Professional Documents

Culture Documents

Automatic Board Above Gen-Set Control Microprocessor Logic

Uploaded by

Asif ShahOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Automatic Board Above Gen-Set Control Microprocessor Logic

Uploaded by

Asif ShahCopyright:

Available Formats

BGGCM01

GCM01BG

AUTOMATIC BOARD ABOVE THE GEN-SET FOR THE

CONTROL OF

MAINS STAND-BY GENERATING SETS

• MICROPROCESSOR LOGIC.

• DIGITAL INSTRUMENTS WITH THREE DISPLAYS.

• PROGRAMMING COMMUTATOR TO ASSURE NORMAL RUNNING EVEN WHITH

ELECTRONIC FAILURE

• SINGLE-PHASE AND THREE-PHASE MAINS SENSOR WITH DISSYMETRY.

• BUILD-IN AUTOMATIC BATTERY CHARGER 5A

• DUAL-VOLTAGE: 12 AND 24V.

• RE-PROGRAMMABLE FROM PC.

• HIGH DEGREE OF ISOLATION IN THE INTERFACING WITH MAINS >8KV.

• DIRECT CONTROL OF THE MAINS/GENERATING SET SWITCH-OVER.

• INTERNAL TIMER FOR AUTOMATIC TESTING, STOP AND MAINTENANCE

• RS232C SERIAL OUTPUT WITH REMOTE CONTROL SOFTWARE

• REMOTE CONTROL BY LOCAL, MODEM OR GSM NETWORK

FILE VER. DATE LANGUAGE PAGE

QBG-M01-ING B/03 11/07/06 ING 1 of 5

GENERAL

GENERAL FEATURES

FEATURES

The electronic control board M01 is used to command and control the STAND-BY generating units. The high

control level makes it particularly suitable for highly powerful units.

The graphics that illustrate the system, the single program switch-over and the build-in digital instruments

guarantee extreme simplicity of use for the operators.

It supervises the mains power supply, the engine, the generator and the battery to assure the intervention.

It can withstand excessive mains voltage of over 8.0000Volts.

Some direct manual controls are provided that, in the event of abnormal running conditions of the electronics,

guarantee the operational capacity of the unit.

The fundamental safety devices of the engine and generator are enabled even when running in manual mode.

The GC-M01 is pre-arranged to be remotely operated and controlled with PC, TELEPHONE LINE and GSM.

It is also provided with a powerful and accurate battery charger that assures the efficiency and life of the

battery for more than five years.

CONTROLS

- Programming switch:

1. Automatic test;

2. Automatic run;

3. Locked engine;

4. Forced power supply from mains;

5. Manual starting enabled;

6. Forced power supply from generator;

- Start push button.

- Stop push button enabled at all times or enabled only in manual start position (selectable).

- Reset /silence push button.

- Two parameter selection push buttons.

- Key combination for LED test

VARIOUS FUNCTIONS

- Programmable two or three-phase mains sensor:

- Programmable two-phase mains sensor - 80 to 300V +10 –20%;

- Programmable three-phase mains sensor - 100 to 500V +10 –20%;

- Programmable single-phase generator sensor - 80/260V;

- Generator and mains voltage alarm thresholds with programmable hysterisis.

- Programmable starting cycles.

- Command for spark plug pre-heating or starter;

- Generator tripping delay.

- Safety devices tripping delay.

- Switch back to mains delay.

- GC / MC switch-over delay of 1sec

- Contactor anomaly alarm GC / MC

- Motor cooling delay.

- Self-programmed stop.

- Pre-arrangement for remote emergency stop.

- Remote alarm indication.

- Automatic test by means of internal timer

- Automatic stop by means of internal timer

- Remote controlled stop

- Forced starting (with output) by means of timed remote control

- EJP function (only for France)

- Function for two balanced generators

FILE VER. DATE LANGUAGE PAGE

QBG-M01-ING B/03 11/07/06 ING 2 of 5

INDICATIONS AND SAFETY DEVICES

- Low oil pressure

- High motor temperature

- Fuel reserve

- Water level

- Battery charger generator

- One reserve alarm

- Failed starting

- Min/max battery voltage

- min/max mains voltage

- min/max generator voltage

- Min/max generator frequency

- Overload

- Emergency stop

- Low oil pressure and high motor temperature alarms in positive and negative logic (programmable)

DIGITAL PARAMETERS

- mains voltage 80/500V

- Generator voltage 80/500V.

