Professional Documents

Culture Documents

Astm C143

Astm C143

Uploaded by

Carlos Alberto Oviedo0 ratings0% found this document useful (0 votes)

8 views3 pagesOriginal Title

ASTM_C143

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

8 views3 pagesAstm C143

Astm C143

Uploaded by

Carlos Alberto OviedoCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 3

fb Designation: C 143/C 143M @D

Standard Test Method for

Slump of Hydraulic-Cement Concrete*

“Ths standard is ied under the fxd designation C H4/C 143M: the sen immediacy folowing the deignaton inti: the

{yor ol ongisd slopton in the one of vison, tbe yar of lax revise A sumer ix pareathees indicates Ibe year of lt

Feaproel A supencrnt splea(Q iniestoran etal ange since te fat eviion Gx reapprcval

Tis pecan has ben approved for te by agence the Depend ef Defers,

1. Scope

1.1 This test method covers determination of slump of

sydraulc cement concrete, both inthe laberatery ands the

1.2 The valves stated in either inch-pound units or ST

unils are to be regarded separatcly as standard. Within the

text, the Sluaits are shown in brackets. The valucs stated in

zach system are not exact equivalents; therefore, each system

3‘ used independently of the other. Combining values

from the two systems may result in noaconformance with

the standard.

1.3 This standakd does not purport to address all of the

safety concems, if any, associated with its use, It ts the

responsibility of the user of this standard to establish appro-

priate salety and health practices and determine the applica

bility of regulatory lieitations prior to use.

14 The text of this standard references notes and foot-

notes which provide explanatory material. These notes and

footnotes (excluding those in tables and figures) shall not be

considered as requirements of the standard.

2, Referenced Documeat

2.1 ASTM Standard:

€.172 Practice for Sampling Freshly Mixed Concrete

3. Samay of Test Method

3.1 A sample of frechly mixed concrete is placed and

compacted by rodding ina mold shaped asthe fructum of

& The mold i raised, and the conciet allowed to

Suustle. The distance between the original end displaced

position of the center of the top surface of the concrete is

Treasured and roported as tne stump of the concrete

4 Significance and Use

4.1 This test method is intended to provide the user with 2

procedure to determine dump of plastic hydranlic-cement

once

[Nore |_Thic txt method was eriinly deroped to provide

tuchsiue ic mottos the cousctrcy of uneadsne cones, Und

{Ghomtney concen, wis seat cocaol ofa cmeree material the

‘iiip t pocaly fund to occu peovorionaly wih the wale

neat ofa ren comsc sions and testo be twenty mid fo

SESS techeas‘Uedar ded conaitoay, howerey Hac = sere

‘This st method fs uncer the jurialicion of ASTM Commie C3 o2

cence aod Aggregate art respons of

(C19.60 oa Fresh Consree Testo.

‘Curent edton approval Aust 10, 1997. Publsbed Api 1998. Oeinty

Trax preous adios C1398

relationship is not clearly and consistently shown. Care shonld theefore

‘be takea in rebating slump results obtained under field cocditions t

42 This test method is considered applicable to plastic,

concrete having coarse aggregate up to 1 1/2 in. (37.5 mmjin

sve Ifthe coarse aggregate is lager than | [/2 in. [37.5 mm]

in size, the test method is applicable when it is performed on

the fraction of concrete passing a | 1/2-in. [375mm] sicve,

with the larger ageregate being removed in accordance with

the section titled “Additional Procedure for Large Maximum.

Size Aggregate Conerete” in Practice C172.

43 This test method is not considered applicable to

non-plastic and non-cohesive concrete.

Nore 2—Conereies having slumps less than 1/2 in. (15 mm} may

not be adaquately plati= and conertes having slumps greater than

about 9 in, [230 mm] may not be adequately cohesive for this tt 10

bhave signficsnce Caution should be exercised in interpreting euch

rule,

5. Apparatas

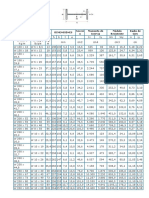

5.1 Mold—The test specimen shall be formed in a meld

made of metal not readily attacked by the cement paste. The

metal shall not be thinner than 0,060 in. [1.5 mm] and if

formed by the spinning process, there shall be no point on

the mold at which the thicknoss is less than 0.045 in. [1.15

mm]. The mold shall be in the form of the lateral surface of

the frustum of a cone with the base 8 in. (200 mz] in

diameter, the top 4 in. [100 mm] in diameter, ond the height

12 in. [300 mm]. Individual diameters and heights shall be

within +4 in. [3 mm] of the prescribed dimensions. The

base and the top shall be open and parallel to each other and

at right angles to the axis of the cone. The mold shall be

provided with foot picors and handles similar to these shown

in Fig. 1. The mold shall be constructed without a seam. The

intecor of the mold shall be relatively smooth and free from

‘projections. The mold shall be free from dents, deformation

for adhered mortar. A mold which clamps toa nonabsorbent

‘base platc is acceptable instead of the one illustrated pro-

‘vided the clamping arrangement is such that it can be fully

released without movement of the mold and the beseis large

‘enough to contain all of the slumped concrete in an

ie test.

