Professional Documents

Culture Documents

PMR 2005 S1 Girtler

Uploaded by

David JohnOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PMR 2005 S1 Girtler

Uploaded by

David JohnCopyright:

Available Formats

A general concept of design procedure for floating docks regarding their reliability, safety and ecological aspects

A general concept of design procedure

for floating docks regarding their reliability,

safety and ecological aspects

Jerzy Girtler, Prof., D.Sc.

Gdańsk University of Technology

ABSTRACT

In this paper is presented a concept of design procedure, and problems resulting from it, for

floating docks with a view of taking into account their reliability and operational safety. It

has been stressed that such design procedure is necessary for ensuring the docks appropriate

pro-ecological features. It has been also shown that the design procedure should have several

stages. The following kinds of design stages have been proposed to be accounted for : offer

(canvassing) design, contract (ordered) design, concept (study) design, preliminary design,

technical (classification) design and working design as well as the stage of elaboration of

technical operational (delivery-acceptance) documentation. Knowledge areas necessary for such design

procedure have been indicated. Attention has been also drawn to the necessity of accounting for, in desig-

ning the floating docks, diagnostic systems suitable to aid operational decision making .

Keywords : safety, floating dock, reliability, design procedure

INTRODUCTION of the docks. The reliability problems should be undertaken in

all design stages of floating docks in parallel with the problems

Every floating dock should be so designed as to ensure its associated with forming their energy merits [13].

use with the profitability as great as possible in given condi-

tions and not causing any contamination of port waters during DESIGN STAGES OF FLOATING DOCKS

docking operations associated with building new ships or repair WITH ACCOUNTING FOR THEIR

works on existing ships [6, 7, 11]. RELIABILITY AND SAFETY

One of the crucial problems in designing the floating dock is

to reach its required reliability, especially of its energy systems, Reliable and safe operation of floating docks makes it pos-

because mainly on these systems the dock’s profitability, its sible to use them in a pro-ecological way. To estimate reliability

pro-ecological features and operational safety, depends. A dif- of a dock not always is possible. It results from that design

ficulty in realizing the postulate results from that the floating methods used in the contemporary designing of floating docks

docks built on the basis of the same design form statistical sets are deterministic. Though their application makes it possible to

of a small number of elements or even are singular and unique. elaborate the designs whose realization results in building the

Moreover an additional difficulty associated with forming their floating docks of reliability intuitively estimated to be high, but

reliability is that they are technical systems of a long lifetime. it does not allow for determining the reliability in the form of

Additionally, design offices do not render their surveillance reliability indices. In this case the subjective probability serves

over the docks in service. For this reason they have not in their as an estimate of dock’s reliability. Such probability – though

disposal any relevant data bases necessary in design phase to possible to be graded – has no numerical measure. However

estimate reliability indices demanded for particular structural the reliability indices even such as logical or statistical pro-

units of floating docks. Also, there is a lack of probabilistic babilities, are necessary for rational planning and control of

design methods to make it possible to build a floating dock for operational processes of the docks. Hence there is a need to

a given reliability [7, 8, 11, 12, 14]. elaborate the probabilistic methods for forming reliability of

Two approaches to design procedure of floating docks, floating docks and to apply them in the phase of designing.

accounting for reliability are possible [12] : [3, 9, 11, 12].

To this end the following theoretical tools should be applied :

design procedure consisting first in determining reliability contemporary theory of reliability and safety of complex techni-

indices of the devices intended to be installed in a given cal systems, probability calculus and mathematical statistics as

dock, and next in determining total reliability of the dock well as theory of the devices (mainly heat engines and electrical

in question machines) installed in the docks, and theory of stochastic pro-

design procedure consisting first in assuming such total cesses, especially semi-Markovian ones [1, 2, 3, 4, 5, 6, 8, 11,

reliability of a given dock, which is available for technical 13]. And, technical diagnostics and results of failure analysis of

and economical reasons, but not less than that demanded by devices of the docks similar to designed ones should be applied

its future user, and then in selecting such particular devices to elaborate sets of reliability states of designed floating docks

intended to be installed in the dock as to reach the demanded [13]. Knowing the indices of operational reliability and safety

reliability. of particular floating docks with accounting for diagnostics, one

Each of the design approaches first of all requires to describe is able to make more rational operational decisions.

a method for forming the reliability and safety of floating docks, Requirements concerning reliability of floating docks or

next to determine reliability structures of their subsystems and only their energy systems, as well as operational safety of the

systems and to perform an analysis and synthesis of reliability systems and whole dock should be submitted in writing by its