- Generator frequency 0/100Hz.

- Phase current on TA 50-100-150-200-250-400-500-600-1000/5A (programmable).

- Battery voltage: 7/32V

- Battery charger current: 0/5A

- Hour meter from 0 to 9990 hours.

AUTOMATC RUNNNING MODE

- Automatic starting with adjustable delay for the mains power supply inconsistencies (even on one phase only,

with adjustable threshold) or for phase irregularities (60).

- 4 starting cycles of five seconds each, at regular intervals.

- Buzzer alarm and LED indicators in the event of failed starting attempts.

- Load-to-generator delayed switch-over (adjustable up to 6’’ to 60’’ approx.) the safety devices are inoperative in

this phase: at the end of the delay interval the mains/generator switch-over is performed and the safety devices

are enabled.

- The following safety devices are enabled while running: low oil pressure, dynamo anomaly, high engine

temperature, fuel reserve, failed starting, overload, (51) min/max generator frequency (81), min/max generator

voltage (27 and 59), one input available. When triggered the relative LED lights up, the buzzer sounds and the

unit stops immediately. The alarm cause is stored.

- When the main is restored within the established parameters, after the adjustable established delay, the

units/mains switch-over is performed (CG/CR).

- The stop may command any energ./de energ. Device and the time is self-programmed when the engine is

stopped.

LOCK STATUS

- Releases the alarm status and completely disables every possibility of starting the unit even when the mains

power supply is disconnected. It guarantees safe conditions during maintenance.

MAINS POWER SUPPLY

- Permanently enables the mains power supply and disables all the automatic functions.

MANUAL STARTING

- Enables the manual starting push button that is disabled in all the other functions.

-

FILE VER. DATE LANGUAGE PAGE

QBG-M01-ING B/03 11/07/06 ING 3 of 5

GENERATOR

- Enables the power supply of the utility by means of the safety devices.

UTILITIES

- Automatic 5A battery charger.

- 3 relays: start/stop/utilities – 16A 24V=

- 2 switch-over control relays with free contacts – 10A 250V ~.

- Alarm buzzer.

- Battery voltage: 12V and 24V

- Extractable connection terminal board – inserted flat or upright.

- Dimensions: H127 L 216 D100

- Weight 1200 g.

- Working temperature – 20 + 80°C

- Protection rating IP 54

- Humidity: 80% w/o. condensation

- Conformity: EN60255-1 std

POWER CIRCUITS

- Tetrapolar switch-over switch with mechanical and electrical interlocking achieved using powered contactors or

switch-over switches sized in AC1(ISO/DIS 8528-4), with copper bar connections exceeding 125A

- Unit switch and differential safety device on request

- Lines connection terminal board

- Overload capability: 10% for temperatures of 40°C

- Power supply voltage: 400/230V 50/60Hz

- Isolation 3000V a.c. 1000V d.c.

TESTING

- All control panels are completely tested and set for standard running conditions that may be modified by means

of the appropriate easy-access trimmer. The constructional conformity with technical and safety standards is

also checked.

• They are provided with documents in the pre-established language including:

• Test certificate

• Electric wiring diagram

• Operational instruction, installation and maintenance handbook

• Operational standards

MANUFACTURE

- ANS type electric control panel

- Conformity with European standard EN 60439-1, EMC, EIC 439

- Colour: standard RAL 7032 siliceous grey

Protection degree: IP 42 external and IP 20 internal

- Room temperature: -20 / +40°C

ITEMS SUPPLIED

- Wiring diagram.

- Installation, use and maintenance manual

OPTIONAL

- RS232C Serial output for remote control;

- Programmable from PC, LOCAL or REMOTE CONTROL via MODEM or GSM.

