Professional Documents

Culture Documents

General Description Features: Cost Effective LED Controller

Uploaded by

anilOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

General Description Features: Cost Effective LED Controller

Uploaded by

anilCopyright:

Available Formats

OB3 3 5 0

Cost Effe ct iv e LED Con t r olle r

FEATURES

GENERAL DESCRIPTION

Current Mode PWM Controller With Good

OB3350 is a highly integrated and cost effective

Dynamic Response

Light Emitting Diode (LED) driver optimized for

8V to 35V Input Voltage Range

LCD monitor and LCD TV backlighting application.

External PWM Dimming Mode

It provides a high performance LED backlight

Over Voltage Protection

solution with minimized BOM count.

Over Current Protection

The OB3350 contains a PWM boost driver which

Under Voltage Lockout (UVLO)

uses current mode control and fixed frequency

Thermal Shutdown

operation to regulate the LED current. The LED

current is sensed through an external current

sense resistor. The voltage across the sensing

resistor is compared with reference level of 300mV, APPLICATIONS

the error is amplified to control the pulse width of LCD Monitor

the power switch thus to regulate the current LCD TV

flowing the LED. Flat panel display

play

The OB3350 offers external low frequency PWM

(LPWM) dimming method for a wide range of

dimming control. 350 is offered

The OB3350 ed in

i SOP

SOP-8 Packages.

The OB3350 offers comprehensive protection

such as power MOSFET over current protection

(OCP), output over voltage protection (OVP), IC

power supply under voltage lockout (UVLO), and

LED open protection.

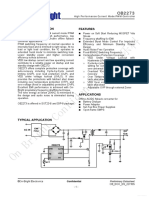

TYPICAL APPLICATION

Figure1. OB3350 Typical Application Schematic

©On-Bright Electronics Confidential Preliminary datasheet

OB_DOC_DS_335000

-1-

OB3 3 5 0

Cost Effe ct iv e LED Co n t ro lle r

Absolute Maximum Ratings Recommended Operating Range

Parameter Value Parameter Value

VIN Input Voltage to GND -0.3V to 40V Vin Voltage 8V to 35V

I/O to GND -0.3V to 7V Burst Dimming Frequency 100Hz to 1KHz

Operating Ambient Temp. TA -40 ~ 85

Operating Junction Temp. TJ -40 ~ 150 Package Thermal Characteristics

Min/Max Storage Temp. Tstg -55 ~150 Parameter Value

Lead Temp. (10 Sec) 260 Thermal Resistance JA

150 /W

Note: Stresses beyond those listed under absolute maximum (SOP)

ratings may cause permanent damage to the device. These

are stress ratings only, functional operation of the device at Ordering Information

these or any other conditions beyond those indicated under Part Number Description

ription

recommended operating conditions is not implied. Exposure OB3350CP SOP8,

8, pb-free in ttube

to absolute maximum-rated conditions for extended periods OB3350CPA SOP8,

SOP8 pb-free

free iin T&R

may affect device reliability.

OB3350 X X X

Package Package Pb- free Packing

Cost Effective LED Controller

Blank:Tube

C:SOP8 P:Pb-free

A: Taping

Package Marking Information

Y:Year Code

WW:Week Code(01-52)

ZZZ:Lot Code

C:SOP8 Package

P:Pb-free Package

S:Internal Code(Optional)