30 POLISH MARITIME RESEARCH, Special issue 2005

A general concept of design procedure for floating docks regarding their reliability, safety and ecological aspects

future user in the form of the design assumptions. In this project is especially important to propose a concept

The design offices do not have in their disposal any selective of operation of the dock in accordance with its intended use,

data bases on failures of devices of floating docks and other that requires to show a model of control over its operational

important events occurred in their service. Hence they do not process with accounting for expected operational costs or

apply models and techniques aimed at forming reliability and expected incomes, i.e. profits at a given operational outlays.

operational safety. For such reasons the design procedure of flo- The concept should be supported by economical calculations

ating docks should be multi-stage one. Like in ship power plant demonstrating profitability of building and purchase of such

designing the following design stages could be distinguished in a dock for its future user.

the case in question [11, 13] : offer (canvassing) design, contract The offer design is useful not only during negotiations

(ordered) design, concept (study) design, preliminary design, and next in elaborating the contract design with accounting

technical(classification) design , working design, as well as the for requests from the side of a body ordering the design, but

stage of elaboration of technical operational (delivery-accep- also for preliminary justification of the need for elaborating

tance) documentation. As a result of realization of the above a study design.

specified design stages the respective design projects should

The contract design is the first stage of floating dock design

be elaborated. Finally, its technical operational documentation

procedure, during which concepts presented in the offer design

would be delivered together with the dock.

as well as requirements of future buyers and users of the dock

In contemporary designing the first design stage resulting are taken into account.

in an offer design, is especially important. The offer design is The contract design is elaborated in compliance with desig-

aimed at gaining interest of future buyers of the dock. ner’s proposals included in the offer design as well as with the

In such design, apart from design solutions of the systems ordering body’s decisions made on the basis of its operational

intended for installing in the dock , should be contained reliable strategy for technical systems.

information on its durability, reliability and operational safety. In the contract design should be also contained suggestions

From the design of the dock it must be clearly seen which its if the successive design stage has to result in elaboration of the

elements are novel as far as its construction , technology and preliminary design, or to elaborate the concept (study) design

design procedure is concerned. To demonstrate merits of a novel first is more justified.

solution of a dock the following items should be included in The concept design should be a continuation of the contract

the project [13] : design. This design is an improved and detailed development

of the contract design as well as elaboration of novel design

general data on the dock such as type of the dock (autono-

solutions.

mous or non-autonomous), its use (for building new ships,

ship repair, shiprepair and new building), load carrying In the concept design stage should be realized the scientific

capacity, main dimensions (total length, internal and exter- research projects (planned in advance in the contract design

nal breadths, depth, pontoon height, height of keelblocks, phase) such as modelling, calculations, composition, analysis and

freeboard to the upper deck, freeboard to the pontoon deck), synthesis of a few variants of design solutions of the designed

lifting time of a ship of a given mass, capacity of tanks for floating dock, aimed at selection of an optimum solution satis-

energy media (diesel and heavy fuel oils, lubricating oil, fying the criteria vital for the dock’s user. Therefore already in

wash water, boiler water, cooling water) and waste liquids the initial part of the design should be presented the problems

(bilge water, residuals from centrifugal separators and oil to be solved and research topics resulting from them in order to

separators, sewage) etc. make it possible to assess the scope of the mentioned research

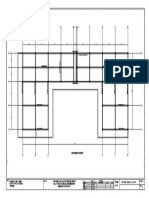

schematic general arrangement plan of the dock distinctly projects and costs of their realization.

showing its crucial energy systems and pipe lines as well In this design stage special attention should be paid to ope-

as reliability structures of its energy systems rational reliability and safety and pro-ecological features of the

data on output of electric generating sets, kind and type of designed dock by analyzing first of all : correctness of operation

driving engines and generators of the sets of energy systems of the dock, their durability, repairability,

technical specification of energy systems (kind, type, functionality, ergonomic features and lifetime. Next one should

output and rotational speed of combustion engines and estimate quantitive reliability measures in order to make relia-

electric motors, output and capacity of compressors and bility analysis and synthesis of the systems, verification of the

main and drying water pumps, steaming rate and pressure economically justified solutions and elaboration of data bases.

of boilers, pulling power of capstans, hoisting capacity of In this stage, methods to improve reliability during designing,

dock cranes etc.) manufacturing and operating the floating docks, should be

reliability description of devices, systems and the dock itself proposed. Also, cost of application of the methods should be

(reliability indices of devices, energy systems and dock estimated.

such as : probability of correct work till the first failure, Choice and effectiveness of application of the methods for

probability of correct work between successive failures, improving the reliability of particular systems of the docks

kind of risk function, expected value of correct work time depend on :

and standard deviation, availability factors etc.)

