Professional Documents

Culture Documents

Problems: Mitesh Ajay Pawar Om Ravindra Ingole

Problems: Mitesh Ajay Pawar Om Ravindra Ingole

Uploaded by

Yashika Gupta0 ratings0% found this document useful (0 votes)

7 views2 pagesThe document describes performing finite element analysis of orthogonal machining using Abaqus/explicit. It involves:

1) Determining the contour plot of chip formation showing von-Mises stress and temperature.

2) Plotting cutting forces and temperature at the tool tip over time.

3) Measuring the shear angle.

It provides a table with material properties and test parameters for 26 experiments on Ti6Al4V, Inconel 718, and Al2024 aluminum. It also includes a diagram of the workpiece-tool geometry.

Original Description:

Original Title

Orthogonal_Machining_Problems

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document describes performing finite element analysis of orthogonal machining using Abaqus/explicit. It involves:

1) Determining the contour plot of chip formation showing von-Mises stress and temperature.

2) Plotting cutting forces and temperature at the tool tip over time.

3) Measuring the shear angle.

It provides a table with material properties and test parameters for 26 experiments on Ti6Al4V, Inconel 718, and Al2024 aluminum. It also includes a diagram of the workpiece-tool geometry.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

7 views2 pagesProblems: Mitesh Ajay Pawar Om Ravindra Ingole

Problems: Mitesh Ajay Pawar Om Ravindra Ingole

Uploaded by

Yashika GuptaThe document describes performing finite element analysis of orthogonal machining using Abaqus/explicit. It involves:

1) Determining the contour plot of chip formation showing von-Mises stress and temperature.

2) Plotting cutting forces and temperature at the tool tip over time.

3) Measuring the shear angle.

It provides a table with material properties and test parameters for 26 experiments on Ti6Al4V, Inconel 718, and Al2024 aluminum. It also includes a diagram of the workpiece-tool geometry.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

Problems

Perform finite element analysis of orthogonal machining, for workpiece-tool geometry as shown in

the figure, using Abaqus/explicit and determine following things:

