Professional Documents

Culture Documents

High Performance VAM For District Cooling

Uploaded by

Dewanjee AshrafOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

High Performance VAM For District Cooling

Uploaded by

Dewanjee AshrafCopyright:

Available Formats

73

High-Performance Absorption Chiller for

District Heating and Cooling

Shuichi Matsushita*1 Ryo Fukushima* 1

Makoto Fujiwara * 2 Mikiharu Otake*2

An efficient absorption chiller for district heating and cooling was developed. This chiller is an epoch-making

chiller which was developed by full use of the state-of-the-art high performance technology of heat exchanger utilizing

CFD, and an efficient cycle. And it has reduced the rate of steam consumption by 10% of the conventional chiller, and

14% to 25% in installation space. Moreover, this absorption chiller is highly reliable in design, manufacturing, and

verification. It can contribute to the environmental preservation by efficient use of energy.

This paper summarizes the technology that has

1. Introduction been adopted in these high efficiency absorption chill-

The effective use of energy in measures to counter ers and describes their operation and verification of

global warming and address various energy problems their performance.

is a critical issue of human activity. At the same time,

the ever-greater desire for comfort in the living envi- 2. Development of 5000 USRt absorption chillers

ronment highlights the importance of air 2.1 General

conditioning. Accordingly, the demand for ever-more MHI has developed the largest capacity steam-

efficient air conditioners has become increasingly in- drive absorption chiller in the world, which has a

tense year after year. capacity of 5000 USRt (2500 USRt was previously

Absorption chillers are heat driven type air cool- the largest capacity absorption chiller in existence).

ers that can be driven by a low enthalpy heat source. The newly developed absorption chiller enhances ef-

They are the most suitable chillers for the effective ficiency by 10% in terms of the rate of steam

use of energy to generate cold using waste heat gen- consumption compared with that of conventional

erated from power generators or other facilities. The district heating and cooling units. The new absorp-

introduction of large-scale systems in urban areas, tion chiller was installed at the No.2 Plant of

where air conditioning loads are most concentrated, Minato Mirai 21 District Heating and Cooling Ser-

for district heating and cooling is becoming a com- vice Co., Ltd. in Yokohama City, and test operations

mon way to achieve efficient heating and cooling. were conducted for one year prior to commercial

Large-scale absorption chillers play a major role in operation.

district heating and cooling systems. In this regard, 2.

2.22 Specifications and features of the newly devel-

Mitsubishi Heavy Industries, Ltd. (MHI) has devel- oped absorption chiller

oped an epoch-making, high efficiency absorption Table1 shows a comparison of the specifications

chiller that makes full use of the state-of-the-art high between the newly developed chiller and a conven-

performance technology of heat exchangers utilizing tional chiller. The newly developed chiller is an

cutting edge computational fluid dynamics (CFD). absorption chiller that occupies 25% less space and

The absorption chiller thus developed has been op- consumes 10% less steam than a conventional

erating smoothly at the Minato Mirai 21 District chiller or a high-efficiency and space-saving absorp-

Heating and Cooling Service Co., Ltd. located in tion chiller.

Minato Mirai 21 District, Yokohama. It is the world’s

largest scale system of its type at 5000 USRt and

achieves a steam consumption rate that is 10% lower Newly Conventional

than that of conventional adsorption chillers used developed chiller

chiller

for district heating and cooling. In addition, MHI has Refrigeration capacity 5 000 USRt 2 500 USRt X 2 unit

also developed a new high efficiency MDUE Series Steam consumption

absorption chiller based on this technology. The

Rate of steam cansumption

MDUE Series provides epoch-making absorption

Chilled water temperature 13oC/ 6oC 13oC / 6oC

chillers that achieve 3.9 kg/h-USRt, representing a oC / 40oC

Cooling water temperature 32 32oC / 40oC

10% reduction in the rate of steam consumption com- Installation space 74.1 m2 98.1 m2

pared with conventional units.

*1 Air-Conditioning & Refrigeration Systems Headquarters Mitsubishi Heavy Industries, Ltd.

*2 Takasago Research & Development Center, Technical Headquarters Technical Review Vol.39 No.2 (Jun. 2002)

74

: Refrigeration capacity

6 000 : Rate of steam consumption 4.9

5 500 4.7

5 000 4.5

Refrigeration capacity (RT)

4 500 4.3

4 000 4.1

3 500 3.9

3 000 3.7

2 500 3.5

2 000 3.3

1 500 3.1

1 000 2.9

500 2.7

0 2.5

Aug. 3 Aug. 4 Aug. 7 Aug. 8 Aug. 9

Fig

Fig.. 1 shows an external view of the chiller, while

Tabl

ablee 2 shows the main features of the chiller, along with

the methods used to achieve each respective feature. In tion chiller, MHI carried out a simulation of the dy-

addition to the high-efficiency and space-savings pro- namic characteristics of the system. The dynamic

vided by the system, other features of the chiller include characteristics simulator that was adopted was pre-

improvements in efficiency under partial loads at which pared by modeling individual components by

ordinary chillers generally operate, shortened start-up concentrated approximation. The model was verified

and shut-down times, and improvements in follow-up with a small-scale chiller. Through the analyses car-

performance to load variations. ried out, it was confirmed that the start-up time could

2.

