Professional Documents

Culture Documents

Lifting Operations: Supervisor Instructions 2

Uploaded by

PhilOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lifting Operations: Supervisor Instructions 2

Uploaded by

PhilCopyright:

Available Formats

Lifting Operations

Supervisor Instructions 2

LIFTING

TOOLBOX TALK

OPERATIONS

This toolbox talk is to help your team spot problems in different Lifting Operations situations; to encourage them to stop work if

they see similar situations on site and to describe how the work should be undertaken.

Carry out this tool box talk before:

• Beginning any work where any of your team will be doing lifting operations

• Beginning any work where other contractors are doing lifting operations

It is best to complete this talk in small groups – maximum 15 people.

1. Give a copy of the photographs and questions to the group. This could be by hard copy or on a computer projector.

2. Ask them to discuss the images for five minutes and try to suggest some answers (below).

3. If your team do not know the answers, describe the issues and then speak to your local manager about additional training that

they might need.

4. Ask if any of the unsafe situations in the photos are similar to any the group have seen on site and what your team should do if

they see them – (The answer is stop the job!)

Record the names of the team you give this talk to – and send these names to your local BG Group Manager.

NB. These images are of industry examples - NOT BG Group examples.

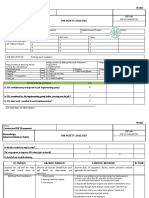

Answers:

1. There are two colour codes of lifting accessories in use (red on the master crane link and blue on the other links in this

picture). Each site should only have one colour code for its lifting accessories. In this case, which is the colour for current

inspection? Some of the certifications for links may have expired.

2. There are three things wrong:

i. The bolt through the pad eye is not correctly tightened.

ii. It also does not have its split pin in place.

iii. A band of metal is placed around the shackle. Lifting operations must never be carried out under these conditions.

3. In this picture, the load has been left on top of the wire sling. This can crush the sling, and separate the wires, leading to

loss of strength.

4. The cylinders are not secured, meaning they could fall against the sides of the cage when lifting or even fall out of the cage.

If you identify any specific gaps in knowledge or practice and for guidance on how to manage these, please contact Mashood

Ahmed, Group Technical Authority Lifting Operations - mashood.ahmed@bg-group.com

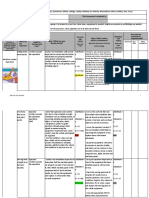

COMPETENT CORRECT LIFT PLAN

PEOPLE EQUIPMENT UNDERSTOOD

TRAINED AND INSPECTED AND AND FOLLOWED

CERTIFIED CERTIFIED

Lifting Operations

Supervisor Instructions 2

LIFTING

TOOLBOX TALK

OPERATIONS

1 2

3 4

These are industry images - not related

to any incident at BG Group

COMPETENT CORRECT LIFT PLAN

PEOPLE EQUIPMENT UNDERSTOOD

TRAINED AND INSPECTED AND AND FOLLOWED

CERTIFIED CERTIFIED

Lifting Operations

Group Sheet 2

LIFTING

TOOLBOX TALK

OPERATIONS

1 2

3 4

These are industry images - not related

to any incident at BG Group

COMPETENT CORRECT LIFT PLAN

PEOPLE EQUIPMENT UNDERSTOOD

TRAINED AND INSPECTED AND AND FOLLOWED

CERTIFIED CERTIFIED

Lifting Operations

Group Record 2

TOOLBOX TALK

Worksite Company

Date of

Name of Supervisor

Toolbox talk

Work team

Name Signature

You might also like

- CBLM 1 - Carpentry NC Ii Core 1Document25 pagesCBLM 1 - Carpentry NC Ii Core 1gillian marbebe96% (24)

- 00AG9603 UserGuideDocument15 pages00AG9603 UserGuideadu666100% (2)

- TR Heo-He NciiDocument117 pagesTR Heo-He NciihelaNo ratings yet

- 6.JSA of Batching Plant InstallationDocument4 pages6.JSA of Batching Plant InstallationNitesh Kumar100% (1)

- TR-HDD Front-Of-line Operation NC IIDocument70 pagesTR-HDD Front-Of-line Operation NC IIAmhier MokamadNo ratings yet

- Mark Off OutDocument38 pagesMark Off OuttereveNo ratings yet

- DDDocument34 pagesDDDraciv VicardNo ratings yet

- Review Summary Chapter 5: It Infrastructure and Emerging TechnologiesDocument1 pageReview Summary Chapter 5: It Infrastructure and Emerging Technologiesghina adhha hauraNo ratings yet

