Professional Documents

Culture Documents

Teroson MS 9399: Product Description Technical Data

Uploaded by

Bib Gmz0 ratings0% found this document useful (0 votes)

135 views2 pagesLoctite 2081733

Original Title

Loctite-2081733

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentLoctite 2081733

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

135 views2 pagesTeroson MS 9399: Product Description Technical Data

Uploaded by

Bib GmzLoctite 2081733

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

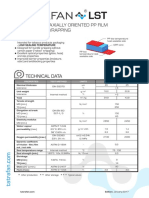

Technical Data Sheet

Teroson MS 9399

August-2014

PRODUCT DESCRIPTION TECHNICAL DATA

Teroson MS 9399 provides the following product Component A

characteristics: Density, white, grey, black, g/cm³: approx. 1.4

Component B

Technology Silane-modified polymer Component B, density, black, g/cm³: approx. 1.3

Product Type Adhesive/Sealant Component B, density, white, g/cm³: approx. 1.3

Components Two-component Mixture (Component A+B)

Cure Room temperature cure after mixing Density, black g/cm³: approx. 1.35

Application Assembly Density, white, grey, g/cm³: approx. 1.35

Appearance Component A: black, grey, white Sag resistance: in joints up to 15

Component B: black, white mm (DIN profile)

Remark: A-component grey to be Processing time/

used with b-component white Open time 23° C, min:

Consistency Pasty, Thixotropic Black: approx. 30

Odor Characteristic White: approx. 20

Grey: approx. 20

Mix Ratio, by volume - 1 : 1

Strength for further handling 23° C, h:

Part A: Part B

Black: approx. 2.5 to 3

Grey: approx. 1.5 to 2

Teroson MS 9399 is a highly viscous, sag-resistant, two-component

White: approx. 1.5 to 2

adhesive based on silane-modified polymers, which cures

independently of the atmospheric moisture to an elastic product. It is Shore-A-hardness (ISO 868, Durometer A)*: approx. 55

free from solvents, iscoyanates and silicones. Teroson MS 9399 has Tensile strength (acc. to ISO 37), MPa: approx. 3.0

good UV and weathering resistance and can be employed for Elongation at break approx. 150

bondings in indoor and outdoor uses. (acc. to ISO 37, speed 200 mm/min)*,%:

Tensile shear strength approx. 2

Application Areas: (acc. to ISO 4587), MPa: (1 mm thick sheet

Teroson MS 9399 can be used for elastic bondings, for example in metal)

the caravan manufacture, in the railroad vehicle industry or in Substrates: Al 99.5

shipbuilding. Layer thickness, mm: 2

Cross head speed, mm/min: 10

UV resistance: no signif. changes

UV source: Osram

Vitalux 300W,

dry UV

Distance to the specimen, cm: 25

Test period, weeks: 6

Application temperature, °C: 15 to 40

In service temperature range, °C: -40 to +100

Short exposure (up to 1 h), °C: 120

* ISO 291 standard climate: 23°C, 50% relative

air humidity

______________________________________________________________________________________________________

Henkel AG & Co.KGaA

40191 Düsseldorf. Germany

Phone: +49-211-797-0

www.henkel.com

DIRECTIONS OF USE ADDITIONAL INFORMATION

Preliminary statement: Disclaimer:

Prior to application it is necessary to read the Material Safety Note:

Data Sheet for information about precautionary measures The information provided in this Technical Data Sheet (TDS) including the

recommendations for use and application of the product are based on our

and safety recommendations. Also, for chemical products knowledge and experience of the product as at the date of this TDS. The

exempt from compulsory labeling, the relevant precautions product can have a variety of different applications as well as differing

should always be observed. application and working conditions in your environment that are beyond our

control. Henkel is, therefore, not liable for the suitability of our product for the

Pre-Treatment: production processes and conditions in respect of which you use them, as well

as the intended applications and results. We strongly recommend that you

The adhesion surfaces must be clean, dry, oil and grease free. carry out your own prior trials to confirm such suitability of our product.