2.33 Component Development be shortened to 15 minutes by optimizing the concen-

2.3.1 Tests of absorber and evaporator components tration of the solution during the stop period.

A two-dimensional slice model was prepared to simu- 2.

2.44 Results of on-site test operation

late the evaporator and absorber, which was then used Verification tests carried out over a period of one

to evaluate and verify the performance of the evapora- year demonstrated that the chiller met designed per-

tor and absorber of the system. In an actual chiller, formance levels for both static characteristics, such

longitudinal temperature distributions exist that are as full and partial load performance, and dynamic

mainly caused by temperature variations in the chilled characteristics, such as start-up time. FigFig.. 2 shows

water and cooling water. The impact of these longitudi- the performance observed during the performance test

nal temperature distributions was evaluated in period. The tests demonstrated that the unit is ca-

component tests under varied temperature conditions pable of maintaining a sustained capacity of 5000

of chilled water and cooling water. In addition, an esti- USRt or more for a period of five days.

mation of the three-dimensional distribution and 2.

2.55 Summary

resulting impact was obtained using a CFD combined with MHI has developed an ultra-large and high effi-

a heat transfer model, which is described hereunder. ciency absorption chiller that has the world’s largest

2.3.

2.3.22 Simulation of dynamic characteristics single-unit capacity and that reduces the rate of steam

In developing the world’s largest capacity absorp- consumption by 10% from that of conventional dis-

Features Method for attaining features

Rate of steam consumption: Adoption of high performance heat transfer tubes for the evaporator

Improved and low-pressure generator.

efficiency (10% reduction from Adoption of high performance solution heat exchanger.

conventional level)

Reduction in power at partial loads through the adoption of an inverter.

Capacity of single unit: 5 000 USRt Minimizing steam pressure drop by optimizing the arrangement of

Size and

Reduction in installation space: heat transfer tubes in the absorber.

weight

(25% reduction from

reduction Adoption of two-stage cycle for the evaporator and absorber.

conventional level)

Improve- Control range: 10 to 100% Improvement in efficiency under low load conditions through

ments in half-unit operation.

operability Start-up time: 15 min Shortening start-up time through optimum concentration control while

stopping condition.

Mitsubishi Heavy Industries, Ltd.

Technical Review Vol.39 No.2 (Jun. 2002)

75

trict heating and cooling units. The newly developed

absorption chiller was shown to achieve designed per-

formance levels for both static characteristics, Developed chiller Conventional chiller

Refrigeration capacity 800 to 2 500 USRt

including rated and partial loads, and dynamic char-

Rate of steam consumption

acteristics through on-site operations.

Chilled water Inlet 13oC (15oC) 13oC

3. Development of MDUE Series temperature Outlet 6oC (5oC) 6 oC

Inlet 32oC 32oC

3.

3.11 Objective Cooling water

temperature Outlet 38oC 40oC

In 1993, MHI developed the MDA Series of absorp-

tion chillers for use in district heating and cooling

facilities and industrial plants. Seven years after the development was carried out assuming a large tem-

introduction of the MDA Series to the market, MHI perature variation with increased temperature

developed the MDUE Series, a new series of high per- differences of chilled water and cooling water between

formance, high reliability absorption chillers for use the inlet and outlet in order to reduce the power re-

in district heating and cooling as well as industrial quirements of the pumps for chilled water and cooling

plant service, based on the 5000 USRt absorption water. Tabl e 3 shows a comparison of the specifica-

able

chiller described above. tions between the newly developed chiller and a

.

(1) Reduction of operating costs

Steam consumption rate: 3.9 kg/h-USRt

conventional one. The chilled water was designed to

satisfy the two levels of temperature difference be-

(Comparison with prior con-ventional system: 10% t w e e n t h e i n l e t a n d o u t l e t o f 1 0 oC a n d 7 oC ,

.. increase in efficiency)

Reduction in auxiliary equipment power

respectively.

The results showed significant reductions in run-

Accommodation of specifications for large tem- ning costs. Based on calculations for a 1 500 USRt

perature differences between inlet and outlet of chiller, cost reductions amounting to about fifteen

chilled water and cooling water million yen per year can be expected, as shown in

.

(2) Improved reliability

Adoption of high performance extracting unit of

Fig

Fig.. 3 .

3.2.

3.2.3 3 Improvement of reliability

. non-condensible gas

Reduction in the number of welding sections

District heating and cooling systems need to be

used in such a way as to ensure a stable supply of

3.

3.22 Product Features chilled water to contract users. Accordingly, the de-

3.2.

