Professional Documents

Culture Documents

Uploaded by

kanishk0 ratings0% found this document useful (0 votes)

21 views35 pagesOriginal Title

26847_1594742838482_pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

21 views35 pagesUploaded by

kanishkCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 35

rs

fat

Tit

g* Monufoctwring = gt in & procom of Gorwerting mus wateriale into a.

Sirished object. ot in a proces Vale, -addition to tie

Stee waar Rep

ow Classification Of Manu fact ig Faroe)

ee ‘> Casting Tid Fabricasion proces Gquid)

i> Foret ' ° ~

55 are : mnt . i> Matosial rumgval procens - Gastrgy

eS ) Casting: XD Ze HD Additive ii) Sublmdbve Procemes « "

es

St iw a proem in which. molten metal Cui dL be allowed

a3 7 Saldify im 9. pre dapivad mould Cavity. Afton tis solidificakion by

a5 raking The mould, quired shape of tHe abjut aon be producad .

a > Padloan . 2 Moulding Sand~ "D Tools-

BS D Paro =

62 Mould tox”

=: @ To box + Ore box

Gpe py +

PL The cheede

mea ___| ; ‘

5 Complax shape of th. ebject con be prduad -

4 dn a bos expawore procers:

PE 5 Dil 5 ite abr eon he pr

Z Dla sized obpids au be proaicd by eaoting op

a :

-

«.

Scanned with CamScanner

* DGADIANTANER f=

Non-uniforn Garin stare tene

Sinweed = ote

Tro time At

Ce degen of sepenlaat

(100? aso’)

> Gonting objects ant. & nck having smooth sunfaes, finish «

Camrnren Bs conse

% SM Ho toboviou, % fime- Comauiming. process °

> Thue ts a fowsibliliy of, gee dafects in costing, (AH20 = 2M, +02)

> Coding

objeds ome mat having uniform rachanical propention clus to

nor Gr vfoim Cooling.

© Saecrion OF The Manuracturing Process

BD with diponds vpon t

Db the shape & Size Of Me objects -

Y propeues vquira ny AL tbjedts-

» Aceumey % surface. finish requietl -

® Cos of object

© Parienn = db io the seplia of fit costing to be froduead wily come

All pdemens

Type 4 Ailouoourers

} Shrinkage ot Contraction .

D> Dyoft or Taper

1) Machining er Finish.

‘

10 Shake or Rapping,

Y> Dietostion of Cosnber >

» Shitrkage oF Contraction allowrmnet, ‘>

we Whi the Lyall maal Oo allowsel

od we to solidify in ty cavity, thou o

; a porsbbty 4 aldinkage or

conteschion a TKa madodad +

-

Scanned with CamScanner

ep OE SOS OHESOE

eo

6 PO SOGSHHOAOOPSS

Wher He Lua amdal cooling cooled from pouring to frag 4 jemp, vy

et b> Yiquid shrinkage

Vre phase THonafounakon, shrinks of the material to

vata: shynkoge « I

When “the solid caating 4 cooled from Sresig to ambit: irate,

The Shrinkage, ip solid shrinkage -

Lawid and solidification shrinkage con be ompawated by providing

Yee RIGER: These values aru expensed 09 "7%-of shrinkage volume

Sf the matoial: Solid Shainkoge con be Gmpenmtad by providing

Ssinkage ollavonme on he PATTERN. hese vojpus sone. e pressed tn

Aouns of “Linear dimensions”.

L

| J (Ty - a) —6l= teal

A+8l

Seared

Frownat apamion coe(t.

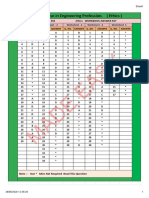

SHRINKAGE VALUES FoR DIFFERENT MATERIALS t- (Solid Shrinkoyo)

D Bismuth —+ Negligible 5> Coppez —* 17 rnm/m

D> While Metal —- 5 mmy/m 6) Heal —» 20 nase

> Cost foo ——r 10 mm/m D Brass —r 23 wom/pm

“3 » Peurriniuinn —+ 13 men/m 9 Zine —r a4 mm/r «

3

cudddidcede

or Liquid avid solidification shvinkage in mraximure. for Zine Atuin!

urhidh Maqui vee loge sized siser

—r Total shrvinkinge © oximuny stett -

i

p

olin

> Cubiad cooking, Of 50 more

4% ond em sot amtaction of 67° thou is no

rico provided What vw The final stee of th costing t

a

fo. gol “3

orm one] ae _

Ve abs 112800 fink *

as Ube3t tom

99 9 92%,

www UUs

ww

Scanned with CamScanner

| => dn cam of [954 Tain), dua to canienmon Of (onvore oo =

guaprite, flakes » Avwou in O possiblity © f, expomilorne of, the matoiat: &

Dean hie one Sn solid se frou iow powibiy of &

vmatadal Te ownerne tala, oe of tHe pattown com

| “be et aa providing chicinki'yy allowance,»

is A gy cot iron block, of dimensions. 00x 100 x10 con ee o

3 by gand moulding. « Casey mtg olin, (> Yh: Whar @

oe

rao of whine ofp, ORS mg ; °

al be (eA) Sinks Voturme of paler (0042) (10041) (04 0 » @

Volurn. of casting ~ = ~~ a0 100% to ®@

‘L “GS : = 1.03 e

> i

® €

ero

© Davey OR, TAPER = x

|

|

1

i

i

oe cna removal of the potion from Th. mould

Jo yrinimice tha continuus eondack b/g patton. & mould

Surfer for ths vedic surfen Of te tina , ob

J atsouna. io prove Of the PPE f safe Or Tape

° MadHINING 68, FINISHING AULDANCE ! a

More. powmaskily + ore pour

Scanned with CamScanner

bELUU YUU v were er ~ -

7

v

3Nd8

a 5)

av

SSOSSOSH OOF ODIMDHO®

(raking objets ou not having smodth sidan sfinith . Te yr

better swaaee -finith, machining io required Dus to machining. ,

glee of the canting will be decrensed - To overcome this, size of

eth patlom com be inereaaed by poosiching- machining allowomer

oo C@

“OO Catentate The immanatows of HR gator fr The. casting chien

8 , .