3.1.1 Mold with alternative materiale

S.LL1 Molds other than metal are permitted if the

following requirements are met: The mold shall moet the

dimensional requirements of 5.1. The mold shall be sufl-

ccicatly rigid to” maintain the specified dimensions and

‘tolerances during use, resistant to impact forces, and shall be

nonabsorbeat. The mold shall be demonsiated to provide

test results comparable to those obtained when using @ metal

=

*

am

“1 3 ww 4 6 @

1) Po) (eo) 000) oo) RO

FIG 1 Mold for Stamp Test

mold meeting the requirements of 5.1. Comparzbility shall

be demonstrated on behalf of the manufacturer by an

independent testing laboratory. Test for comparcblity shall

consist of not less than 10 individual comparisons performed

ateach of 3 different slumps ranging from 2 in. [50 mm] to 5

in, (125 mm]. No individual test results shall vary by more

than 0,50 in. [15 mm] from that obtained using the metal

mold. The average test results of cach slump range obtained

using the mold constructed of alternative matcrial shall not

vary by more than 0.30 in. [10 mm] from the average of test

results obtained using the metal mold. If any charges in

material or method of manufacture are made, tests for

comparability shall be repeated.

5.1.12 If the condition of any individual mod is sus-

pected of being out of tolerance from the as manufactured

condition, a single comparative test shall be performed. IFthe

test results differ by more than 0.50 ia. [15 mm] from that

obtained using the metal mold, the mold shall be removed

from service.

5.2 Tamping Red—A round, straight steel rod 5% in. (16

mm] in diameter and approximately 24 in. [600 mm] in

length, having the tamping end or both ends rounded to a

hemispherical tip, the diameter of which is 4 in. [16 mm].

6. Sample

6.1 The sample of concrete from which test specimens are

made shall be representative of the entire batch. It shall be

obtained in accordance with Practice C172.

7. Procedure

7A Dampen the mold and place it on 2 fat, moist,

30

@ c 143/c 143m

onabsorbent (rigid) surfce. It shall be held firmly in place

daring filling by the operator standing on the two foot piccce

From the sample of concrete obtained in accordance with

Scction 6, immediately fill te mold in three layer, each

‘approximately one third the volume of the mold.

Note 3—One third of the wolame ofthe lump mold fist 10

cf 2% in [70 sl two thirds of A

ape 24a (Om! ‘Be volume Ms toa depth of

7.2 Rod each layer with 25 strokes of the tamping rod.

Uniformly distribute the strokes over the cross section of

‘ech layer. For the bottom layer this will necessitate inctining

the rod slightly aad making approximately haf ofthe strokes

‘ear the perimeter, and then progressing with vertical strokes

spirally toward the center. Red the bottom layer throughout

its depth. Rod the second layer and the top layer cach

throughout its depth, so that the strokes just penetrate into

the underlying layer.

7.3 In filing and rodding the top layer, heap the concrete

above the mold before rodding is started. If the rodding

‘operation results in subsidence of the concrete below the top

edge of the mold, add additional concreie to Keep an exc

‘of concrete above the top of the mold at ail times. After the

top layer has boca rodded, strike off the surface of the

concrete by means of a screeding and relling motion of the

tamping rod. Remove the mold immediately from the

concrete by raising it carefully in a vertical dizcction. Raise

the mold a distance of 12 in. [300 mm] in 5 = 2s by asteady

‘upsard lif with no lateral or torsional motion. Complete the

‘cafe test from the stat of the filing through removal of the

‘mold without interruption and complete it within an elapsed

time of 2% min.

7.4 Immediately measure the stump by determining the

Vertical difference between the top of the mold and the

displaced original center of the top surface of the spesimen.

fa decided falling away or shearing off of concrete from one

‘side or portion of the mass occurs (Note 4), disregard the test

and make a new test on another portion of the sampie.

Note 4—IF two coasautive tess on a sample of concrete show 2

ling sway o ering of of pros ofthe concrete fom the man of

the specimen, the cooeete probly backs mememary plasty and

cobsernes forthe Samp te tobe pliable 2

8. Report z

8.1 Report the stump in teoms of inches [millimetres] to *

the nearest % in. [5 mm] of subsidence of the specimen

ring the test as follows:

‘Slump = 12 ~ inches of height afte subsidcoce

[Stump = 300 — mm of height after sabsideace]

9. Precision and Biss

9.1 Precision -

911 Interlaboratory Test Method—No intertaboratory

‘test program has been run on this test method. Since it is not

‘possible to provide equivalent concretes at various test sites

five of errors from souress other than the stump measure-

ment, a multlaboratory preciéon statement on different

‘concretes would not be meaningfal. i

9.1.2 Mulit-Operaior Test Resulis—Extcasive field data’

23 Baler, W, M, mi McMaboa TF, “Quiliy Assraee of Prtand Csrent

(Coere” Publi Roads, Vol 35, No. 81969.

allow a statement regarding the multi-operator precision of

this test method (Note 5).

