Professional Documents

Culture Documents

CS Ball Valve TM-590

Uploaded by

Hector Dario Tobon BenjumeaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CS Ball Valve TM-590

Uploaded by

Hector Dario Tobon BenjumeaCopyright:

Available Formats

www.nibco.

com

A H E A D O F T H E F L O W™

Carbon Steel Ball Valves

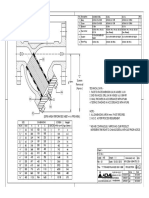

Three-Piece Body • Threaded, Butt or Socket Weld Ends • Blowout-Proof Stem • Conventional Port •

Enclosed Bolt Design • PTFE Seats • SS Trim • Cast ISO Mounting Pad • Vented Ball

2000 PSI/138 Bar Non-Shock Cold Working PressureK

CONFORMS TO API-607 FOURTH EDITION FIRE SAFE •

MSS SP-110 • MSS SP-72 (BUTT WELD) •

API 608 ANTI-STATIC FEATURE • NACE MR0175

MATERIAL LIST

PART SPECIFICATION TM-590-CS-R-66-FS-LL

1. Stem Stainless Steel ASTM A 276 Type 316 Threaded

2. Handle Nut Stainless Steel ASTM A 276 Type 304 Stainless Steel Trim

3. Flat Washer Stainless Steel ASTM A 240 Type 304 ISO Mount Pad

4. Locking Handle Stainless Steel ASTM A 240 Type 304

5. Stop Plate Stainless Steel ASTM A 240 Type 304 KM-590-CS-R-66-FS-LL

6. Pack Gland Stainless Steel ASTM A 276 Type 316 Socket Weld

7. Stem Packing Graphite Stainless Steel Trim

8. Body End Seal Graphite

ISO Mount Pad

9. Bolt Carbon Steel ASTM A 193 Type B7

10. Body End Carbon Steel ASTM A 216 Grade WCB

Phosphate Coated BM-590-CS-R-66-FS-LL

11. Body Carbon Steel ASTM A 216 Grade WCB Butt Weld

Phosphate Coated Stainless Steel Trim

12. Ball (Vented) Stainless Steel ASTM A 276 Type 316 or ISO Mount Pad

ASTM A 351 Type CF8M

13. Seat Reinforced TFE 15% Glass

14. Thrust Washer Reinforced TFE 15% Glass

15. Static Grounding Devices Stainless Steel ASTM A 276 Type 304

16. Stop Pin Stainless Steel ASTM A 276 Type 304

Note: Valves are static grounded by two ball detents that insure electro-continuity

between the stem body and ball. The valve has electro-continuity across the

discharge path with a resistance of not more than 10 ohms.

TM 590-CS-R-66-FS-LL

NPT x NPT

DIMENSIONS—WEIGHTS—QUANTITIES

Dimensions

H J K Socket Butt

G Socket Socket Butt Threaded Weld Weld

Size A B C D E F Thread Flange Weld Weld Weld Weight Weight Weight

In. mm. In. mm. In. mm. In. mm. In. mm. In. mm. In. mm. Tap Type In. mm. In mm. In. mm. Lbs. Kg. Lbs. Kg. Lbs. Kg.

¹⁄₂ 15 2.72 69 2.47 63 4.07 103 .43 11 .12 3 1.00 25 M5 F03 .86 22 .38 10 .84 21 1.80 .82 1.70 .78 1.60 .73

³⁄₄ 20 2.94 75 2.70 69 4.07 103 .57 14 .12 3 1.00 25 M5 F03 1.08 27 .50 13 1.05 27 2.40 1.09 2.30 1.05 2.20 1.00

1 25 3.50 89 3.19 81 4.92 125 .81 21 .18 5 1.17 30 M5 F04 1.34 34 .50 13 1.32 34 3.80 1.73 3.60 1.64 3.50 1.59

1 ¹⁄₄ 32 3.90 99 3.64 92 5.91 150 .98 25 .20 5 1.17 30 M5 F04 1.69 43 .50 13 1.66 42 5.90 2.68 5.70 2.59 5.60 2.55

1 ¹⁄₂ 40 4.42 112 3.88 99 7.68 195 1.25 32 .23 8 1.39 35 M6 F05 1.93 49 .50 13 1.90 48 7.60 3.45 7.40 3.36 7.30 1.61

2 50 5.04 128 4.09 104 7.68 195 1.50 38 .23 8 1.39 35 M6 F05 2.42 61 .62 16 2.38 60 10.50 4.77 10.30 4.68 10.20 4.64

K

For detailed Operating Pressure, refer to Pressure Temperature Chart on pages 71 and 72.