- Au 480 OlympusDocument10 pagesAu 480 Olympusamen fadzly rahmatNo ratings yet

- Lifting Operations: Supervisor Instructions 3Document4 pagesLifting Operations: Supervisor Instructions 3PhilNo ratings yet

- Lifting Operations: Supervisor Instructions 1Document4 pagesLifting Operations: Supervisor Instructions 1PhilNo ratings yet

- Coupling Inspection SOP GSE FinalDocument11 pagesCoupling Inspection SOP GSE FinalPravin Kangne100% (1)

- System Analysis - Noddy GuideDocument2 pagesSystem Analysis - Noddy Guidegeorge moyoNo ratings yet

- Risk Assessment (RA) : Part 1: Location DetailsDocument3 pagesRisk Assessment (RA) : Part 1: Location DetailsPandu BirumakovelaNo ratings yet

- Masonry Cblm1 EpmDocument31 pagesMasonry Cblm1 Epmernest macalaladNo ratings yet

- Modul Praktik Aircraft Structure 1 20170220 - DipakeDocument47 pagesModul Praktik Aircraft Structure 1 20170220 - DipaketmarizNo ratings yet

- Thyssenkrupp Industrial Solutions (India) Job Safety Analysis 1 6Document6 pagesThyssenkrupp Industrial Solutions (India) Job Safety Analysis 1 6Nitesh kumar yadavNo ratings yet

- Industrial Solutions, Inc: Lean Assessment ScorecardDocument5 pagesIndustrial Solutions, Inc: Lean Assessment Scorecardrgrao85No ratings yet

- Risk Assessment (RA) : Part 1: Location DetailsDocument4 pagesRisk Assessment (RA) : Part 1: Location DetailsPandu BirumakovelaNo ratings yet

- TR-Semiconductor Back-End Operation NC IIDocument70 pagesTR-Semiconductor Back-End Operation NC IIAmhier Mokamad100% (1)

- Risk Assessment (RA) : Part 1: Location DetailsDocument3 pagesRisk Assessment (RA) : Part 1: Location DetailsPandu BirumakovelaNo ratings yet

- Control of Work Training For Performing AuthoritiesDocument35 pagesControl of Work Training For Performing AuthoritiesbutahraNo ratings yet

- JH Step 4 - General InspectionDocument3 pagesJH Step 4 - General InspectionDeepakNo ratings yet

- Plum Training NC IiDocument88 pagesPlum Training NC Iigillian marbebe100% (1)

- Safer by Association 2dec22Document48 pagesSafer by Association 2dec22mohamed Abo-EwishaNo ratings yet

- FG RSCQ0207 Injection Moulding Operator 25 01 2018 PDFDocument235 pagesFG RSCQ0207 Injection Moulding Operator 25 01 2018 PDFprashanthNo ratings yet

- GGH Basket RemovelDocument9 pagesGGH Basket Removeltamoor sarwarNo ratings yet

- INS8000ENG STAR Threaded Installation ManualDocument55 pagesINS8000ENG STAR Threaded Installation Manualgeoff mussellNo ratings yet

- 06 ISO 19443 FMEA Practical Application HandoutDocument45 pages06 ISO 19443 FMEA Practical Application HandoutRoberto Eduardo Hilal100% (1)

- Working Instruction: Building Maintenance TeamDocument6 pagesWorking Instruction: Building Maintenance TeamRobertNo ratings yet

- Team Working AgreementDocument12 pagesTeam Working AgreementPraveenNo ratings yet

- Technician JDDocument3 pagesTechnician JDMulgi YonNo ratings yet

- 5.JSA of Batching Plant InstallationDocument4 pages5.JSA of Batching Plant InstallationNitesh kumar yadavNo ratings yet

- Sewing Team Member's Increment Based On Skill UpgradationDocument5 pagesSewing Team Member's Increment Based On Skill UpgradationFazle RubbiNo ratings yet

- DFMEA - Robustness in Design Package - BlankTemplateDocument20 pagesDFMEA - Robustness in Design Package - BlankTemplateMoham'medAlthafAs'lamNo ratings yet

- HEO - Hydraulic Excavator NC IIDocument117 pagesHEO - Hydraulic Excavator NC IIVergelio ColiNo ratings yet