bo iduni chi all of Amr ch sunace:

“B beter soe ning loans om each sunhocs

. Po

e i

(50 (48)

lio

(38)

Gating Patten

got oe

© SHapinlg OR RAPPING *

| _ 1 1 ee as — (100-2)

ore

\ - adlewoe

"ZZ

- CASTING «PATTERN

Moulding ead. will stick, to the pallou's surfoe during femnmirg « Por

dmemnl Gf tee (eHow, some clearamer io sequived + 5

~s PF quired + yyy pattem.

npwld swrfoer - con be produced by Shaking of tha pation » PA

to dhaking, siee of HH enwil will be increnad . Ts me this,

Size of the patton con be wecueed by providing shalee Qulewonee «

Ut in a ve allowoner provided On the patton.

© DISTORNON OR CAMBER MLOWANE, i

DsvoRDON Ree o—

lV AS

NE”

[seooee

|

Scanned with CamScanner

|

i

, are ;

Popenting we the shape & shat thy ensting. » OM 40 sition ‘ny 4

: scien wy the osty

Jinoar dimemions » rine io & powiblbly of distostion » v

&

sees 3s

wring aheinkage:. hovercore. this dishoston allennce bs providid.

“oppose, tot direction H, Aistetion Sw a-zex0 aplowomee. + :

)- Cohculatt the Aimunsions 22 The pation. far the acting © e

4) Machining. > mn /suraea, @

B) Ghrinkage > 3% @

Wa) Shake > 1 mefewrface ¢

rial = 58.56 AAAS Sag, ®

pasto - ol of PMO 59:56 U3.26 UIST yoy a

Val™ of casting S09 x GOx15 fae @

@

© Parrern Materiats + =

| > Wood : e

ma Metals & Atloys = AL, C.T., Steals , Brass ete ‘

B> Plaoles +. Polyeterane » Foam , PVC; Themmnocole sek:

Masten, pass @

. A ee €

‘ato, 5

vi] YY (wood) Double Srinkg. Alanis ®

\ © Cort inom (10 rv fpn’) te @

100 ; 1000 mm —> 10.1

peed tol GG Patou 100 mm —> 4 e

Cee) ann. 3

03-02 \ 7 @ Steal (20 emn/mn’) o- 7

1000 ym —> 20 sng 6

WL P.

_ wo | Y/. Cease Few) 101 ron > 208 ni ‘

8

: ‘ 8

me a

Scanned with CamScanner

233

pyegetneare

4

a

ote lw ts ety Tp 7,

‘ 5 7 "Expandable pation’

. " Disporat tasjou

SP Using AA 5 thyeatmuad: ‘nahn . ;

e Using Hg > Mexcaat tasting «

.

G66eGe4eGuewt

© 9 Tyres OF Patten

a .

bd Soy a .

2 Solid ov, Single Piece :- 4} object to be pridiacad in. Simpl, in

2 - 2

9

°

3 For.

9 Split Pies Radlow

2 - ~

3 wf yap lll soa

Pins -

2 PG?

2 5, Fee complex shaped objects, " Prag box

3 2 ie can be Split indo no. of spur Pieces olovg ts poreting Une such.

they can be wuinoved from ome and

> . Salen dma. boxes seperately

2 D Loose’ Piect* Pattenn :- ve

Loose Piecé” Paslenn +

2 8h the ied ou having inten preins or

, Undircut, loose. piece pattems con he weed: Aiton

: -@ | Temoving tk main part of The patton loose peice cam

> @ Temoved from the fF moulil ty ged the ‘epived cowl «

= — G 4 Gated Patton +

—

a sition Err eos af caste by

4 Mga» production. producing of

5 —r Rina the gthing elements. manu}

Got. will Jala mere time To |

; overtone ‘This, nO OL Patton

Scanned with CamScanner

along -esith geting Bemunts will produce. w Single ate knavon oo

geist pattern.

5) Motch Plot, Paton :

|

the wv ion, n> Hens

«be shh oly the share HE 1 mors pi of pation: gy

_ sis ws randeh ple along uit ot se, pom & sgl

patton “de é

eae yradche plot potteruns e

> Sweep Pockls .

ae * plone patios, 6

con be retake in &

The mould. This @

qeeewally ued for @

axis Symmetic objec

dy | To produce 3-D c

Complex shape

AS Ke act cote A

awe @®

se

T Follow boond Posttenn :-

: Ay tee pos ove not hour ¢

Super’ choath, dur Le

aru supprated bi

fora, ike is a powili

| Followboand —- 2% Poss

Fatleny ak anny he at

A poiding Prwboard , That awit is roeeail :

len en Red etary a te, per

Scanned with CamScanner

siti

e

SHEEGD Pry

Net buyoney force = lb. of Liquid

co6e _sond

Mpulding som

nd

ojoric. bindue

flinsesd oil,

molasses ek

— WE. of the come -

© pMelorne of the core

VgSm- VS > Ps LSe- Sec} Demy hoon

Dorit of the molten

Liquid mate

rT)

eae

9 Core pinks are AKL prijetione om the patlrwn usd to produce, a recon, in

© He comity to portion te core propody.

e

Chali i Thane anu the mule objects wad fo cuppuit the come. i

the Comily » These ane wode Mp of sam. material os casting «

QA hollow coating jo fo be portused uni

% ctindmtal core of 200 mn height

‘t iHome hrizendally.