©On-Bright Electronics Confidential Preliminary datasheet

OB_DOC_DS_335000

-2-

OB3 3 5 0

Cost Effe ct iv e LED Co n t ro lle r

Pin Configuration

VIN 1 8 PWM

GATE 2 7 OVP

OB3350

GND 3 6 COMP

CS 4 5 FB

No. Name I/O Pin

in Function

Funct

1 VIN Power Po

Power Supply IInput

2 GATE I/O Gate Driver

Dr

D O

Output Pin

3 GND GND Ground

4 CS I/O Curr

Current Sense Input

5 FB I/O LED Current Feedback Input

6 COMP I/O Boost

Boos Converter Loop Compensation Pin

7 OVP I/O Over Voltage Protection Sense Input

8 PWM I/O

O External PWM Dimming Control

©On-Bright Electronics Confidential Preliminary datasheet

OB_DOC_DS_335000

-3-

OB3 3 5 0

Cost Effe ct iv e LED Co n t ro lle r

Functional Block Diagram

UVLO

DIM

OSC

VIN

Ramp Thermal 5V Reference

Adjust Shutdown

Soft-start

Control Gate

S PW GATE

Logic Drive

M

COMP

PWM

Comparator

EA

FB Vth_ovp DIM

PWM

Control

Sense

Amplifer

CS GND

OVP

O VP

P

unctional

ctional Block

Figure2. OB3350 Functional Blo Diagram

©On-Bright Electronics Confidential Preliminary datasheet

OB_DOC_DS_335000

-4-

OB3 3 5 0

Cost Effe ct iv e LED Co n t ro lle r

Electrical Characteristics

VDDH=12V,PWM=5V, TA=25 , if not otherwise noted.

Parameter Symbol Conditions Min Typ Max Units

Current Consumption

Input voltage range 8 - 35 V

Vin=12V,PWM=5V no

Operating supply current IVDD - 2.5 3 mA

load

IVDD _ STB PWM low >50ms sleep

Stand by current - 310 400 uA

mode

VDD UVLO

UVLO UVLO(ON) 6 7 8 V

UVLO Hysteresis UVLO(Hys) 500 mV

Soft start

Soft start slope I sst _ slop 400 mV/mS

PWM Control

Operating frequency FOSC 175 200 225 KHz

Max duty cycle Dmax 93 95 97 %

PWM(high) High Level 2.5 V

PWM Input Threshold

PWM(low) Low Level 1.3

1 V

Error Amplifier

Vref _ ea Reference

erence

ce voltage a at

Reference voltage 0.289 0.3 0.311 V

non-inverting

inverting inpu

input

Open loop voltage gain Am 70 dB

Transconductance of EA Gm 80 100 120 uA/V

Output source current I source 24 30 36 uA

Output sink current I sin k 48 60 72 uA

Protection Threshold

Threshold of output

OVP VOVP

VP OV 1.8 2.0 2.2 V

over voltage

Threshold of over

OCP Vth_OCP

_OCP current protection 330 mV

(duty=90%)

OTP ON TOTP _ ON 140 160 180

OTP OFF TOTP _ OFF 120 140 160

Connectt detect time Tdio 1 mS

Normal operation 200 mV

OVP

P UVLO

LO threshold VOVP UV

System startup 100 mV

Gate

e Driver O

Output

Gate rise tim

time Trise 500pF load - 40 80 ns

Gate fall time T fall 500pF load 20 40 ns

©On-Bright Electronics Confidential Preliminary datasheet

OB_DOC_DS_335000

-5-

OB3 3 5 0

Cost Effe ct iv e LED Co n t ro lle r

Function Description switching operation when the voltage at pin VIN

increases to a voltage above 7.5V.

General Operation LED Current Regulation

The OB3350 is a LED driver designed for boost The LED current is sensed by current sense

DC-DC converters in a constant frequency mode. resistors connected between pin FB and GND.

The controller implements a peak current mode The sensed error signal is amplified and compared

control scheme and an internal transconductance to the CS pin sensing current signal plus the sslope

amplifier to accurately control the output current compensation to determine the on-time the

time of tth

over a wide input and load conditions. switching MOSFET. The error amplifiermplifier

plifier sources o

or

Low frequency PWM dimming input that can sinks the current to the COMP P pin to adjust the

accept an external control signal with a duty ratio required inductor current as thehe load d changes.

chang The

Th

of 1%-100%. OB3350 offers comprehensive slope-compensation signal gnal is added to the

protection features to protect the system in various current-sense signal to improve

proveve the stability

stabilit at high

fault conditions such as output over voltage duty cycles.

protection, boost diode disconnection protection The average LED current approximated by the

rrent is ap

app

approxi

and output short circuit protection. The following equation

cycle-by-cycle current limit function limits the 300[ mV ]

I LED

ED [mA]

maximum current flowing through the external R FB [ ]

MOSFET. The over temperature protection

ensures that the system will not run into condition At light

ght loading, the OB3350

OB automatically skips

of thermal runaway and blow up. some

ome e pulses to imimprove efficiency and prevent

Startup overcharging

ercharging th the output capacitor. In this

pulse-skipping mode, the inductor current ramps

OB3350 is enabled by applying a voltage of up for a miminimum on-time (typical 300ns), then

greater than approximately 2.5V to PWM pin. An deliver the stored energy to the output. The switch

on-chip internal 150k ohm pull down resistor istor is remains off until another pulse is needed to boost

remain

inserted between PWM pin and ground. When hen the output voltage.