1. Contour plot of chip formation with von-mises stress and temperature

2. Plot cutting forces and temperature at tool tip with the time of machining, and

3. Measure shear angle.

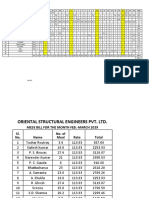

S. No. Material Cutting speed Depth of cut ( Coefficient Name of student

(m/s) x 10-3 m) of friction

1 Ti6Al4V 0.5 0.1, 0.2, 0.3 .3 Love Kush Tak

2 Ti6Al4V .5, 1, 1.5 .2 .2 Naman Agarwal

3 Ti6Al4V 1 .2 .1, .2, .3 Abhinav Apurva

4 Inconel 718 1 0.1, 0.2, 0.3 .3 Aditi Raj

5 Inconel 718 .5, 1, 1.5 .2 .2 Dnyandeep

Chandrashekhar Kale

6 Inconel 718 0.5 .2 .1, .2, .3 Himanshu Kumar

7 Al2024 2 0.1, 0.2, 0.3 .3 Patel Vijayantmonu

Narendrakumar

8 Al2024 1, 2, 3 .2 .2 Prasann Jaiswal

9 Al2024 2 .2 .1, .2, .3 Sunil Chandel

10 Ti6Al4V, Inconel 1 .2 .2 Tejas Sanju Pawar

718, Al 2024

11 Ti6Al4V, Inconel 1 .3 .2 Utkarsh Sahu

718, Al 2024

12 Ti6Al4V, Inconel 1 .2 .1 Yashika Gupta

718, Al 2024

13 Ti6Al4V, Inconel 1 .1 .4 Akshat Shriwas

718, Al 2024

14 Ti6Al4V, Inconel 1 .3 .3 Amey Praphull Kavade

718, Al 2024

15 Ti6Al4V 1 0.1, 0.2, 0.3 .3 Durgaraj Sriram

16 Inconel 718 0.5 0.1, 0.2, 0.3 .3 Mitesh Ajay Pawar

17 Al2024 2 0.1, 0.2, 0.3 .3 Om Ravindra Ingole

18 Ti6Al4V 1 0.1, 0.2, 0.3 .2 Prajjawal Singh-

19 Inconel 718 0.5 0.1, 0.2, 0.3 .2 Shardul Burde

20 Al2024 2 0.1, 0.2, 0.3 .2 Sudhanshu Dharmapal

Meshram

21 Ti6Al4V .5, 1, 1.5 .3 .1 Vanshika Gupta

22 Al2024 1, 2, 3 .3 .1 Viren Dipakkumar

Parmar

23 Inconel 718 .5, 1, 1.5 .3 .2 Aniket Ghosh

24 Ti6Al4V 1 .3 .1, .2, .3 Somya Singh

25 Inconel 718 0.5 .3 .1, .2, .3

26 Al2024 2 .3 .1, .2, .3

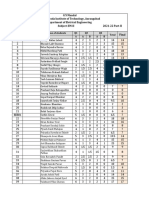

4 mm

Cutting speed

4 mm

Depth of cut

4 mm

18 mm

Fig: Workpiece-tool geometry for orthogonal geometry

Note: Consider rake angle and clearance angle constant as 150 and 100 respectively.

You might also like

- Module 2B - Readiness For Enhanced Breastfeeding - BSN 2ADocument4 pagesModule 2B - Readiness For Enhanced Breastfeeding - BSN 2ALuis Gatchalian Lacanilao100% (2)

- SEL-787 Pickup and Slope Test Calculations For AG2011-09Document17 pagesSEL-787 Pickup and Slope Test Calculations For AG2011-09jigyeshNo ratings yet

- Emerging Roles of The Lymphatic System in Herbal MedicineDocument26 pagesEmerging Roles of The Lymphatic System in Herbal MedicineplantwisdomNo ratings yet

- CFM56Document378 pagesCFM56yasanuNo ratings yet

- Tabel Penilaian Afektif A. Kelas Eksperimen No. Nama Pertemuan Rata-Rata I II III IV VDocument4 pagesTabel Penilaian Afektif A. Kelas Eksperimen No. Nama Pertemuan Rata-Rata I II III IV VAyu AnnisahNo ratings yet

- Analisis PTS Kelas 5Document6 pagesAnalisis PTS Kelas 5Reka NofiantiNo ratings yet

- MessDocument13 pagesMessPartha Sarathi BiswasNo ratings yet

- Problem 1: ME 370: Adams Lab.: 2021: Session 9Document5 pagesProblem 1: ME 370: Adams Lab.: 2021: Session 9Aadhya SinghNo ratings yet

- Format Analisis PASDocument4 pagesFormat Analisis PASelisa fitriNo ratings yet

- Borang Transit MTDocument42 pagesBorang Transit MTSivasakty NadarasonNo ratings yet

- MQ MarksDocument3 pagesMQ MarksAbhishek KumarNo ratings yet

- FlightDetail ReportDocument3 pagesFlightDetail ReportAbedur Rahman KhanNo ratings yet

- Daftar Nama Admen Bab 1,2,3 BaruDocument3 pagesDaftar Nama Admen Bab 1,2,3 Barusakerani 77No ratings yet

- Penilaian k13 Pengetahuan Dan Keterampilan SMPN 4 Satap Kls Vii-IxDocument11 pagesPenilaian k13 Pengetahuan Dan Keterampilan SMPN 4 Satap Kls Vii-IxLsdaNo ratings yet

- IGCSE (9-1) Maths - Practice Paper 5H Mark SchemeDocument13 pagesIGCSE (9-1) Maths - Practice Paper 5H Mark SchemeHan ZhangNo ratings yet

- IS 460 (Part 1) : 2020Document10 pagesIS 460 (Part 1) : 2020bestenlabNo ratings yet