Depending on the surface it may be necessary to roughen the Any liability in respect of the information in the Technical Data Sheet or any

surface by mechanical means or to use a primer/adhesion promoter other written or oral recommendation(s) regarding the concerned product is

to provide best adhesion. For plastics surfaces we recommend the excluded, except if otherwise explicitly agreed and except in relation to death or

use of Teroson SB 450. When manufacturing plastics, external personal injury caused by our negligence and any liability under any applicable

release agents are often used; these agents must be absolutely mandatory product liability law.

removed prior to starting bonding or sealing. Due to the different In case products are delivered by Henkel Belgium NV, Henkel Electronic

compositions of paints, especially powder paints and the large Materials NV, Henkel Nederland BV, Henkel Technologies France SAS and

Henkel France SA please additionally note the following:

number of different substrates, application trials before use are In case Henkel would be nevertheless held liable, on whatever legal ground,

necessary. When bonding and sealing PMMA, e.g. Plexiglas®, and Henkel’s liability will in no event exceed the amount of the concerned delivery.

polycarbonate, e.g. Makrolon® or Lexan®, under tension, stress In case products are delivered by Henkel Colombiana, S.A.S. the

corrosion cracking may occur. Application trials before use are following disclaimer is applicable:

necessary. There is no adhesion to polyethylene, polypropylene and The information provided in this Technical Data Sheet (TDS) including the

PTFE. Substrates not mentioned above should be subject to trials. recommendations for use and application of the product are based on our

knowledge and experience of the product as at the date of this TDS. Henkel is,

Application: therefore, not liable for the suitability of our product for the production

Teroson MS 9399 is contained in a 2 x 200 ml cartridge set processes and conditions in respect of which you use them, as well as the

intended applications and results. We strongly recommend that you carry out

(components A and B) which also contains a static mixer. To open your own prior trials to confirm such suitability of our product.

the cartridges, the metal cap must be removed and the green plug Any liability in respect of the information in the Technical Data Sheet or any

pulled out. Now, the static mixer is screwed onto it. The cartridge set other written or oral recommendation(s) regarding the concerned product is

is then placed into the suitable compressed-air pistol. When the pistol excluded, except if otherwise explicitly agreed and except in relation to death or

handle is actuated, the material is pressed through the static mixer, personal injury caused by our negligence and any liability under any applicable

whereby the two components are automatically mixed. The first 10 ml mandatory product liability law.

of the adhesive pass should be rejected, owing to the fact they may In case products are delivered by Henkel Corporation, Resin Technology

not have been mixed correctly. If the application of adhesive is Group, Inc., or Henkel Canada Corporation, the following disclaimer is

applicable:

interrupted for more than 5 minutes at 23° C, the static mixer should The data contained herein are furnished for information only and are believed

be replaced. Otherwise, the increase in viscosity could cause the to be reliable. We cannot assume responsibility for the results obtained by

static mixer to burst. At higher processing temperatures interruption others over whose methods we have no control. It is the user's responsibility to

times will decrease. Teroson MS 9399 is applied directly to the determine suitability for the user's purpose of any production methods

substrate. For the processing equipment that we recommend, the mentioned herein and to adopt such precautions as may be advisable for the

processing pressure should not exceed 5 bars. The parts which are protection of property and of persons against any hazards that may be involved

to be bonded must be joined within the specified processing time. in the handling and use thereof. In light of the foregoing, Henkel Corporation

specifically disclaims all warranties expressed or implied, including

Surplus material is to be removed immediately after application. warranties of merchantability or fitness for a particular purpose, arising

Other packagings are available on request. from sale or use of Henkel Corporation’s products. Henkel Corporation

specifically disclaims any liability for consequential or incidental

Cleaning: damages of any kind, including lost profits. The discussion herein of various

For cleaning application equipment contaminated with uncured processes or compositions is not to be interpreted as representation that they

Teroson MS 9399 we recommend the use of Cleaner+Diluent are free from domination of patents owned by others or as a license under any

Teroson A, D or FL. Henkel Corporation patents that may cover such processes or compositions.

