Professional Documents

Culture Documents

ASTM G 59 - 97 (Reapproved 2009)

Uploaded by

ABINASH BEHERAOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ASTM G 59 - 97 (Reapproved 2009)

Uploaded by

ABINASH BEHERACopyright:

Available Formats

Designation: G 59 – 97 (Reapproved 2009)

Standard Test Method for

Conducting Potentiodynamic Polarization Resistance

Measurements1

This standard is issued under the fixed designation G 59; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope test method is also useful for training operators in sample

1.1 This test method covers an experimental procedure for preparation and experimental techniques for polarization resis-

polarization resistance measurements which can be used for the tance measurements.

calibration of equipment and verification of experimental 3.2 Polarization resistance can be related to the rate of

technique. The test method can provide reproducible corrosion general corrosion for metals at or near their corrosion potential,

potentials and potentiodynamic polarization resistance mea- Ecorr. Polarization resistance measurements are an accurate and

surements. rapid way to measure the general corrosion rate. Real time

1.2 The values stated in SI units are to be regarded as corrosion monitoring is a common application. The technique

standard. No other units of measurement are included in this can also be used as a way to rank alloys, inhibitors, and so forth

standard. in order of resistance to general corrosion.

1.3 This standard does not purport to address all of the 3.3 In this test method, a small potential scan, DE(t), defined

safety concerns, if any, associated with its use. It is the with respect to the corrosion potential (DE = E – Ecorr), is

responsibility of the user of this standard to establish appro- applied to a metal sample. The resultant currents are recorded.

priate safety and health practices and determine the applica- The polarization resistance, RP, of a corroding electrode is

bility of regulatory limitations prior to use. defined from Eq 1 as the slope of a potential versus current

density plot at i = 0 (1-4):3

2. Referenced Documents

2.1 ASTM Standards:2 Rp 5 S D

] DE

]i i50, dE/dt→0

(1)

G 3 Practice for Conventions Applicable to Electrochemical The current density is given by i. The corrosion current

Measurements in Corrosion Testing density, icorr, is related to the polarization resistance by the

G 5 Reference Test Method for Making Potentiostatic and Stern-Geary coefficient, B. (3),

Potentiodynamic Anodic Polarization Measurements

B

G 102 Practice for Calculation of Corrosion Rates and icorr 5 106 R (2)

p

Related Information from Electrochemical Measurements

The dimension of Rp is ohm-cm 2, icorr is muA/cm2, and B is

3. Significance and Use in V. The Stern-Geary coefficient is related to the anodic, ba,

3.1 This test method can be utilized to verify the perfor- and cathodic, bc, Tafel slopes as per Eq 3.

mance of polarization resistance measurement equipment in- ba bc

cluding reference electrodes, electrochemical cells, poten- B5 (3)

2.303~ba 1 bc!

tiostats, scan generators, measuring and recording devices. The The units of the Tafel slopes are V. The corrosion rate, CR,

in mm per year can be determined from Eq 4 in which EW is

1

This test method is under the jurisdiction of ASTM Committee G01 on the equivalent weight of the corroding species in grams and r

Corrosion of Metals and is the direct responsibility of Subcommittee G01.11 on is the density of the corroding material in g/cm3.

Electrochemical Measurements in Corrosion Testing.

Current edition approved May 1, 2009. Published May 2009. Originally

icorr EW

CR 5 3.27 3 10–3 r (4)

approved in 1978. Last previous edition approved in 2003 as G 59–97(2003).

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on The boldface numbers in parentheses refer to the list of references at the end of

the ASTM website. this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

--`,,,,`,`````,,`,,`,,`,`,,,``

Copyright ASTM International

Provided by IHS under license with ASTM

1Licensee=University of Alberta/5966844001, User=sharabiani, shahramfs

No reproduction or networking permitted without license from IHS Not for Resale, 03/14/2014 11:17:51 MDT

G 59 – 97 (2009)

Refer to Practice G 102 for derivations of the above equa- requires 900 mL of test solution. The temperature must be

tions and methods for estimating Tafel slopes. maintained at 30°C within 1°.

3.4 The test method may not be appropriate to measure 6.2 The test cell is purged at 150 cm3/min with an oxygen-

polarization resistance on all materials or in all environments. free gas such as hydrogen, nitrogen, or argon. The purge is

See 8.2 for a discussion of method biases arising from solution started at least 30 min before specimen immersion. The purge

resistance and electrode capacitance. continues throughout the test.