NIBCO INC. WORLD HEADQUARTERS • 1516 MIDDLEBURY ST. • ELKHART, IN 46516-4740 • USA • PH: 1.800.234.0227

TECH SERVICES PH: 1.888.446.4226 • FAX: 1.888.336.4226 • INTERNATIONAL OFFICE PH: +1.574.295.3221 • FAX: +1.574.295.3455 59

www.nibco.com

You might also like

- Wily Walnut BRAIN SQUEEZERS Vol.1Document116 pagesWily Walnut BRAIN SQUEEZERS Vol.1tarzaman88% (8)

- SPC英文版教材Document83 pagesSPC英文版教材bing cai100% (2)

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Yanmar Mechnical PumpDocument16 pagesYanmar Mechnical Pump송성훈100% (9)

- Fire and Blast in The Future OffshoreDocument45 pagesFire and Blast in The Future OffshoredrgNo ratings yet

- Materials Data for Cyclic Loading: Low-Alloy SteelsFrom EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsRating: 5 out of 5 stars5/5 (2)

- Swing Check Valves Dimensions and SpecificationsDocument4 pagesSwing Check Valves Dimensions and SpecificationsTheVirus PapaNo ratings yet

- Engineering StudiesDocument4 pagesEngineering StudiesSamuel PhegelloNo ratings yet

- Ductile Iron Gate ValveDocument4 pagesDuctile Iron Gate ValveShuvro SoikotNo ratings yet

- Valvula Globo en AnguloDocument1 pageValvula Globo en AnguloRobertoNo ratings yet

- Spesifikasi Siemens MRI AERA 1,5 TDocument2 pagesSpesifikasi Siemens MRI AERA 1,5 TDr.gendjutNo ratings yet

- T376APBI-Nibco Angular Bronze ValveDocument1 pageT376APBI-Nibco Angular Bronze Valvemax_powerNo ratings yet

- CI Wafer / DI Lug Butterfly Valves: Series 0160Document2 pagesCI Wafer / DI Lug Butterfly Valves: Series 0160Vignesh NadimuthuNo ratings yet

- Flowjet Valves Product BrochureDocument18 pagesFlowjet Valves Product BrochureUday GokhaleNo ratings yet

- Bronze Ball ValvesDocument1 pageBronze Ball ValvesmasherifNo ratings yet

- B8 ValvulasDocument1 pageB8 ValvulasPROCESOS PROCESOSNo ratings yet

- 285 PSI Ductile Iron Butterfly Valve: WD 5022 LD 5022Document2 pages285 PSI Ductile Iron Butterfly Valve: WD 5022 LD 5022Instratec InstratecNo ratings yet

- F607RWSFPDocument1 pageF607RWSFPleonardo ramirezNo ratings yet

- KT-403-WFP Bronze Check ValveDocument1 pageKT-403-WFP Bronze Check ValveIlyas sagriNo ratings yet

- Fox ™ Triple Effect Air Vent + Anti Water Hammer: FeaturesDocument5 pagesFox ™ Triple Effect Air Vent + Anti Water Hammer: FeaturesNicolás Polito MuñozNo ratings yet

- Wafer Check Valve 1Document10 pagesWafer Check Valve 1Roly AnggaraNo ratings yet

- Valvula Compuerta Una y MediaDocument1 pageValvula Compuerta Una y MediaRobertoNo ratings yet

- Valvula Compuerta Nibco T-113-LfDocument1 pageValvula Compuerta Nibco T-113-LfRobertoNo ratings yet