3.2.11 High efficiency and space-savings velopment of the system necessitates consideration

District heating and cooling absorption chillers are being given to suitable means of preventing such prob-

expected to be highly efficient and occupy compact

installation spaces because they are designed in large

scale and are adopted by urban districts where large

demand exists. In this regard, the MDUE Series of

chillers is a high efficiency and space-saving series

of chillers that reduces the rate of steam consump-

tion by 10% and realizes an average space savings of

about 14% when installed. These notable achieve-

ments have been made possible by the application of

the high efficiency cycle and high performance tech-

nology of heat exchangers as described above.

3.2.

3.2.22 Reduction of running costs

Since the chillers for district heating and cooling

as well as for industrial plant service are operated

for long hours each year, they significantly contrib-

ute to a reduction in running costs for users not only

by achieving reductions in the rate of fuel consump-

tion, but also by reducing the need for power from

auxiliary units.

In developing the new absorption chiller, the de-

sign focused on reducing the power of the pumps used

to circulate fluids and refrigerant, as well as on re-

ducing the fuel consumption rate. Furthermore,

Mitsubishi Heavy Industries, Ltd.

Technical Review Vol.39 No.2 (Jun. 2002)

76

Low concentration Low High

concentration concentration

Pressure

High concentration Cooling water

Wide concentration range

temperature

Narrow concen-

Pressure

Large

tration range temperature

difference Second stage

absorption

Improvement

of absorption

B

performance

Improvement A

of regeneration

performance First stage absorption

Small temperature difference

High-efficiency cycle

Conventional cycle Temperature

Temperatue

levels for each. Thus the lowest temperature of the

lems as equipment failures and degradation of per- fluid solution was increased from A to B at the same

formance, and how best to enhance equipment concentration level, and the temperature difference

reliability ever further as the system is directly con- between the fluid solution and the cooling water

nected with production lines. was increased in order to improve heat transfer

With regard to this point, the newly developed capability.

chiller employs a high performance extracting unit (3) Cooling water branch cycle

of non-condensible gas and reduces the number of As illustrated in Fig Fig.. 6 , the flow of cooling water

welded sections in pipe to improve the reliability of through the absorber was branched to the low-pres-

hermetic sealing, thereby preventing any degradation sure side of the absorber and to the condenser, thus

in performance or the occurrence of corrosion in the optimizing the relation between the inside heat trans-

equipment caused by insufficient hermetic sealing. In fer performance of the absorber and the condenser

addition, filter units have been added to each solu- tube and the pressure drop so as to improve overall

tion system and refrigerant system in order to prevent performance.

performance degradation triggered by the occurrence 3.3.

3.3.22 Improvement of performance of heat exchangers

of fouling on the surface of the heat transfer tubes. (1) Adoption of high performance heat transfer tubes

3.

3.33 Technologies and techniques applied High performance trapezoidal acicular fin tubes

Technologies to increase cycle efficiency and en- w e r e e m p l o y e d i n t h e a b s o r b e r, w h i l e h i g h

hance the performance of the heat exchangers were performance acicular fin tubes were employed in

applied to achieve the increased performance levels the evaporator in order to improve heat transfer

and space-savings of the chiller. performance.

3.3.

3.3.11 Technology to increase cycle efficiency (2) Adoption of high performance tube bundle

(1) Absorption cycle of low circulation rate and wide arrangement

concentration range of solution In order to improve the performance of absorber

As shown in F i g . 4 , a cycle that widens the and evaporator, CFD was applied to optimize the

concentration range was achieved by improving the tube arrangement pattern. The impact of steam

absorption performance and regeneration flow in evaporator and absorber was simulated

performance of the system. This made it possible using analytical codes taking into account the heat

to reduce the circulation rate of the fluid solution, and mass transfer phenomena in the absorber.

and to reduce in heat loss in individual fluid Using the subsequently derived codes, the impact

solution heat exchangers along with improvements of flow distributions in the absorber and the

in the performance of these heat exchangers. evaporator was evaluated. Fig Fig.. 7 shows an example

(2) Two-stage absorption and two-stage evaporation results of this analysis.

cycle 3.3.

3.3.33 Realization of high reliability

As seen in F i g . 5 , each of the absorbers and The verified simulation techniques of heat trans-

evaporators were divided to two sections, and fer, flow distribution, structure, and others were

absorption was conducted at different pressure applied to evaluate the impact of flow distribution

Mitsubishi Heavy Industries, Ltd.

Technical Review Vol.39 No.2 (Jun. 2002)

77

High-temperature

High-pressure heat exchanger Low-pressure

regenerator Condensor

regenerator

Steam

Heat

recovery

unit

Low-temperature

heat exchanger 2

Low-temperature

drain heat

recovery unit 1st stage 1st stage

Low-temperature of of

heat exchanger 1 absorber evaporator

Cooling water

2nd stage 2nd stage

of of

absorber Chilled

evaporator water

Cooling water

P1 Microcomputer

control board Evaporator Absorber

7.0

7.2

Condensor

7.5

7.7

Low-pressure

7.9 generator

8.1

8.4

8.6

High-pressure

generator

inside the heat exchanger as well as to evaluate struc-

tural strength, which becomes significant in large

systems, thereby attaining the high reliability of the

equipment.