6.3 The working electrode should be prepared as detailed in

4. Apparatus Test Method G 5. The experiment must commence within 1 h

4.1 The apparatus is described in Test Method G 5. It of preparing the electrode. Preparation includes sequential wet

includes a 1 L round bottom flask modified to permit the polishing with 240 grit and 600 grit SiC paper. Determine the

addition of inert gas, thermometer, and electrodes. This stan- surface area of the specimen to the nearest 0.01 cm2 and

dard cell or an equivalent cell can be used. An equivalent cell subtract for the area under the gasket (typically 0.20 to 0.25

must be constructed of inert materials and be able to reproduce cm2).

the standard curve in Test Method G 5. 6.4 Immediately prior to immersion the specimen is de-

4.2 A potentiostat capable of varying potential at a constant greased with a solvent such as acetone and rinsed with distilled

scan rate and measuring the current is needed. water. The time delay between rinsing and immersion should

4.3 A method of recording the varying potential and result- be minimal.

ing current is needed.

NOTE 2—Samples of the standard AISI Type 430 stainless steel (UNS

5. Test of Electrical Equipment S45000) used in this test method are available to those wishing to evaluate

their equipment and test procedure from Metal Samples, P.O. Box 8,

5.1 Before the polarization resistance measurement is made, Mumford, AL 36268.

the instrument system (potentiostat, X-Y recorder or data

acquisition system) must be tested to ensure proper function- 6.5 Transfer the test specimen to the test cell and position

ing. For this purpose, connect the potentiostat to a test the Luggin probe tip 2 to 3 mm from the test electrode surface.

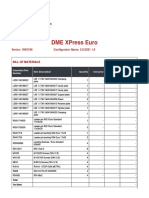

electrical circuit (5). While more complex dummy cells are The tip diameter must be no greater than 1 mm.

sometimes needed in electrochemical studies, the simple resis- 6.6 Record the corrosion potential Ecorr after 5 and 55-min

tor shown in Fig. 1 is adequate for the present application. immersion.

5.2 Use R = 10.0 V. Set the applied potential on the 6.7 Apply a potential 30 mV more negative that the re-

potentiostat to E =– 30.0 mV and apply the potential. The corded 55 min corrosion potential (See Note 3).

current should be 3.0 mA by Ohm’s Law, I = E/R. NOTE 3—Practice G 3 provides a definition of sign convention for

NOTE 1—When polarization resistance values are measured for systems potential and current.

with different corrosion currents, the value of R should be chosen to cover 6.8 One minute after application of the –30 mV potential,

the current range of the actual polarization resistance measurement.

Expected corrosion currents in the microampere range require R = 1 to 10

begin the anodic potential scan at a sweep rate of 0.6 V/h

kV. (within 5 %). Record the potential and current continuously.

Terminate the sweep at a potential 30 mV more positive than

5.3 Record the potentiodynamic polarization curve at a scan the 55 min corrosion potential.

--`,,,,`,`````,,`,,`,,`,`,,,```,-`-`,,`,,`,`,,`---

rate of 0.6 V/h from DE = –30 mV to DE = +30 mV and back

6.9 Plot the polarization curve as a linear potential-current

to DE = –30 mV. The plot should be linear, go through the

density plot as shown in Practice G 3. Determine the polariza-

origin, and have a slope 10 V. The curves recorded for the

tion resistance, Rp, as the tangent of the curve at i=0.

forward and reverse scans should be identical.

5.4 If the observed results are different than expected, the

7. Report

electrochemical equipment may require calibration or servicing

in accordance with the manufacturer’s guidelines. 7.1 Report the following information:

7.1.1 The 5 and 55 min corrosion potentials and the polar-

6. Experimental Procedure ization resistance value,

6.1 The 1.0 N H2SO4 test solution should be prepared from 7.1.2 Duplicate runs may be averaged, and

American Chemical Society reagent grade acid and distilled 7.1.3 Note any deviation from the procedure or test condi-

water as described in Test Method G 5. The standard test cell tions established in this test method.