degree of recognition of physical processes leading to

schematic diagrams and description of automation of the

failures

energy systems

possibility to remove failures occurred in the dock’s life

specification of kinds and values of operational parameters

time

of energy media, e.g. maximum values of pressure and tem-

possibility to predict occurrence of failures and to counteract

perature of air in compressed air system, water for cooling

them by removing causes of their occurrence.

the combustion engines, fuel and lubricating oils

schematic diagrams and description of main and emergency The study design should be of a breakthough importance for

systems of electric energy supply (output, voltage, current designing any type of docks. From operational practice of vario-

frequency). us technical objects it results that the initial designing phase has

POLISH MARITIME RESEARCH, Special issue 2005 31

A general concept of design procedure for floating docks regarding their reliability, safety and ecological aspects

a main impact for ensuring an appropriate level of durability, within the study design stage are already known. In the stage

reliability, serviceability, operational safety etc. As the course in question design solutions of the dock energy systems and

of the designing phase is decisive of whether a study design its other structural units should be finally and unambiguously

would be ahead of a current technical level, or only keeping determined. Also, classification schematic diagrams of all

up with the level, hence the study design should be at least that systems of the dock should be elaborated in compliance with

ensuring to keep up with the current technical level. the requirements of the classification societies. Draining plan

The study (concept) design project, being a result of the of the dock is of special importance for ensuring the required

considered designing stage, should contain proposals of possi- stability of the dock.

bly most up-to-date design solution of floating dock together

The technical (classification) design should be approved

with description of its technical operational merits (including

by a relevant classification institution, e.g. Polish Register of

those economical as well as concerning reliability, durability

Shipping. All amendments which could be introduced in the

and safety with accounted for environmental protection de-

further designing phases must be agreed with surveyors of

mands). In the case if the assumed technical operational para-

a classification society supervising the dock’s design. After

meters are not achieved , a justification of this fact has to be

obtaining the classification society’s approval for the technical

presented together with conclusions about causes of that failure

design the last designing stage – the working designing can be

and suggestions on what should be done in further phases of

commenced.

design process, including also future modernization and even

recycling of the dock.

The working design is a result of the designing stage

In the concept (study) design a concept of operational pro-

characteristic of that to elaborate the documentation deep

cess of the designed dock should be included. States of opera-

knowledge of manufacturing processes and organization of

tion and maintenance are quantities of such process. The state

an enterprise intending to build the dock in accordance with

of modernization can be distinguished out of the latter ones.

the elaborated technical (classification) design, is required.

Contemporary design process of the dock cannot be ended in

In the working design all reservations from the side of the

the moment of elaboration of its technical operational docu-

classification society should be accounted for. In this phase

mentation but must also include actions to initiate and support

all detail technical drawings of every element of the dock to

the process of disclosing the manufacturing errors (made

be built in the builder workshops should be elaborated and its

during phases of designing and manufacturing the dock) and

manufacturing processes described. Also, in the documentation

operational ones , as well as their analysis. From the analysis

all standard elements not subject to further processing, should

it should result whether the proposed design solutions do not

be specified.

force by chance the user to make errors leading to failures of

the dock devices and systems. The modernization of the dock An important part of the working documentation are the

is necessary as it makes it possible to remove possible defects assembly drawings showing the designed structures in the form

and design faults, and their causes in particular. of appropriate projections and cross-sections. On the drawings

more important dimensions should be given , and each element

The preliminary design is a result of making the concept should be specified by providing its gabarites, mass, used ma-

(study) design more exact. In the case when in designing the terials, symbol of a relevant standard etc.

dock no novel solution is required the design stage is only In the documentation results of all energy tests performed

a continuation of the design process with taking into account to unambiguously confirm operational usefulness of the devices

the contract design and the agreements made with the body being elements of the dock’s energy systems, should be also

ordering the dock. accounted for.