(1) Heat transfer and flow analyses sections, in order to confirm that the stress levels

The internal flow conditions in each heat at each section were within the design range,

exchanger in the absorption chiller were estimated thereby verifying reliability.

quantitatively using the above-described analytical 3.4 Verification of performance

codes. This made it possible to achieve reliability As part of development, a prototype 1 000 USRt

of the equipment by optimizing of the extracting chiller was fabricated for testing as a means of con-

location of non-condensible gas in the tube bundle, ducting a final verification of the planning and design

reducing pressure drops across the tube bundle, stages. Verification was conducted on the chiller fo-

and by preventing carry-over. cusing on system performance, controllability, and

(2) Flow analysis extracting performance of non-condensible gas. Once

A cyclone gas-liquid separator located at verification of the reliability of the system had been

solution inlet of low-pressure generator was completed, sale of the chiller began from April 2001.

designed in order to realize a compact low-pressure The first order received was for a 2500 USRt chiller,

generator. The performance of the separator was which was delivered to the customer in October 2001

confirmed using flow analysis prior to installation after performance and verification tests were con-

of the system. ducted. Fig

Fig.. 8 shows the external appearance of the

(3) Structural strength analysis 2500 USRt chiller. Tabl e 4 shows the results of the

able

Structural analysis was carried out on performance and verification tests carried out on the

individual structural members, including shell 2500 USRt chiller. The refrigeration capacity satis-

Mitsubishi Heavy Industries, Ltd.

Technical Review Vol.39 No.2 (Jun. 2002)

78

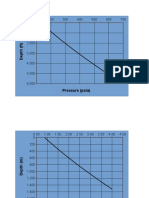

Table 4 The performance test result of MDUE 2500 USRt model chiller 120

Specified Observed

value value

100

Refrigeration capacity 2 500 2 505 2 503

Steam consumption (%)

Partial load characteristics on

Rate of steam consumption 3.9 3.80 3.74 conventional system

80

Steam consumption 9 750 9 530 9 360

Chilled water inlet temperature 14 14.0 14.1 60

Chilled water outlet temperature 6 6.0 6.1

Chilled water flow rate 945 947 952 40

: Data of MDUE 2 500 USRt system

Cooling water inlet temperature 32 32.0 31.9

Cooling water outlet temperature 40 39.9 39.8 20

Cooling water flow rate 1 680 1 682 1 680

0 20 40 60 80 100 120

fied the specified 2500 USRt, and proved to give a Refrigeration capacity (%)

steam consumption rate of 3.74 to 3.80 kg/h-USRt,

which is 2.5 to 4.0% lower than the specified value of

3.9 kg/h-USRt. As can be seen in FigFig.. 9 , the chiller

also performed quite favorably under partial load con-

ditions, as well. In addition, performance and efficiency absorption cycle and techniques for improv-

verification tests were conducted on a commercially ing the performance of heat exchangers using CFD.

delivered 1 000 USRt chiller, which was the same type The chiller was developed on the basis of detailed

as the above prototype, in order to prove the steam plans and sufficient component tests during the de-

consumption rate was lower than the specified level velopment stage and through full-scale verification

of 3.80 kg/h-USRt. at the manufacturing plant. Practical applications of

As described above, confirmation of the perfor- the chiller allows the district heating and cooling sys-

mance of the MDUE Series was carried out on a 1000 tem to enjoy increased efficiency, while reducing

USRt chiller and 2500 USRt chiller which proved operating costs and installation space. This, in turn,

the adaptability of the basic plan and design further leads to the effective use of energy, which con-

method. tributes to measures that help to address the issue of

global warming.

4. Conclusion It is expected that this kind of highly energy effi-

The high efficiency and large scale absorption cient chiller will come to find ever-greater application

chiller developed for use in district heating and cool- over a wide range, and thus play a special part in

ing and described in this paper is an epoch-making contributing to conservation of the global environ-

chiller that fully utilizes the most advanced technolo- ment. MHI will continue to develop chillers of

gies and techniques, such as the technology of high ever-higher efficiency.

Mitsubishi Heavy Industries, Ltd.

Technical Review Vol.39 No.2 (Jun. 2002)

You might also like

- Ejectors for Efficient Refrigeration: Design, Applications and Computational Fluid DynamicsFrom EverandEjectors for Efficient Refrigeration: Design, Applications and Computational Fluid DynamicsNo ratings yet

- Toward Net Zero Energy Building: Ir - Kafiuddin, MTDocument35 pagesToward Net Zero Energy Building: Ir - Kafiuddin, MTsigit ekoNo ratings yet

- FXVQ-NTL (Edmt391613) (En)Document60 pagesFXVQ-NTL (Edmt391613) (En)Arthur OliveiraNo ratings yet

- Design & Analysis of Radiator: M.DhanunjaiahDocument8 pagesDesign & Analysis of Radiator: M.DhanunjaiahvinodNo ratings yet