We recommend that each prospective user test his proposed application before

repetitive use, using this data as a guide. This product may be covered by one

STORAGE or more United States or foreign patents or patent applications.

Frost-Sensitive No Trademark usage

Except as otherwise noted, all trademarks in this document are trademarks of

Recommended Storage Temperature, °C 10 to 25

Henkel Corporation in the U.S. and elsewhere. ® denotes a trademark

Shelf-life (in unopened original packaging), 9 registered in the U.S. Patent and Trademark Office.

months

Reference 0.2

______________________________________________________________________________________________________

Henkel AG & Co.KGaA

40191 Düsseldorf. Germany

Phone: +49-211-797-0

www.henkel.com

You might also like

- Terostat Ms 939-EnDocument2 pagesTerostat Ms 939-EnZoli PoliNo ratings yet

- EluCad InstructionsDocument2 pagesEluCad InstructionsIng Admir MatoshiNo ratings yet

- Hardtop XP Alu PDFDocument5 pagesHardtop XP Alu PDFBiju_PottayilNo ratings yet

- Hardtop XP AluDocument5 pagesHardtop XP AluAsebaho BadrNo ratings yet

- Hardtop XP Alu: Technical Data SheetDocument5 pagesHardtop XP Alu: Technical Data SheetAfrizal Albar RamadhanNo ratings yet

- CT1 Product Info Sheet TRIBRID 10 09 2020 PDFDocument2 pagesCT1 Product Info Sheet TRIBRID 10 09 2020 PDFPranshu JainNo ratings yet

- Impact Modified PS Clear for Sneeze Guards and Face ShieldsDocument1 pageImpact Modified PS Clear for Sneeze Guards and Face ShieldsIceMan3No ratings yet

- Akulon FC-X9200: PA6 CopolymerDocument2 pagesAkulon FC-X9200: PA6 CopolymerDiegoTierradentroNo ratings yet

- PG 23Document1 pagePG 23azeem bilalNo ratings yet

- Teroson Ms 935-EnDocument2 pagesTeroson Ms 935-EnakosirhockzNo ratings yet

- Pressure Gauges Afriso BrandDocument14 pagesPressure Gauges Afriso BrandsssydorenkoNo ratings yet

- Jotamastic Plus: Technical Data SheetDocument5 pagesJotamastic Plus: Technical Data SheetBiju_PottayilNo ratings yet

- PP White c60 Gni-01 Gl65wDocument1 pagePP White c60 Gni-01 Gl65wIván CsörgőNo ratings yet

- TDS - HZ 01CPR - V02 - enDocument2 pagesTDS - HZ 01CPR - V02 - enFakhreddine BousninaNo ratings yet

- TDS Penguard HSP ZP GB English ProtectiveDocument5 pagesTDS Penguard HSP ZP GB English Protective폴로 쥰 차No ratings yet

- Barrier 80Document5 pagesBarrier 80Biju_PottayilNo ratings yet

- PF63RDocument1 pagePF63RJavierNo ratings yet

- Ultrason® E 2010 G6 UN en SI - Product DatasheetDocument2 pagesUltrason® E 2010 G6 UN en SI - Product Datasheetshahin_723No ratings yet

- Macal® 8200 Pro: Technical Data SheetDocument2 pagesMacal® 8200 Pro: Technical Data SheetMOHAMEDNo ratings yet

- Coextruded Biaxially Oriented PP Film For Tobacco Wrapping: Technical DataDocument2 pagesCoextruded Biaxially Oriented PP Film For Tobacco Wrapping: Technical DataJan GawełNo ratings yet

- Bourdon Tube Pressure Gauge SpecificationsDocument1 pageBourdon Tube Pressure Gauge SpecificationsAlfred GarciaNo ratings yet

- JT TDSDocument5 pagesJT TDSKingsman 86No ratings yet

- Temasil NG: CSF Sheet JointingDocument3 pagesTemasil NG: CSF Sheet JointingTài TrầnNo ratings yet

- Protective DTM Wash Primer: Fast-Drying Rust-Resistant PrimerDocument4 pagesProtective DTM Wash Primer: Fast-Drying Rust-Resistant PrimerAna CabreraNo ratings yet