- Class 150 Bronze Globe Valves: Union Bonnet - Integral Seat - Renewable Seat DiscDocument1 pageClass 150 Bronze Globe Valves: Union Bonnet - Integral Seat - Renewable Seat DiscSujitH Sekar GnanasekaranNo ratings yet

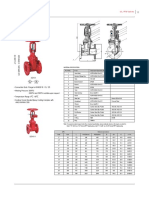

- Class 125 Iron Body Gate Valves: Bolted Bonnet - Outside Screw and Yoke - Solid Wedge - Bronze MountedDocument1 pageClass 125 Iron Body Gate Valves: Bolted Bonnet - Outside Screw and Yoke - Solid Wedge - Bronze MountedJOSE GABRIELNo ratings yet

- B3000 & Eb3000Document1 pageB3000 & Eb3000husamNo ratings yet

- U B W, I .: Nited Rass Orks NCDocument1 pageU B W, I .: Nited Rass Orks NCMartin Villafuerte CruzNo ratings yet

- 175 PSI WWP Bronze Gate Valves: 175 PSI/12 .1 Bar Non-Shock Cold Water (400 PSI Non-Shock CWP General Service)Document1 page175 PSI WWP Bronze Gate Valves: 175 PSI/12 .1 Bar Non-Shock Cold Water (400 PSI Non-Shock CWP General Service)Ncmii AppnNo ratings yet

- Class 125 Bronze: Butterfly Valves - 200 PsiDocument1 pageClass 125 Bronze: Butterfly Valves - 200 Psithilina lakhithaNo ratings yet

- Sakti Suria CatalogueDocument112 pagesSakti Suria CatalogueChoon Wei WongNo ratings yet

- T301WFPDocument1 pageT301WFPcristian villegasNo ratings yet

- 2309+QT04 - Gala-Motorized Butterfly ValveDocument4 pages2309+QT04 - Gala-Motorized Butterfly ValveNam Đỗ100% (1)

- Valvula Kt585 BolaDocument1 pageValvula Kt585 BolaPaola LopezNo ratings yet

- KT-580 & KT-585 70UL Bronze Ball ValveDocument1 pageKT-580 & KT-585 70UL Bronze Ball ValveIlyas sagriNo ratings yet

- Resilient Wedge Gate Valve AWWA C 509 Kennedy KS-FW 8561 & 8068Document2 pagesResilient Wedge Gate Valve AWWA C 509 Kennedy KS-FW 8561 & 8068Anonymous S9qBDVky100% (1)

- Lead-Free Bronze Gate Valves: T-113-LF S-113-LFDocument1 pageLead-Free Bronze Gate Valves: T-113-LF S-113-LFAlessandro1975No ratings yet

- Query4 PDFDocument1 pageQuery4 PDFAlessandro1975No ratings yet

- 300 PSI CWP Iron Body Gate Valves: 300 PSI/20 .6 Bar Non-Shock Cold Working PressureDocument1 page300 PSI CWP Iron Body Gate Valves: 300 PSI/20 .6 Bar Non-Shock Cold Working PressureayaNo ratings yet

- T-413-B, Class 125 Bronze Check ValvesDocument1 pageT-413-B, Class 125 Bronze Check ValvesBalderas Rosas WilibaldoNo ratings yet

- Valvula de Globo de MediaDocument1 pageValvula de Globo de MediaRobertoNo ratings yet

- DPCVDocument4 pagesDPCVjamil voraNo ratings yet

- Valvula Bola KT 585 580 UlDocument1 pageValvula Bola KT 585 580 UlOscar Fernandez SanchezNo ratings yet

- Check Ranurado RH84X MechDocument1 pageCheck Ranurado RH84X MechFLOW INDUSTRIAL SACNo ratings yet

- 175 PSI WWP Iron Body Gate ValvesDocument1 page175 PSI WWP Iron Body Gate ValvestremendousNo ratings yet

- Valv. Bola Bronce T580-85-70Document1 pageValv. Bola Bronce T580-85-70byron_a24No ratings yet

- NIBCO Check Valve (T-433)Document1 pageNIBCO Check Valve (T-433)kuraimundNo ratings yet