- A Review Paper On Gas Turbine Blade Cooling MethodsDocument6 pagesA Review Paper On Gas Turbine Blade Cooling MethodsEditor IJTSRDNo ratings yet

- Technical Manual For Air-Cooled Rooftop Package - (FDXA04-2020,21B)Document32 pagesTechnical Manual For Air-Cooled Rooftop Package - (FDXA04-2020,21B)yusuf mohd sallehNo ratings yet

- Applied Sciences: New Developments and Progress in Absorption Chillers For Solar Cooling ApplicationsDocument35 pagesApplied Sciences: New Developments and Progress in Absorption Chillers For Solar Cooling ApplicationsHuilber MartínezNo ratings yet

- Aicool XB - SeriesDocument9 pagesAicool XB - Seriessarjono100% (1)

- Commercial Operation of 600 MW UnitDocument5 pagesCommercial Operation of 600 MW Unitwaleed emaraNo ratings yet

- Water-Cooled-Split-Unit-FM4-Series-Water-Cooled-Packaged-Unit-CHF4-Series-R410A - HadiDocument48 pagesWater-Cooled-Split-Unit-FM4-Series-Water-Cooled-Packaged-Unit-CHF4-Series-R410A - HadiHasrul RosliNo ratings yet

- DW Success StoryDocument2 pagesDW Success StorySallyNo ratings yet

- Installation of Condenser for Steam Turbine by Large Block Construction: A Case Study of Hokuriku Electric Power Company’s Shika Nuclear Power Station Unit 2Document6 pagesInstallation of Condenser for Steam Turbine by Large Block Construction: A Case Study of Hokuriku Electric Power Company’s Shika Nuclear Power Station Unit 2selviraNo ratings yet

- Precision Chilled Water SolutionsDocument6 pagesPrecision Chilled Water SolutionsYanuar Eka RadityaNo ratings yet

- Hitachi Boiler PDFDocument5 pagesHitachi Boiler PDFRichard Andrianjaka LuckyNo ratings yet

- Cryostar Lo CDocument16 pagesCryostar Lo CNarayan MarndiNo ratings yet

- عرض تقديم عن بعض مشاكل التصميم الخاصه بالمستشفيات مع التطبيق علي بعض مستشفياتDocument35 pagesعرض تقديم عن بعض مشاكل التصميم الخاصه بالمستشفيات مع التطبيق علي بعض مستشفياتmohammad.haidaryNo ratings yet

- Super Multi Catalogue PDFDocument36 pagesSuper Multi Catalogue PDFWai Lwin KoNo ratings yet

- KoppelDocument2 pagesKoppelLeomark RespondeNo ratings yet

- 38LB - catalog แคเรียDocument2 pages38LB - catalog แคเรียPiyawat JirateanthumNo ratings yet

- Water ChillerDocument3 pagesWater Chillermohsen_267No ratings yet

- Hydrofixx Prospekt Eng 2011-12-29Document12 pagesHydrofixx Prospekt Eng 2011-12-29Istvan MadacsyNo ratings yet

- Capacity Improvement of Reactor Charge HeaterDocument7 pagesCapacity Improvement of Reactor Charge HeaterArash AbbasiNo ratings yet

- Chiller Vs VRF Comparison: October 2020Document7 pagesChiller Vs VRF Comparison: October 2020HR UAENo ratings yet

- Yokota MhiDocument35 pagesYokota MhiElliott Russell100% (1)

- Crafft Smart Air ConditionerDocument2 pagesCrafft Smart Air ConditionerMohanad ElgayarNo ratings yet

- York ManualDocument52 pagesYork ManualDenis TirtayasaNo ratings yet

- Aquaedge 19Xr Two-Stage Centrifugal Chiller: High Efficiency Two-Stage Compression 600 To 3,400 Tons / 2,110 To 11,957 KWDocument4 pagesAquaedge 19Xr Two-Stage Centrifugal Chiller: High Efficiency Two-Stage Compression 600 To 3,400 Tons / 2,110 To 11,957 KWLeonardo SilveiraNo ratings yet

- 000-All MHI Folleto #HB91-06P003E-1-A-0 - VRF KX4-60hz #ABR2007-2BRDocument58 pages000-All MHI Folleto #HB91-06P003E-1-A-0 - VRF KX4-60hz #ABR2007-2BRJC FinNo ratings yet

- Robatherm EcoDry EngDocument8 pagesRobatherm EcoDry Engcandra ramadhanNo ratings yet

- Daikin FXM-LVE - IMDocument32 pagesDaikin FXM-LVE - IMmr dangNo ratings yet

- Heat Pumps Co2Document8 pagesHeat Pumps Co2Domagoj VulinNo ratings yet

- TEKQ0882-00 Fan Arrangements For CAT 785CDocument6 pagesTEKQ0882-00 Fan Arrangements For CAT 785C----No ratings yet

- Chiller 160 73-Eg1 Yk Tech DataDocument80 pagesChiller 160 73-Eg1 Yk Tech DataMIGUEL ANGEL SALAZAR VALLEJONo ratings yet