COMPONENTS AND OPTIONALS

GC-M01 standard drive module

GC-M01-IS with serial RS232C

GSM-01 GSM for remote control

GSM-01-SW Software for GSM remote control

FILE VER. DATE LANGUAGE PAGE

QBG-M01-ING B/03 11/07/06 ING 4 of 5

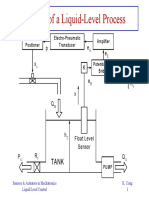

SINGLE

SINGLELINE DIAGRAM

LINE DIAGRAM

QGE

GC-M01

R

G M

CR CG

Fig. 1

USE

The boards are realized with different commutations:

1. Commutation with contactors, with the advantage of a high number of manoeuvrings => 400.000

Disadvantages: sensitive to short circuit current, constant consumption of energy and not manually

manoeuvrable.

2. Commutation with motorized change over switch, with the advantage of no consumption of energy,

manually manoeuvrable and not sensitive to short circuit current.

Disadvantages: limited number of manoeuvrings about 1500 with full charge.

3. Commutation with motorized switches, with the advantage of high current of short circuit, no

consumption of energy, number of manoeuvrings => 7000 and manually manoeuvrable.

AMPER Ith

KVA BATT.

AC1 B.C.

CODE 400Vac 50Vac SWITCHING SIZE VOLTAGE

ISO DIS AMP

100% 110%

8528-4

15 17 25 Contact+c.breaker4P 600X400X250 12Vdc 3A

GCM010025

GCMO10040 25 28 40 Contact+c.breaker4P 600X400X250 12Vdc 3A

GCM010060 37 41 60 Contact+c.breaker4P 600X400X250 12Vdc 3A

GCM010090 50 55 90 Contactors 4P 700X500X250 12Vdc 3A

GCM010110 78 86 110 Contactors 4P 700X500X250 12Vdc 3A

GCM010140 88 97 140 Contactors 4P 700X500X250 12Vdc 3A

GCM010200 125 138 200 Contactors 4P 800X600X300 24Vdc 3A

GCM010325 204 224 325 Contactors 4P 800X1500X400 24Vdc 3A

GCM010400 251 276 400 Contactors 4P 800X1500X400 24Vdc 3A

GCM010500 314 345 500 Contactors 4P 800X1500X400 24Vdc 5A

GCM010600 220 242 600 Contactors 4P 1900X800X500 24Vdc 5A

GCM010700 440 484 700 Contactors 4P 1900X800X500 24Vdc 5A

GCM01000 629 692 1000 Contactors 4P 1900X800X500 24Vdc 5A

GCM010250 157 173 250 Motorized switch 1500X600X400 24Vdc 3,5A

GCM010400 251 276 400 Motorized switch 1500X600X400 24Vdc 3,5A

GCM010630 396 436 630 Motorized switch 1500X600X400 24Vdc 3,5A

GCM010800 503 553 800 Motorized switch 1900X800X500 24Vdc 5A

GCM011000 629 692 1000 Motorized switch 1900X800X500 24Vdc 5A

FILE VER. DATE LANGUAGE PAGE

QBG-M01-ING B/03 11/07/06 ING 5 of 5

You might also like

- Bernini OverviewDocument7 pagesBernini Overviewaberardo1No ratings yet

- DKG 309Document48 pagesDKG 309Dikr ElhakimNo ratings yet

- Dkg-309 Automatic Mains Failure Unit: Canbus and Mpu VersionsDocument61 pagesDkg-309 Automatic Mains Failure Unit: Canbus and Mpu VersionsKhaleel KhanNo ratings yet

- DataKom 309J - USERDocument61 pagesDataKom 309J - USERKhaleel KhanNo ratings yet

- Dkg-119 Manual and Remote Start UnitDocument45 pagesDkg-119 Manual and Remote Start Unitرمآآد انسآآنNo ratings yet

- DKG-507-J User Manual Explains Generator Control Panel FeaturesDocument42 pagesDKG-507-J User Manual Explains Generator Control Panel FeaturesElsad HuseynovNo ratings yet

- Dkg-309 Automatic Mains Failure UnitDocument47 pagesDkg-309 Automatic Mains Failure UnitjbalderramabNo ratings yet