- Qualifications Pack Production SupervisorDocument33 pagesQualifications Pack Production SupervisorANKITNo ratings yet

- Albarracin, Basak, Cajigas, Genterone, Gillana, Labiaga, Labajo, Maloloy-On, Masuta, Morandarte, Obera, Pueblas, Roa, ToroyDocument18 pagesAlbarracin, Basak, Cajigas, Genterone, Gillana, Labiaga, Labajo, Maloloy-On, Masuta, Morandarte, Obera, Pueblas, Roa, Toroyanon ggNo ratings yet

- Technical Instructor - JD - DSD - 0119 - V1 - 23.08.20Document7 pagesTechnical Instructor - JD - DSD - 0119 - V1 - 23.08.20Rakesh RuchpaulNo ratings yet

- Universidad Autónoma de Nuevo León Facultad de Ingeniería Mecánica y EléctricaDocument6 pagesUniversidad Autónoma de Nuevo León Facultad de Ingeniería Mecánica y EléctricaFrancisco NiñoNo ratings yet

- Bearing Inspection SOPDocument7 pagesBearing Inspection SOPRianAwangga100% (1)

- Job Safety Analysis PSA-MailDocument50 pagesJob Safety Analysis PSA-MailechaNo ratings yet

- Project ProposaltemplateDocument4 pagesProject Proposaltemplateendawoke anmawNo ratings yet

- JSA-Scaffolding Erection & Dismantling Works RV-00Document2 pagesJSA-Scaffolding Erection & Dismantling Works RV-00abou bakarNo ratings yet

- Training Need IdentificationDocument58 pagesTraining Need Identificationrohitbagga100% (1)

- DRV Common Uc1 - NewDocument49 pagesDRV Common Uc1 - NewRomally Antonette TagnipezNo ratings yet

- Underchassis Engine Module 1213Document214 pagesUnderchassis Engine Module 1213Gillian MarbebeNo ratings yet

- TR - Automotive Electrical Assembly NC IIIDocument76 pagesTR - Automotive Electrical Assembly NC IIINestor CruzNo ratings yet

- Supplier Audit Check SheetDocument5 pagesSupplier Audit Check SheetMotive Post100% (2)

- TR - Plastic Machine Operation-NCIIDocument65 pagesTR - Plastic Machine Operation-NCIISSVTC LRCNo ratings yet

- Lifting Accessories Diploma (LAC) GlobalDocument154 pagesLifting Accessories Diploma (LAC) Globalqa-qcNo ratings yet

- CBLM Stripping Formwork Components PDFDocument24 pagesCBLM Stripping Formwork Components PDFRHAYAMIE D. LIBENo ratings yet

- PDF Applied Failure Analysis 1 NSW - CompressDocument2 pagesPDF Applied Failure Analysis 1 NSW - CompressAgungNo ratings yet

- TR Plumbing NC IIDocument88 pagesTR Plumbing NC IIJoseph Angelo Evangelista CoronelNo ratings yet

- Performance Appraisal Form For ManagerDocument12 pagesPerformance Appraisal Form For Managervandana_dubey15No ratings yet

- Safe Work Method Statement (SWMS) : Hot Work (Welding, Cutting, Grinding, Gas Cutting, in FGD-Unit#1&2)Document6 pagesSafe Work Method Statement (SWMS) : Hot Work (Welding, Cutting, Grinding, Gas Cutting, in FGD-Unit#1&2)tamoor sarwarNo ratings yet

- Fitter Ring SpinningDocument54 pagesFitter Ring Spinninggizex2013No ratings yet

- SWMS - Replacement of Light BulbsDocument5 pagesSWMS - Replacement of Light BulbsHanindita Widhi PangestiNo ratings yet

- CATV Operation & Maintenance NC IIIDocument69 pagesCATV Operation & Maintenance NC IIIjayson platinoNo ratings yet

- TECHOP (P-01 - Rev1 - Jan21) PART 2 - COMPETENCY FOR DP PROFESSIONALS - DP SMEsDocument44 pagesTECHOP (P-01 - Rev1 - Jan21) PART 2 - COMPETENCY FOR DP PROFESSIONALS - DP SMEsGMNo ratings yet

- The Sarbanes-Oxley Section 404 Implementation Toolkit: Practice Aids for Managers and AuditorsFrom EverandThe Sarbanes-Oxley Section 404 Implementation Toolkit: Practice Aids for Managers and AuditorsNo ratings yet