- PSD 16DJ - 11 82Document32 pagesPSD 16DJ - 11 82Muhammad azeemNo ratings yet

- Air Cooled Packaged Air Conditioner R410A RefrigerantDocument12 pagesAir Cooled Packaged Air Conditioner R410A RefrigerantArmanNo ratings yet

- Starlette Plus: The Small Range of Refrigeration DryersDocument4 pagesStarlette Plus: The Small Range of Refrigeration DryersJas SumNo ratings yet

- Ceiling Cassette Chilled Water Fan Coil Unit - Koppel PDFDocument2 pagesCeiling Cassette Chilled Water Fan Coil Unit - Koppel PDFatramanathanNo ratings yet

- heatsinkDocument5 pagesheatsinkpranav2131No ratings yet

- DAIKIN PCV0915 (VRVIII) CATALOG Selection MalaysiaDocument72 pagesDAIKIN PCV0915 (VRVIII) CATALOG Selection MalaysiaAminul HassanNo ratings yet

- 08PP134 PDFDocument5 pages08PP134 PDFkasreedharNo ratings yet

- Chiller Performance Limitations: District Cooling GuideDocument1 pageChiller Performance Limitations: District Cooling GuideQdlm KnocNo ratings yet

- Daikin VRV IIIDocument72 pagesDaikin VRV IIIsythuc_dt50No ratings yet

- Development of Large-Capacity Indirect Hydrogen-Cooled Turbine Generator and Latest Technologies Applied To After Sales ServiceDocument7 pagesDevelopment of Large-Capacity Indirect Hydrogen-Cooled Turbine Generator and Latest Technologies Applied To After Sales Service권용수No ratings yet

- Improve Chiller Efficiency With a Holistic ApproachDocument3 pagesImprove Chiller Efficiency With a Holistic ApproachAjay BromaNo ratings yet

- Design and Development of Solar Powered 360degree Automatic Air CoolerDocument6 pagesDesign and Development of Solar Powered 360degree Automatic Air CoolerIJRASETPublicationsNo ratings yet

- Mitsubishi Catalogue - Packaged Unit PDFDocument8 pagesMitsubishi Catalogue - Packaged Unit PDFmurugesan100% (1)

- Modeling of Automotive Radiator by Varying Structure of Fin and CoolantDocument8 pagesModeling of Automotive Radiator by Varying Structure of Fin and CoolantAyush punjNo ratings yet

- Chiller TerminologiesDocument4 pagesChiller Terminologiesmuhammad ahmadNo ratings yet

- Advanced Heat Recovery: Source: HVAC Pump HandbookDocument12 pagesAdvanced Heat Recovery: Source: HVAC Pump HandbookDaring CodybillyNo ratings yet

- Optyma™ Slim Pack Just Mount, Connect Piping and Plug: CatalogueDocument36 pagesOptyma™ Slim Pack Just Mount, Connect Piping and Plug: CatalogueCarlos MarroNo ratings yet

- Koppel Ceiling SuspendedDocument2 pagesKoppel Ceiling SuspendedLeomark RespondeNo ratings yet

- Air Condition Refrigeration Installation RepairDocument6 pagesAir Condition Refrigeration Installation RepairshsggNo ratings yet

- USHYBRITEC HybritecComboDryer 08-2011 67-37009Document8 pagesUSHYBRITEC HybritecComboDryer 08-2011 67-37009Adan Serrano CaroNo ratings yet

- Chiller VS VRFDocument7 pagesChiller VS VRFridNo ratings yet

- Cassette Cool Only / Heat Pump 10 SEER R22Document2 pagesCassette Cool Only / Heat Pump 10 SEER R22bram samyNo ratings yet

- Optyma™ Slim Pack Just Mount, Connect Piping and Plug: CatalogueDocument30 pagesOptyma™ Slim Pack Just Mount, Connect Piping and Plug: CatalogueKPM BUVANNo ratings yet

- ERV-500 IC Energy Recovery VentilatorDocument3 pagesERV-500 IC Energy Recovery VentilatorDewanjee AshrafNo ratings yet

- Select An Actuator - DamperDocument1 pageSelect An Actuator - DamperDewanjee AshrafNo ratings yet

- ARANER International Seminar On Cooling Energy StorageDocument66 pagesARANER International Seminar On Cooling Energy StorageDewanjee AshrafNo ratings yet

- Global Steel Plant Tracker March 2022Document420 pagesGlobal Steel Plant Tracker March 2022Dewanjee AshrafNo ratings yet

- Guide To A Walking Hajj - FlipHTML5 PDFDocument63 pagesGuide To A Walking Hajj - FlipHTML5 PDFDewanjee AshrafNo ratings yet

- Some Aspects of Estimating Geometric Characteristics of Screw ComDocument11 pagesSome Aspects of Estimating Geometric Characteristics of Screw ComDewanjee AshrafNo ratings yet