Lovciliy 2 yaothon, Weta '> 7800 4a fe3

, Te on arin 1600 gh

Colenats ak bangoarey fora om The tore 2

S@SSEMTEOKO0

Ps E (eof 0) x10" x8} (7800~ 1600) = 21496 N-

@ © paoueping sann

[PRefradines Tetp']

Silica —. 70-857, ae

“Zirconium > 2sdie’c,

Gram 5. 3500"

| es9

Additives = _1- 6.%

Scanned with CamScanner

_

)

Ee eed

marek KO

‘a

“PROPERTIES 7 be ao é

: 4 Sgh femy

1. Refenctoviness == AbIbT. Of Wh moulding sand 40 joithstennd high emp e

ee matal witkow fusion :

the >

> Pormenbiliky Ability of Ake moulding, cand to ue wt -

fp escape to known a» pormrebiliy « eh

by foweabibly nusrnbon:

PESOS EER

Ve Vol? of civ possing Som We De a!

+ aod em) = ava.SH = SORGM

He Helghh of standard cylindical specimen. :

Pe Diffounes of pressune of ain presi

trmgh Be spina Co jem}

A= Ceos- sectional Area The specinan ee]

T= Tims takin by ain tp eseape [in]

Uniform Grains hove mur povmuabililyy When compared

4 comcunotm gains: SERGE

8 Gtoortoa ‘the povmeabily of tha snouldhing bam Uf a000 om? is alocel @

to esope ineugh a stodand aiivirial sfalren for {min Qo seo ®

at a proasinn of S grev/em* .

go, We bona HAP

Pa = WHY = sx2000 x 5.08 _

es PAT] 8 x-xx(o08)1S

s flow cely

“Te Ghethy fa vanasy snd te flew free),

ge

r

= z

iL

trod

a

3

HHOPQHNHOAO®D

a

DHADAG® AMM E

webetscedesde

$ 8 0 2

Zr of wonder

24

2751}

Sa

| aad ty (Pabtety & 2

3 Hooabitly ~ Abb of the mmiding ® 4 fro'nio nil the

oro 4 the mould bye due to anand force» Ste portal a

. rs Leseed @ a

AL i do achiin the shape ste 9, mn ay Plovrbe

dhe conky omd to withstand KT @y

fou appind by De: Uigyld red Ke / < ef

mould eonfaa, if rut ke having Buffiient- a ey

Thongtly x % of soak — ‘ >

6?

»

%

Scanned with CamScanner

4

2

pe

~

~

~

~?

~

~

~s

=)

~o

~~

~~

~s

~s

» Sh AKe moulding sand bo howtng ynnishwu, oe Win calbd Gaon Sond.

~, Attn evaporation tf thy muistue, green Sond in converted “elo

Dry Sand Aptin beaming the sond dey, shill Ui rita is haw

, mareheat , that will incresse, temp. of the Bond and ir ill boop.

hots Rat tand io cad Hot Samd -

6

@

eS

°

© > Hondnurs :- To minimize the owostion ond 4o withstand the forces

8S applied by the Liquid meal On “the mould cunjpers

@ mowd’ must be hosing supticion handnis. St is a surface property

. Mowd hardin No- 040100

8 Aug = 60-80 5 4 haindnws aged

GE 80 dirmunsionat change can sake placs in casting» and if th és

@ mre tkan 30, poumrabiliky will be decreasech *

© & Adhunive Proputy :> Bord fosmastion lyiy ‘two aiffeunt madoiats «

® 1. Cohesive. Propedsy -~ Bord. forinahon bye samilan matewals . +

? apt ae

~~

; ee ‘ Lo ,

Se atte peed Ol fequae, Suibidemt- Thusumal Comduckivi hj»

e and

3 pspoSipaned Mrs 2 coeffidort” of, “Thounal - © pansion .

9 ES © Collaper bility 2 Abit of the moulding sand dito whin

3 e mould surface will rot provide, ony meristems due to

: G SAA contraction of the cooks :

>> 6 ny

“> | pres “use (8 mouining san

+3 :

9 ees } Collpsiltlity ond pourruabilisy-

oa 6 ' Wood flour

Linseed dil, Molasses hovdnass

aa) ard duxtine wef Song ond

s> 5 e@ 2 Coal Ara ace finish,

62> - @ 5 sm Rumer

<3 © © ELEMENTS oF Gating DESIEN *

> 6

a @ Sprue --}

32 &

2 | Spry, Case 41

beeen

Scanned with CamScanner

© Objectives ating Design

into the GW aot optimum

causing twrbulancs . 5) x

> Kinige the gating thmunts sweh Had pos mich on be odode

We conily tottheut aie aspiration effect.

> Produce “the gat

DOH O&M a

eluminis to git maximem

Orie fora ib lee

4o ren-Seefous -

Founing basin & dacienal to

molitn mdal whith is

wihimice. emotion.

@ > > ay GY AD ay i ab

Spot & posts. To relia wanubeios goon

® comin as taprud caplndin | UrRaty sp

3 Sn 0 gg eyes Soe b atid to aes

Spl He bai metab a aolgs. Sq resid &

Assume height” 4 SPS 08 0 ems

5 gins» (alenlate. “Ht Simearions

2nd edhe

—

OT

Scanned with CamScanner

wh Ob Oy ha OOD @

VDUEUULEUWS

» mF 9AV /

B ae = aoe 2 2.56441 my = O56" UnP/s.

a 2564 - 2

a de AgVan > Aas & - SSS = = a5.88en*.

5 GEAR Mee at pears * ORES ST

Q = AsVs- py Gee oo ed) . es

Qe Aaly > Ags qe pee tee « U Sren

Ass Edy = 1.57 > [da= 3-830" .

& gating derign y height of tk. sprue & 200mm - Vélocily of Uy.

&

= vwctal at He begining ip 0-5 emf Whot ts Hat vel of the Gy. matol

Gat He bot of tha oprur?