The working documentation should make it possible to

In the preliminary design process manufacturing condi- build the dock with maintaining all its features provided for in

tions and capabilities of a shipyard intending to build the dock the study design, and even better if they are in accordance with

should be taken into account after making a prior analysis of those established either in the offer design or contract one.

manufacturing capabilities of other shipyards also prepared for

building such objects. The technical operational documentation can be ela-

The preliminary design should contain precise arrange- borated only after completion of the dock. It should contain

ment of the dock systems and devices being elements of the information making it possible to use the dock rationally. The

systems. Also, complete technical operational characteristics following items belong to it : principles and procedures of

of the devices intended to be installed in the dock, including putting the dock’s devices into operation, of their loading and

those dealing with their reliability, safety and pro-ecological stopping, carrying out maintenance , main repairs and those

features, should be presented. after failure. Information concerning reliability and operational

The final result of the preliminary design stage should be safety is especially important.

the design documentation including its most important element

– the general arrangement plan of the dock together with its con- The documentation should contain the assembling drawings

cise description and justification of the presented solutions. as well as technical specification of the dock’s power plant

The design should be verified by an independent group of and other systems characteristic for particular types of docks.

experts and after obtaining their positive opinion – submitted Also, reports containing results of delivery-acceptance tests

to the ordering body to get its acceptance. and operational trials of energy systems of the dock should

If the verifying procedure is finished the next stage of be included.

designing, i.e. the technical (classification) design stage may

be commenced. FINAL REMARKS AND CONCLUSIONS

The technical (classification) design is a more exactly From the presented considerations it results that verification

determined version of the preliminary design. It is crucial of reliability and safety indices should be carried out in all

that results of the earlier planned empirical research realized the described designing stages of docks.

32 POLISH MARITIME RESEARCH, Special issue 2005

A general concept of design procedure for floating docks regarding their reliability, safety and ecological aspects

The necessity of verifying reliability and operational safety Engineering and Ship Technology, Gdańsk University of

of floating docks as well as their pro-ecological features Technology. Gdańsk, 2004

during elaboration of their technical operational documen- 7. Bastian E.: Analysis and synthesis of technical design

tation (delivery-acceptance one), cannot be excluded. assumptions concerning floating docks (autonomous, non-

-autonomous, for ship building and ship repair) with accounting

During elaboration of the offer design reliability structures for the docks built in Polish shipyards (in Polish). Research

of all energy systems should be considered and the sim- Reports (Prace badawcze) No. 83/E/2004 of Faculty of Ocean

plest ones applied. At this stage to estimate reliability and Engineering and Ship Technology, Gdańsk University of

safety of docks accurately may be difficult due to the lack Technology. Gdańsk, 2004

8. Girtler J.: Probabilistic model of operational process of floating

of sufficient amount of results of empirical investigations.

docks (in Polish). Research Reports (Prace badawcze)

However it would be possible to assess the reliability from No. 91/E/2004 of Faculty of Ocean Engineering and Ship

above and from below practically for all devices of floating Technology, Gdańsk University of Technology. Gdańsk, 2004

dock, as their risk functions are ascending , e.g. by applying 9. Girtler J.: Probabilistic model of occurrence of situations

the suitable formulae [13]. hazardous for dock and environment (in Polish). Research

Reports (Prace badawcze) No. 92/E/2004 of Faculty of Ocean

The above mentioned formulae are of practical importance Engineering and Ship Technology, Gdańsk University of

because they make it possible to assess reliability of the Technology. Gdańsk, 2004

dock’s systems if only expected values of their correct 10.Girtler J.: Analytical critical study on formulation of technical

operation till failure are known. Therefore they enable design assumptions and principles of current and final

to make operational decisions by applying the statistical verification of a floating dock regarding its operational

decision theory if only consequences of the decisions are reliability and safety as well as problems of environmental

known. Also they make it possible to assess reliability of protection (in Polish). Research Reports (Prace badawcze)

the whole dock . No. 110/E/2004 of Faculty of Ocean Engineering and Ship

Technology, Gdańsk University of Technology. Gdańsk, 2004

BIBLIOGRAPHY 11. Girtler J.: A method of forming reliability and safety of floating

docks (in Polish). Research Reports (Prace badawcze)

1. Benjamin J.R., Cornell C.A.: Probability, Statistics and Decision No. 79/E/2004 of Faculty of Ocean Engineering and Ship

for Civil Engineers (in Polish). Technical Scientific Publishers Technology, Gdańsk University of Technology. Gdańsk, 2004

(WNT). Warszawa, 1977 12.Girtler J.: Identification of problem of docking the ships by using

2. Girtler J.: Semi-Markov model of changes of sea-ships’ and floating docks in the aspect of their designing and operating (in

aircrafts’ moving. Archives of Transport, vol.11, iss.1-2/99 pp. Polish). Research Reports (Prace badawcze) No. 75/E/2004

3. Girtler J.: Possible applications and usefulness of semi-Markovian of Faculty of Ocean Engineering and Ship Technology, Gdańsk

processes as models of operational processes of machines University of Technology. Gdańsk, 2004

(in Polish). Zagadnienia Eksploatacji Maszyn, No. 3/1996 13.Girtler J.: A concept of design procedure for floating docks with