- Options in Gas Turbine Power Augmentation Using Inlet Air ChillingDocument10 pagesOptions in Gas Turbine Power Augmentation Using Inlet Air ChillingDewanjee AshrafNo ratings yet

- Amtrol HandbookDocument112 pagesAmtrol HandbookKokchuan WangNo ratings yet

- WHP Reference-Guide FINALDocument24 pagesWHP Reference-Guide FINALDewanjee AshrafNo ratings yet

- A Review of Absorption RefrigerationDocument30 pagesA Review of Absorption RefrigerationSoni Rodríguez Castellanos100% (1)

- SDH Technology - Slide PackDocument21 pagesSDH Technology - Slide PackDewanjee AshrafNo ratings yet

- The Condition Monitoring of An Upstream Oil and Gas Dry Screw ComDocument11 pagesThe Condition Monitoring of An Upstream Oil and Gas Dry Screw ComDewanjee AshrafNo ratings yet

- Yr SGDocument8 pagesYr SGDewanjee AshrafNo ratings yet

- 886 - Hajj Preparation Week 4Document25 pages886 - Hajj Preparation Week 4Dewanjee AshrafNo ratings yet

- Isoflow Absorption Chillers With Buffalo Pumps: Installation InstructionsDocument44 pagesIsoflow Absorption Chillers With Buffalo Pumps: Installation InstructionsDewanjee AshrafNo ratings yet

- Surge Detection and Surge Control Systems For Centrifugal Compressors - Part 2Document3 pagesSurge Detection and Surge Control Systems For Centrifugal Compressors - Part 2Dewanjee AshrafNo ratings yet

- Carrier Sanyo 16NK IOMDocument193 pagesCarrier Sanyo 16NK IOMDewanjee AshrafNo ratings yet

- Product Drawing M E: Performance SpecificationsDocument20 pagesProduct Drawing M E: Performance SpecificationsDewanjee AshrafNo ratings yet

- Why absorption chillers fail: Air leaks and improper chemistryDocument9 pagesWhy absorption chillers fail: Air leaks and improper chemistryDewanjee AshrafNo ratings yet

- YR ModA-EG1Document40 pagesYR ModA-EG1Dewanjee AshrafNo ratings yet

- Maintaining VAMs - ASHRAEDocument8 pagesMaintaining VAMs - ASHRAEDewanjee AshrafNo ratings yet

- Model Yr TB TB T0 Thru Yr VD VD T1 Style A 200 THRU 300 TONS (525 THRU 880 KW)Document20 pagesModel Yr TB TB T0 Thru Yr VD VD T1 Style A 200 THRU 300 TONS (525 THRU 880 KW)Dewanjee AshrafNo ratings yet

- 600TR VAPOR ABSORPTION CHILLER SPECDocument36 pages600TR VAPOR ABSORPTION CHILLER SPECaleemhakNo ratings yet

- Yr-Sss Point ListDocument4 pagesYr-Sss Point ListDewanjee AshrafNo ratings yet

- Liquid Cooled Solid State Starter: OperationDocument28 pagesLiquid Cooled Solid State Starter: OperationDewanjee AshrafNo ratings yet

- YR Chiller Point ListDocument4 pagesYR Chiller Point ListDewanjee AshrafNo ratings yet

- Oil Injected Rotary Screw Compressors With Direct Transmission, Fixed or Variable SpeedDocument12 pagesOil Injected Rotary Screw Compressors With Direct Transmission, Fixed or Variable SpeedDewanjee AshrafNo ratings yet

- Product Drawing M E: Performance SpecificationsDocument20 pagesProduct Drawing M E: Performance SpecificationsDewanjee AshrafNo ratings yet

- Model Yr TB TB T0 Thru Yr VD VD T1 Style A 200 THRU 300 TONS (525 THRU 880 KW)Document20 pagesModel Yr TB TB T0 Thru Yr VD VD T1 Style A 200 THRU 300 TONS (525 THRU 880 KW)Dewanjee AshrafNo ratings yet

- Welding of Steel PipingDocument8 pagesWelding of Steel PipingElias EliasNo ratings yet

- Lec 40Document33 pagesLec 40khaledaj1977No ratings yet

- Investigation of The Effect of Different Cleaning Forces On Ce-O-Si Bonding During Oxide Post-CMP CleaningDocument12 pagesInvestigation of The Effect of Different Cleaning Forces On Ce-O-Si Bonding During Oxide Post-CMP CleaningAverage JoeNo ratings yet

- SuperconductorsDocument11 pagesSuperconductorspranavabaascaran100% (1)

- Optical Properties of Two-Dimensional GaS and GaSe Monolayers (2018)Document26 pagesOptical Properties of Two-Dimensional GaS and GaSe Monolayers (2018)cuong nguyen quangNo ratings yet

- TP2Document2 pagesTP2Manu BharatamNo ratings yet

- Rupture Disk - Application and InspectionDocument33 pagesRupture Disk - Application and InspectionLudi D. LunarNo ratings yet