& oe Ss hy osha he | Mar daghe

& Sieeg ae whe 500 - [and ax emer,

2 = 0.2 40-0137

g 2 Vge Pevsivoa ” anos > tye hes 0, 0147.

e = 20MM - :

e

O° GATE (wente)

- : y.

e Gr io He. detual entry point through which Uysid metal con be

G erdoud inb The cowily -

be Trees Of Gate + ’

© Top Gate (Vertile) aa

© Dd fotbm Gate

© 2 Parting Une Gate

® Step Gote- Ligaid stat will divecthy. entered

into the cowily from bation of Ae

Spru at abn, pressure. Velé of “fre

liquid metal vohich ercloud into Th

eps igh . Thus io a

possiblily of turubwhasce © =plerky

ates Geren te Need fected ce

Ke Uquid mmckal

> Top Gare >

BHSBSoOSogn @

Scanned with CamScanner

= Vey th >,

y» at Aggro”

‘4

5 Fi : hn

—s at gy 2 Ayn hm

V3, Yq : Jagh 4

Vr0.

Vm 2 = =

; —

ot = Agi, Paghy AY

' °

Paar eae bes he: hs be

\ ave hy = hy = 0.

ers? pe 2 5.05 See

; wens

Aq %4 * Trnava!

Sy EsTIOM. GATE >

a fomous melartals Thurs is

waborte [SEE unfatiabuabl. Jonp. gmdiont

hela mana tn The enw - 7

As

or)

tee Uq= LGC)

dt. Ag Vq = Am’ dh:

Wn, t=0; h-0, Aw cy

whan, tty she hm? fet . (

Scanned with CamScanner

@ Ya bm hy > . Ai» (TR

thy

o

So ee

° :

se] ) Gate is provided along the porting,

i) > Line such. thot, below Wie pantiny

) > line, onsily com be filled by

@ . asumniag top galt. and bere the

: be pau. patinyh Ainwe , cuyily com be

~ Filled by ansuming bottom galt

9 S: a te ete clog both -

“DF ced bottom. ole, ah in the inast comanavily and “Lipa of gpiong sytten

ys © Lipid meatal con filled in the comiky within a given time without

- Consing Turrboubyeet. avd splechihy :

ad = - a ae sy Mie a o

Fe > G Roundne tar Ante req’ fo fill the caltly along wit, afsen .

- 3 - — Bison ty > ty tee

v Am \

: 3 tye a + AAm NM (Th fag

2 a

i > I Faghe hy fq ms

> : 2 ae eanOn IO

2 5 S4Rxeixao *

r .

e ax% (sy

iS % + US) (fo0- far)

3 5 ott bin » we con apply ax J axl :

fotes tye Ate ete Gost 7s = [pF see | Ane

he 4

. id fe = alta), a

: 2.

m8 22 fits fae] «0 me

2 3B aya | = Ay 5, [2x92

a2

c

2p fe Ty = 403+ 7 13 = Ws Mee

ita

Scanned with CamScanner

@

(

AD Step Gare > To FU Wu mmobken Liquid mete fgfo vou a '

: Longe sind mous castion, no. of gales ame gy |

Provided vedically, bo The form of steps gy

sich hal Uguid vattal tur be “ e '

{adiing into the cowie, within a quer @

plodhing , huxddulencr Of Ha Uiyaisl onoial - é

Test: of fluidity *- ® |

D Spina Test ~~ 6

Avilily of the Liquid meat e.

Xo flora into tra comity io 1 BS

abled fit Lt io the Of the Uyuid mital: Ip eambe @ |

dhominad by Corduching Spiral dest. atdoume tanned by. the mela @ |

Mmutal before solidification by ths shundased’ spit will gic te. =| GS

Vou. of Flusdity = 3 @

@e

Properties OF lig.Metat] PLylprry S ¢

39%] 1. Powning Temp f i ee

[2 Viceasiby 1 ‘ @ ¢

3. Denil 1 + © ¢

4. Surface Finish OF Cavity}! 4 @ .

5.1. Wren in Sand _t q @ .

© e

® CHoke AREA SF vw the minimum Ye, fren in all the gating = G ‘

clemunts «SF will control th flow the iy macat whic, @ ‘

ortes tao ha awit SF ve tk fist parameter to be citedatet @ |

hn al Ue qthing clernwsila’ 1 ‘ '

™m B.S

Chie un” SEC aie as

~ 8

Unpressuntcal . BAe y @é

Gating 4 ( ¢

2 a

CA: As 7 te @

o very

Scanned with CamScanner

weenie!

, IE TF S|

éddeecce?

a

¢d

¢d ¢ d

p

é

@

8

yo Of ARe Liquid mal which is ended

@

@

Hilides

* n- pressurized Gol

Un- pres ong Si . .

wand Gang Splen Oroke onatoh the hon ya, |

. , - Spur. Velocity . * \

6 ie hs owt, Wise Th tn ended nt ih

6 . ee foe casting A non-fowoun materiale “Thin te |

& powabidy af alk expiration: Coating yeild will bea

& Promunizad i ‘ F

Mia ES un = Cheke ano. is ok the gate. Veleaty

ol. . . indo he cami,

ea Woh - Thou iso possiblity of hwebulin & rindi 3

Com ie ward -for enoting of fermour materials . Thar ip no chance,

Of che cxpiratiom- Casting yall is more é i

1 hh a gating derign, thx gating ratio in 12:3. SF w word to

produ oO of was 30 Ig. Reainky of, walat io 8900 ba fn

Malling ay ~ Prune “hai 5

Pilling firme roy 2 10.6 seo Fourtng buighst of Lig. metal & 240 ron

Acroumning. Ca = 0698, Calculsti Hu Bimenaiors of the gee

*

Sot” __ me 22 = G49 6x10

~~ €R-* “Ae Cy (Tgp) — Awa 10x OBA gy, yaa?

ae a an™ Ar = QAs2 998 om.

