Professional Documents

Culture Documents

SC Reaper

Uploaded by

Als اي AlsOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SC Reaper

Uploaded by

Als اي AlsCopyright:

Available Formats

Pipelines are used to transport a variety of gases and :.

] هـ١٤٤٣/١/٢٥ , ص٤:٢٧[

liquids to their destinations. Most fluids contain

small amounts of water and hydrogen sulfide or

.other substances which are harmful to the steel pipe

The fluids may contain compounds which stick to

the pipe wall, or may contain sand and other debris

that stay inside the pipeline. All of these result in

corrosion of the pipeline and reduce flow through

the line or contamination of the fluid being

transported. For these reasons a scraper is used to

.clean the pipeline

The scraper is a device which is inserted into a

pipeline, pushed to the other end of the line by a

pressurized gas or liquid and then removed from the

pipeline. The scraper is designed to pass through

bends, valves, and other equipment found in piping

.systems

Since the uncoated transfer lines have been in use :. ] هـ١٤٤٣/١/٢٥ , ص٤:٢٩[

.for a time, scale and sludge build up inside the pipe

This buildup holds up the flow of water. Scale and

sludge must be removed to keep the water flow

from being restricted and the pipeline from being

damaged. Scrapers remove the scale and sludge

FUNCTION AND PARTS OF SCRAPEA :. ] هـ١٤٤٣/١/٢٥ , ص٤:٢٩[

,Scrapers clean out pipelines. As the scraper travels

scrapes and cleans the inside of the pipe. Scrapers

.are made to fit different sized pipes

A scraper has a steel body, front and rear cups, and

one or more sets of brushes depending on the size

of the scraper. A rubber seal around the cups forms

a seal in the pipeline. Pressurized water against the

.cups moves the scraper along the pipeline

FUNCTION AND PARTS OF SCRAPER :. ] هـ١٤٤٣/١/٢٥ , ص٤:٣٠[

LAUNCHER

The scraper launcher places the scraper into the

.saltwater injection pipeline that is to be scraped

The main parts of the scraper launcher are the

launcher barrel

kicker valve

drain valve

vent valve

pressure relief valve

scraper outlet valve

NCTION AND PARTS OF THE :. ] هـ١٤٤٣/١/٢٥ , ص٤:٤٢[

SCRAPER RECEIVER

The scraper receiver receives a scraper from

pipeline. The scraper is unloaded from the pipeline

.at the scraper receiver

The main parts of the scraper receiver are the

O receiver barrel

I vent valve

drain valve

pressure relief valve

pressurizing valve

SCraper indicator

SCraper inlet valve

pressure indicator

SCRAPING OPERATION AND SAFETY :. ] هـ١٤٤٣/١/٢٥ , ص٤:٤٢[

REQUIREMENTS

Because of the long distance between the scraper

launcher and the scraper receiver, launching

operators and receiving operators are involved in the

SCraping operation. lhese twO groups communicate

.by two-way radio

Launcher Operation

While operating the launcher, the operator will

visually check the launcher barrel for leaks. If leaks

are found and cannot be corrected, they are reported

.to the supervising operator

The launcher is emptied, depressurized, and one :. ] هـ١٤٤٣/١/٢٥ , ص٤:٤٣[

,A scraper is inserted into the launcher barrel

pene

The

launcher is then closed, and the scraper is launched

The launching operator then tells the receiving

operator that the scraper has been launched and to

.prepare for its arrival

The scraper is detected as it travels along the

pipeline by indicators. When a scraper passes an

indicator, the indicator sends a signal to the control

room of the receiving station to mark the progress

.of the scraper through the pipeline

he indicators must be checked for correct :. ] هـ١٤٤٣/١/٢٥ , ص٤:٤٣[

.operation and reset after the scraper passes them

There are two types of indicators, the type-1

.indicator and the type-2

To check the type-1 indicator, place a metal bar into

-the slots on the indicator cover and move counter

clockwise until the cover is free. Check that the

.wiring is clean and dry and then retighten the cover

Type-1 Indicator :. ] هـ١٤٤٣/١/٢٥ , ص٤:٤٧[

To check the type-2 indicator, lift off the cover. Trip

the indicator by pushing the limit switch against the

trigger mechanism. When the trigger is released, it

sends a signal to the UWSS control room. The

UWSS operator watches to see if the indicator and

the electronic alarm are working correctly. The

UWSS will tell you if a fault is found. Report any

.fault to your supervisor

Receiver Operation :. ] هـ١٤٤٣/١/٢٥ , ص٤:٥٣[

While operating the receiver, the receiving operator

checks the receiver barrel for leaks. If leaks are

.found, he reports them to the supervising operator

After the scraper docks inside the receiver barrel, the :. ] هـ١٤٤٣/١/٢٥ , ص٤:٥٤[