the ou

first rising edge is applied to PWM input,, also the

pin of PWM is logic high, the OB3350 willl power up Slope Compensation

immediately, and remains power up until ntil the PWM The OB3350 uses a current mode control scheme.

input has been hold low for at least 50ms(typ)

50ms(typ), at The main advantages of current mode control are

this time the chip will enter sleepeep mo sleep

mode.. At slee inherent cycle-by-cycle current limit for the switch

mode, the power of theOB3350 lower than

3350 will be lowe and simpler control loop characteristics. However,

400uA (typ). current mode control has an inherent instability for

Once OB3350 is enabled nabled the internal 5V regulator duty cycles greater than 50%, which is also called

will be activated to source less than 4mA

ource a current les sub-harmonic oscillation. The OB3350 has a

to the whole chip. build-in slope compensation to avoid sub-harmonic

When PWM is active high, the OB OB3350 checks the oscillation.

topology connection

onnection first. The chip monitors the

OVP pin in Schottky diode (boost diode)

n to see if the Schottk

Scho

is connected

nnected or the boo output is short to GND, if

boost o

the age at OVP pin is lower than 100mV, the

he voltage

output disabled. The OB3350 will also

tput will be disab

check other faulfaults (UVLO, OCP and OTP), if there

is no fault, then the boost converter will boost up

output with the internal soft start.

the outpu

UVLO

LO

An under-voltage lockout protection feature with a

hysteresis of about 300mv is provided for VDDH.

When the voltage at this pin exceeds a threshold Figure4 Sub-harmonic oscillation at duty>50%

of approximately 7.5V (typ), the IC starts the and compensation slope to avoid sub-harmonic

normal operation. If the voltage at this pin drops oscillation

below a threshold of approximately 7(typ) V, the IC If the control signal (which applied to the negative

stops switching operation. The IC resumes input of the PWM comparator) has no slope and

©On-Bright Electronics Confidential Preliminary datasheet

OB_DOC_DS_335000

-6-

OB3 3 5 0

Cost Effe ct iv e LED Co n t ro lle r

the slope which representing inductor current ramp Dimming Control

up until the comp signal is reached, then ramp

The LED brightness is controlled by the PWM

down. If the duty > 50%, any distribution wont be

signal at PWM pin which has different duty cycle.

converged from duty to duty and thus

OB3350 can accept an external PWM signal to

sub-harmonic oscillation happens. For the

PWM pin in the range of 100Hz to 1 KHz with a

equation below:

swing voltage of 0V to a level greater than 2.5V.

S f Se

I ( n 1) I ( n) OVP Protection

Sn Se

To avoid sub-harmonic oscillation happening, just OB3350 shuts down the output iff the he output

make sure (Sf-Se) / (Sn+Se) smaller than 1. termined

voltage is higher than the predetermined mined threshold

For boost applications, the slopes Se, Sf and Sn level. In case of LED failing, the he

e current

curren

urrent

rrent of LED

can be calculated with the formulas below and a and the resulted voltage drop opp on sensing

ensing

sing re

rresisto

resistor

typical value of VSL is 50mV. rter

is nearly zero; the converterter will run att maximum

max

maxim

maxi

S e VSL f s duty cycle that boosts the ou tput voltage tto a very

output

high level. To preventnt this happen,

appen,, the output

his happ

Sf R sen Vout Vin / L voltage is monitored

red

ed through Pin O OVP and

S n R sen Vin / L converter is shutt down output voltage

n if the outp

outpu

When Se increases then the factor which can exceeds the predeterm

predetermined

predeter

termined

rmined levlevel. This protection

le

determine whether the sub-harmonic oscillation is latched and OB3350 can be reset from VIN or

will occur decreases. When the duty cycle is PWM.

greater than 50% and the inductance becomes VOUT

T SHORT Protection

HORT Prote

less, the factor increases. And for more flexibility

slope compensation amplitude can be increased VOUT condition is monitored by the voltage

UT short condi

by adding one external resistor, RSL, in the CS at pins OVP. During normal operation, when the

path. Figure 4 shows the setup. The externally voltage at O OVP pin drops below a threshold of

generated slope compensation is then added ed to approximately 0.2V, the VOUT-short protection

approxima

3350.

the internal slope compensation of the OB3350. functio is activated and the GATE is turned off.

function

When using external slope compensation,ation,, the This state is latched and can be reset from VIN or

formula for Se becomes: PWM.