FIG. 1 Arrangement for Testing of Electrical Equipment (Potentiostat, X-Y Recorder)

Copyright ASTM International

Provided by IHS under license with ASTM

2Licensee=University of Alberta/5966844001, User=sharabiani, shahramfs

No reproduction or networking permitted without license from IHS Not for Resale, 03/14/2014 11:17:51 MDT

G 59 – 97 (2009)

8. Precision and Bias TABLE 1 Interlaboratory Test Program Polarization Data for

Stainless Steel Type 430 in 1.0 N H2SO4 at 30°C

8.1 Precision—Precision in this test method refers to the Laboratory Ecorr–5min Ecorr–55min Rp

closeness of agreement between randomly selected measured

(mV) (mV) (ohm-cm2)

values. There are two aspects of precision, repeatability and

1 –0.519 –0.506 6.47

reproducibility. Repeatability refers to the closeness of agree- –0.519 –0.505 5.88

ment between measurements by the same laboratory on iden- 2 –0.542 –0.521 5.95

tical Type 430 stainless steel specimens repeated with as close –0.540 –0.519 5.04

3 –0.524 –0.513 6.93

as possible adherence to the same procedure. Reproducibility –0.520 –0.508 6.40

refers to the closeness of agreement between different labora- 4 –0.555 –0.545 7.70

–0.565 –0.545 7.70

tories using identical Type 430 stainless steel specimens and 5 –0.539 –0.524 7.58

the procedure specified. An interlaboratory test program with –0.530 –0.510 6.18

13 laboratories participating and two, three or four replicate 6 –0.519 –0.510 7.60

–0.522 –0.512 7.16

measurements was carried out to establish the precision. The –0.521 –0.509 6.65

measured values included (Table 1) the corrosion potential 7 –0.522 –0.510 9.06

–0.520 –0.511 7.07

measured after 5 and 55 min and the polarization resistance. A –0.523 –0.510 5.85

research report has been filed with the results of this program. 8 –0.520 –0.508 7.11

–0.520 –0.508 7.52

8.1.1 Repeatability— The lack of repeatability is measured –0.521 –0.510 6.94

by the repeatability standard deviation sr. The 95 % confidence 9 –0.529 –0.513 7.11

interval was calculated as 6 2.8 sr. The values obtained are –0.530 –0.513 7.22

–0.529 –0.514 7.19

shown in Table 2. The 95 % confidence interval refers to the –0.529 –0.515 7.19

interval around the average that 95 % of the values should be 10 –0.514 –0.505 5.17

found. –0.516 –0.506 6.90

11 –0.543 –0.529 5.07

8.1.2 Reproducibility— The lack of reproducibility is mea- –0.538 –0.524 4.64

sured by the reproducibility standard deviation, sR. The 95 % 12 –0.520 –0.505 5.63

–0.519 –0.507 6.16

confidence interval was calculated as 6 2.8 sR. The values 13 –0.531 –0.519 5.08

obtained are shown in Table 3. –0.529 –0.517 5.38

–0.529 –0.517 5.90

8.2 Bias—The polarization resistance as measured by the

Test Method G 59 has two sources of bias. The potentiody-

namic method includes a double layer capacitance charging 9. Keywords

effect that may cause the polarization resistance to be under- 9.1 anodic polarization; auxiliary electrode; cathodic polar-

estimated. There is also a solution resistance effect that may ization; corrosion; corrosion potential; corrosion rate; current

cause the polarization resistance to be overestimated. This bias density; electrochemical cell; electrochemical potential; Lug-

will depend on the placement of the reference electrode and gin probe; mixed potential; open-circuit potential; overvoltage;

electrolyte conductivity. Refer to Practice G 102 for further polarization resistance; potentiodynamic; reference electrode;

discussion on the effects of double layer capacitance and solution resistance; Stern-Geary coefficient; Tafel slope; work-

solution resistance on polarization resistance measurements. ing electrode

--`,,,,`,`````,,`,,`,,`,`,,,```,-`-`,,`,,`,`,,`---

Copyright ASTM International

Provided by IHS under license with ASTM

3Licensee=University of Alberta/5966844001, User=sharabiani, shahramfs

No reproduction or networking permitted without license from IHS Not for Resale, 03/14/2014 11:17:51 MDT

G 59 – 97 (2009)

