Professional Documents

Culture Documents

EUBP BP Energy Recovery

Uploaded by

Donato GalloOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

EUBP BP Energy Recovery

Uploaded by

Donato GalloCopyright:

Available Formats

FACT

European Bioplastics e.V. Marienstr. 19/20 10117 Berlin

SHEET European Bioplastics e.V.

APR 2015

Marienstr. 19/20, 10117 Berlin

phone +49.30.28 48 23 50

fax +49.30.28 48 23 59

e-mail info@european-bioplastics.org

web www.european-bioplastics.org

ENERGY RECOVERY

VR 19997 Nz, Amtsgericht Charlottenburg, USt-IdNr. DE235874231

HypoVereinsbank Rosenheim, BLZ 711 200 77, Konto 6356800, IBAN DE26 7112 0077 0006 3568 00, BIC/SWIFT HYVEDEMM448

FACT

SHEET

INDEX APR 2015

European Bioplastics e.V. Marienstr. 19/20 10117 Berlin European Bioplastics e.V.

Marienstr. 19/20, 10117 Berlin

phone +49.30.28 48 23 50

1. DESCRIPTION OF TECHNOLOGY fax +49.30.28 48 23 59

e-mail info@european-bioplastics.org

2. CURRENT DISTRIBUTION web www.european-bioplastics.org

3. LEGAL AND POLITICAL FRAMEWORK

3.1 Landfill Directive

3.2 Waste incineration Directive

3.3 Waste Framework Directive

3.4 Packaging and Packaging Waste Directive

3.5 Review of waste policy and legislation

4. STANDARDS, CERTIFICATION AND LABELLING

5. INTERACTIONS BETWEEN BIOPLASTICS AND ENERGY RECOVERY

6. BENEFITS AND CHALLENGES

6.1 Benefits

6.2 Challenges

7. REFERENCES

VR 19997 Nz, Amtsgericht Charlottenburg, USt-IdNr. DE235874231

HypoVereinsbank Rosenheim, BLZ 711 200 77, Konto 6356800, IBAN DE26 7112 0077 0006 3568 00, BIC/SWIFT HYVEDEMM448

2

FACT

SHEET

APR 2015

European Bioplastics e.V. Marienstr. 19/20 10117 Berlin European Bioplastics e.V.

Marienstr. 19/20, 10117 Berlin

1. DESCRIPTION OF TECHNOLOGY phone +49.30.28 48 23 50

fax +49.30.28 48 23 59

Energy recovery from waste means the conversion of (non-recyclable) waste Afterwards, it is convertede-mail info@european-bioplastics.org

to a transportable form of energy, e.g. electricity,

web www.european-bioplastics.org

into usable heat, electricity, or fuel through a variety of processes, including heat, or fuels. In a further step, the emissions are cleaned-up to ensure

combustion, gasification, pyrolization, anaerobic digestion, and landfill gas waste gases are safe. The incineration produces also solid outputs in a

recovery. The most common thermal treatment is incineration; less common magnitude of around 30 percent of the input stream's weight. In many cases,

is the so-called advanced thermal treatment (ATT) implying technologies the incinerator bottom ash is further treated in order to extract ferrous and

such as gasification or pyrolysis. non-ferrous metals, such as aluminium, copper, zinc and lead. The remaining

bottom ash can be re-used by aggregate recyclers or in road construction.

The incineration of municipal solid waste (MSW) is a technology to treat

waste while both exploiting the energy content of the material and reducing Refuse derived fuels (also called solid recovered fuels) constitute a specific

the amount of solid material to be landfilled. Waste incineration plants can case of energy recovery in so far as the input materials are pre-processed.

be used to produce electricity, steam and heating. Waste can also be used These fuels are treated to assure that they show defined characteristics,

as fuel in certain industrial processes. The technology is also called thermal like physical properties (e. g. particle size, bulk density, heating value and

recovery or incineration with energy reclamation. Accordingly, such waste moisture) and a certain chemical composition (e. g. content of chlorine and

treatment schemes are also called Energy from Waste (EfW) or Waste to heavy metals). The solid recovered fuels are used in incinerators that can treat

Energy (WtE). high calorific input materials. The material can be used for co-incineration

in MSW incineration or cement kilns.

