Professional Documents

Culture Documents

501 World Way Parking Structure in LA

501 World Way Parking Structure in LA

Uploaded by

Farhan Danish0 ratings0% found this document useful (0 votes)

10 views3 pagesOriginal Title

501 world way parking structure in LA

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

10 views3 pages501 World Way Parking Structure in LA

501 World Way Parking Structure in LA

Uploaded by

Farhan DanishCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 3

PT TREASURES

501 WORLD WAY—

FIRST PARKING STRUCTURE AT

LOS ANGELES INTERNATIONAL AIRPORT

BY KEN BONDY

it is located at

S01 World Way and is now designated as “PS” for the

terminal it primarily serves, Terminal 5. With an elevated

floor area of slightly over 200,000 ft (18,500 m*) and

71,000 f (6600 m*) on grade, the building provides

eee ones ener

ith oy PSE BSSATRDS, ith the

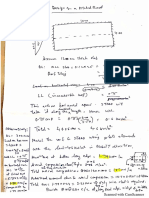

four-span beams spaced typically at 20 ft (6 m) on center.

‘he two exterior beams span $9 ft 6 in. (18 m) and the

two interior beams span $7 ft 6 in. (17.5 m). The total out-

to-out building dimension in the east/west (beam span)

direction is 237 ft 8 in. (72.5 m) and in the north/south

(slab span) direction it is 314 ft 10 in. (96 m). The slab

thickness is 5 in. (127 mm), the beam is 12 in, (300 mm)

wide and 36 in. (900 mm) deep, and columns are 24 in.

(600 mm) square. The floor-to-floor height is 10 ft6in. (3m).

‘The building is founded on spread footings, except for

a few locations where cast-in-drilled-hole piles were used

to clear underground airport utilities. All members are

cast-in-plac and all slab and

beam concrete is lightweight with a density of 110 Ib/ft*

(1762. kg/m*). Figure 1 shows part of the south elevation

of the building, as seen from the entrance to Terminal 5,

across World Way. Figure 2 shows the airport in plan with,

the location of PS, along with the other seven parking

structures (courtesy of Google Earth).

‘This type of framing is commonly referred to asa “clear-

span” garage because there are no columns in the parking

or driving areas. S01 World Way was not the first cast-in-

place post-tensioned clear-span garage built in southern

California, but because of its location, it was certainly the

‘most prominent of the early one:

Fig. 1—South elevation.

Fig. 2—LAX plan (courtesy of Google Earth)

‘This building is very personal for me. In 1964, I had

been working as a Structural Designer for TY. Lin and

Associates for over a year when I was assigned to be the

Project Engineer for 501 World Way. Under the supervi-

sion of Lin’s Chief Structural Engineer Ray Itaya, I person-

ally designed every structural member in the building and

PTIJOURIVAL | August 2014 29

observed much of the construction. One of the great joys

of being a structural engineeris to physically see the results

of your work; it is hard to describe the feelings of pride

and satisfaction that I feel when I see and use this building,

at my home airport, which is still in service now after

almost a half century. (Based Oitimy Personal OBSEHVatiONS

‘made over the years, the building has been fully loaded

with cars at peak hours (Fig. 3 and 4) and almost empty

at slack hours every day now for 49 years, and despite

this punishing loading cycle, it remains in good structural

condition today.

Fig. 3—Top Deck Level 4.

Fig. 4—Level3.

‘The building was designed for eight levels (seven

levated) but only four (three elevated) were built

tially and the upper levels were never added. Original

seismic framing was with 10 in. (250 mm) thick by 60 ft

30. August 2014 | PTI JOURNAL

(18 m) long shear walls perpendicular to the beams (in

the north/south direction on two interior column lines)

and rigid beam-column frames parallel to the beams in

the east/west direction. This Was Before Ehe efa|OF Seisinic

‘moment-resisting frames (SMF), or “ductile frames,” so

the seismic rigid frames were designed as nonprestressed

beams and columns, using moments and shears from a

static frame analysis with code-prescribed lateral seismic

loads. Seismic beam moments were resisted with nonpre-

stressed reinforcement only (capacity provided by the

tendons was ignored). Governed by the 1963 Los Angeles

City Building Code (the City of Los Angeles has had its

own building code since 1937), no particular attention

was paid to containment or ductility beyond that required

for gravity members.

‘501 World Way (BEHfSzied) Wellin Ee) Spmiae|eartD

quake in 1971 and the Northridge earthquake in 1994,

Contributory to that may have been the fact that it was a

three-story building designed for seven stories, and it was

about 30 and 25 miles (48 and 40 km) from the epicenters,

respectively (however, significant structural damage was

recorded in buildings as far as 85 miles (137 km] from

the epicenter of the Northridge event). Nonetheless,

the earthquakes produced no significant damage to the

building and it was fully functional after each one.

