv-26s550a 32s530a 32s550a-L-T 37s550a Chassis Ex2t SMHarshad RathodNo ratings yet

- NE Datasheet ManDocument20 pagesNE Datasheet ManszenandreiNo ratings yet

- CC Pump Manual-Full (Original)Document109 pagesCC Pump Manual-Full (Original)friendbce100% (1)

- VCV ManualDocument30 pagesVCV Manualali_gudarzi2249No ratings yet

- Siemens Polymobil - Function DescriptionDocument12 pagesSiemens Polymobil - Function Descriptionsadeq03100% (1)

- RDSO Specification IRS S - 91 - 2013Document13 pagesRDSO Specification IRS S - 91 - 2013nvnrajesh123No ratings yet

- Chapter 7 - NT PWC SDM Current Transformer Rev 2 - 20-12-2012Document11 pagesChapter 7 - NT PWC SDM Current Transformer Rev 2 - 20-12-2012Ahmad AshrafNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Pag 14 010 ATC03 Rev 01Document1 pagePag 14 010 ATC03 Rev 01maggamNo ratings yet

- Pag 04 070 112130 Rev 04Document1 pagePag 04 070 112130 Rev 04maggamNo ratings yet

- Transformer-oil-cooler-BETA CETA EN A07Document16 pagesTransformer-oil-cooler-BETA CETA EN A07maggamNo ratings yet

- Pag 03 070 112120 Rev 04Document1 pagePag 03 070 112120 Rev 04maggamNo ratings yet

- An DL001Document12 pagesAn DL001maggamNo ratings yet

- Pag 09 010 AT03 Rev 02Document1 pagePag 09 010 AT03 Rev 02maggamNo ratings yet

- Pag 12 010 ATC01 Rev 01Document1 pagePag 12 010 ATC01 Rev 01maggamNo ratings yet

- Pag 09 010 AT03 Rev 02Document1 pagePag 09 010 AT03 Rev 02maggamNo ratings yet

- RTKF Porip - General InfoDocument11 pagesRTKF Porip - General InfomaggamNo ratings yet

- 06-DAROC Check Valve Rev3Document16 pages06-DAROC Check Valve Rev3maggamNo ratings yet

- Catalog Cabluri SCHRACKDocument196 pagesCatalog Cabluri SCHRACKmaggamNo ratings yet

- Filtre de Aer 01E700CATR01-EDocument12 pagesFiltre de Aer 01E700CATR01-EmaggamNo ratings yet

- Relee Buchholz 04RRCATR03-EDocument22 pagesRelee Buchholz 04RRCATR03-EmaggamNo ratings yet

- Danfoss Vane Tip LUG SylaxDocument18 pagesDanfoss Vane Tip LUG SylaxmaggamNo ratings yet

- Ari Butterfly Valves PDFDocument14 pagesAri Butterfly Valves PDFvalimorsk ltd.No ratings yet

- Supape 10VSCATR06-EDocument25 pagesSupape 10VSCATR06-EmaggamNo ratings yet

- Cutii Terminale 15SM2S M16CEG R00-EDocument7 pagesCutii Terminale 15SM2S M16CEG R00-EmaggamNo ratings yet

- 00en PDFDocument158 pages00en PDFmaggam100% (1)

- Cutii Terminale SM2 15SM2CATR07-EDocument19 pagesCutii Terminale SM2 15SM2CATR07-EmaggamNo ratings yet

- Relee Buchholz 04RRCATR03-EDocument22 pagesRelee Buchholz 04RRCATR03-EmaggamNo ratings yet

- Disp Prelevare Gaze 07RAGA2CATR00-EDocument9 pagesDisp Prelevare Gaze 07RAGA2CATR00-EmaggamNo ratings yet

- Cutii Terminale SM2-LA 15SM2LACATR00-EDocument4 pagesCutii Terminale SM2-LA 15SM2LACATR00-EmaggamNo ratings yet

- 00enDocument62 pages00enmaggamNo ratings yet

- Catalog Relee Buchholz EmbDocument28 pagesCatalog Relee Buchholz EmbmaggamNo ratings yet

- Transformer Oil Cooler BETA + CETADocument8 pagesTransformer Oil Cooler BETA + CETAmaggamNo ratings yet

- Standar TrafoDocument182 pagesStandar TrafoKevinNo ratings yet

- HV Full CatalogueDocument17 pagesHV Full CataloguemaggamNo ratings yet

- Indicator Spargere MembranaDocument16 pagesIndicator Spargere MembranamaggamNo ratings yet