Two main types of EfW systems can be distinguished: mass burn or

refuse-derived fuel systems. In the first case, the input material is unsor- The energy efficiency of energy recovery installations for MSW can be

ted municipal solid waste burned without any pre-treatment, while in the distinguished in electrical and thermal efficiency. A number of plants are

latter case, the input stream is the result of a sorting process and has a producing electricity or heat only. Others combine heat and electricity pro-

defined quality. The basic steps are similar in all energy from waste plants. duction, these are so-called combined heat and power plants.

The thermal treatment essentially releases the energy from the waste.

2. CURRENT DISTRIBUTION

Energy recovery of MSW is a widespread technology in Europe. There is for post-consumer plastics waste in Europe. The installed capacity can be

an inverse correlation to the landfilling practice in the single European expected to grow significantly, especially in those countries that seek rapid

countries. Countries with high level of landfill typically have few incineration exit from landfilling. Eastern and Southern Europe will be the main drivers

capacities and vice versa. Figure 1 shows the waste management routes in this development.

VR 19997 Nz, Amtsgericht Charlottenburg, USt-IdNr. DE235874231

HypoVereinsbank Rosenheim, BLZ 711 200 77, Konto 6356800, IBAN DE26 7112 0077 0006 3568 00, BIC/SWIFT HYVEDEMM448

3

FACT

SHEET

APR 2015

European Bioplastics e.V. Marienstr. 19/20 10117 Berlin European Bioplastics e.V.

Marienstr. 19/20, 10117 Berlin

Switzerland

phone +49.30.28 48 23 50

fax +49.30.28 48 23 59

Countries with landfill ban

Germany

Austria e-mail info@european-bioplastics.org

Luxembourg web www.european-bioplastics.org

Belgium

Denmark

Sweden

Netherlands

Norway

Finland

France

Estonia

Ireland

Slovakia

Italy

Slovenia

Czech Republic

Portugal

Spain

Hungary

Poland

Romania

United Kingdom

Latvia

Bulgaria

Greece

Lithuania

Cyprus

Malta

10% 20% 30% 40% 50% 60% 70% 80% 90% 100%

Recycling rate Energy recovery rate Disposal rate

FIGURE 1 SHOWS THE WASTE MANAGEMENT ROUTES FOR POST-CONSUMER PLASTICS WASTE AROUND EUROPE (EU 27 + CH / NO IN 2012). COUNTRIES WITH

LANDFILL BAN HAVE MORE THAN 90 PERCENT RECOVERY, I.E. BOTH MATERIAL RECOVERY (=RECYCLING) AND ENERGY RECOVERY. IT DEMONSTRATES FURTHER THAT

COUNTRIES WITH ESTABLISHED ENERGY RECOVERY PERFORM WELL IN RECYCLING.

3. LEGAL AND POLITICAL FRAMEWORK

3.1 Landfill Directive

The EU Directive 1999/31/EC on the landfill of waste foresees that "only enhance recovery". This directive gives a strong push towards any option

waste that has been subject to treatment is landfilled." In this context, for recycling and recovery. The Commission proposal from July 2014 (see

the treatment is defined as "the physical, thermal, chemical or biological 3.5 below) aims at phasing out landfilling by 2025 for recyclable waste

processes, including sorting, that change the characteristics of the waste (including plastics, paper, metals, glass and bio-waste) in non-hazardous

in order to reduce its volume or hazardous nature, facilitate its handling or waste landfills, corresponding to a maximum landfilling rate of 25 percent.

VR 19997 Nz, Amtsgericht Charlottenburg, USt-IdNr. DE235874231

HypoVereinsbank Rosenheim, BLZ 711 200 77, Konto 6356800, IBAN DE26 7112 0077 0006 3568 00, BIC/SWIFT HYVEDEMM448

4

1

FACT

SHEET

APR 2015

European Bioplastics e.V. Marienstr. 19/20 10117 Berlin European Bioplastics e.V.