- DKG 705Document4 pagesDKG 705taleb 6269No ratings yet

- DataKom 537 - USERDocument39 pagesDataKom 537 - USERKhaleel KhanNo ratings yet

- Datakom DKG109 Control Auto Start Panel Engine GensetDocument46 pagesDatakom DKG109 Control Auto Start Panel Engine GensetWira Karya DieselNo ratings yet

- DKG 545 EnglishDocument49 pagesDKG 545 EnglishrogerioNo ratings yet

- Dkg-329 User ManualDocument43 pagesDkg-329 User ManualKỹ Sư TđhNo ratings yet

- Kg-545 Automatic Mains Failure UnitDocument35 pagesKg-545 Automatic Mains Failure UnitJack GehlotNo ratings yet

- Datakom-Dkg 517Document39 pagesDatakom-Dkg 517Hernan100% (2)

- Genset AMF Controller DKG-309Document2 pagesGenset AMF Controller DKG-309SAMEERNo ratings yet

- DataKom 507 - J - USERDocument42 pagesDataKom 507 - J - USERKhaleel KhanNo ratings yet

- Dkg-507-J Automatic Mains Failure Unit With J1939 Interface: DescriptionDocument2 pagesDkg-507-J Automatic Mains Failure Unit With J1939 Interface: DescriptionThao Nguyen XuanNo ratings yet

- Empr DMPR CatalogueDocument44 pagesEmpr DMPR CatalogueECATOnlineNo ratings yet

- DKG-307 User Manual Concise OverviewDocument54 pagesDKG-307 User Manual Concise OverviewrogerioNo ratings yet

- DKG 705 User ManualDocument58 pagesDKG 705 User ManualMarioEnriqueAlcocerÁvila100% (1)

- Dkg-517-J Manual and Remote Start Unit With J1939 Interface: DescriptionDocument2 pagesDkg-517-J Manual and Remote Start Unit With J1939 Interface: DescriptionJorge Omar ToroNo ratings yet

- DKG 517 J Manual de UsuarioDocument38 pagesDKG 517 J Manual de Usuarioenriquecourtadep100% (1)

- Optimize ACP Panel Control OverviewDocument6 pagesOptimize ACP Panel Control OverviewRakib HasanNo ratings yet

- 6.51-56 SSMDocument6 pages6.51-56 SSMWanessa SuárezNo ratings yet

- Ca EMPR Eng PDFDocument44 pagesCa EMPR Eng PDFNguyễn ĐứcNo ratings yet

- DKG 509 - UserDocument56 pagesDKG 509 - Userhackerland_1No ratings yet

- Dkg-109 Automatic Mains Failure UnitDocument46 pagesDkg-109 Automatic Mains Failure UnitmohsenNo ratings yet

- Product Introduction - Series MG: Rotary Power Conditioning SystemDocument51 pagesProduct Introduction - Series MG: Rotary Power Conditioning SystemLOST_IN_THE_WORLDNo ratings yet

- 7PCC1301Document20 pages7PCC1301gsantosh06100% (4)

- IMP Intelligent MotorProtectionRelay E 0910Document20 pagesIMP Intelligent MotorProtectionRelay E 0910Người TốtNo ratings yet

- Dkg-509 Automatic Mains Failure Unit With J1939 Port: FeaturesDocument59 pagesDkg-509 Automatic Mains Failure Unit With J1939 Port: FeaturesAziz ArrahalNo ratings yet

- Automatic Board For Emergency Gen-Sets: ManualDocument14 pagesAutomatic Board For Emergency Gen-Sets: ManualKaiser IqbalNo ratings yet

- Automatic Board For Emergency Gen-Sets: ManualDocument14 pagesAutomatic Board For Emergency Gen-Sets: ManualLuis JesusNo ratings yet

- Dkg-307 Automatic Mains Failure Unit: DescriptionDocument2 pagesDkg-307 Automatic Mains Failure Unit: DescriptionThao Nguyen XuanNo ratings yet

- 307 DataDocument2 pages307 DataynadeemNo ratings yet

- B&A Noodstroomsystemen - Woodward Easygen Overview ToepassinDocument56 pagesB&A Noodstroomsystemen - Woodward Easygen Overview ToepassinBojan KitanovskiNo ratings yet