- Superlite 111: Technical Data Sheet Material CompositionDocument4 pagesSuperlite 111: Technical Data Sheet Material CompositionSrikumar Krishnamuruthy100% (1)

- Technical Data Sheet for Zinc Epoxy Barrier CoatingDocument5 pagesTechnical Data Sheet for Zinc Epoxy Barrier CoatingSanjay PatelNo ratings yet

- Blend ExDocument5 pagesBlend Exserge.pungweNo ratings yet

- ULTRASON Sup ® Sup +E1010+NATURALDocument2 pagesULTRASON Sup ® Sup +E1010+NATURALnikos.a.kyriakouNo ratings yet

- JOTUN TDS - Penguard E50Document5 pagesJOTUN TDS - Penguard E50Sachin SinghalNo ratings yet

- Penguard Express ZP: Technical Data SheetDocument5 pagesPenguard Express ZP: Technical Data Sheetinfospinster0% (1)

- Jotatop BC800 加强型聚氨酯叶片涂料 (0K9) United Kingdom - EnglishDocument5 pagesJotatop BC800 加强型聚氨酯叶片涂料 (0K9) United Kingdom - Englishlong chanNo ratings yet

- Teroson RB 3203-EnDocument2 pagesTeroson RB 3203-EnAlbNo ratings yet

- Jotun Jota Ep Mastic 66Document4 pagesJotun Jota Ep Mastic 66Abi PutraNo ratings yet

- SikaGrout-215 2011-11 - 1Document2 pagesSikaGrout-215 2011-11 - 1Fajar SodiqNo ratings yet

- Technical Data Sheet for Protective CoatingDocument5 pagesTechnical Data Sheet for Protective CoatingBiju_PottayilNo ratings yet

- Hardtop CA PDFDocument5 pagesHardtop CA PDFBiju_PottayilNo ratings yet

- PDS Stopaq Insulwrap FR V1 enDocument1 pagePDS Stopaq Insulwrap FR V1 enAndyNo ratings yet

- TDS Penguard Tie Coat 100 Euk GBDocument6 pagesTDS Penguard Tie Coat 100 Euk GBIliyan PetrovNo ratings yet

- Express MIO 80Document5 pagesExpress MIO 80shnauserNo ratings yet

- KD2DB1301Document1 pageKD2DB1301Customer ServiceNo ratings yet

- TDS 2920 Penguard Express ZP Eng USDocument5 pagesTDS 2920 Penguard Express ZP Eng USnatig samedovNo ratings yet

- TDS 01ofg V08 enDocument2 pagesTDS 01ofg V08 enDenisTarasNo ratings yet

- Jotaprime 500: Technical Data SheetDocument5 pagesJotaprime 500: Technical Data SheetRudhi AfghaniNo ratings yet

- KLINGERSIL C-4430plus Data SheetDocument3 pagesKLINGERSIL C-4430plus Data SheetMichael PhamNo ratings yet

- Ficha Técnica SUNLITE - X - Lite - 16 - Data - SheetDocument1 pageFicha Técnica SUNLITE - X - Lite - 16 - Data - Sheetinmaangulo060382No ratings yet

- Ultimaker PP: Technical Data SheetDocument3 pagesUltimaker PP: Technical Data SheetFelipe TeixeiraNo ratings yet

- Jotun Hardtop XPL TDSDocument4 pagesJotun Hardtop XPL TDSRajan SteeveNo ratings yet

- Asian Heat Resisting Aluminium PaintDocument1 pageAsian Heat Resisting Aluminium Paintrumi_2kNo ratings yet

- THERMIADocument3 pagesTHERMIAGaurav SalujaNo ratings yet

- PA66 Ultramid A4H BASFDocument2 pagesPA66 Ultramid A4H BASFAlan MoraisNo ratings yet

- DTM Bonding Primer: Protective & Marine CoatingsDocument4 pagesDTM Bonding Primer: Protective & Marine CoatingsAna CabreraNo ratings yet