Marienstr. 19/20, 10117 Berlin

3.2 Waste Incineration Directive phone +49.30.28 48 23 50

fax +49.30.28 48 23 59

The Directive 2000/76/EC on the incineration of waste covers incineration possible. There are strict limit values for incineration plant emissions to air

e-mail info@european-bioplastics.org

and co-incineration with a view on prevention or limiting negative effects concerning heavy metals and webmany other toxic emissions. The Directive

www.european-bioplastics.org

on the environment. In order to guarantee complete waste combustion, requires the installation of measurement systems to monitor the parame-

the Directive requires all plants to keep the incineration or co-incineration ters and relevant emission limits. Emissions to air and to water must be

gases at a temperature of at least 850°C for at least two seconds. The heat measured periodically.

generated by the incineration process has to be put to good use as far as

3.3 Waste Framework Directive

The EC Directive 2008/98/EC on waste generally advises to prefer any 2009, and 65 percent for installations permitted after 31 December 2008.

form of recycling over other types of recovery (e.g. energy recovery) and The efficiency is depicted by the “R1 factor” (i.e. R1 ≥ 0.60/0.65). The

disposal. It requires that incineration facilities dedicated to the processing efficiency is a cumulated value from electrical and thermal energy resulting

of municipal solid waste need to have an energy efficiency equal to or abo- from the incineration.

ve: 60 percent for installations in operation and permitted before 1 January

3.4 Packaging and Packaging Waste Directive

The EC Directive 94/62/EC on packaging and packaging waste foresees a quota of 22,5 percent by weight has to be recycled or incinerated with

quotas for the recovery of packaging waste. For plastic packaging waste, energy recovery.

3.5 Review of waste policy and legislation

In July 2014, the European Commission adopted a legislative proposal should gradually increase between 2020 and 2030, to reach 60 percent

under the umbrella of the Circular Economy Package to review waste- and for plastics by the end of 2030.This proposal, however, was deleted to-

recycling-related targets from several Directives. Concerning the Was- gether with the whole Circular Economy Package from the Commission’s

te Framework Directive, recycling and preparing for re-use of municipal work programme 2015. A new and more comprehensive proposal – again

waste should be increased to 70 percent by 2030. Concerning recycling including amendments regarding waste legislation – will be presented by

and preparing for re-use of packaging waste, the material-specific targets the Commission presumably in 2015.

4. STANDARDS, CERTIFICATION AND LABELLING

Energy recovery is applicable for all types of bioplastics and their composi- EN 13431 Packaging - Requirements for packaging recoverable in the

tes, regardless of their raw material basis, biodegradability or compostabi- form of energy recovery, including specification of minimum inferior

lity. There is no material-specific standard in place. However, packaging in calorific value

thermal recovery is governed by some standards:

A specific label or certification scheme is not required for being eligible to

EN 13439 Packaging - Rate of energy recovery - Definition and energy recovery. With regard to solid recovered fuels or refused derived fu-

method of calculation els, the biomass content can be specified with radiocarbon measurement.1

The determination of the renewable content of a product / waste stream

CR 13686 Packaging - Optimization of energy recovery from packaging can become relevant with regard to Emission Trading Schemes.

waste

1

CEN/TS 15747: Solid recovered fuels — 14C-based methods for the determination of the biomass content

VR 19997 Nz, Amtsgericht Charlottenburg, USt-IdNr. DE235874231

HypoVereinsbank Rosenheim, BLZ 711 200 77, Konto 6356800, IBAN DE26 7112 0077 0006 3568 00, BIC/SWIFT HYVEDEMM448

5

FACT

SHEET

APR 2015

European Bioplastics e.V. Marienstr. 19/20 10117 Berlin European Bioplastics e.V.

Marienstr. 19/20, 10117 Berlin

5. INTERACTIONS BETWEEN BIOPLASTICS ANDphone

ENERGY RECOVERY

+49.30.28 48 23 50

fax +49.30.28 48 23 59

The energy content of bioplastics can be similar or equal to that of con- Compostable bioplastics that are certified

e-mail according to EN 13432 poten-

info@european-bioplastics.org

ventional plastics2. The difference lies in the chemical structure, meaning tially have lesser environmental

web impacts due to controlled low levels of

www.european-bioplastics.org

that a polyolefin has a higher heating value than a polyester, regardless heavy metals. Nevertheless, a main difference exists between conventional

of the biodegradability or renewability of the material. Accordingly, energy and biobased plastics. The CO2 generated by incineration of purely bio-

recovery is suitable for all kinds of bioplastics waste regardless of their based polymers is neutral regarding the global warming potential, because

renewability, biodegradability and compostability. the carbon content does not stem from fossil sources.