- DG Application AMF / Synchroniser: Conzerv Systems PVT LTDDocument4 pagesDG Application AMF / Synchroniser: Conzerv Systems PVT LTDjaikolangaraparambilNo ratings yet

- Dkg-705 Amf, Parallel To Mains and Dual Genset Synchronization Unit With J1939 InterfaceDocument4 pagesDkg-705 Amf, Parallel To Mains and Dual Genset Synchronization Unit With J1939 InterfacerepelindNo ratings yet

- Generator 307 USERDocument54 pagesGenerator 307 USERLiviu PopaNo ratings yet

- Dkg-309J Automatic Mains Failure Unit With J1939 Interface: DescriptionDocument2 pagesDkg-309J Automatic Mains Failure Unit With J1939 Interface: DescriptionThao Nguyen XuanNo ratings yet

- WoodWard Egcp 2Document4 pagesWoodWard Egcp 2Julian Pompy Buitrago Carrascal100% (1)

- 105 DataDocument2 pages105 DataKarim OmranNo ratings yet

- Dkg-109J Automatic Mains Failure UnitDocument51 pagesDkg-109J Automatic Mains Failure UnitMostafa ShannaNo ratings yet

- DKG-705 Automatic Mains Failure and Remote Start Unit User ManualDocument58 pagesDKG-705 Automatic Mains Failure and Remote Start Unit User ManualJefferson VieiraNo ratings yet

- Modular Parallel Panel (MPP) : 1.1 System DescriptionDocument7 pagesModular Parallel Panel (MPP) : 1.1 System DescriptionRakib HasanNo ratings yet

- Deep Sea Electronics PLC: Model 606 Comprehensive Amf ModuleDocument4 pagesDeep Sea Electronics PLC: Model 606 Comprehensive Amf ModulemohammedalathwaryNo ratings yet

- DSE 6010 DatasheetDocument2 pagesDSE 6010 DatasheetRabih MradNo ratings yet

- Dkg-307 Automatic Mains Failure and Remote Start UnitDocument29 pagesDkg-307 Automatic Mains Failure and Remote Start UnitSalmaan HaiderNo ratings yet

- DKG207 PDFDocument2 pagesDKG207 PDFRoberto MerizaldeNo ratings yet

- Dkg-517-J Automatic Mains Failure UnitDocument38 pagesDkg-517-J Automatic Mains Failure Unitjose luis SerraNo ratings yet

- DataKom 207 - USERDocument28 pagesDataKom 207 - USERKhaleel KhanNo ratings yet

- Dkg-329 Automatic Transfer Switch With Uninterrupted Transfer and Multiple Genset SupportDocument43 pagesDkg-329 Automatic Transfer Switch With Uninterrupted Transfer and Multiple Genset SupportLuis Fernando CuaspudNo ratings yet

- 507 DataDocument2 pages507 DatavasilimertzaniNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Analog Circuit Design: A Tutorial Guide to Applications and SolutionsFrom EverandAnalog Circuit Design: A Tutorial Guide to Applications and SolutionsRating: 3.5 out of 5 stars3.5/5 (6)

- Offshore Electrical Engineering ManualFrom EverandOffshore Electrical Engineering ManualRating: 4 out of 5 stars4/5 (9)

- Low Voltage Alternator - 4 Pole: 70 To 200 kVA - 50 HZ / 88 To 250 kVA - 60 HZ Electrical and Mechanical DataDocument16 pagesLow Voltage Alternator - 4 Pole: 70 To 200 kVA - 50 HZ / 88 To 250 kVA - 60 HZ Electrical and Mechanical DataAsif ShahNo ratings yet

- X2 X1 Z2 E+ E-0V 110 220 380 Z1: Installation and MaintenanceDocument16 pagesX2 X1 Z2 E+ E-0V 110 220 380 Z1: Installation and MaintenanceAhmed El-AdawyNo ratings yet

- Serology: Test Name Current Result Previous Result Unit Cut-Off FactorDocument1 pageSerology: Test Name Current Result Previous Result Unit Cut-Off FactorAsif ShahNo ratings yet

- Hematology (CBC Profile) : MR. No. 21011543546 Lab No. Collection: Name: Gender: Male Age: 66 YearsDocument1 pageHematology (CBC Profile) : MR. No. 21011543546 Lab No. Collection: Name: Gender: Male Age: 66 YearsAsif ShahNo ratings yet

