Professional Documents

Culture Documents

Brosur New Galaxy Separators

Brosur New Galaxy Separators

Uploaded by

Zikin Pieur0 ratings0% found this document useful (0 votes)

6 views12 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

6 views12 pagesBrosur New Galaxy Separators

Brosur New Galaxy Separators

Uploaded by

Zikin PieurCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 12

DUET SAY Oa AY Tiel t)

About New Galaxy Separator

* Trusted Name for Getting Screening Solutions

Enjoying Customer Loyalty with more than

40% repeat orders

More than 2000 successful installations

Dependable Sales & Service Network

Stringent Quality Parameters set for

Products and parts

Products are of International class and Par

Excellence Performance

Capability to Design for Specific Customer

Requirements

Offering Customized Screening Solutions

Industries Served

* Paper Mills + Pharmaceutical

* Sugar Mills + Bio-chemical

* Ceramic Industry + Fertilizers

+ Mineral & Mica + Palm Oil Mills

+ Food & Beverages + Dehydrated Foods

* Chemical Industry + Rubber

+ Plastic polymer * Defense & Explosives

+ Glass Mfg. + Hydrocolloids

NEW GALAXY SEPARATORS:

NEW GALAXY Vibro Separator™ Super NEW GALAXY Separator™

=a

4 a]

‘Tetra NEW GALAXY Separator™ —_ Inline NEW GALAXY Separator™

DUET SAY Oa AY Tiel t)

NEW GALAXY Vibro Separator™

+ Designed to Outperform Normal Vibro

Screens from Indian Manufacturers by

approx 20% - 40%

+ Available in 7 sizes from 24” — 84” dia.

+ Available with Glue-less Easy Replaceable

Screen Design

* Comparable with International Brands

+ Retrofit kits available for International Brands

for after market parts

+ External Lubrication Mechanism to prevent

Bearing Failures of Motor

* Spring Balance Mechanism helps to stabilize

the machine fast.

+ Low Maintenance Cost

NEW GALAXY SEPARATORS

NEW GALAXY SEPARATOR MAXIMIZER™

+ Designed to increase output by 50% plus

in existing machines.

+ Saves huge Cost and Space for increase

in output

+ Available for NEW GALAXY Vibro Separators

and Super NEW GALAXY Vibro Separators.

NEW GALAXY SEPARATORS

360 Degree Product Discharge

+ Higher through put possible

+ Less chances of clogging as oversize

comes out fast from the screen.

+ Suitable for check screening application in

liquid - solid separation

+ Suitable for de-dusting requirement of

higher capacities

NEW GALAXY SEPARATORS

360 Degree Product Discharge

+ Higher through put possible

+ Less chances of clogging as oversize

comes out fast from the screen.

* Suitable for check screening application in

liquid — solid separation

+ Suitable for de-dusting requirement of

higher capacities

DUET SAY Oa AY Tiel t)

Tetra NEW GALAXY Separator

+ Designed to perform higher throughput in

Low Headroom Space.

+ Itcan be made available with 1 or 2 motor

design as per application requirements.

+ Feeding at rear end gives more retention

time for product on screen resulting in

better efficiency.

NEW GALAXY SEPARATORS:

Inline NEW GALAXY Separator

+ A Low Headroom Design Separator

for higher capacity & better efficiency.

+ Feeding Inlet and material discharge

Outlet in same centerline helps in

reduction of process time by reducing the

movements of products.

NEW GALAXY SEPARATORS:

Infrastructure - Plant

Quality Assured

sng ;

la

|

Ba. LI ail

NEW GALAXY SEPARATORS

Quality Assured

NEW GALAXY SEPARATORS

Installation Pictures

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5808)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (843)

- CNC 128Document18 pagesCNC 128Zikin Pieur100% (1)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- RB Model 2020Document37 pagesRB Model 2020Zikin PieurNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- S.O.P. Shinko RB4 & RB5 Model (Bahasa Indonesia)Document6 pagesS.O.P. Shinko RB4 & RB5 Model (Bahasa Indonesia)Zikin PieurNo ratings yet

- Standar Operasional Prosedure MESIN EMPTY BUNCH PRESS KH-777-15 Dan KH-777-8Document2 pagesStandar Operasional Prosedure MESIN EMPTY BUNCH PRESS KH-777-15 Dan KH-777-8Zikin Pieur100% (1)

- Brosur MGE Lubricants-1Document2 pagesBrosur MGE Lubricants-1Zikin PieurNo ratings yet

- Brosur MilleniumDocument23 pagesBrosur MilleniumZikin PieurNo ratings yet

- Brosur KriptoniumDocument2 pagesBrosur KriptoniumZikin PieurNo ratings yet

- Prosedur Ukur Debit Air Yg Melalui Water BasinDocument1 pageProsedur Ukur Debit Air Yg Melalui Water BasinZikin PieurNo ratings yet

- Prosedur Kalibrasi FlowmeterDocument1 pageProsedur Kalibrasi FlowmeterZikin Pieur100% (1)

- Prosedur Operasional DegasifierDocument1 pageProsedur Operasional DegasifierZikin Pieur100% (1)

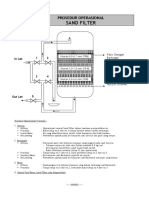

- Prosedur Operasional Sand FilterDocument1 pageProsedur Operasional Sand FilterZikin PieurNo ratings yet

- Jurnal KEPUASAN KONSUMEN PADA WARUNG TENDA AYAM BAKAR-GORENG (BAGOR) EYANG PROGO MENGGUNAKAN METODE KANO (STUDI KASUS WARUNG TENDA AYAM BAKAR-GORENG (BAGOR) EYANG PROGO) PDFDocument13 pagesJurnal KEPUASAN KONSUMEN PADA WARUNG TENDA AYAM BAKAR-GORENG (BAGOR) EYANG PROGO MENGGUNAKAN METODE KANO (STUDI KASUS WARUNG TENDA AYAM BAKAR-GORENG (BAGOR) EYANG PROGO) PDFZikin PieurNo ratings yet

- Surat Keterangan Sedang Penelitian UINDocument6 pagesSurat Keterangan Sedang Penelitian UINZikin PieurNo ratings yet

- LK Smart 31 Mar 11Document96 pagesLK Smart 31 Mar 11Zikin PieurNo ratings yet