‘One interesting design decision, influenced by the fact

that lightweight concrete was used in the floor system, was

the use of an expansion joint in each direetion. In the east/

‘west direction, parallel to the beams, an expansion joint

was placed in a short 10 ft (3 m) bay near the center of the

building using a double-slab cantilever (Fig. 5). South of this

joint, down the center of the building (perpendicular to

the beams), a north/south expansion joint was placed at

the center column line, with two beam spans on either side

of the joint, thus separating the building into three inde-

pendent pieces. It was decided that a north/south joint

‘was not required north of the east/west joint because the

northeast comer of the building is notched (Fig. 2) and

the east/west building dimension is substantially reduced

in this area,

‘The beam on the east side of the joint is cast mono-

lithically with the column; the beam on the west side

of the joint rests on a corbel cast with the column, with

steel plates placed at the bottom of the beam and top of

the corbel to provide a sliding surface (Fig. 6). As with

‘many such “sliding” details, this one was met with limited

success and produced significant spalling over the years.

Although the spalling was largely cosmetic (the corbel

concrete provided fire protection for the structural steel

el,

Fig, 6—North/south expansion joint atc

assembly inside but did not function structurally), a major

retrofit of the corbels was executed about 10 years after the

building went into service. In retrospect, the north/south

expansion joint caused more problems than it solved. The

238 ft (72.5 m) building dimension in the four-span beam

direction would generally be considered adequate without

an expansion joint by today’s standards, particularly with

normalweight concrete in the floor system.

ACKNOWLEDGMENTS:

‘Thanks to V. Cuevas, I. Kashefi, R. Chan, and

C. Nuezca Gaba, all with the Los Angeles Department of

Building and Safety, and to S. Markle with Los Angeles

World Airports for helping me with historical information

about the building.

Structural Engineer: TY. Lin & Associates, Van Nuys, CA

Architect: Paul Williams & Associates, Los Angeles, CA

Tendons and Reinforcing Steel: Atlas Prestressing Corp.

Ken Bondy has specialized in the design and construc-

tion of post-tensioned concrete buildings for SO years.

He is a Charter Officer and Director of the Post-

Tensioning Institute (1976), a PTI Legend, Past Pres-

ident, Fellow, Lifetime Member, and former member of

the Technical Advisory Board (TAB). Now retired, he

is a licensed civil and structural engineer in California

and has been licensed in many other states

PTIJOURNAL | August 2014 31

You might also like

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (347)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Amended Portal MethodDocument15 pagesAmended Portal MethodFarhan DanishNo ratings yet

- Characterization of Cold Formed Steel Shear Wall Behavior Under Cyclic Loading For The CFS-NEES BuildingDocument19 pagesCharacterization of Cold Formed Steel Shear Wall Behavior Under Cyclic Loading For The CFS-NEES BuildingFarhan DanishNo ratings yet

- Wind - Static MethodDocument17 pagesWind - Static MethodFarhan DanishNo ratings yet

- Seismic Analysis of Building Using Staad-ProDocument8 pagesSeismic Analysis of Building Using Staad-ProFarhan DanishNo ratings yet

- Pitched RoofDocument2 pagesPitched RoofFarhan DanishNo ratings yet

- Ijert Ijert: Foundations On Expansive SoilsDocument4 pagesIjert Ijert: Foundations On Expansive SoilsFarhan DanishNo ratings yet

- Affordances of Building Information Modeling in Construction A Sequential AnalysisDocument12 pagesAffordances of Building Information Modeling in Construction A Sequential AnalysisFarhan DanishNo ratings yet

- Bond Stress-Slip Characteristics of FRP RebarsDocument50 pagesBond Stress-Slip Characteristics of FRP RebarsFarhan DanishNo ratings yet

- A Finite Element Based Analysis of Residual Stresses of Welded Joints Through Mechanical VibrationDocument6 pagesA Finite Element Based Analysis of Residual Stresses of Welded Joints Through Mechanical VibrationFarhan DanishNo ratings yet

- A Study On The Ductility of Bolted Beam Column ConnectionsDocument5 pagesA Study On The Ductility of Bolted Beam Column ConnectionsFarhan DanishNo ratings yet

- Methodology For Forensic Investigations of Seismic DamageDocument19 pagesMethodology For Forensic Investigations of Seismic DamageFarhan DanishNo ratings yet

- Behavior of Multistoried Building Under The Effect of Wind LoadDocument7 pagesBehavior of Multistoried Building Under The Effect of Wind LoadFarhan DanishNo ratings yet

- Fatigue Behaviour of Thin Walled Cold Formed Steel ProfilesDocument11 pagesFatigue Behaviour of Thin Walled Cold Formed Steel ProfilesFarhan DanishNo ratings yet

- Assesments of Defects at Construction & Occupancy StageDocument7 pagesAssesments of Defects at Construction & Occupancy StageFarhan DanishNo ratings yet

- Building Collapse During ConstructionDocument2 pagesBuilding Collapse During ConstructionFarhan DanishNo ratings yet

- Building Performance During ConstructionDocument12 pagesBuilding Performance During ConstructionFarhan DanishNo ratings yet

- Aging Effect On Bond Strength in Composite SectionsDocument5 pagesAging Effect On Bond Strength in Composite SectionsFarhan DanishNo ratings yet