- Perkins Sets - Generator Set - Technical Operation and Maintenance Manual - TMANP - US - May 1998 - OLYMPIANDocument49 pagesPerkins Sets - Generator Set - Technical Operation and Maintenance Manual - TMANP - US - May 1998 - OLYMPIANalstomNo ratings yet

- Be11 enDocument12 pagesBe11 enSaqlain Mir100% (1)

- X2 X1 Z2 E+ E-0V 110 220 380 Z1: Installation and MaintenanceDocument16 pagesX2 X1 Z2 E+ E-0V 110 220 380 Z1: Installation and MaintenanceAhmed El-AdawyNo ratings yet

- 2250 kVA Cummins Diesel Generator Set - Non EPA - 50Hz TP-C2250-T1-50 PDFDocument5 pages2250 kVA Cummins Diesel Generator Set - Non EPA - 50Hz TP-C2250-T1-50 PDFMyo Kyaw KyawNo ratings yet

- Be15Xbe2K Sofware User Manual Be15 User ManualDocument36 pagesBe15Xbe2K Sofware User Manual Be15 User ManualAsif ShahNo ratings yet

- Quadro Automatico Per Gruppo Elettrogeno: Automazione IndustrialeDocument8 pagesQuadro Automatico Per Gruppo Elettrogeno: Automazione IndustrialeAsif ShahNo ratings yet

- Be2K-Plus USER Manual: Customer Support Bernini Design SRL ItalyDocument17 pagesBe2K-Plus USER Manual: Customer Support Bernini Design SRL ItalyAsif ShahNo ratings yet

- Be-One OEM's ManualDocument26 pagesBe-One OEM's ManualAsif ShahNo ratings yet

- Be 2K User's Manual: Bernini Design SRL - ItalyDocument17 pagesBe 2K User's Manual: Bernini Design SRL - ItalyAsif ShahNo ratings yet

- Cea6 Pro - in - 1.4Document98 pagesCea6 Pro - in - 1.4Asif Shah100% (2)

- Auto-Start Digital Controller CEM6 IngDocument12 pagesAuto-Start Digital Controller CEM6 IngJaffer Hussain50% (2)

- Auto-Start Digital Controller CEM6 IngDocument12 pagesAuto-Start Digital Controller CEM6 IngJaffer Hussain50% (2)

- Boards For Gen-Sets in Automatic Parallel Mains and Cogeneration'SDocument13 pagesBoards For Gen-Sets in Automatic Parallel Mains and Cogeneration'SAsif ShahNo ratings yet

- Merlin Gerin Technical Guide Medium VoltageDocument80 pagesMerlin Gerin Technical Guide Medium Voltagepavlovicg100% (1)

- A. T. S. - Switching Line BoardDocument6 pagesA. T. S. - Switching Line BoardAsif ShahNo ratings yet

- 4N35 OptocouplersDocument7 pages4N35 OptocouplersattapapaNo ratings yet

- UCAB232 - RS232 Interface For USB: Connector PinoutsDocument2 pagesUCAB232 - RS232 Interface For USB: Connector PinoutsAsif ShahNo ratings yet

- Boards For Gen-Sets in Automatic Parallel Mains and Cogeneration'SDocument13 pagesBoards For Gen-Sets in Automatic Parallel Mains and Cogeneration'SAsif ShahNo ratings yet

- Air Circuit Breakers For The 21st Century: Catalogue No.'00-P55EDocument4 pagesAir Circuit Breakers For The 21st Century: Catalogue No.'00-P55EAsif ShahNo ratings yet

- SS8050 NPN Epitaxial Silicon Transistor: FeaturesDocument7 pagesSS8050 NPN Epitaxial Silicon Transistor: Featurescbdk71No ratings yet

- Installation RecommendationsDocument22 pagesInstallation RecommendationsAsif ShahNo ratings yet

- PL159Document140 pagesPL159Kiran KarthikNo ratings yet

- Installation RecommendationsDocument19 pagesInstallation RecommendationsAsif ShahNo ratings yet