PWM

S e (VSL I s RSL ) f s Thermal Shutdown

A typical value of Is is 40uA. The OB3350 includes a thermal protection circuit.

When the junction temperature exceeds 160°C

(typical), the controller and current sources shut

down and do not restart until the junction

temperature drops below 140°C (typical).

Figure5 Addin external slope compensation to OB3350

Adding e

de

Its good design practice to only add as much

slope compensation as needed to avoid

sub-harmonic oscillation. Additional slope

compensation minimized the influence of the

sensed current in the control loop. With very large

slope compensation the control loop

characteristics are similar to a voltage mode

regulator which compares the error voltage to a

saw tooth waveform rather than the inductor

current.

©On-Bright Electronics Confidential Preliminary datasheet

OB_DOC_DS_335000

-7-

OB3 3 5 0

Cost Effe ct iv e LED Co n t ro lle r

Reference Application

Figure6. OB3350 for external LPWM dimming Reference Application Schematic

©On-Bright Electronics Confidential Preliminary datasheet

OB_DOC_DS_335000

-8-

OB3 3 5 0

Cost Effe ct iv e LED Co n t ro lle r

PACKAGE MECHANICAL DATA

Dimension In Millimeters

Dimensions Dimensions In Inches

Symbol

Min Max Min Max

A 1.350 1

1.750 0.053 0.069

A1 0

0.050

050 0.250 0.002 0.010

A22 1

1.250 1.650 0.049 0.065

b 0.310 0.510 0.012 0.020

c 0.100 0.250 0.004 0.010

D 4.700 5.150 0.185 0.203

E 3.800 4.000 0.150 0.157

E1

E 5

5.800 6.200 0.228 0.244

e 1.270 (BSC) 0.050 (BSC)

L 0.400 1.270 0.016 0.050

0º 8º 0º 8º

©On-Bright Electronics Confidential Preliminary datasheet

OB_DOC_DS_335000

-9-

OB3 3 5 0

Cost Effe ct iv e LED Co n t ro lle r

Important Notice

Right to make changes

On-Bright Electronics Corp. reserves the right to make corrections, modifications, enhancements,

improvements, and other changes to its products and services at any time and to discontinue any product

or service without notice. Customers should obtain the latest relevant information before placing orders

and should verify that such information is current and complete.

Warranty information

On-Bright Electronics Corp. warrants performance of its hardware products to the specifications ions applicable

applicabl

ontrol techniques

at the time of sale in accordance with its standard warranty. Testing and other quality control technique

are used to the extent it deems necessary to support this warranty. Except where ere

e mandated by

government requirements, testing of all parameters of each product is not necessarilyy performed.

performed

perform

rformed.

ormed.

ustomer

stomer produ

On-Bright Electronics Corp. assumes no liability for applications assistance or customer product

roduct des

design.

Customers are responsible for their products and applications using On-Brights s components, dat

data sheet

and application notes. To minimize the risks associated with customer products produc

ducts and applications,

app

customers should provide adequate design and operating safeguards.

Life support

On-Bright Electronics Corp.s products are not designed to be used as s comp

omponents

mponents in d

components de

devices intended to

liab for any

support or sustain human life. On-bright Electronics Corp. will not be held liable an damages or claims

resulting from the use of its products in medical applications.

Military

On-Bright Electronics Corp.s products are not designed ned for use in milmili

military applications. On-Bright

Electronics Corp. will not be held liable for any damagess or claims resulting from the use of its products in

military applications.

©On-Bright Electronics Confidential Preliminary datasheet

OB_DOC_DS_335000

- 10 -

You might also like

- OB2269Document12 pagesOB2269Juan Ballon100% (1)

- BGH3299A Manual Servicio PDFDocument36 pagesBGH3299A Manual Servicio PDFaldoNo ratings yet

- Express Luck Group: Specification PhotoDocument1 pageExpress Luck Group: Specification PhotoYesenia Jaime RoaNo ratings yet

- M236HGE-L20 - Led LCD Display Panel TV SamsungDocument31 pagesM236HGE-L20 - Led LCD Display Panel TV Samsungyiyus1No ratings yet