- AssignmentsFE 6 To 8Document34 pagesAssignmentsFE 6 To 8itsmeatherbukhariNo ratings yet

- Survey - No Village Hobli Taluk AREA (Acre) Survey - No Village Hobli Taluk AREA (Acre) 482 481Document1 pageSurvey - No Village Hobli Taluk AREA (Acre) Survey - No Village Hobli Taluk AREA (Acre) 482 481Venkat RSNo ratings yet

- Class Time Day Teacher Start Room Remark 1Document5 pagesClass Time Day Teacher Start Room Remark 1Mei AstutiNo ratings yet

- Chapter - 3 Experimentation & Results and DiscussonDocument17 pagesChapter - 3 Experimentation & Results and Discussonthalla rajenderNo ratings yet

- FarmerDocument445 pagesFarmerchandra DiveshNo ratings yet

- KNN052Document5 pagesKNN052531Binod KumarNo ratings yet

- Ms 2 XLBRDocument5 pagesMs 2 XLBRTungstenCarbideNo ratings yet

- Jadwal Shift Logistik November 2023Document1 pageJadwal Shift Logistik November 2023Andrean AzzkaNo ratings yet

- Promes Pjok Kelas 9 K13Document4 pagesPromes Pjok Kelas 9 K13smkypk sumedangNo ratings yet

- ELECTRONICA 1 Labo 4 Alba Uriona MijaelDocument10 pagesELECTRONICA 1 Labo 4 Alba Uriona Mijaelvladimir quispe condoriNo ratings yet

- Data Hasil Pengujian Organoleptik Uji Hedonik Produk Dendeng Daging Sapi (Excell)Document11 pagesData Hasil Pengujian Organoleptik Uji Hedonik Produk Dendeng Daging Sapi (Excell)Rizki Aulia NuzullinaNo ratings yet

- LandDocument3 pagesLandSamarakoon GroupNo ratings yet

- 11 12 National Income - Copy 2Document5 pages11 12 National Income - Copy 2gargee thakareNo ratings yet

- Mobpls Raw DataDocument145 pagesMobpls Raw DataRoudell BautistaNo ratings yet

- Rekapitulasi AngketDocument10 pagesRekapitulasi Angketagung webinarNo ratings yet

- Analisis KD Baru KLS A 2021 BDocument175 pagesAnalisis KD Baru KLS A 2021 BDp IndahNo ratings yet

- Coral Reef - SummaryDocument3 pagesCoral Reef - SummaryHikal GmailNo ratings yet

- Lesson 08 17 Calculations Summary EndDocument72 pagesLesson 08 17 Calculations Summary EndmatinNo ratings yet

- Asignments RemainDocument1 pageAsignments Remainshaikhmehar29No ratings yet

- Balrampur Chini Mills Limited: 21 March 2007Document52 pagesBalrampur Chini Mills Limited: 21 March 2007Rajeev NegiNo ratings yet

- ANABUT PTS 2 AQIDAH 7 Aisyah 22-23Document9 pagesANABUT PTS 2 AQIDAH 7 Aisyah 22-23Muhammad AhsanNo ratings yet

- 26-08-23 JR - Super60 Nucleus BT Jee-Main Wtm-06 Key & Sol'sDocument12 pages26-08-23 JR - Super60 Nucleus BT Jee-Main Wtm-06 Key & Sol'sSanthosh KasulavadhaNo ratings yet

- CF CS1 CF CN 602Document179 pagesCF CS1 CF CN 602vivek guptaNo ratings yet

- Assignment 1: Sr. No. Name Assigned Problems Section No. Problem NosDocument1 pageAssignment 1: Sr. No. Name Assigned Problems Section No. Problem NosSairamkaliraj AnbareeswaranNo ratings yet

- Jadual Spesifikasi Ujian (Jsu) Tahun: 4: Nama Guru: Suriani Mata Pelajaran: Pendidikan Islam KertasDocument4 pagesJadual Spesifikasi Ujian (Jsu) Tahun: 4: Nama Guru: Suriani Mata Pelajaran: Pendidikan Islam KertasKhairi KamaliahNo ratings yet