- Adam Fuss-2Document14 pagesAdam Fuss-2api-385683587No ratings yet

- Essay - Seli AnrianaDocument2 pagesEssay - Seli AnrianaShely AndhrianyNo ratings yet

- SSC JE Mechanical Syllabus and Exam Pattern PDFDocument15 pagesSSC JE Mechanical Syllabus and Exam Pattern PDFSajid AnsariNo ratings yet

- At 2402 - Vehicle Dynamics - Question Bank: Unit I: Introduction To Degree of Freedom Two Mark QuestionDocument13 pagesAt 2402 - Vehicle Dynamics - Question Bank: Unit I: Introduction To Degree of Freedom Two Mark QuestionCody LeeNo ratings yet

- Case Studies in Superconducting Magnets-Y.iwasaDocument717 pagesCase Studies in Superconducting Magnets-Y.iwasaArjun GarvaNo ratings yet

- KLM Restriction Orifice Plate ProgramDocument37 pagesKLM Restriction Orifice Plate ProgramSiddharth BhattacharjeeNo ratings yet

- Sheet Metal FormingDocument13 pagesSheet Metal FormingjotikaNo ratings yet

- De-Icing Anti Icing Program ManualDocument155 pagesDe-Icing Anti Icing Program ManualSon NguyenNo ratings yet

- 1725 UV-Vis GlossaryDocument16 pages1725 UV-Vis GlossaryEdi RismawanNo ratings yet

- Lesson PlanDocument4 pagesLesson PlanNagamani RajeshNo ratings yet

- Gas Lift Valve SpacingDocument23 pagesGas Lift Valve SpacingLuis Carlos SaavedraNo ratings yet

- Science 10 - Lesson 1.3Document15 pagesScience 10 - Lesson 1.3Alfredo L. CariasoNo ratings yet

- XRF FlourescenceDocument5 pagesXRF Flourescencedesireeh2009No ratings yet

- Pipe DimensionsDocument11 pagesPipe DimensionsmnsNo ratings yet

- Birth of Quantum MechanicsDocument25 pagesBirth of Quantum MechanicsTejas DeshmukhNo ratings yet

- GR9677 SolutionsDocument132 pagesGR9677 SolutionsDavid Latchman0% (1)

- Iare Ttps LNDocument100 pagesIare Ttps LNVirat DesaiNo ratings yet

- 4thweek Molebal BatchdataDocument48 pages4thweek Molebal BatchdataEmine SöylemezNo ratings yet

- Open Cooling Tower Design ConsiderationsDocument5 pagesOpen Cooling Tower Design ConsiderationsvictorvikramNo ratings yet

- 251Document14 pages251Menchie LabadanNo ratings yet

- ICGSE Physic PaperDocument64 pagesICGSE Physic PaperTheint TheintNo ratings yet

- Assessment of Man's Thermal Comfort - Fanger 1973Document12 pagesAssessment of Man's Thermal Comfort - Fanger 1973haniskamis82No ratings yet

- Electromagnetic Induction - Formula SheetDocument4 pagesElectromagnetic Induction - Formula Sheetraahimb6No ratings yet

- Einstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseFrom EverandEinstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseRating: 4.5 out of 5 stars4.5/5 (51)

- Waves and Beaches: The Powerful Dynamics of Sea and CoastFrom EverandWaves and Beaches: The Powerful Dynamics of Sea and CoastRating: 4 out of 5 stars4/5 (1)

- The Laws of Thermodynamics: A Very Short IntroductionFrom EverandThe Laws of Thermodynamics: A Very Short IntroductionRating: 4.5 out of 5 stars4.5/5 (10)

- Hyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionFrom EverandHyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionRating: 4.5 out of 5 stars4.5/5 (3)

- CATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchFrom EverandCATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchRating: 4 out of 5 stars4/5 (10)

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationFrom EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationRating: 4 out of 5 stars4/5 (18)

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedFrom EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedRating: 5 out of 5 stars5/5 (1)

- Handbook of Mechanical and Materials EngineeringFrom EverandHandbook of Mechanical and Materials EngineeringRating: 5 out of 5 stars5/5 (4)

- Marine and Offshore Pumping and Piping SystemsFrom EverandMarine and Offshore Pumping and Piping SystemsRating: 4.5 out of 5 stars4.5/5 (2)

- Advanced Computer-Aided Fixture DesignFrom EverandAdvanced Computer-Aided Fixture DesignRating: 5 out of 5 stars5/5 (1)

- Audio IC Circuits Manual: Newnes Circuits Manual SeriesFrom EverandAudio IC Circuits Manual: Newnes Circuits Manual SeriesRating: 5 out of 5 stars5/5 (1)

- A Quick Guide to API 653 Certified Storage Tank Inspector Syllabus: Example Questions and Worked AnswersFrom EverandA Quick Guide to API 653 Certified Storage Tank Inspector Syllabus: Example Questions and Worked AnswersRating: 3.5 out of 5 stars3.5/5 (19)

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisFrom EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisRating: 4 out of 5 stars4/5 (2)

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AFrom EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ANo ratings yet