ND a >

aps 338R

Dae Uedb ow

'

> Soupiecarios IME ©), 2G)

Chyosinoy's Panipl. + bs XK

‘ vie

tex (x) ea

uy °

ke F Ry tex

wo 2 2

Cube = ie qa %

. 3 sa *

ym 22% —

v ve

gyiows ke a ee

Scanned with CamScanner

8g

DS

. . 2 -

Cyindin SY By ah oa

Bra andh ; t

Slay Moy eH 6 of

e A © 2(Le+ eHrhe) b4 e

Wipheal Cybindr v bch __. ° e-

arab +Tax (FE )| e™

. - \s a a

res e i Qo

: i wit @

fhe maton dep of Uge madat wobith cin ephuviok form 2 «

wstaifiy io Asee. tahar to Ht Sebiffeetion Hime af emmmr ge

pander drop with doubt. the caBiw ee

e &

te Nes ay = eo

tas? oe

ts<(%) — OF

ryt ee

« (§) » tres) e &

te . (des be (Er) | et Ge

bo < ay > 4G ee

2 . 5 jhe goldifiaho. Bs

2 ar «Whol 8

: Hing eoUidifion ia & wm” , tg *

A a ved wth ffi Howden Fame ENG

How of nan cuca a”

coats” = 8m e¢

fg, = dwn ma = 8 My ——. @§

yes? > Napae a pags 8a? » (ase) ‘ a

a > Var 8M :

2 vse (¥) $e

ae GY a \* 9 b= Be @°

® (ey? 2 -(3) , F

eo

Scanned with CamScanner

we yeVY Us

)

of

My i.

= Us = wy)

i = 0.97% 108 (2) 2 1077-78 see

B - ws

Ble Kay. :

an

5 Sle BL Gal, G2. greg

5 Bete Ca, NP CN"

%

Vou: Vp) 8 ane 4-(2)° & G) = oe

Pa Wey =p (de . Uren, My

BR, BOOS

ey | . (2) ‘dt

7 Age Ed Adly Fi (mp?) GR

4 a = Msp 6

3 ze GS)

a)" faa

‘ 7)

rye Y ww WE

\e

Cteou 2K act = 0 5685

ay

acah §

» cooling

ya fhe hope theo" yy

a

Scanned with CamScanner

vill be ort

Bp

® Top Risen

@

®

(PTIMUM CONDITIONS 2 8

> Side _sisens @

Ax 2. Ka? andh-

i av

q

V> Rath > he >:

> Ae ak av

> Ae a Fara nd ae

k= Rare

xy VRg™ +xdh .

A. Sel A Shea

Eee

A yt «9%: %

vs a Vv

Vv H, 3®

Q

“Tor RISER *

“Tor Rie

a

8

Risen Des . 5 wal: of costing e@

soto 9 fan 2H RO °

» ww). u (#), 5 unr > ‘

Milfods 49 ineeoot Hidwey hg 5 heda 3

O[nweisting OF é

8

@

@ Lxothounic waters

» Coine's Method =

My le

Frosting ratio + Ky

Scanned with CamScanner

wero r he FPP PV OOESCECEECECEES

BOS FOCOOSOHDORGGHO

3 Motified Caine's Method .

(Naval Reseanch Lobsatory Method) . .

Vr

facey = Lilt

2 =

“2 Se) =

®2O02D@

vs

Wet > vy= x Ve

D Gabe + Se = ata. y DOptindan - p= HED

Meds 2Me % AF?”

26x 12.5 x5) “140. 6a5 em.

Vier a= 140.625)

hide 5-63 am sae

re 225x495 + 1R% SF sxa5) 0-64 +

» (*) . AS XIDSKS

A 6 b£ = |.06

é Wie ~ “a * $63

e (a (4) 5» £2 ok > hed= 0-375 un-

= hve ? d

wit , a

, : A 2 (QDx AD + aHOAG-+ SDx250 soa

Be ax asx 90 mm? on BIDx 9502 SD

@ 020-1 be 003, Ce]

6 a Gy: &.

6 ‘ ve a

@ ~ 0058 5 Y* Ve > Gamo

e Ya

6 0.56 ese. Ere

> 2

@ 2 eos

6 e B1R5O0

ra [ar 0284 mm |

Scanned with CamScanner

25415 15 ot

4) >

gM

a _UrB . 25418 2g e.

LC) ea “ 2 us

oa loss [os | on ote

5 on e

Ve, 05 5 Wi 0S (a5 2555) = 937 :

~ 7 e

Wee Bad pe 9305 > i °

Lirden'eal ise (h=d) ke poiona on te top He eylindesiend

are catede The

gsi He 100 mm and di en i 200mm Ot e*

Gon of tht rise Osing modulus raathod «2 8

fa) my ham

“y= 100 rom a y c ig (a00)"C100 _ ®

D = 200 mre yee A). —_ )

2 (axa) 9 (and)

ly > J.axaS = 30°

Me yy Mah

wo Beas

V,\2

& ww. , We

Gr (ar

7 .

> 1:36 -= Gen TxD WT, a) - (Lee> Bram

t. “ 7 bye é

g “ z (¢ )

pa] | eho

®

@

e

8

[ae 150]

6

e

.

:

Bi (finan + Sqpo poulteleript “,

Az axhd?4 adh 7 :

ie ee patrqa( Ys)

Cy 9 Gade

7a ae

fare

(tslog Calin Ie - 6HI* | fare

q Dep (hye Dey (2=)* (HS) at

OMe Vi.

ag Sp > Be 08 3(8). ee (2): (a) 2 MIF

Scanned with CamScanner

“(yee

© Posmon OF Ri

38> Min. Widenes 4 Mece'S:A. io

he Ey

‘ (Fn

2 Non- unifoon Thickness = i ye eae

: 4 Enducal

: ert

4A grein)

SL = =

| L, ara

Dwi enduoall grodient :

L=13t (tuo vies) 3 Le St (one siser)

> Wittstterduvall gradient‘

“ast Le Bt (uo sow) 5 At (onewrisen).