- Marsianah - Analisis NilaiDocument4 pagesMarsianah - Analisis Nilaimarsianah2016No ratings yet

- INFLATIONDocument3 pagesINFLATIONSnehasis MukhopadhyayNo ratings yet

- Sept Ijmte - CWDocument9 pagesSept Ijmte - CWA JNo ratings yet

- Cities in RajasthanDocument2 pagesCities in RajasthanHemant ChopraNo ratings yet

- DsdasdsadasDocument9 pagesDsdasdsadasNoella Faith HipolitoNo ratings yet

- Borang Transit BMDocument6 pagesBorang Transit BMNuurHafiza SaadNo ratings yet

- Sri Hadiliani, SeDocument2 pagesSri Hadiliani, SeHastariNo ratings yet

- KEY Subject: Electrical EngineeringDocument3 pagesKEY Subject: Electrical Engineeringnk1224No ratings yet

- Analisis Cross CheckDocument2 pagesAnalisis Cross Checkyuli firliNo ratings yet

- Roll No PRN No Name of Students Q1 Q2 Q3 Total A A B A BDocument2 pagesRoll No PRN No Name of Students Q1 Q2 Q3 Total A A B A BShankar BhauNo ratings yet

- Nama Nomor Soal Skor Total Ganjil Genap Awal Akhir 1 2 3 4 5 6 7 8 9 10 11 12 13 14Document3 pagesNama Nomor Soal Skor Total Ganjil Genap Awal Akhir 1 2 3 4 5 6 7 8 9 10 11 12 13 14Alda RizkyNo ratings yet

- LampiranDocument47 pagesLampirank74q4tvdrsNo ratings yet

- Nominal Run Pipe Reference Standards Thicknesses (E MM) TUBASYS SLU Manufacturing Standards (E MM)Document1 pageNominal Run Pipe Reference Standards Thicknesses (E MM) TUBASYS SLU Manufacturing Standards (E MM)Justin ReyesNo ratings yet

- Siddaganga Institute of Technology, Tumakuru - 572 103: Department of Electronics & Communication EngineeringDocument6 pagesSiddaganga Institute of Technology, Tumakuru - 572 103: Department of Electronics & Communication EngineeringkiranNo ratings yet

- BN - 82213 Pozi Flat Countersunk Head Machine Screws Form ZDocument3 pagesBN - 82213 Pozi Flat Countersunk Head Machine Screws Form ZMSD ENGRNo ratings yet

- Analisis Ulangan Semester Genap 17-18Document27 pagesAnalisis Ulangan Semester Genap 17-18محمد ارهمNo ratings yet

- Analisis Soal Uh Tema 1-EditDocument10 pagesAnalisis Soal Uh Tema 1-Editannisa muslihah rahmayantiNo ratings yet

- Remedial UKK1Document1 pageRemedial UKK1smkn1 muarauyaNo ratings yet

- Document PDF 409Document16 pagesDocument PDF 409SAURABH KUMARNo ratings yet

- Cuadro de Matriz Teoria de JeugosDocument3 pagesCuadro de Matriz Teoria de JeugosMiguel Angel Huaranga AguilarNo ratings yet

- Multi-Sulfur and Sulfur and Oxygen Five- and Six-Membered Heterocycles, Part 2From EverandMulti-Sulfur and Sulfur and Oxygen Five- and Six-Membered Heterocycles, Part 2David S. BreslowNo ratings yet

- Personality: Unit B (Topic 3)Document47 pagesPersonality: Unit B (Topic 3)REHANRAJNo ratings yet

- Ayurvedic Management of Acute Food Induced Anaphylactic Reaction - A CaseDocument5 pagesAyurvedic Management of Acute Food Induced Anaphylactic Reaction - A CaseShivam TrivediNo ratings yet

- CH 18 Lecture PresentationDocument127 pagesCH 18 Lecture PresentationMaski03No ratings yet

