Basic VLSI Design Concept

Very-large-scale integration (VLSI) is the process of creating an integrated

circuit (IC) by combining thousands of transistors into a single chip. VLSI began in

the 1970s when complex semiconductor and communication technologies were

being developed. The microprocessor is a VLSI device.

Before the introduction of VLSI technology, most ICs had a limited set of

functions they could perform. An electronic circuit might consist of a CPU, ROM,

RAM and other glue logic. VLSI lets IC designers add all of these into one chip.

5-layer cross-section of chip

The electronics industry has achieved a phenomenal growth over the last few

decades, mainly due to the rapid advances in large scale integration technologies

and system design applications. With the advent of very large scale integration

(VLSI) designs, the number of applications of integrated circuits (ICs) in high-

performance computing, controls, telecommunications, image and video

processing, and consumer electronics has been rising at a very fast pace.

The current cutting-edge technologies such as high resolution and low bit-rate

video and cellular communications provide the end-users a marvelous amount of

1

� Basic VLSI Design Concept

applications, processing power and portability. This trend is expected to grow

rapidly, with very important implications on VLSI design and systems design.

Why VLSI?

Integration improves the design

– Compactness: less area, physically smaller

– Higher speed: lower parasitics (reduced interconnection

length)

– Lower power consumption

– Higher reliability: improved on-chip interconnects

Integration significantly reduces manufacturing cost

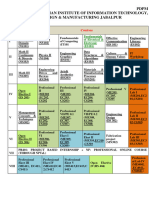

VLSI Design Flow

The VLSI IC circuits design flow is shown in the figure below. The various levels of

design are numbered and the blocks show processes in the design flow.

Specifications comes first, they describe abstractly, the functionality, interface,

and the architecture of the digital IC circuit to be designed.

2

� Basic VLSI Design Concept

Behavioral description is then created to analyze the design in terms of

functionality, performance, compliance to given standards, and other

specifications.

Behavioral or Functional Design

– Only behavior and timing without implementation issue

– Specify behavior based on Input + output + timing

– Fast emulation and debugging for the system

RTL description is done using HDLs. This RTL description is simulated to test

functionality. From here onwards we need the help of EDA tools.

Logic Design

– Control flow, word widths, register allocation, arithmetic operations, and logic

operations

– RTL (Register Transfer Level)

– HDL (Hardware Description Language)

» Verilog – most popular

» VHDL – Europe and Eastern

» Literal + Timing Information

RTL description is then converted to a gate-level netlist using logic synthesis

tools. A gate level netlist is a description of the circuit in terms of gates and

3

� Basic VLSI Design Concept

connections between them, which are made in such a way that they meet the

timing, power and area specifications.

Simulation: The functional behavior of the design (or a parameter such as power)

is determined by applying a set of excitation vectors to a circuit model.

Circuit Design

– Boolean Expression → Circuit Elements (Cells, Macros, Gates, Transistors) +

Interconnection

– Each component has specific timing and power Info.

– Circuit Simulation: Verify the correctness and timing

– Terms – Netlist, Schematic

– Logic Synthesis Tools : RTL → Netlist

Physical Design

– Netlist → Layout (Geometry Representation)

» Design rules of applied fabrication process

– Layout Synthesis Tools

» Automatic conversion (Fully/Partially)

4

� Basic VLSI Design Concept

» Area and performance penalty

– Crucial Challenges – Area/Delay

5

� Basic VLSI Design Concept

Fabrication

– Layout→ Photo-lithographic mask

» One mask for each layer

– Wafer : Silicon crystal are grown & sliced

– Deposition, and diffusion of various materials on the

wafer : each step uses one mask

– Term : Tape Out, 8 inch/20cm, 12 inch/30cm

6

� Basic VLSI Design Concept

Packaging, Testing, and Debugging

– For PCB (Printed Circuit Board) : DIP (Dual In-line

Package), PGA (Pin Grid Array), BGA (Ball Grid

Array), and QFP (Quad Flat Package)

– For MCM (Multi-Chip Modules): no packaged

– Testing

» Before Package –Probe line testing

» After Package –Tester machine applies test patterns.

VLSI Design Styles

7

� Basic VLSI Design Concept

Full Custom Design

Following the partitioning, the transistor level design of the building block is

generated and simulated.

The example shows a 1-bit full-adder schematic and its SPICE simulation results.

The main objective of full custom design is to ensure fine-grained regularity and

modularity.

8

�Basic VLSI Design Concept

9

�Basic VLSI Design Concept

10

� Basic VLSI Design Concept

Full Custom SRAM

11

� Basic VLSI Design Concept

HDL-Based Design

The design is synthesized and mapped into the target technology. The logic gates

have one-to-one equivalents as standard cells in the target technology.

12

� Basic VLSI Design Concept

Standard Cells Standard Cells

Library Construction:

– To enable automated placement of the cells and routing of inter-cell

connections, each cell layout is designed with a fixed height, so that a

number of cells can be abutted side-by-side to form rows.

13

� Basic VLSI Design Concept

After chip logic design being done by using standard cells from the library

– Place the individual cells into rows

– Interconnect them that meets the design goal in circuit speed, chip area and

power consumption.

14

� Basic VLSI Design Concept

Mask Gate Array

Metal mask design and processing

Chip utilization factor is higher than the FPGA and so is speed.

Number of gates: hundreds of thousands of logic gates

15

�Basic VLSI Design Concept

16

� Basic VLSI Design Concept

FPGA Field Programmable Gate Array: FPGA

User programming

Very short turn around time

Price is higher than standard cell and mask gate array.

Number of gates: 25,000 ~ 20,000 gates

17

�Basic VLSI Design Concept

18