~ CHILLS 9 PAPDINGS :-

Chile :- t ye eRe

E = WLLL AYA

Fe ai :

iE

“Pree utts & t

®@

de ers Ww cxbss section Yn mould coil fo maximize The hol fn

ke ond to Prouide. unifoum & directional setiifietion wekallic objets

fowral to coy ih

eclonal chill mode up dy high -hotowal - 44 GL into

+-K@

> to He owily wt wade bp of Ste enaterial oa the cooky

aes di tp moulds covitien , Jo minimize, the ewmsion

b dif divwhonal. cclidifieation , mall

and to ide way ae a

objects SEL provide, Loa au knewu ar padding!

Scanned with CamScanner

» By providing ill & pubing @ *

: > Yhap

ajecckiomal silidifietion on be © gr ¥

poseable + eS oe s ,

> Sg fabennol chile an sate bs oye

eee dif ostiom ome es

provisle dactctioweh $0) i i =v) 4 i

® CUrcsiFicAon’ DE CASTING ae ees Q- >

> Lxpardable Mow Expendable. Moulds Moulds ee a ye @

Cimperny, crits) Wwurtrnunk reowdlni ©“

& Cu moulding £ e

* Co, mows

moulding + @

FS Centrifugal @

By Poxmanent Moulds Rooke 7 &

7 gush casting

B qpreze cyting-

} Grtinuous Coking *

Scanned with CamScanner

dpe to D bie tolocks Ee egies

> Rockin abums

Value plates of wefaypratss abe

© Patton i2) producat by mule. dloiol, and iF ctw be hint

.

xp 250°C . . ,

© Mouiding pratental io mode in contac with huoted patbenn +

By Aclivating. the bonding. propution 4 pnatic eins moutting

Squid wil Shek to fhe surfaen of patown in the foun of

Aneb . Thideness a autt will dipend on contnet: time bho

Gand, moulding, macteriat lnerin on Dut tees Affer getting

required Ricken of thu chill pation & Aull. com be coperoted

Soom Whe mouth box & thay will be healed upto 250%:

98, iding no. stalls thoy, will bee odelad 4 prodane

1 3 ; | Inching, Sond +

pegpirel comiliy Sb supposed by Pf .

@ Lydd meal will be allmwoed to solidify. ir Shull ores -

A os thish we ypse. ;

0 Aeaunsty ee 4 pen foe Longe sire costing -

CEd¢bbea

FUPWSVWVUYUT WY UTYUwWYwwWYwYuUwwww YY www wo wow www:

© |b wd) Upmrsive process 7

Lovett Sa” Patton iby =

Rosin: 08

— A

VUE U TUTTE bobo d dS desi Es

Scanned with CamScanner

Rapa Gar Tibtne Ploden

Cel Angin pords ,

Modicat Imeplamts »

Dewdiynrds '

Gold: Ormamads ele»

Patio i» peoducod by won wabodal » °

YF No. of Prtows wit be addid to prdve O pation os

long ptt. geting clouds / by. odding. . clusmp .Coatiags 0”

pation, fine FY Cromule inalvrialla com be added to produce

& coramic shell, “Thad prowess ip codid ” Stuccoing Procen”,

f+ By hating Te Ghomic shut vox will be Converted into quid @

fem § ib will be removed frm: shu to seb the tepeived cowie ®

into hich Uquid milal will be. alLewed * to sobiclify « e

To minimice the gna dafecs, thls prow will beeaiied oul gs

undur voauum+ . x” @

F Cast of Hu proce may be mom Ub is vosd to produce

Omnpinxe Shapemo| Hu. objects which ane produced boy hit o

wuthing ph with mer, accuracy. eS

Fut_MMouling + [Cavitylon Moulding. / EPC / Los Foam Procen| ©

fatloun + Plootin Pobystoune , Foam, PVE, Thuumoele et.

Scanned with CamScanner

O9GBSSHSSOO

a a ee ee

QB2DOSBOe®WOaS é

o

wi

Z

®

as

zg

Vunid od moulding maoria, (Non forrows tno 14.P.))

produced by plsshe modeual -

> By cctding: erin Lindans:, moulding, cond will be oddad anound

the patleous & ik uss” be suppoated by backing rd “in

He mould bx.

4 -mutol will be Olivet atlowet: on The pattenn -

% By emposoting, palo, “ar will be alised To escape from

You mould such That comily con be pooduced into ushich.

Liqnid ymstod wrill be allowed to soliclifiy. .

DW yeould i prepared by pop wo alfa noi a vars”

fran ir called plaster moulding and at ia gavel

Soe producing of Low MiPey non Ferrous at

© Ge, Moulding t- ‘

Na, 303 2-67

ny GIDe + Na, COs -

Nag Si0s + COz TP Gitien Get

por

> Gorsing fine oe

ote, This

bonds of mowd & ©

treaae “The steength, ond

Jagirtque com be acd»

i gollioee silicate. binder +

et to not for sufficient” time ot

sb which 4

ste Sodium. siitale om protuce, silk get —

goat wi * opin Gua fothis , shength. &

1 oe ae . po le

WA Cam be wer e

tol

' ty CO. ¥

of | road wr agen om Hine. HP TG

rhb th 4

#

nose or (On Goring Hime

Scanned with CamScanner

sh A hott sti, ote .