- The Sarbanes-Oxley Section 404 Implementation Toolkit: Practice Aids for Managers and Auditors with CD ROMFrom EverandThe Sarbanes-Oxley Section 404 Implementation Toolkit: Practice Aids for Managers and Auditors with CD ROMNo ratings yet

- Scilab - Ece ProgramsDocument5 pagesScilab - Ece ProgramsYash PatelNo ratings yet

- Msi h310m Pro VH Plus Datasheet PDFDocument1 pageMsi h310m Pro VH Plus Datasheet PDFEka NugrahaNo ratings yet

- Font SpecDocument130 pagesFont SpecIlda KhakiNo ratings yet

- Be 2K OEM's Manual: Bernini Design SRL - ItalyDocument48 pagesBe 2K OEM's Manual: Bernini Design SRL - ItalySergio Ricardo IbañezNo ratings yet

- 02.TAC03001-HO02-I1.6-7302 7330 ISAM Product Overview Intro HW CE PDFDocument24 pages02.TAC03001-HO02-I1.6-7302 7330 ISAM Product Overview Intro HW CE PDFSameh Eddine HachaichiNo ratings yet

- GC 01Document2 pagesGC 01Josue SanchezNo ratings yet

- Name: Washim Raja: Career ObjectiveDocument5 pagesName: Washim Raja: Career ObjectiveWashim RajaNo ratings yet

- Maintenance and Service Guide - HP Elite Mini 800 G9 Desktop PCDocument120 pagesMaintenance and Service Guide - HP Elite Mini 800 G9 Desktop PCBelle KissNo ratings yet

- Hand Gesture RecognitionDocument28 pagesHand Gesture Recognitionmayur chablaniNo ratings yet

- eclipse Installation Checklist (Form A) and MDE-4227 Encore/Eclipse Start-Up Checklist (Form B)Document1 pageeclipse Installation Checklist (Form A) and MDE-4227 Encore/Eclipse Start-Up Checklist (Form B)Ahmed AbdoNo ratings yet

- System Analysis and Development and Models ClassDocument92 pagesSystem Analysis and Development and Models ClassLakskmi Priya M CNo ratings yet

- Myhack Guide - Myhack PDFDocument11 pagesMyhack Guide - Myhack PDFRizka MaharanaNo ratings yet

- Pipeline Control Data Hazard PDFDocument31 pagesPipeline Control Data Hazard PDFJjcp CornejoNo ratings yet

- Shortcut KeysDocument45 pagesShortcut KeysdundunNo ratings yet

- Digital Signal Processing Using Smart Biometric SolutionsDocument10 pagesDigital Signal Processing Using Smart Biometric SolutionsARVINDNo ratings yet

- Session Plan-Gas Engine Tune UpDocument16 pagesSession Plan-Gas Engine Tune UpJeffrey RamirezNo ratings yet

- Digital Electronics and Microprocessor Lecture NotesDocument187 pagesDigital Electronics and Microprocessor Lecture Notes514 Vaibhavi PawarNo ratings yet

- AutomationStudioDesigner ManualDocument57 pagesAutomationStudioDesigner ManualLeonardo Beckmann BosaipoNo ratings yet

- Power Supply ExportDocument8 pagesPower Supply ExportAldino Sahin ELzhaarNo ratings yet

- LeJOS NXJ TutorialDocument183 pagesLeJOS NXJ TutorialAndrew WittenNo ratings yet

- Peri Komponentu Katalogas Klojiniams 2015 enDocument948 pagesPeri Komponentu Katalogas Klojiniams 2015 enLuôn HồNo ratings yet

- Rfid Based AttendanceDocument4 pagesRfid Based AttendanceAnthony Jade Brosas100% (1)

- Tow Haul - Lowboy Serie 9199model RGS-275!44!21Document102 pagesTow Haul - Lowboy Serie 9199model RGS-275!44!21Roberto Minchán Huamán60% (5)

- FL6051 Maint Kit 358Document3 pagesFL6051 Maint Kit 358rburtonshawNo ratings yet

- Vienna Instruments Manual English v2.2.2Document27 pagesVienna Instruments Manual English v2.2.2David Johnson Jr.No ratings yet

- Lab ManualsDocument22 pagesLab ManualsHailRodNo ratings yet

- GE Mac 400 - Quick Guide PDFDocument7 pagesGE Mac 400 - Quick Guide PDFNur CholisNo ratings yet