- Y STRAINER FLANGED END 150 Model PDFDocument1 pageY STRAINER FLANGED END 150 Model PDFsajanchaudhariNo ratings yet

- ASTM F593 Fasteners: Stainless Steel Bolts, Nuts, Washers & MoreDocument7 pagesASTM F593 Fasteners: Stainless Steel Bolts, Nuts, Washers & MoreProcurement MCCLNo ratings yet

- Forged Steel Three Piece Design Ball ValveDocument18 pagesForged Steel Three Piece Design Ball ValvenagarajhebbarNo ratings yet

- Valtech Catalogue-1Document44 pagesValtech Catalogue-1Bashir AliNo ratings yet

- Class 150 Bronze Gate ValvesDocument1 pageClass 150 Bronze Gate Valvescristian villegasNo ratings yet

- Swing Check Valve - Flanged: Technical FeaturesDocument1 pageSwing Check Valve - Flanged: Technical FeaturesAhmed El MorsyNo ratings yet

- 600scjs#cy 2-12 - 15Document2 pages600scjs#cy 2-12 - 15MohamadIbnuHassanNo ratings yet

- FT918BBI (1) Cheque NipcoDocument1 pageFT918BBI (1) Cheque NipcoRobertoNo ratings yet

- Lead-Free 250 PSI WWP Iron Body Check Valves: Material ListDocument1 pageLead-Free 250 PSI WWP Iron Body Check Valves: Material ListArturo JimenezNo ratings yet

- Class 125 Bronze Gate Valves: Material ListDocument1 pageClass 125 Bronze Gate Valves: Material ListJeffry GabilanNo ratings yet

- Filtro Tipo yDocument5 pagesFiltro Tipo yKaren BasoaltoNo ratings yet

- Plummech OS&Y Gate ValvesDocument1 pagePlummech OS&Y Gate ValvesNguyễn Đăng PhúcNo ratings yet

- MECH - Valvula de Compuerta OSY XZ41XDocument1 pageMECH - Valvula de Compuerta OSY XZ41XAlfredo BravoNo ratings yet

- TS413BIDocument1 pageTS413BILawrenceNo ratings yet

- 47XU Gate CraneFS DS p103 0620Document1 page47XU Gate CraneFS DS p103 0620Younis JanNo ratings yet

- ANSI ValvesDocument28 pagesANSI ValvesBenadict JoshuaNo ratings yet

- 47XU F Gate CraneFS DS 1021 p103Document1 page47XU F Gate CraneFS DS 1021 p103Alexander HuamanNo ratings yet

- Union Bonnet Globe Valve: Submittal SheetDocument1 pageUnion Bonnet Globe Valve: Submittal SheetRajesh ChoudharyNo ratings yet

- 1078 Butter y Valve (Wafer Type) PN 16 With S.G Iron Disc: Salient FeaturesDocument17 pages1078 Butter y Valve (Wafer Type) PN 16 With S.G Iron Disc: Salient FeaturesSanket PhatangareNo ratings yet

- ScrewDownNonreturnValve PDFDocument2 pagesScrewDownNonreturnValve PDFokaNo ratings yet

- High Performance Butterfly Valve Series 400: FeaturesDocument4 pagesHigh Performance Butterfly Valve Series 400: FeaturesHector Dario Tobon BenjumeaNo ratings yet

- BallValve Vba UkDocument17 pagesBallValve Vba UkHector Dario Tobon BenjumeaNo ratings yet

- BallValve Vba UkDocument17 pagesBallValve Vba UkHector Dario Tobon BenjumeaNo ratings yet

- High Performance Butterfly Valve Series 400: FeaturesDocument4 pagesHigh Performance Butterfly Valve Series 400: FeaturesHector Dario Tobon BenjumeaNo ratings yet

- Fire Protection ProductsDocument56 pagesFire Protection ProductsHector Dario Tobon BenjumeaNo ratings yet

- Bronze & Iron CatalogueDocument116 pagesBronze & Iron CatalogueHector Dario Tobon BenjumeaNo ratings yet