- (Ethics) AttitudeDocument46 pages(Ethics) AttitudeAbhishek SinghNo ratings yet

- Methodology and Specifications Guide: Crude OilDocument34 pagesMethodology and Specifications Guide: Crude Oil066709No ratings yet

- Diy AquariumsDocument108 pagesDiy Aquariumshalo_bing100% (2)

- trivia questions 学生版Document9 pagestrivia questions 学生版YING YUNo ratings yet

- Flex-10 Virtual ConnectDocument2 pagesFlex-10 Virtual ConnectArif HusainNo ratings yet

- Frenkel Exercise Protocol For Patient With Parkinsons DiseaseDocument39 pagesFrenkel Exercise Protocol For Patient With Parkinsons DiseaseHumaira Rahman0% (1)

- Soil Resources Inventory For Land Use PlanningDocument9 pagesSoil Resources Inventory For Land Use PlanningmehNo ratings yet

- Hardware Catalog No Prices (PTHW0208.1C) PDFDocument11 pagesHardware Catalog No Prices (PTHW0208.1C) PDFAhmed TahaNo ratings yet

- Destructive Ray: Bioluminescent Wizard's FamiliarDocument2 pagesDestructive Ray: Bioluminescent Wizard's FamiliarBen LNo ratings yet

- Math Model Qs by NRBDocument4 pagesMath Model Qs by NRBapi-3825027No ratings yet

- Mua prc007 en - 12042009Document73 pagesMua prc007 en - 12042009sachinsaklani23No ratings yet

- OCDM2223 Tutorial7solvedDocument5 pagesOCDM2223 Tutorial7solvedqq727783No ratings yet

- ISolutions Lifecycle Cost ToolDocument8 pagesISolutions Lifecycle Cost ToolpchakkrapaniNo ratings yet

- Lecture 1-5 EEEN323 March2022Document139 pagesLecture 1-5 EEEN323 March2022Lekono KagoNo ratings yet

- Preliminary Term Examination Cytogenetics 001Document16 pagesPreliminary Term Examination Cytogenetics 001MICHAEL JOHN AGUILARNo ratings yet

- Nsejs Exam Solutions Paper 2019 PDFDocument27 pagesNsejs Exam Solutions Paper 2019 PDFMrinalini SinghNo ratings yet

- P.B.B.SC Nsg. Syllabus Original PDFDocument57 pagesP.B.B.SC Nsg. Syllabus Original PDFRajalakshmi SrinivasanNo ratings yet

- Relative Clauses - Revisión Del IntentoDocument4 pagesRelative Clauses - Revisión Del IntentoYordy Rodolfo Delgado RosarioNo ratings yet

- BP503T Unit 1-3Document432 pagesBP503T Unit 1-3Solomon GyampohNo ratings yet

- Laporan Hasil Praktik Bahasa Inggris Dengan Tamu Asing Di Pantai KutaDocument12 pagesLaporan Hasil Praktik Bahasa Inggris Dengan Tamu Asing Di Pantai KutaEnal MegantaraNo ratings yet

- The Empire in FlamesDocument73 pagesThe Empire in FlamesSergio Esperalta Gata100% (2)

- Msds NitobenzeneDocument5 pagesMsds NitobenzeneAnngie Nove SimbolonNo ratings yet

- Just Walk Across The RoomDocument8 pagesJust Walk Across The Roomstuutterrs100% (1)

- Pharmacology SamplexDocument12 pagesPharmacology SamplexLiezel Dejumo BartolataNo ratings yet

- Anatomy-Head and NeckDocument94 pagesAnatomy-Head and NeckXahid IqbalNo ratings yet

- An Open Letter To Annie Besant PDFDocument2 pagesAn Open Letter To Annie Besant PDFdeniseNo ratings yet

- Bot115 Picaxe Create: RevolutionDocument33 pagesBot115 Picaxe Create: Revolutionabiel fernandezNo ratings yet

- Lab 6 - Wide Flange BeamDocument4 pagesLab 6 - Wide Flange BeamJanithNo ratings yet

- 10th PET POW EM 2023 24Document6 pages10th PET POW EM 2023 24rpradeepa160No ratings yet

- AD GT3000 Catalogue en 12-07 CDocument52 pagesAD GT3000 Catalogue en 12-07 CMohamed AlkharashyNo ratings yet