TABLE 2 Repeatability Statistics

95 % Confidence

Average Sr

Interval

Ecorr 5 min, mV versus SCE –0.5287 0.00260 6 0.0073 V

Ecorr 55 min, mV versus SCE –0.5151 0.00273 6 0.0076 V

Rp, ohm-cm2 6.46 0.713 62.00 ohm-cm2

TABLE 3 Reproducibility Statistics

95 % Confidence

Average SR

Interval

Ecorr 5 min, mV versus SCE –0.5287 0.0127 6 0.0356 mV

Ecorr 55 min, mV versus SCE –0.5151 0.0111 6 0.0311 mV

Rp ohm-cm2 6.46 1.01 62.83 ohm-cm2

--`,,,,`,`````,,`,,`,,`,`,,,```,-`-`,,`,,`,`,,`---

REFERENCES

(1) Stern, M., and Roth, R. M., Journal of the Electrochemical Society, (4) Mansfeld, F., “Evaluation of Polarization Resistance Round Robin

Vol 104, 1957, p. 390. Testing Conducted by ASTM G01.11,” Paper No. 106, CORROSION/

(2) Stern, M., Corrosion, Vol 14, 1958, p. 440. 76, NACE, Houston, TX, March 22-26, 1976.

(3) Mansfeld, F., “The Polarization Resistance Technique for Measuring (5) Gileadi, E., Kirowa-Eisner, E., and Penciner, J. Interfacial Electro-

Corrosion Currents,” Corrosion Science and Technology, Plenum chemistry, an Experimental Approach, Chapter III.1, Addison-Wesley

Press, New York, NY, Vol VI, 1976, p.163. Publishing Co., Reading, MA 1975.

ASTM International takes no position respecting the validity of any patent rights asserted in connection with any item mentioned

in this standard. Users of this standard are expressly advised that determination of the validity of any such patent rights, and the risk

of infringement of such rights, are entirely their own responsibility.

This standard is subject to revision at any time by the responsible technical committee and must be reviewed every five years and

if not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or for additional standards

and should be addressed to ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the

responsible technical committee, which you may attend. If you feel that your comments have not received a fair hearing you should

make your views known to the ASTM Committee on Standards, at the address shown below.

This standard is copyrighted by ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959,

United States. Individual reprints (single or multiple copies) of this standard may be obtained by contacting ASTM at the above

address or at 610-832-9585 (phone), 610-832-9555 (fax), or service@astm.org (e-mail); or through the ASTM website

(www.astm.org).

Copyright ASTM International

Provided by IHS under license with ASTM

4Licensee=University of Alberta/5966844001, User=sharabiani, shahramfs

No reproduction or networking permitted without license from IHS Not for Resale, 03/14/2014 11:17:51 MDT

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5796)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- CSI Specification Section Numbers and TitlesDocument186 pagesCSI Specification Section Numbers and TitlesKatinskagomesNo ratings yet

- Day4a - Goals of Anthropology, Political Science, and SociologyDocument42 pagesDay4a - Goals of Anthropology, Political Science, and SociologyFfrekgtreh Fygkohk100% (1)

- Urban Planning in IndiaDocument22 pagesUrban Planning in IndiaSakshi MohataNo ratings yet

- Astm G74 - 08Document7 pagesAstm G74 - 08ABINASH BEHERANo ratings yet

- Astm G76 13Document6 pagesAstm G76 13ABINASH BEHERANo ratings yet

- Protective Barriers in and Around Buildings - Code of SafetyDocument5 pagesProtective Barriers in and Around Buildings - Code of SafetyABINASH BEHERANo ratings yet

- Indian Hndard: Safety Corie For Piling and Other Deep FoundationsDocument13 pagesIndian Hndard: Safety Corie For Piling and Other Deep FoundationsABINASH BEHERANo ratings yet

- IS 1893.2005 Part-4Document23 pagesIS 1893.2005 Part-4ABINASH BEHERANo ratings yet

- Indian Standard: Safety Code For Tunneling Work (Document24 pagesIndian Standard: Safety Code For Tunneling Work (ABINASH BEHERANo ratings yet

- Indian Standard: Safety Code For Constructions Involving Use of Hot Bituminous MaterialsDocument11 pagesIndian Standard: Safety Code For Constructions Involving Use of Hot Bituminous MaterialsABINASH BEHERANo ratings yet

- Eddy Current - Basics II: Abinash Behera Asnt NDT Level-Iii in RT, Ut, MT, PT, EtDocument50 pagesEddy Current - Basics II: Abinash Behera Asnt NDT Level-Iii in RT, Ut, MT, PT, EtABINASH BEHERANo ratings yet

- Eddy Current - Basics I: Abinash Behera Asnt NDT Level-Iii in RT, Ut, MT, PT, EtDocument29 pagesEddy Current - Basics I: Abinash Behera Asnt NDT Level-Iii in RT, Ut, MT, PT, EtABINASH BEHERANo ratings yet