4. Grabski F.: Semi-Markovian processes of reliability and accounting for their reliability and safety as well ecological

operation. (in Polish). Polish Academy of Sciences (PAN), problems during their production and use (in Polish). Research

IBS. Series: System Research (Badania Systemowe), Vol. 30. Reports (Prace badawcze) No. 119/E/2004 of Faculty of Ocean

Warszawa, 2002 Engineering and Ship Technology, Gdańsk University of

5. Jaźwiński J., Borgoń J.: Operational reliability and safety Technology. Gdańsk, 2004

of flight (in Polish). Communication Publishers (WKiŁ). 14. Kubiak A.: General design assumptions for floating docks

Warszawa, 1989 (autonomous, non-autonomous, for ship building and ship repair)

6. Bastian E.: Comparative analysis of technical operational with accounting for technical economical aspects and environ-

parameters of existing floating docks of the lifting capacity mental protection (in Polish). Research Reports (Prace badawcze)

ranging from 4.500 to 55.000 t (in Polish). Research Reports No. 81/E/2004 of Faculty of Ocean Engineering and Ship

(Prace badawcze) No. 93/E/2004 of Faculty of Ocean Technology, Gdańsk University of Technology. Gdańsk, 2004.

Photo : Cezary Spigarski

POLISH MARITIME RESEARCH, Special issue 2005 33

You might also like

- Pedestrian Bridge DesignDocument188 pagesPedestrian Bridge DesignMuzamil Maqbool RatherNo ratings yet

- Construction Supervision Qc + Hse Management in Practice: Quality Control, Ohs, and Environmental Performance Reference GuideFrom EverandConstruction Supervision Qc + Hse Management in Practice: Quality Control, Ohs, and Environmental Performance Reference GuideRating: 5 out of 5 stars5/5 (2)

- Design Criteria Float Walks PontoonsDocument23 pagesDesign Criteria Float Walks Pontoonsdiki100% (1)

- Shipbuilding Process: Planning and Production Control in ShipbuildingDocument61 pagesShipbuilding Process: Planning and Production Control in ShipbuildingLai QuocNo ratings yet

- Jacket Construction of OilDocument5 pagesJacket Construction of OilLousianna MariaNo ratings yet

- Dyn Anal DSGN PRGM App FEMDocument125 pagesDyn Anal DSGN PRGM App FEMyouceftliNo ratings yet

- Process Commissioning Plant David HorsleyDocument130 pagesProcess Commissioning Plant David HorsleyEileen Low60% (5)

- Ashrae 2011 HVAC CommissioningDocument12 pagesAshrae 2011 HVAC CommissioningRodrigo Lobos AguilarNo ratings yet

- Asphalt Bs 598-104Document22 pagesAsphalt Bs 598-104David JohnNo ratings yet

- Asphalt Bs 598-104Document22 pagesAsphalt Bs 598-104David JohnNo ratings yet

- Uae QuestionnaireDocument3 pagesUae QuestionnaireevahNo ratings yet

- A Tool For Analysis of Costs On The Manufacturing of The HullDocument7 pagesA Tool For Analysis of Costs On The Manufacturing of The HullCleber001No ratings yet

- Aace 48r-06 Schedule Constructability ReviewDocument11 pagesAace 48r-06 Schedule Constructability Reviewaugusto5615100% (2)

- Managing Well CasingDocument18 pagesManaging Well CasingElena Herrera VasquezNo ratings yet

- Ship Design Concept From NarcikiDocument6 pagesShip Design Concept From NarcikiFerdy Fer DNo ratings yet

- Model-Driven Online Capacity Management for Component-Based Software SystemsFrom EverandModel-Driven Online Capacity Management for Component-Based Software SystemsNo ratings yet

- 5 Ship Design: Fulfil Performance CriteriaDocument6 pages5 Ship Design: Fulfil Performance Criteriaryan310393No ratings yet

- FPSO Hull Structural Design Concept Supporting Controlled Project ExecutionDocument8 pagesFPSO Hull Structural Design Concept Supporting Controlled Project ExecutionihllhmNo ratings yet

- Planning Design Marine TerminalsDocument9 pagesPlanning Design Marine TerminalsJoemarbert YapNo ratings yet

- Placement Information SystemDocument51 pagesPlacement Information SystemAnil Kumar Singh67% (3)

- Process Engineer CVDocument29 pagesProcess Engineer CVcenter01No ratings yet

- Department of Energy Bechtel MemoDocument24 pagesDepartment of Energy Bechtel MemoKevin MooneyNo ratings yet