} whet a} Te am inside, diamelor ard 780mm, @

fo. pre yy CC. ttle ace? af mould of 789.@ “v

Cote ae rolediont sptid of jas moutl« { b 789 6

SP Rim ve Pot di » BSF TR 2 8h. mm. 4 .

i - uv

TEXAS 00382 x BBN” 5 ple 427.) span @:%

* G . 5 é e

© Die ale SPN nom st lacoee © = %,

Costing, Prosowe« Soi (uo pax) ey

: %,

“Liguci ,rata oyill oes int ns

‘Wu. dio- comity by mua ca @e*

oot force. @ vy

eo 4 wuded to @ vy

psieple shape o eatings €%

. . vy

| “i @ ‘Aceunsey & surfece fal ~

| ean of objets one voy hgh - *

& 2)

: te produced

ww . in shuctwie, 4

@ pus, to foot Tole of coating. fires Gl ret

; such. poopartis + lo + ee

faring. eto mich popes ae é

yaad ps mor petuction bs

|e Gane be in qukernabiles wale tp te gad

tion 3 slows ane + os

| os

] we

es

| Pid

| e

re

i

@

“

@

a

e

2

—

Scanned with CamScanner

a Ligue mutelwsll be fotted into aie cadfing? cauil? velar,

= orteorral plunger, premune u

DB « VF in weak to produce complex shape of dbject with Hate

BP coctiom: / i

Ruiner wv. urdegaaded wit Co ee .

& MK i> word to poocbua, Lew MP. wnatisdals Uke Lead, h'p

®

°

a x .

e ‘ty eer ns getting, soliclified undue Ce Price

7 ty dawst eteustone with bette meshowical peopartion,

ann , cing. Fa grin, ghrcdunt. Cm be

© Dux to feck Fate SUNG * "

produuted *

any & aunpen Bh in veg UA ,

as i ahs pl oil

aig rote © Org AYR BD ie op. ance ruck. sil

@ Porc bing vendomeyy a Lae

e Due to nny waa in pot camber Ae OFT"

be sedwwed - Tr bo net Teed pow, vases EE

Castine en NS, ids,

© CoD. _Ginmaper, DIE ERENT oul pipe se Te a

pr Sopdass +

ted ot

ane e Ting MLO

Scanned with CamScanner

. Applications‘ D Caidoune tens

: ad Crank Cover”

3> Valve Bodies

Friak “Injectiow Purr ports °

2) Toile fichirus

© Comparison of Die Casting. & Iweatmuwt- Coating.

ming & buna” Go

de:

Investinent|

f FRcTORS Die

>| Paroduction Rote | High

Loo

| Gomploaly of Obes

M.Putomp- of rnotovats | Lovo

“@ Stusn Casting

te (Yay > bath? 2 4

hur, too Me tad of cating 5

4, He solidification time teqd. :

C)BCo Mu Ha cmularits which depends ew proportion +f Wy & die

Yo jrriver thin canting & hull tim acting, withouk wing one,

a wad: Uguid viele do atlowesk +0 solidify On

hin ehniga ae be

eda After gelling the ry thi

jw die aetng

unyatiaified muta cone bee

| 5 an partied aldifiertion. GF io generally ved for leo”

ike

APs mon fou anatoriels ti

Thin casting.

Mollna-Hits

aatig,

Hollows techies,

sloys.,

Pasrative il

Thin ormamunts 8

Cults + Cy

dena, by rotating IK dle

from solidified nnetak . This

Lead, Hin, alumriniven kee

©2OOB2FHRGEDHOBMAD

PERLLALALIT TEP!

Scanned with CamScanner

QHOOLADHOOVSVOG |

9

ens

o999999e

IFIIIFIIIID

2

‘@S

» AL-ollg matal'ie allved to sibility On’ tadin’. St in oeonwed “pape

Ale 4D cee 6 BO'sec + the Heicbenes Ors 3mm & 4.5 mum. int

a ie Sie

=

; bo tte Huickuen of the coming agin solidification Hime of 100 sec -

5 a = 0s tye3 mm oct? Galt + Ge

Q. te, 230s 2 Bs CIO Ge,

@ fags A008 Aen bulio fa

© 215 = 1 (fi - 30)

| yO 2 LhS = 0644

eS ZA gs 6-647 fide +.0.954 (0-83)

oS = 7-42 mm > (y= 6.954»

>

© 6 Saueeze Casting t-

es

clique meal will be find intothe die.

) “ yt

“e ae * Exounal preawe to appliel on The

- \ smndial Jushg the plunger such thal

d : ig the pls

8 Va «Lig mated ts solatified bho plungin

%e LL : and die ada extovul presun:

“8

Ye From the plunger

ey 2 & The EMbination, of cashing and foxging -

se © Promun of the plunger decides the Shope & Sian a the crating

® High dance Shudun willy beter mechanical properties can be produc

Applications >

“Ie > Break shoes mode up of Aluiminiun.

stig, } Buch mode Upof brass & bronze-

—%S © Continuous Castin Tecenique !-

Long. Wath boo ods , billets ok»

velallic objet

“undish: 7 To dure Loom fergie mele!

cobinunicly from 1 by metal >

o> Bi ) u cue can be used .