receiver barrel is depressurized and opened. The

scraper and any scale formation or sludge is

removed. The barrel is then closed, and the scraper

.receiver is isolated

Operation of the valves on the scraping system is

the responsibility of the launching and receiving

stations; however, the well services operator should

.know the locations and functions of all valves

Sometimes it is necessary to replace the receiver

barrel cap (door) seal. This requires two or more

operators. One operator takes the end of the new

seal and presses it into the seal groove. He presses in

a section about two feet long and holds it. The

.second operator does the same with the next section

They repeat, in turn, until the seal groove is

.completely filled with the seal

Safety Precautions :. ] هـ١٤٤٣/١/٢٥ , ص٤:٥٥[

ke certain

When scraping a pipeline, you

Jf and

yourse

safety

precautions to avoid injuries to

.damage to the equipment

You must wear chemical handling cothes when

.receiving a scraper

are

Check that the launcher and receiver barre

.depressurized before opening the doors

Check the crane shackles for cracks in the metal and

bent pins. Check the wire slings for frayed wire and

.damaged sleeves

Use the correct crane hand signals when directing

the crane operator loading and unloading the

Scraper. Refer to unit 3 for crane operation hand

.Signals

.Secure the slings to the scraper and crane correctly

Shackle lugs are located on the steel body of the

.scraper

Shackles and slings are fastened to the shackle lugs

and the sling is fastened to the crane hook. One or

two slings are used depending on the number of

.shackle lugs on the scraper and weight of scraper

,When loosening the UWSS receiver door clamp

you must loosen both clamp bolts at the same time

.to prevent damage to the clamp

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Method Statement For Installation of Chilled Water Pump & Condenser Water PumpDocument14 pagesMethod Statement For Installation of Chilled Water Pump & Condenser Water Pump721917114 47No ratings yet

- Complaint: Employment Sexual Harassment Discrimination Against Omnicom & DDB NYDocument38 pagesComplaint: Employment Sexual Harassment Discrimination Against Omnicom & DDB NYscl1116953No ratings yet

- Derivative Investment!Document24 pagesDerivative Investment!Asif Riaz100% (2)

- Iso 9227Document13 pagesIso 9227Raj Kumar100% (6)

- 10 Chapter 3 Occupancy Classification AnDocument10 pages10 Chapter 3 Occupancy Classification AnMatt BaronNo ratings yet

- Case StudyDocument7 pagesCase StudyLeighvan PapasinNo ratings yet

- Chapter Six Account Group General Fixed Assets Account Group (Gfaag)Document5 pagesChapter Six Account Group General Fixed Assets Account Group (Gfaag)meseleNo ratings yet

- Tuyet W3 Unit 2 Tenses Adverbial Clause of Time Zalo HSDocument16 pagesTuyet W3 Unit 2 Tenses Adverbial Clause of Time Zalo HSVũ Thanh GiangNo ratings yet

- CASE DIGEST GAISANO CAGAYAN vs. INSURANCE COMPANY OF NORTH AMERICADocument3 pagesCASE DIGEST GAISANO CAGAYAN vs. INSURANCE COMPANY OF NORTH AMERICAclaireNo ratings yet

- BV DSG eDocument18 pagesBV DSG eIulianIonutRaduNo ratings yet

- Vaccination Schedule in Dogs and CatsDocument3 pagesVaccination Schedule in Dogs and CatsAKASH ANANDNo ratings yet

- 2020 Q2 CushWake Jakarta IndustrialDocument2 pages2020 Q2 CushWake Jakarta IndustrialCookiesNo ratings yet

- Grand Hyatt Manila In-Room Dining MenuDocument14 pagesGrand Hyatt Manila In-Room Dining MenuMetroStaycation100% (1)

- Microsoft Security Intelligence Report Volume 21 EnglishDocument180 pagesMicrosoft Security Intelligence Report Volume 21 EnglishAlejandro CadarsoNo ratings yet

- Tractor Price and Speci Cations: Tractors in IndiaDocument4 pagesTractor Price and Speci Cations: Tractors in Indiatrupti kadamNo ratings yet

- NURTURE Module-V 11 1 en PDFDocument4 pagesNURTURE Module-V 11 1 en PDFJorge SingNo ratings yet

- Facts About Concussion and Brain Injury: Where To Get HelpDocument20 pagesFacts About Concussion and Brain Injury: Where To Get HelpJess GracaNo ratings yet

- Total Elbow Arthroplasty and RehabilitationDocument5 pagesTotal Elbow Arthroplasty and RehabilitationMarina ENo ratings yet

- Abfraction, Abrasion, Biocorrosion, and The Enigma of Noncarious Cervical Lesions: A 20-Year PerspectivejerdDocument14 pagesAbfraction, Abrasion, Biocorrosion, and The Enigma of Noncarious Cervical Lesions: A 20-Year PerspectivejerdLucianoNo ratings yet

- Formulation and Evaluation of Mefenamic Acid Ointment Using Penetration EnhancersDocument5 pagesFormulation and Evaluation of Mefenamic Acid Ointment Using Penetration EnhancersIndradewiNo ratings yet

- Missoula County Fairgrounds Phase 2Document10 pagesMissoula County Fairgrounds Phase 2Olivia IversonNo ratings yet

- Boeco BM-800 - User ManualDocument21 pagesBoeco BM-800 - User ManualJuan Carlos CrespoNo ratings yet

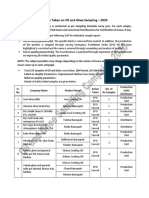

- Action Taken On Oil and Ghee Sampling - 2020Document2 pagesAction Taken On Oil and Ghee Sampling - 2020Khalil BhattiNo ratings yet

- Biology Q PDFDocument9 pagesBiology Q PDFsumon chowdhuryNo ratings yet

- 3 Ways To Take Isabgol - WikiHowDocument6 pages3 Ways To Take Isabgol - WikiHownasirNo ratings yet

- 2015 12 17 - Parenting in America - FINALDocument105 pages2015 12 17 - Parenting in America - FINALKeaneNo ratings yet

- Constipation Treatment For Infants and ChildrenDocument2 pagesConstipation Treatment For Infants and Childrenapi-559575515No ratings yet

- Liebherr 2956 Manual de UsuarioDocument27 pagesLiebherr 2956 Manual de UsuarioCarona FeisNo ratings yet

- 7 Fuel Failure in Water Reactors - Causes and MitigationDocument165 pages7 Fuel Failure in Water Reactors - Causes and MitigationLauri RubertiNo ratings yet