6. BENEFITS AND CHALLENGES OF ENERGY RECOVERY

6.1 Benefits

The process can treat mixtures of plastic waste that are hardly recy Energy recovery can be the final destination in a use-cascade with

clable otherwise (e.g. contaminated materials, small volumes that previous re-use or recycling cycles.

make separation economically unattractive or multilayer-materials). In the case biobased plastics are incinerated with heat recovery,

Energy recovery from bioplastics waste can contribute to resource renewable energy is produced, since the carbon is coming from a

saving by substituting emissions from oil / coal / gas firings for energy renewable resource – similar to using wood for renewable energy

and heating purposes. production.

6.2 Challenges

Energy recovery limits the opportunities of cascade-uses, while other Poor or incomplete burning of waste materials can result in environ

end-of-life options that allow for additional cycles may be more mental and health damage through the release of hazardous chemi-

resource-efficient. cals, including dioxins and acid gases.

The effective use of thermal energy often requires the use of district Incineration of wet wastes reduces the energy efficiency of the pro-

heating systems. cess.

2

Endres, H.J., Siebert-Raths, A: Technische Biopolymere, Munich 2009

VR 19997 Nz, Amtsgericht Charlottenburg, USt-IdNr. DE235874231

HypoVereinsbank Rosenheim, BLZ 711 200 77, Konto 6356800, IBAN DE26 7112 0077 0006 3568 00, BIC/SWIFT HYVEDEMM448

6

FACT

SHEET

APR 2015

European Bioplastics e.V. Marienstr. 19/20 10117 Berlin European Bioplastics e.V.

Marienstr. 19/20, 10117 Berlin

7. REFERENCES phone +49.30.28 48 23 50

fax +49.30.28 48 23 59

Stellenwert der Abfallverbrennung in Deutschland, Umweltbundesamt, 2008. e-mail info@european-bioplastics.org

http://www.umweltbundesamt.de/uba-info-medien/mysql_medien.php?anfrage=Kennummer&Suchwort=3649

web www.european-bioplastics.org

CEWEP Energy Report III (Status 2007-2010)

http://www.cewep.eu/m_1069

Incineratin of Municipal Solid Waste. DEFRA. February 2013.

https://www.gov.uk/government/uploads/system/uploads/attachment_data/file/221036/pb13889-incineration-municipal-waste.pdf

Waste-to-Energy. State-of-the-Art Report, 6th Edition 2012, ISWA The International Solid Waste Association

https://www.iswa.org/en/290/iswa_publications_detailview/publicationdetail/energy-from-waste-state-of-the-art-report-statistics-5th-edition.html

http://www.waste-management-world.com/content/dam/wmw/online-articles/documents/2013/ISWA_WtE_State_of_the_Art_Report_2012_08_

FV.pdf

Assessment of the Environmental Advantages and Drawbacks of Existing and Emerging Polymers Recovery Processes, European Commission Joint

Research Council, 2007

http://ipts.jrc.ec.europa.eu/publications/pub.cfm?id=1532

April 2015

European Bioplastics e.V.

Marienstraße 19/20

10117 Berlin

Phone: +49 (0) 30 284 82 350

Fax: +49 (0) 30 284 84 359

info@european-bioplastics.org

www.european-bioplastics.org

VR 19997 Nz, Amtsgericht Charlottenburg, USt-IdNr. DE235874231

HypoVereinsbank Rosenheim, BLZ 711 200 77, Konto 6356800, IBAN DE26 7112 0077 0006 3568 00, BIC/SWIFT HYVEDEMM448

7

You might also like

- EUBP BP Mechanical RecyclingDocument7 pagesEUBP BP Mechanical RecyclingDonato GalloNo ratings yet

- EUBP BP LandfillDocument4 pagesEUBP BP LandfillDonato GalloNo ratings yet

- EuBP FS AutomotiveDocument4 pagesEuBP FS AutomotiveDonato GalloNo ratings yet

- What Are Bioplastics?: Fact SheetDocument4 pagesWhat Are Bioplastics?: Fact SheetDonato GalloNo ratings yet