- Deepstar - Multiphase FlowDocument1,122 pagesDeepstar - Multiphase Flowfebrian100% (1)

- Lecture 15 - Earned Value AnalysisDocument41 pagesLecture 15 - Earned Value AnalysisDavid JohnNo ratings yet

- Design Review Procedure For Projects in Fertilizer PlantsDocument9 pagesDesign Review Procedure For Projects in Fertilizer PlantsmanuNo ratings yet

- Real-Time Software Design For Embedded Systems - Hassan GomaaDocument1,172 pagesReal-Time Software Design For Embedded Systems - Hassan GomaaAhmad Abdulrahem100% (1)

- Simulation of Block Assembly Process in ShipbuildingDocument13 pagesSimulation of Block Assembly Process in ShipbuildingCURRITOJIMENEZ100% (2)

- Lecture10 Mat FoundationsDocument65 pagesLecture10 Mat FoundationsCao_Thanh_470896% (24)

- Ship Design & Construction: From A To ZDocument6 pagesShip Design & Construction: From A To ZmalayrevaNo ratings yet

- ASHRAE Journal-Design Phase Commissioning - Feb 2014Document6 pagesASHRAE Journal-Design Phase Commissioning - Feb 2014WahidHamedNo ratings yet

- OrganizationDocument34 pagesOrganizationalphabeeNo ratings yet

- Performance Based Durability Design of A Bored Tunnel With Concrete LiningDocument10 pagesPerformance Based Durability Design of A Bored Tunnel With Concrete LiningHarold TaylorNo ratings yet

- Movable Bridge: Eng. Skills Project Brief Page 1 of 3Document3 pagesMovable Bridge: Eng. Skills Project Brief Page 1 of 3WaqasNo ratings yet

- Leading-Edge Concepts: Section 5Document73 pagesLeading-Edge Concepts: Section 5jgguiaNo ratings yet

- Energies 14 02706Document15 pagesEnergies 14 02706Ricardo Luís BarataNo ratings yet

- MARINE CAPABILITIES-Rev2Document4 pagesMARINE CAPABILITIES-Rev2Jaowad DabielNo ratings yet

- Early-Stage Design For Electric Ship: by Julie ChalfantDocument15 pagesEarly-Stage Design For Electric Ship: by Julie ChalfantViniciusNo ratings yet

- IWDe Unit4Document80 pagesIWDe Unit4Ayele ErmiyasNo ratings yet

- Performance-Based Design - RMSP PDFDocument16 pagesPerformance-Based Design - RMSP PDFdiegoNo ratings yet

- Kim 2014Document15 pagesKim 2014Moe GyiNo ratings yet

- Cui 2013Document16 pagesCui 2013pidutNo ratings yet

- Performance-Based Design: 2.1 BackgroundDocument16 pagesPerformance-Based Design: 2.1 BackgroundMadhu KumarNo ratings yet

- Concurrent Engineering Development and Practices For Aircraft Design at AirbusDocument9 pagesConcurrent Engineering Development and Practices For Aircraft Design at Airbusanon_658728459No ratings yet

- On Case Studies For Concurrent Engineering Concept in Shipbuilding IndustryDocument16 pagesOn Case Studies For Concurrent Engineering Concept in Shipbuilding IndustryAman BaghelNo ratings yet

- SMR Samindi 2015Document12 pagesSMR Samindi 2015saulolmNo ratings yet

- Lecture Note 1Document17 pagesLecture Note 1Fun JinNo ratings yet

- Automation in Construction: SciencedirectDocument19 pagesAutomation in Construction: SciencedirectKai Sheng SimNo ratings yet

- OK CONSTRAINT-BASED SIMULATION OutfittingDocument11 pagesOK CONSTRAINT-BASED SIMULATION Outfittingjavier diazNo ratings yet

- 2011 01 19 Bridge - Construction - Partner PDFDocument36 pages2011 01 19 Bridge - Construction - Partner PDFwpchengNo ratings yet

- DBPPCTF 01jul11Document20 pagesDBPPCTF 01jul11Michael DavisNo ratings yet

- 2007 135 PDFDocument13 pages2007 135 PDFALIALIRAZARAZAMALIKNo ratings yet

- 2021 A Systematic Approach of Lean Supply Chain ManagementDocument11 pages2021 A Systematic Approach of Lean Supply Chain Managementİsmet AkyelNo ratings yet