- Masterpact: Installation RecommendationsDocument16 pagesMasterpact: Installation RecommendationsAsif ShahNo ratings yet

- SACE Low Voltage Air Circuit-Breakers: Sometimes Evolution Takes A LeapDocument16 pagesSACE Low Voltage Air Circuit-Breakers: Sometimes Evolution Takes A Leaphonafa- R.O.N.ONo ratings yet

- Altivar Machine ATV320 ATV320U15N4C DocumentDocument11 pagesAltivar Machine ATV320 ATV320U15N4C DocumentPhaniNo ratings yet

- Zurn X6915-XL TroubleshootingDocument1 pageZurn X6915-XL Troubleshootingbo cephusNo ratings yet

- Samsung KodeDocument4 pagesSamsung KodeAgus WahyudiNo ratings yet

- Brochure Pisotecho LXGUDocument2 pagesBrochure Pisotecho LXGUjizas1205No ratings yet

- JBL Duet NC Spec Sheet EnglishDocument2 pagesJBL Duet NC Spec Sheet EnglishHilaNo ratings yet

- Cne LabDocument8 pagesCne LabAnonymous 1BHS6a100% (2)

- WIC1 - CT Powered Time Overcurrent And: Earth Current RelayDocument38 pagesWIC1 - CT Powered Time Overcurrent And: Earth Current RelaysadeghzendehboodiNo ratings yet

- Liquid Level ControlDocument47 pagesLiquid Level ControlranjithkrajNo ratings yet

- Architectural Acoustics GuideDocument10 pagesArchitectural Acoustics GuideNupur Bhadra100% (1)

- 500 Word EassyDocument1 page500 Word Eassyapi-429052973No ratings yet

- Network capacity and user distribution scenario analysisDocument7 pagesNetwork capacity and user distribution scenario analysisRaul Rambo LongboenNo ratings yet

- Introduction To Signal ProcessingDocument162 pagesIntroduction To Signal Processingapi-26157851No ratings yet

- 415V LVAC Switchborad Ver1Document7 pages415V LVAC Switchborad Ver1g.HtrughtreNo ratings yet

- ComNet CNGE2FE24MSPOE Instruction ManualDocument139 pagesComNet CNGE2FE24MSPOE Instruction ManualJMAC SupplyNo ratings yet

- VasudevanDocument461 pagesVasudevanBrajesh KumarNo ratings yet

- Mercury Mariner 1Document54 pagesMercury Mariner 1Shoaib Ahmed100% (1)

- DDF Week 05Document6 pagesDDF Week 05Anusha ChidagniNo ratings yet

- ARB Compressor DualDocument5 pagesARB Compressor DualSteveNo ratings yet

- Philips AZ 2558 Service ManualDocument51 pagesPhilips AZ 2558 Service ManualgbacarimNo ratings yet

- Lightning Electron TransferDocument11 pagesLightning Electron TransferElizabeth DouglasNo ratings yet

- Crystallinity of PolymerDocument26 pagesCrystallinity of PolymerChetan BholeNo ratings yet

- MAYTAG MDE28PNCGW0 TechSheet-W10589718-RevADocument8 pagesMAYTAG MDE28PNCGW0 TechSheet-W10589718-RevAAngel MartinezNo ratings yet

- Murata IsolatorsDocument4 pagesMurata Isolatorskn65238859No ratings yet

- MA200 ManualDocument16 pagesMA200 ManualciprinisNo ratings yet

- Ece III Electronic Instrumentation (10it35) NotesDocument129 pagesEce III Electronic Instrumentation (10it35) NotesAsha Kumar100% (2)

- MobileAppTracking Android SDKDocument18 pagesMobileAppTracking Android SDKEdward HarrisNo ratings yet

- Serway 6 e Problems 27Document12 pagesSerway 6 e Problems 27David SaucedoNo ratings yet

- High Frequency Transformer GuideDocument8 pagesHigh Frequency Transformer Guideyugandhar_yadamNo ratings yet

- Basic FCR SystemDocument50 pagesBasic FCR SystemAdhe Vendy (Garvi Chanel)50% (2)

- Ev 100 ManualDocument1 pageEv 100 Manualbugsbunny321No ratings yet