- EuBP FS Renewable ResourcesDocument4 pagesEuBP FS Renewable ResourcesDonato GalloNo ratings yet

- EUBP BP Anaerobic DigestionDocument8 pagesEUBP BP Anaerobic DigestionDonato GalloNo ratings yet

- EUBP BP Home CompostingDocument8 pagesEUBP BP Home CompostingDonato GalloNo ratings yet

- EUBP BP Additive-Mediated PlasticsDocument5 pagesEUBP BP Additive-Mediated PlasticsDonato GalloNo ratings yet

- Bioplastics Packaging - Combining Performance With SustainabilityDocument4 pagesBioplastics Packaging - Combining Performance With SustainabilityDonato GalloNo ratings yet

- EUBP PP Plastics StrategyDocument2 pagesEUBP PP Plastics StrategyDonato GalloNo ratings yet

- Plastic Shopping Bags: Position of European BioplasticsDocument2 pagesPlastic Shopping Bags: Position of European BioplasticsDonato GalloNo ratings yet

- EUBP PP LCA As A Basis For Policy FormulationDocument3 pagesEUBP PP LCA As A Basis For Policy FormulationDonato GalloNo ratings yet

- EUBP PP Sustainability AssessmentDocument3 pagesEUBP PP Sustainability AssessmentDonato GalloNo ratings yet

- Home Composting of Compostable BioplasticsDocument2 pagesHome Composting of Compostable BioplasticsDonato GalloNo ratings yet

- Marine Litter: Position of European BioplasticsDocument2 pagesMarine Litter: Position of European BioplasticsDonato GalloNo ratings yet

- EuBP PP Feedstock AvailabilityDocument2 pagesEuBP PP Feedstock AvailabilityDonato GalloNo ratings yet

- EUBP PP Circular Economy PackageDocument4 pagesEUBP PP Circular Economy PackageDonato GalloNo ratings yet

- EUBP EuropaBio PP Fertilizer RegulationDocument2 pagesEUBP EuropaBio PP Fertilizer RegulationDonato GalloNo ratings yet

- Criteria For Switching Products To Certified Compostable PlasticsDocument2 pagesCriteria For Switching Products To Certified Compostable PlasticsDonato GalloNo ratings yet

- Recycling and Recovery: End-Of-Life Options For BioplasticsDocument2 pagesRecycling and Recovery: End-Of-Life Options For BioplasticsDonato GalloNo ratings yet

- Discussion Paper Biodegradable Plastics To The Circular Economy in EuropeDocument2 pagesDiscussion Paper Biodegradable Plastics To The Circular Economy in EuropeDonato GalloNo ratings yet

- Report Bioplastics Market Data 2019Document4 pagesReport Bioplastics Market Data 2019Donato GalloNo ratings yet

- NATUREPLAST Plaquette ENG BD V2Document6 pagesNATUREPLAST Plaquette ENG BD V2Donato GalloNo ratings yet

- Frequently Asked Questions On Bioplastics: European Bioplastics E.VDocument26 pagesFrequently Asked Questions On Bioplastics: European Bioplastics E.VDonato GalloNo ratings yet

- Research and Development: Your Customized Bioplastic SolutionDocument4 pagesResearch and Development: Your Customized Bioplastic SolutionDonato GalloNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5796)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Mini ProjectDocument33 pagesMini ProjectMeenakshi ChaudhariNo ratings yet

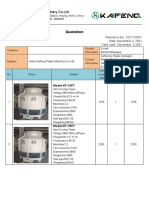

- KAIFENG Quotation For 150T Cooling TowerDocument13 pagesKAIFENG Quotation For 150T Cooling TowerEslam A. FahmyNo ratings yet

- Pages de ASME VIII - DIV.1 (2019) Table UW-12Document1 pagePages de ASME VIII - DIV.1 (2019) Table UW-12HamdiMallouli100% (1)

- 1.layout Rig 1503 Meters - Dos Mud Pump-ModeloDocument1 page1.layout Rig 1503 Meters - Dos Mud Pump-ModeloJUAN JOSE VESGA RUEDANo ratings yet