- In-Service DefectsDocument34 pagesIn-Service DefectsABINASH BEHERANo ratings yet

- Design Fabrication of A Solar Powered Stirling EngineDocument65 pagesDesign Fabrication of A Solar Powered Stirling EngineSirajus Salekin [Id:37]No ratings yet

- Probability Practice - 6TDocument5 pagesProbability Practice - 6Tnguyenduckien054No ratings yet

- Components of Valve Assembly Shown 27 and 28. Ofthe Are Figures 37. Use Bottom-Up Approach AssemblyDocument2 pagesComponents of Valve Assembly Shown 27 and 28. Ofthe Are Figures 37. Use Bottom-Up Approach AssemblyLuis Perez MarquezNo ratings yet

- Regulations PDFDocument32 pagesRegulations PDFAmit SinhaNo ratings yet

- Tcs Book FinalDocument16 pagesTcs Book FinalAbinash MohantyNo ratings yet

- DBMS & SQL Assignment 1Document5 pagesDBMS & SQL Assignment 1Madhuri PatelNo ratings yet

- Dme Xpress Euro: Series: 196X196 Configurator Name: 5/2/2021 1.0Document3 pagesDme Xpress Euro: Series: 196X196 Configurator Name: 5/2/2021 1.0Ahmed SamirNo ratings yet

- GLC 353 MC3 GLC 503 MC3 GLC 553 MC3: MIG/MAG Welding MachineDocument122 pagesGLC 353 MC3 GLC 503 MC3 GLC 553 MC3: MIG/MAG Welding Machinematadorishe0% (1)

- Resume of Arif MohiuddinDocument2 pagesResume of Arif MohiuddinMohammad Arif MohiuddinNo ratings yet

- Mavic 2 Enterprise: User ManualDocument58 pagesMavic 2 Enterprise: User ManualLeoTNo ratings yet

- Exper-10 Digital Comparator CircuitDocument5 pagesExper-10 Digital Comparator CircuitMohammed Dyhia AliNo ratings yet

- 30 Footwear Developer Interview Questions and AnswersDocument16 pages30 Footwear Developer Interview Questions and Answersthanh2501No ratings yet

- Natural and Artificial Rockslide DamsDocument649 pagesNatural and Artificial Rockslide DamsCarlos Augusto Sánchez RondónNo ratings yet

- Kelayakan Usaha Budidaya Ayam Petelur Analisis BiaDocument10 pagesKelayakan Usaha Budidaya Ayam Petelur Analisis BiaJuniNo ratings yet

- Rigstoreef Impact or Enhancement On Marine Biodiversity 2157 7625 1000187Document9 pagesRigstoreef Impact or Enhancement On Marine Biodiversity 2157 7625 1000187tavis80No ratings yet

- MSCI ResponseDocument6 pagesMSCI Responseusman.naeemm1No ratings yet

- Cslplasma Online Health Questionnaire Instructions March2023Document4 pagesCslplasma Online Health Questionnaire Instructions March2023Ivel RhaenNo ratings yet

- EthicsDocument73 pagesEthicsMiechaellaNo ratings yet

- Curve Fitting TutorialDocument13 pagesCurve Fitting TutorialDragan LazicNo ratings yet

- mb1319 L433Document25 pagesmb1319 L433Pablo RodriguezNo ratings yet

- Second Quarter Lesson 2Document22 pagesSecond Quarter Lesson 2Jomarie PauleNo ratings yet

- Dywidag Post Tensioning Catalogue 6Document1 pageDywidag Post Tensioning Catalogue 6PrateekNo ratings yet

- Histology: Neuron Cells Types and StructureDocument7 pagesHistology: Neuron Cells Types and StructureAli HayderNo ratings yet

- Silicon NPN Power Transistors: Savantic Semiconductor Product SpecificationDocument3 pagesSilicon NPN Power Transistors: Savantic Semiconductor Product SpecificationSsr ShaNo ratings yet

- Workflow Example - How To Hide AndOr Remove A Defect Status in ALM v11Document4 pagesWorkflow Example - How To Hide AndOr Remove A Defect Status in ALM v11Aylin SakarNo ratings yet

- Advanced Structural Dynamics and Acoustics 13811 Advanced Structural PDFDocument13 pagesAdvanced Structural Dynamics and Acoustics 13811 Advanced Structural PDFJitendra ItankarNo ratings yet