- The Two Seasons of The PhilippinesDocument59 pagesThe Two Seasons of The PhilippinesZenobia Joy VillarbaNo ratings yet

- Comment: Two Years of COVID-19 in Africa: Lessons For The WorldDocument4 pagesComment: Two Years of COVID-19 in Africa: Lessons For The Worldotis2ke9588No ratings yet

- Dokumen - Tips Introduction To The Ablls RDocument49 pagesDokumen - Tips Introduction To The Ablls Rعلم ينتفع بهNo ratings yet

- Music Keys and BPM Copy 4Document466 pagesMusic Keys and BPM Copy 4gabidjNo ratings yet

- Curs 4 Victorian NovelDocument6 pagesCurs 4 Victorian NovelAnda NeguraNo ratings yet

- WR 6Document8 pagesWR 6trang phạmNo ratings yet

- Clerkship ManualDocument132 pagesClerkship ManualasdfasdfNo ratings yet

- Rights of MinoritiesDocument9 pagesRights of MinoritiesAbdul WasayNo ratings yet

- The Echelon Forest SpreadsDocument15 pagesThe Echelon Forest SpreadsMattia LeonciniNo ratings yet

- Case Study Analysis - An Underwater MeetingDocument3 pagesCase Study Analysis - An Underwater Meetingsiti sri wahyuniNo ratings yet

- Safety QuotesDocument9 pagesSafety Quotessangeethu3304No ratings yet

- Quantum Theory of The Development of Science, Economic and Society.Document41 pagesQuantum Theory of The Development of Science, Economic and Society.Bezverkhniy VolodymyrNo ratings yet

- Optimization of Fermentation Conditions For EthanoDocument9 pagesOptimization of Fermentation Conditions For Ethanovodachemicals20No ratings yet

- National Council of Teachers of Mathematics Is Collaborating With JSTOR To Digitize, Preserve and Extend Access To The Mathematics TeacherDocument2 pagesNational Council of Teachers of Mathematics Is Collaborating With JSTOR To Digitize, Preserve and Extend Access To The Mathematics TeacherPerpetual AmazinggirlNo ratings yet

- Hexametrical Genres From Homer To Theocritus Christopher Athanasious Faraone Full ChapterDocument67 pagesHexametrical Genres From Homer To Theocritus Christopher Athanasious Faraone Full Chapterlouis.cook744100% (16)

- Quantitative ResearchDocument23 pagesQuantitative ResearchMitzie MaliniasNo ratings yet

- Model Engineers' Workshop 11.2021Document68 pagesModel Engineers' Workshop 11.2021Leapfrog100% (2)

- Belt Tensioning ProcedureDocument2 pagesBelt Tensioning Procedureanguyen22153319No ratings yet

- 2014 0224 Aspen Capital Cost Estimator Overview-AACE 25 Feb 2014 PDFDocument37 pages2014 0224 Aspen Capital Cost Estimator Overview-AACE 25 Feb 2014 PDFAbdul RBed IsaNo ratings yet

- O. Gafri, A. Izhar, Y. Livshitz and V. Shribman - Magnetic Pulse AccelerationDocument8 pagesO. Gafri, A. Izhar, Y. Livshitz and V. Shribman - Magnetic Pulse AccelerationCola7890No ratings yet

- 2023 - Associate Professor of Art and TechnologyDocument9 pages2023 - Associate Professor of Art and Technologyartlover30No ratings yet

- Mathematic Question For Board ExamDocument68 pagesMathematic Question For Board ExamDans DepeterNo ratings yet

- Ekman - Universals and Cultural Differences in The Judments of Facial Expressions of EmotionDocument7 pagesEkman - Universals and Cultural Differences in The Judments of Facial Expressions of EmotionEsteban Benjamin Droguett VizcarraNo ratings yet

- Total Quality Management Literature Review and An Agenda For Future ResearchDocument12 pagesTotal Quality Management Literature Review and An Agenda For Future ResearchafdtzfutnNo ratings yet