- Project CommissioningDocument3 pagesProject CommissioningsiswoutNo ratings yet

- Fy13 01Document41 pagesFy13 01Iram ChaviraNo ratings yet

- Micha Los 2015Document19 pagesMicha Los 2015Avinash KumarNo ratings yet

- Industrial Buildings-Guidelines and Criteria: Dr. James M. FisherDocument5 pagesIndustrial Buildings-Guidelines and Criteria: Dr. James M. FisherersinNo ratings yet

- Early Stage Integrated Parametric Ship Design PDFDocument14 pagesEarly Stage Integrated Parametric Ship Design PDFtalabizNo ratings yet

- A Facility Layout Design Support SystemDocument18 pagesA Facility Layout Design Support SystemhenokzewduNo ratings yet

- Optimization Design of Guiding Device On Hydraulic Press Column Based On Axiomatic Design TheoryDocument5 pagesOptimization Design of Guiding Device On Hydraulic Press Column Based On Axiomatic Design Theoryabdullah yousefiNo ratings yet

- IJCIM OriginalDocument16 pagesIJCIM OriginalPutri Fajar PuspitaNo ratings yet

- Design For ProductionDocument3 pagesDesign For ProductionchandranNo ratings yet

- ICAS2012 Multidisciplinary Airframe Design OptimizationDocument14 pagesICAS2012 Multidisciplinary Airframe Design OptimizationHua Hidari YangNo ratings yet

- EntryDetails - IMI2022 TCE GI 2022 0050562Document5 pagesEntryDetails - IMI2022 TCE GI 2022 0050562sayak banerjeeNo ratings yet

- Efficient Design of Outfitting & Machinery Spaces: R. de Góngora, SENER, Ingenieria y Sistemas S.A., SpainDocument7 pagesEfficient Design of Outfitting & Machinery Spaces: R. de Góngora, SENER, Ingenieria y Sistemas S.A., SpainRAwand17No ratings yet

- Instrumentation Engineer (Level II) - EngDocument4 pagesInstrumentation Engineer (Level II) - EngЧингизNo ratings yet

- Part B. Mooring Equipment Design PhilosophyDocument37 pagesPart B. Mooring Equipment Design Philosophy郑辉No ratings yet

- 3 Biggest Challenges in Modular Construction: (And How To Overcome Them)Document4 pages3 Biggest Challenges in Modular Construction: (And How To Overcome Them)Meek MillNo ratings yet

- CFD and CAD in Ship DesignDocument57 pagesCFD and CAD in Ship DesignslamienkaNo ratings yet

- How To Open An Account - Readme!Document2 pagesHow To Open An Account - Readme!David JohnNo ratings yet

- Asphalt BS 598-108Document10 pagesAsphalt BS 598-108David JohnNo ratings yet

- Asphalt BS 598-108Document10 pagesAsphalt BS 598-108David JohnNo ratings yet

- Asphalt BS 598-109Document10 pagesAsphalt BS 598-109David JohnNo ratings yet

- Jonkers George 2003Document127 pagesJonkers George 2003David JohnNo ratings yet

- Retaining Wall AnalysisDocument13 pagesRetaining Wall AnalysisDavid JohnNo ratings yet

- Lecture 1-TM322 - Civil Engineering ProceduresDocument25 pagesLecture 1-TM322 - Civil Engineering ProceduresDavid JohnNo ratings yet

- Lecture 12 - Examples of Cashflow ManagementDocument3 pagesLecture 12 - Examples of Cashflow ManagementDavid JohnNo ratings yet

- Slab/Mat Panels StaticDocument13 pagesSlab/Mat Panels StaticDavid JohnNo ratings yet

- Solid Slab DesignDocument3 pagesSolid Slab DesignModestus SangaNo ratings yet

- Roof Beams Around Water TankDocument3 pagesRoof Beams Around Water TankDavid JohnNo ratings yet

- Structural Design AnalysisDocument100 pagesStructural Design AnalysisDavid JohnNo ratings yet

- Roof Beams Around Water TankDocument3 pagesRoof Beams Around Water TankDavid JohnNo ratings yet

- Ground Floor - RevisedDocument1 pageGround Floor - RevisedDavid JohnNo ratings yet

- Solid Slab DesignDocument3 pagesSolid Slab DesignModestus SangaNo ratings yet

- Lochi Plaza Ground Beam LayoutDocument1 pageLochi Plaza Ground Beam LayoutDavid JohnNo ratings yet

- Crown Tech ReportDocument100 pagesCrown Tech ReportDavid JohnNo ratings yet

- Cover PageDocument1 pageCover PageDavid JohnNo ratings yet

- Lochi Plaza - FoundationDocument1 pageLochi Plaza - FoundationDavid JohnNo ratings yet