- Fire Fighting Hose - 12 Bar - EN 694 Typ A1: Application: Temperature RangeDocument1 pageFire Fighting Hose - 12 Bar - EN 694 Typ A1: Application: Temperature RangeKok WaiNo ratings yet

- 1000 MM PolytheleneDocument1 page1000 MM PolytheleneJaokNo ratings yet

- Jotun Malathon TDSDocument5 pagesJotun Malathon TDSBiju_PottayilNo ratings yet

- Penguard Topcoat: Technical Data SheetDocument4 pagesPenguard Topcoat: Technical Data SheetQuoc VinhNo ratings yet

- Technical Data Sheet for Tankguard Storage CoatingDocument5 pagesTechnical Data Sheet for Tankguard Storage Coatingabdulgafoor54No ratings yet

- MOLYKOTE - HP-300 - Grease - 80-3103E-01Document2 pagesMOLYKOTE - HP-300 - Grease - 80-3103E-01jtelloNo ratings yet

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- On Standardization of The Reliability Basis of Structural DesignDocument9 pagesOn Standardization of The Reliability Basis of Structural DesignMelo PereiraNo ratings yet

- Navy Ship Underwater Shock Prediction and Testing Capability Study PDFDocument105 pagesNavy Ship Underwater Shock Prediction and Testing Capability Study PDFFernando Raúl LADINONo ratings yet

- Safehull Finite Element Analysis of Hull Structures: Guidance Notes OnDocument50 pagesSafehull Finite Element Analysis of Hull Structures: Guidance Notes OntdfsksNo ratings yet

- Navy Ship Underwater Shock Prediction and Testing Capability Study PDFDocument105 pagesNavy Ship Underwater Shock Prediction and Testing Capability Study PDFFernando Raúl LADINONo ratings yet

- Rexroth Hexagon Socket Head Cap Screws Metric - UNCDocument12 pagesRexroth Hexagon Socket Head Cap Screws Metric - UNCSympatyagaNo ratings yet

- ASTM A574 Socket Head Cap Screw Torque-Tension ChartDocument1 pageASTM A574 Socket Head Cap Screw Torque-Tension ChartsenamotoNo ratings yet

- Shaft Alignment GN Sept 19Document156 pagesShaft Alignment GN Sept 19Jose Bustos FuentesNo ratings yet

- Marco Material Datasheet V1005Document2 pagesMarco Material Datasheet V1005Bib GmzNo ratings yet

- Socket Screws MetricDocument32 pagesSocket Screws MetricBib GmzNo ratings yet

- Malakhoff 1973Document11 pagesMalakhoff 1973Bib GmzNo ratings yet

- Investigation of The Effects of Geometric and Load Perturbation To Buckling in Multilayered Torispherical Pressure Vessel HeadsDocument7 pagesInvestigation of The Effects of Geometric and Load Perturbation To Buckling in Multilayered Torispherical Pressure Vessel HeadsBib GmzNo ratings yet

- Drill sizes for tapping metric and imperial threadsDocument1 pageDrill sizes for tapping metric and imperial threadsabhinishane100% (1)

- Bolt of Uniform StrengthDocument3 pagesBolt of Uniform StrengthBib GmzNo ratings yet

- Perturbation Approach To ElasticDocument11 pagesPerturbation Approach To ElasticBib GmzNo ratings yet

- Bounce Sonar Submarine: Bottom ArrayDocument14 pagesBounce Sonar Submarine: Bottom ArrayBib GmzNo ratings yet

- Design of Welded JointsDocument21 pagesDesign of Welded JointsBib GmzNo ratings yet

- QQ N 281D - 2Document38 pagesQQ N 281D - 2phuongNo ratings yet

- Corrosion Resistance in FastenersDocument26 pagesCorrosion Resistance in FastenersShreyas IyengarNo ratings yet

- Supplying Ready Mix in Southeast Asia - Adapting Concrete Mix Design for Hot, Tropical WeatherDocument2 pagesSupplying Ready Mix in Southeast Asia - Adapting Concrete Mix Design for Hot, Tropical Weathermixtoes7647No ratings yet