Tes race 15.0276 ia, B8t070 mn}

‘etal numberof samsiee Bot

Pooled

Sevan (Ie) 030% [8 mm}

95%

‘Limit (€23) 083in [21 me)

Therefore, results of two properly conductod tests by dit

ferent operators in the same laboratory on the same material

sbould not differ by more than 0.83 in. [21 mm] Due to the

limited slump range in the concrete used in this test program,

Qh c143/¢ 143M

caution should be exercised in applying these precision

3.2 Bias—This test method has no bias

defined only in terms of this test method.

Nore $—The precision data are hased upon the mes of metal conce

‘No specific data are availble for mutthopersioe i

eae ‘est reslts with

since slump is

10. Keywords -

.1 concrete; cone; consistency; plasticity; work

an plasticity; slump;

‘Tne American Soci fer Testing end ators tate 0 postion respactng the aka fey palo rips exec in connection

vex ary tar mertond I es ana, Uses OTs NaNO or exe Shae al

PRO its, and te Of RAGA OSU PES, 0 CTY DD OWT Ta.

cetera of th vay of ry set

“Tis ran fe ext reson a ay tke bythe respon tecnica cnmtiee oud tba rove vey i yours and

{tect revel her reaporoved er wilt. Yur Somers ar kv eee fr revaion oth sarc ox bx Socata! earre

5 Pot bo accross Yo ASTM Hocus. Your Corerers Wal Co Car Casterain Bt 8 oten th respons

‘eerie conto, which jeu my Stee I you Tee at yout Camere hare ok Paced a far eating You shold wake Yo

31

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- IMCO-PRC-2030 - Procedimiento de Tendido de Cables Electricos e InstrumentacionDocument12 pagesIMCO-PRC-2030 - Procedimiento de Tendido de Cables Electricos e InstrumentacionCarlos Alberto Oviedo100% (1)

- Tolerancias en Dimensiones de VigasDocument1 pageTolerancias en Dimensiones de VigasCarlos Alberto OviedoNo ratings yet

- IMCO-PRC-2012 - Procedimiento de SoporteriaDocument12 pagesIMCO-PRC-2012 - Procedimiento de SoporteriaCarlos Alberto OviedoNo ratings yet

- IMCO-PRC-2031 - Procedimiento de Conexionado de Cables Electricos e IntrumentacionDocument10 pagesIMCO-PRC-2031 - Procedimiento de Conexionado de Cables Electricos e IntrumentacionCarlos Alberto OviedoNo ratings yet

- Procedimiento de Enderezado de VigasDocument10 pagesProcedimiento de Enderezado de VigasCarlos Alberto OviedoNo ratings yet

- PNT-CO-303960-02-TS-101 - 0 DrenajeDocument21 pagesPNT-CO-303960-02-TS-101 - 0 DrenajeCarlos Alberto OviedoNo ratings yet

- IMCO-PRC-2001 - Procedimiento Soldadura ExotermicaDocument9 pagesIMCO-PRC-2001 - Procedimiento Soldadura ExotermicaCarlos Alberto Oviedo100% (1)

- Direct 50142 PRPD PLN 0005 r1 AprobadoDocument32 pagesDirect 50142 PRPD PLN 0005 r1 AprobadoCarlos Alberto OviedoNo ratings yet

- Medidas de VigasDocument3 pagesMedidas de VigasCarlos Alberto OviedoNo ratings yet

- Procedimiento Fabricación de VigaDocument12 pagesProcedimiento Fabricación de VigaCarlos Alberto OviedoNo ratings yet

- PNT-CO-300000-08-TS-010 - 1 Especif Técnica de Arquitectura Edif IndustrialesDocument18 pagesPNT-CO-300000-08-TS-010 - 1 Especif Técnica de Arquitectura Edif IndustrialesCarlos Alberto OviedoNo ratings yet

- PNT-CO-300000-09-CS-003 - P Montaje de InstrumentosDocument59 pagesPNT-CO-300000-09-CS-003 - P Montaje de InstrumentosCarlos Alberto Oviedo100% (1)

- PATCT-DA-297000-04-TS-510 - 2 Fabricacion y Montaje de EstructurasDocument43 pagesPATCT-DA-297000-04-TS-510 - 2 Fabricacion y Montaje de EstructurasCarlos Alberto OviedoNo ratings yet

- Astm C173Document3 pagesAstm C173Carlos Alberto OviedoNo ratings yet

- ESMDR-CON-004 REV 1 Tuberia HDPEDocument19 pagesESMDR-CON-004 REV 1 Tuberia HDPECarlos Alberto OviedoNo ratings yet

- B567 PDFDocument9 pagesB567 PDFCarlos Alberto Oviedo100% (1)