Bocce) thio Leming fosed omg Ie

Sot alia ie to a solid exert” |

Scanned with CamScanner

|

: prove

ane 1 td rtiaing” a vioracting reehaniom BL seqerading:

D ret /Sawd Blosbing '

tha gin lameet from Maa canis ge

D steal: balls of 3-5 mm

YK. 2 Coarse rein snd»

sees eee whieh are fund om the sigue of. &

hondened Stal balls Will be fared on The coating

sing, ate ain premune, to known as shot blsbing -

coonsed rt sand ib used fir cleaning Hi cxstingg casi

pe a ‘ "re

® © @

€

@ Casting DEFECTS :- 8

OGes sp = _ é

® Blow halos © open blows. > BUFO ase pgm matt B

> ay apo att Oo, Wi ~ €

Bons t. Sy Ss

oles . € 8

‘i 7 s

ya ‘ 2 o@

@

€

Q

- us which oe forrad Oui

Ay Blow bales 6 carl cmp Ho which Ore é

fool nn coning, te Howbdlns é

> Sea + A cholla lower vahion formed ow he surface ef Ae ws

B> Scone * é

, “i oS

Listen - gy bo Soe cownd by athe Ley of, me &

ia Srnglh sted gpoheles formed dust to" Hephroges J. ‘

io a-pinvote pom

a> Pinhole Pososiky *~

ee

Scanned with CamScanner

6@0®

ba Moutiing » vadtteruial & malhod !

oe

Dap Due to ienpzsper. susnimire

A loose silica sand ponkidla

| will be droppr? from Grpe

e- Ba Reg ex forming a

4 58 Projection on The setfac

@ ie cecal i» cath a Drop: Whib, o comity om dha oltun side of

cating be calbd dixt .

OO2GC8

@ 8) Cats & Woke ie + Pete

e

le Dur to improper Younming ab rain”

H ak moud cavily , uf som rouldiy

e Sond Usill be erected from ‘th.

6 gunkare and tr will be. washud

@ Wwlo He mowtd eanity This will from projertions tw the contin,

@ known cuts & Washs:

6 ©} Scab’ che wid muah com be

WY pendeated thto The loose.

Sard loys in te ope, box,

will form a profection Om the sefacee of the costing’

@ 4) Rok

Sur to tnproper (touring and hue

+ to impropin mising of sand, ofa gi

“cwoss section, tf the moulding

expanded will fe 0 prijection ™

gunkace'of, tu cockiong forown 0 Tok bad

> Ging DESISA

oy Shritnkaye Quwitio =

Avr to improper aisor cesign owilt in Formed dee

fo dhninkege of the instowal *

QO®

veoegeeeee

Me)

1908

Scanned with CamScanner

@)fourmnse Merny :-

O Misrun (®) Cold Shacks -

Dur to lack Tao Areas of 7 7

cop tae omy ina IL j |

Aunps before. Zi1\ prpny wat WoO

‘reaikiny. Vou. cawily

Uyuid metal will dhnd solidification.

will form mistun.

com a decorbruily an the contin t

Virtue ax cold abaite

© Mevaoraen Deters --

)

Mot team / Cracker’

Dur ty wom. weifornn carling, infemenrl chery ca,

I be dtveleped tn the sailing. Si Mra shrowven well

LLLL be mon. Hann + chenegthe of Hoe materials Cracks

Wil be. (remed amon os biel deans /emnhe

© Orner Derecis ~

| 9) Mould Shift + Saige

LO) @ iG

|] Dur te preps positioning 4 _ fee {

Ope bow od the day box, th J

Mou i makh alow the Srotting 1 4. core fren ie cxinina!

A me alp “t postion Cis 4 cco et

Tettng Line in the onatingy cow be Gvecmee by

vena

cove ports onde chaplits $

@ TURNACE >

> Gucible Fwmatt & Sh io vest fe pratuhon Of Lous Mething pont,

nom Forrous materials fs gyal scale foundries.

. Chaye = Ore : Ste + Pll + Gee (pubrenind frm threes)

my feeretin stag

ald,

Scanned with CamScanner

SS eee esedeovesoe

SAGAR Qeadaeeeaeaece @eee

ees 92 OO B@ee@eneeeweseeeeseeeeenenenunnunneit......

SS Cupola Funioee

By malting pig. from, oge: quemtitien of

Cask pe OM be prodinced

© OG

Metti “Ratio /Ch Ratin

Metal + Fuel «

4:1 —» it

Cupolat- ford

C> Electric Are Punnace: Loy quantiiien of ferrous matoritle Like

Sheek com be yproduced by mebliny pia yon * ;

4) Induction Furnace.” For melting of foviou & Row feman

i _ ii fo furnace OM

‘yaatoials, br wll ond trge quentitios » the i Sot

be word . Role of vnvlting, thigh « Space required & ©

melting, wD moses

DBOVBOOHSHBHDOODD

.

Scanned with CamScanner

You might also like

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Ob 1-1Document25 pagesOb 1-1kanishk singhNo ratings yet

- 4208b Sustainable Agriculture Part II Transforming Indias Food SystemsDocument8 pages4208b Sustainable Agriculture Part II Transforming Indias Food Systemskanishk singhNo ratings yet

- Public Interest LitigationDocument10 pagesPublic Interest Litigationkanishk singhNo ratings yet

- Ancient History:: Buddhism and Jainism Mauryan and Post Mauryan Tamil SangamDocument44 pagesAncient History:: Buddhism and Jainism Mauryan and Post Mauryan Tamil Sangamkanishk singhNo ratings yet

- PEP History Lecture 3Document82 pagesPEP History Lecture 3kanishk singhNo ratings yet

- Ancient History:: Pre - History Indus Valley Civilisation Vedic PeriodDocument60 pagesAncient History:: Pre - History Indus Valley Civilisation Vedic Periodkanishk singhNo ratings yet

- Scan 02 Sep 2020Document1 pageScan 02 Sep 2020kanishk singhNo ratings yet

- ESE2020Ethicsworkbookanswerkey SheetDocument1 pageESE2020Ethicsworkbookanswerkey Sheetkanishk singhNo ratings yet

- Ethics and Valuesn in Engineering Profession. (Ethics)Document1 pageEthics and Valuesn in Engineering Profession. (Ethics)kanishk singhNo ratings yet

- Gs Prelims Upsc Polity QuestionsDocument12 pagesGs Prelims Upsc Polity Questionskanishk singhNo ratings yet

- 3yr NoticeDocument1 page3yr Noticekanishk singhNo ratings yet