- FORM HSE MATRIX TRAINING (Contoh)Document1 pageFORM HSE MATRIX TRAINING (Contoh)Hifni GhazaliNo ratings yet

- Cost Control ReviewerDocument13 pagesCost Control ReviewerMatthew Ivan HerreraNo ratings yet

- Fire Prevention and Response Plan for Greenergie PlantDocument8 pagesFire Prevention and Response Plan for Greenergie PlantMelba MangabatNo ratings yet

- Engineering ManualDocument27 pagesEngineering ManualThousif Rahman67% (3)

- 2009 IECC Residential Code Requirements Apr 14 Draft InspectorsDocument4 pages2009 IECC Residential Code Requirements Apr 14 Draft Inspectorsbcap-oceanNo ratings yet

- Argumentative EssayDocument5 pagesArgumentative Essayapi-538443988No ratings yet

- Minutes of The MeetingDocument2 pagesMinutes of The MeetingJeremy Gaddi100% (1)

- MYK Grout Card 2Document2 pagesMYK Grout Card 2Abdul Raheem SyedNo ratings yet

- ETR - Part C - Course SyllabusDocument26 pagesETR - Part C - Course SyllabusDon JubacNo ratings yet

- WP Stratasys TopFiveReasonsDocument7 pagesWP Stratasys TopFiveReasonscititorulturmentatNo ratings yet

- Chapter 43 - Lead - 2015 - Handbook On The Toxicology of MetalsDocument57 pagesChapter 43 - Lead - 2015 - Handbook On The Toxicology of MetalsChanWingSanNo ratings yet

- Beginning Algebra 9th Edition Tobey Solutions Manual 1Document39 pagesBeginning Algebra 9th Edition Tobey Solutions Manual 1kyle100% (30)

- Fertilization to Implantation StagesDocument18 pagesFertilization to Implantation StagesNurulAqilahZulkifliNo ratings yet

- Sampling Methods for Terrestrial Amphibians and ReptilesDocument39 pagesSampling Methods for Terrestrial Amphibians and ReptilesBenzu Shawn100% (1)

- Bill of Qty. N.C. Sharma, BILSI, BadaunDocument47 pagesBill of Qty. N.C. Sharma, BILSI, BadaunNazim AliNo ratings yet

- Codex CRD26Document9 pagesCodex CRD26arely svetlana gaspar badilloNo ratings yet

- GER Bangladesh EngDocument12 pagesGER Bangladesh Engfarhan.anjum20032004No ratings yet

- Master FormDocument62 pagesMaster FormsamsulNo ratings yet

- The Electrooculogram (EOG)Document34 pagesThe Electrooculogram (EOG)Prasidha PrabhuNo ratings yet

- Cronidur 30: Maximum Demand by Maximum Demand by Corrosive Stress WearDocument24 pagesCronidur 30: Maximum Demand by Maximum Demand by Corrosive Stress WearVlad PopescuNo ratings yet

- ZavzpretDocument21 pagesZavzpretNeethu Anna StephenNo ratings yet

- Stanley - Your Voice (1957) PDFDocument396 pagesStanley - Your Voice (1957) PDFŠašavi Sam MajmunNo ratings yet

- Finasteride 5mg PDFDocument18 pagesFinasteride 5mg PDFddandan_2No ratings yet

- Specialty Vents & Valves 30 MinDocument15 pagesSpecialty Vents & Valves 30 MinAnonymous Wd2KONNo ratings yet

- CardiovascularDocument155 pagesCardiovascularEric VeranoNo ratings yet

- Method of Statement For Pipeline WorkDocument15 pagesMethod of Statement For Pipeline WorkHalil Güney100% (3)

- 4140DE Data SheetDocument1 page4140DE Data SheetNabeel AmeerNo ratings yet

- Ventilation System Comparison - Constant Air Volume (CAV) and Variable Air Volume (VAV)Document15 pagesVentilation System Comparison - Constant Air Volume (CAV) and Variable Air Volume (VAV)ankurNo ratings yet