- Pages From Greater-Tortue-Ahmeyim-Fact-Sheet-EnglishDocument1 pagePages From Greater-Tortue-Ahmeyim-Fact-Sheet-EnglishMuhammad FadelNo ratings yet

- Format Thesis Gaya UKMDocument52 pagesFormat Thesis Gaya UKMtoomas.ijimNo ratings yet

- 6 02 2022 The MELCs and The 4th Quarter LessonDocument46 pages6 02 2022 The MELCs and The 4th Quarter LessoncatoruNo ratings yet

- Construction of HTA / LV Public Distribution Substations: 1. PreambleDocument24 pagesConstruction of HTA / LV Public Distribution Substations: 1. Preamblesalemg82No ratings yet

- Formulas Charts and TablesDocument56 pagesFormulas Charts and TablesRodolfo MendezNo ratings yet

- Sample Paper Ftre 2022 Class Vii p1 At+pcbmDocument26 pagesSample Paper Ftre 2022 Class Vii p1 At+pcbmSreenandan VNo ratings yet

- Bill CE Donald Collup 02-07-20 0218 CSDocument6 pagesBill CE Donald Collup 02-07-20 0218 CSMike MarchukNo ratings yet

- 2015-16 Indian Scout Service ManualDocument456 pages2015-16 Indian Scout Service Manualotto100% (4)

- 1FK7042-2AK71-1RB0 Datasheet enDocument2 pages1FK7042-2AK71-1RB0 Datasheet enAnonymous xuEZu5KyNo ratings yet

- Regulador Fisher 1era Etapa r622hDocument2 pagesRegulador Fisher 1era Etapa r622hBrayan CJNo ratings yet

- Phy 111 Rhema. KinematicsDocument4 pagesPhy 111 Rhema. KinematicsJoshua OkoghieNo ratings yet

- VHP Series Four L5774Lt: 1067 - 1280 BHP (795 - 954 KWB)Document2 pagesVHP Series Four L5774Lt: 1067 - 1280 BHP (795 - 954 KWB)JerNo ratings yet

- Making Money Out of Thin Air 1Document48 pagesMaking Money Out of Thin Air 1Cph CpNo ratings yet

- Energy Recovery Ventilation System Type FHBQ: Air Handling Units, Chillers & FancoilsDocument6 pagesEnergy Recovery Ventilation System Type FHBQ: Air Handling Units, Chillers & FancoilsЈово КруљNo ratings yet

- P Block Elements - Practice Sheet - (NSEC)Document4 pagesP Block Elements - Practice Sheet - (NSEC)aryanNo ratings yet

- SoloVac III Spray VaccinatorDocument2 pagesSoloVac III Spray VaccinatorAmer Adas100% (1)

- Moleaer XTB Data SheetDocument2 pagesMoleaer XTB Data Sheetsd0058No ratings yet

- Lecture 1 - Joining Processes-1Document9 pagesLecture 1 - Joining Processes-1Shaheer FarrukhNo ratings yet

- Leaves Lives E BrochureDocument18 pagesLeaves Lives E Brochuresumitdatta4uNo ratings yet

- KSB Megabloc: General Service Centrifugal PumpDocument5 pagesKSB Megabloc: General Service Centrifugal PumpFernando Pulgar BarillasNo ratings yet

- East Midlands LTDS Part One Nov 2020Document28 pagesEast Midlands LTDS Part One Nov 2020Khalid HameedNo ratings yet

- Short Circuit SimulatorDocument4 pagesShort Circuit SimulatorMichael DarmstaedterNo ratings yet

- Umap PMU KamparDocument1 pageUmap PMU KamparsyedkacangNo ratings yet

- 1 s2.0 S0360319922046997 MainDocument39 pages1 s2.0 S0360319922046997 MainphysicNo ratings yet

- Finalgirlsspring 19Document7 pagesFinalgirlsspring 19Khadija AlsayedNo ratings yet

- Prestorming 2021 Test 5 - Science and Technology I - Explanation Index Question No Page NoDocument107 pagesPrestorming 2021 Test 5 - Science and Technology I - Explanation Index Question No Page NoarchitscribdNo ratings yet