- Lochi Plaza 4y25 (2col) (C3)Document1 pageLochi Plaza 4y25 (2col) (C3)David JohnNo ratings yet

- 1st Floor - RevisedDocument1 page1st Floor - RevisedDavid JohnNo ratings yet

- Tabora Roads NetworkDocument1 pageTabora Roads NetworkDavid John100% (1)

- 101 Ready-To-Use Excel Formulas - Michael AlexanderDocument2 pages101 Ready-To-Use Excel Formulas - Michael AlexanderDavid JohnNo ratings yet

- Front View Right Hand Side ViewDocument1 pageFront View Right Hand Side ViewDavid JohnNo ratings yet

- Policy Analysis ProcessDocument9 pagesPolicy Analysis ProcesswubeNo ratings yet

- AF302 Course Outline For Semester 1, 2020Document11 pagesAF302 Course Outline For Semester 1, 2020Mithlesh PrasadNo ratings yet

- Orange HRM Test PlanDocument7 pagesOrange HRM Test PlanRowland ObiNo ratings yet

- Principles of Controlled Maintenance Management PDFDocument138 pagesPrinciples of Controlled Maintenance Management PDFjovNo ratings yet

- What Is ManageabilityDocument5 pagesWhat Is Manageabilitynearurheart1No ratings yet

- Module 1 - Management - PlanningDocument30 pagesModule 1 - Management - PlanningPrãvëèñ HêgådëNo ratings yet

- Chapter 1 Introduction To System Dynamics SimulationDocument18 pagesChapter 1 Introduction To System Dynamics SimulationCheng NatalieNo ratings yet

- DCIT 403 - Desining Intelligent Agents - OutlineDocument6 pagesDCIT 403 - Desining Intelligent Agents - OutlineSamuel Sackey (10847179)No ratings yet

- Osteras2006 (NPD)Document17 pagesOsteras2006 (NPD)Raditya AgungNo ratings yet

- Theory of Knowledge ExplainedDocument10 pagesTheory of Knowledge ExplainedimNo ratings yet

- Sybms It ImpDocument24 pagesSybms It ImpSancia DsouzaNo ratings yet

- International University of Travnik Faculty of Polytechnic Sciences TravnikDocument12 pagesInternational University of Travnik Faculty of Polytechnic Sciences TravnikTiross DesignsNo ratings yet

- Iso 9001 - 2015Document16 pagesIso 9001 - 2015QBMontgomeryNo ratings yet

- Software Development Plan Information OutlineDocument3 pagesSoftware Development Plan Information OutlineBeverly WoodNo ratings yet

- 3A668BC6040Document6 pages3A668BC6040Anonymous I3VKoiNo ratings yet

- Web Management for Selam Tour AgencyDocument101 pagesWeb Management for Selam Tour Agencydawit dd3784No ratings yet

- Software Requirements Engineering (SRE) FundamentalsDocument36 pagesSoftware Requirements Engineering (SRE) FundamentalsABDUL MOIZ HUSSAINNo ratings yet

- Abcc1103 Introduction To CommunicationDocument5 pagesAbcc1103 Introduction To Communicationdicky chongNo ratings yet

- Chapter 1-5 Malagnat Student Information SystemDocument79 pagesChapter 1-5 Malagnat Student Information SystemMajal SangdaanNo ratings yet

- Taylor's Scientific ManagementDocument27 pagesTaylor's Scientific ManagementSreenath S KallaaraNo ratings yet

- HEXAGON MI Flyer Energy A4 EN WebDocument2 pagesHEXAGON MI Flyer Energy A4 EN WebSanjay ShelarNo ratings yet

- Level 5 ElecDocument62 pagesLevel 5 ElecUdara DissanayakeNo ratings yet

- Chantzaras 2018 ArchitectureasSystemDesignInnovationDesignDiscipline WorkingPaperDocument17 pagesChantzaras 2018 ArchitectureasSystemDesignInnovationDesignDiscipline WorkingPaperxin xuNo ratings yet

- Predicting Stock Price Using Fuzzy Grey Prediction System: Y.-F. WangDocument6 pagesPredicting Stock Price Using Fuzzy Grey Prediction System: Y.-F. WangNiloy Abu NaserNo ratings yet

- A Survey of Cyber-Physical SystemsDocument6 pagesA Survey of Cyber-Physical SystemsGeraldo CastroNo ratings yet

- 5100333-00 - Salwico Cruise - Installation Manual - M - EN - 2018 - XDocument118 pages5100333-00 - Salwico Cruise - Installation Manual - M - EN - 2018 - XAdegbola AdedipeNo ratings yet