- Bd7682fj LB eDocument30 pagesBd7682fj LB eKartik ShuklaNo ratings yet

- SLC 7015Document1 pageSLC 7015Дмитрий КопышевNo ratings yet

- Sony HCD Rv222 Ver 1.1Document86 pagesSony HCD Rv222 Ver 1.1Carlos Raul100% (2)

- Panel Chimei Innolux v320bj3-p02 0Document30 pagesPanel Chimei Innolux v320bj3-p02 0doniNo ratings yet

- Silicon PNP Power Transistor: INCHANGE Semiconductor Product SpecificationDocument2 pagesSilicon PNP Power Transistor: INCHANGE Semiconductor Product SpecificationElton De Souza CouraNo ratings yet

- Panel LG Display Lc216exn-Sfa1 0Document36 pagesPanel LG Display Lc216exn-Sfa1 0Rinaldy100% (1)

- Enhancement Mode N-Channel Power MOSFET: OSG65R900xTFDocument10 pagesEnhancement Mode N-Channel Power MOSFET: OSG65R900xTFCube7 Geronimo100% (1)

- Maida Catalog Specifications Standard SeriesDocument16 pagesMaida Catalog Specifications Standard SeriesRetanaMaferNo ratings yet

- D 1875 LM 1875 Nte 7143Document2 pagesD 1875 LM 1875 Nte 7143ANTONIO PEREZNo ratings yet

- Oscilador de TV Plasma Samsung MC34067P - MC33067PDocument17 pagesOscilador de TV Plasma Samsung MC34067P - MC33067PAntonio ChavezNo ratings yet

- BM3451Document1 pageBM3451Andrey50% (2)

- Green-Mode PWM Controller With High-Voltage Start-Up CircuitDocument18 pagesGreen-Mode PWM Controller With High-Voltage Start-Up Circuitgoaltech100% (1)

- DC 6-40v Carregador de Bateria DescarregadorDocument5 pagesDC 6-40v Carregador de Bateria DescarregadorNemesio FilhoNo ratings yet

- Datasheet CM6802Document18 pagesDatasheet CM6802Gilson3DNo ratings yet

- Stormshield SN510: Business Continuity in Complex ArchitecturesDocument4 pagesStormshield SN510: Business Continuity in Complex ArchitecturesT AnnapooraniNo ratings yet

- Bd9397efv e PDFDocument30 pagesBd9397efv e PDFshafiuddin7326No ratings yet

- SOYEA LCD Service Manual PDFDocument40 pagesSOYEA LCD Service Manual PDFraipedriNo ratings yet

- Boost Controller For Wled Driver in Medium-Sized LCD Panel: (Top View)Document14 pagesBoost Controller For Wled Driver in Medium-Sized LCD Panel: (Top View)Loengrin MontillaNo ratings yet

- Sony kdl-32v5500 37v5500 40v5500 46v5500 52v5500 Chassis Ex2l CorianderDocument74 pagesSony kdl-32v5500 37v5500 40v5500 46v5500 52v5500 Chassis Ex2l CorianderTara DavisNo ratings yet

- Tps 54628Document22 pagesTps 54628fet_50No ratings yet

- Color TV Horizontal Deflection Output Applications: Data SheetDocument4 pagesColor TV Horizontal Deflection Output Applications: Data SheetJesus Wladimir RondonNo ratings yet

- Datasheet PDFDocument26 pagesDatasheet PDFHoàng Việt HùngNo ratings yet

- JVC DXJ 20 Service ManualDocument101 pagesJVC DXJ 20 Service ManualMuh. Ismail100% (1)

- High Slew Rate Dual Op Amps for LCD DisplaysDocument11 pagesHigh Slew Rate Dual Op Amps for LCD DisplaysstolllleNo ratings yet

- 7cw SMD Mmbt2222a - NXPDocument8 pages7cw SMD Mmbt2222a - NXPnikkoninNo ratings yet

- Current Mode LED Driver: General Description FeaturesDocument1 pageCurrent Mode LED Driver: General Description FeaturesEnrique LandraNo ratings yet

- Samsung+UE32J5000AK CH Ued51Document56 pagesSamsung+UE32J5000AK CH Ued51Miguel Perez Valls100% (1)