- Butterfly Valves: Ahead of The FlowDocument47 pagesButterfly Valves: Ahead of The FlowHector Dario Tobon BenjumeaNo ratings yet

- Ball ValvesDocument124 pagesBall ValvesHector Dario Tobon BenjumeaNo ratings yet

- Butterfly Valves: Ahead of The FlowDocument47 pagesButterfly Valves: Ahead of The FlowHector Dario Tobon BenjumeaNo ratings yet

- Cse Reviewer - MathDocument58 pagesCse Reviewer - MathLyne LerinNo ratings yet

- MX 201110 enDocument1,203 pagesMX 201110 envajrahastaNo ratings yet

- VSD Power Supply Connections and EarthingDocument4 pagesVSD Power Supply Connections and EarthingHumaid ShaikhNo ratings yet

- 4 Floral ClockDocument4 pages4 Floral ClockmiguelibasterNo ratings yet

- Experimental Monitoring of The Humber Bridge UsingDocument7 pagesExperimental Monitoring of The Humber Bridge Using정주호No ratings yet

- Introduction To The Philosophy of The Human PersonDocument14 pagesIntroduction To The Philosophy of The Human PersonDan Niel50% (2)

- Model Question Paper and Solution 2022Document14 pagesModel Question Paper and Solution 2022R Y AnushNo ratings yet

- 11 Physics Test Paper Ch3 1Document4 pages11 Physics Test Paper Ch3 1Devendar SharmaNo ratings yet

- CHS-WWW - Polsteel. TUBOS METALICOS PDFDocument3 pagesCHS-WWW - Polsteel. TUBOS METALICOS PDFEduardo TorreNo ratings yet

- Random Variate Generation-1Document21 pagesRandom Variate Generation-1Christian Delas AlasNo ratings yet

- Communications in Algebra: On The U-Invariant of P-Adic Function FieldsDocument9 pagesCommunications in Algebra: On The U-Invariant of P-Adic Function FieldsKarim ZahidiNo ratings yet

- A Review: HPLC Method Development and Validation: November 2015Document7 pagesA Review: HPLC Method Development and Validation: November 2015R Abdillah AkbarNo ratings yet

- SGDJ PDFDocument334 pagesSGDJ PDFDouglas Rogério de CastroNo ratings yet

- New Patient Needing Continuous Renal Replacement Therapy (CRRT)Document9 pagesNew Patient Needing Continuous Renal Replacement Therapy (CRRT)sergey_1972No ratings yet

- Postmodern EthicsDocument1 pagePostmodern Ethicsgeorge elerickNo ratings yet

- Mañanita Songs Mañanita SongsDocument2 pagesMañanita Songs Mañanita SongsSanchez Bayan100% (1)

- EniSpA - The Corporate Strategy of An International Energy Major PDFDocument24 pagesEniSpA - The Corporate Strategy of An International Energy Major PDFAnonymous 9ZMbuR75% (4)

- Barney's Great Adventure - Barney Wiki - WikiaDocument2 pagesBarney's Great Adventure - Barney Wiki - WikiachefchadsmithNo ratings yet

- Seminar Application of Nitrous Oxide in AutomobilesDocument20 pagesSeminar Application of Nitrous Oxide in AutomobilesSaikat BadyakarNo ratings yet

- MFJ-854 RF MeterDocument5 pagesMFJ-854 RF MeterHappyJoeNo ratings yet

- Comparative Study of Organic Solvents For Extraction of Copper From Ammoniacal Carbonate Solution Hu2010Document6 pagesComparative Study of Organic Solvents For Extraction of Copper From Ammoniacal Carbonate Solution Hu2010mtanaydinNo ratings yet

- 2a CTRL DecDocument75 pages2a CTRL Decramanathan balamoorthyNo ratings yet

- 0610 m16 QP 62Document12 pages0610 m16 QP 62faryal khanNo ratings yet

- B Ed 3 Sem Physics Teaching Group C Science 1 Paper 1 Summer 2018Document3 pagesB Ed 3 Sem Physics Teaching Group C Science 1 Paper 1 Summer 2018Rrr KkkNo ratings yet