- PF6000AGDocument1 pagePF6000AGlibre2009No ratings yet

- LGP4247H 12LPB 3P PDFDocument73 pagesLGP4247H 12LPB 3P PDFroto44No ratings yet

- VDDC DC/DC LDO: Power ConnectorDocument14 pagesVDDC DC/DC LDO: Power Connectorsivanka ranganaNo ratings yet

- MODEL NO.: V236BJ1 Suffix: P01: Product SpecificationDocument32 pagesMODEL NO.: V236BJ1 Suffix: P01: Product SpecificationVeicon VecNo ratings yet

- LP154WX4 TlabDocument31 pagesLP154WX4 TlabsuzukkNo ratings yet

- LG TV 29fu6rsd (RS) Chassis Cw62d, Service ManualDocument22 pagesLG TV 29fu6rsd (RS) Chassis Cw62d, Service Manualjazjcl3269No ratings yet

- 47N60 Mosfet DatasheetDocument5 pages47N60 Mosfet DatasheetBilles GatesNo ratings yet

- FSDM07652R DatasheetDocument16 pagesFSDM07652R Datasheetmarianos67No ratings yet

- STK433 070 eDocument11 pagesSTK433 070 evanuzalopeslopes1No ratings yet

- Advanced Analog Technology, Inc.: One-Channel Step-Up PWM ControllerDocument10 pagesAdvanced Analog Technology, Inc.: One-Channel Step-Up PWM Controllernestor1209No ratings yet

- Max 17126Document34 pagesMax 17126918329078250% (2)

- Okok Sony - kv-2197m3 - Cxp85220a - Tda8375 - str-6707 - La7830 - Ta8248k PDFDocument13 pagesOkok Sony - kv-2197m3 - Cxp85220a - Tda8375 - str-6707 - La7830 - Ta8248k PDFAloui Zakaria100% (1)

- Jiuzhou dtt1609 Service Manual PDFDocument44 pagesJiuzhou dtt1609 Service Manual PDFVishu JoshiNo ratings yet

- 29TC679FDocument29 pages29TC679FGustavo ChavezNo ratings yet

- Bd9423efv e 1223519 PDFDocument61 pagesBd9423efv e 1223519 PDFVươngNo ratings yet

- Samsung Un32b6000 Un40b6000 Un46b6000 Un55b6000 Un6v Led Training PDFDocument117 pagesSamsung Un32b6000 Un40b6000 Un46b6000 Un55b6000 Un6v Led Training PDFGilmar Ferreira100% (1)

- Sony HCD Bx3 Dx3Document66 pagesSony HCD Bx3 Dx3videoson100% (2)

- (Codientu - Org) - 29Q317B, CHASSIS CW4Document14 pages(Codientu - Org) - 29Q317B, CHASSIS CW4GioVoTam100% (1)

- JVC Service Manual mxgt80 PDFDocument48 pagesJVC Service Manual mxgt80 PDFAlex GuerreroNo ratings yet

- BL1118 Datasheet V1.3.sdcDocument8 pagesBL1118 Datasheet V1.3.sdcrahmat tea100% (1)

- Service Manual: LC-32L407IDocument70 pagesService Manual: LC-32L407IJihan ElectronicNo ratings yet

- Ka2206B 2.3W Dual Audio Power Amp: O CC L O CC LDocument4 pagesKa2206B 2.3W Dual Audio Power Amp: O CC L O CC LEdgar Robert DolarNo ratings yet

- Datasheet OB3350 LED DriverDocument10 pagesDatasheet OB3350 LED DriverEnya Andrea Ribba Hernandez0% (1)

- OB2273 On BrightDocument12 pagesOB2273 On BrightCarlos PosadaNo ratings yet

- 1h6VuxLQ OB2216APDocument10 pages1h6VuxLQ OB2216APjaimeNo ratings yet

- LD7523Document18 pagesLD7523AssembleiaDeDeusSepherEloahNo ratings yet

- Ob3350 Inverter ControlDocument10 pagesOb3350 Inverter ControlsorintvrNo ratings yet

- Ob 2269 CapDocument13 pagesOb 2269 Caporkun burkayNo ratings yet

- Instruction Manual: S1DC8-M3Document2 pagesInstruction Manual: S1DC8-M3anilNo ratings yet

- Liebert POWERBANK (6kVA) : FIT - and - Forget UPS System Power Protection and Power SourceDocument2 pagesLiebert POWERBANK (6kVA) : FIT - and - Forget UPS System Power Protection and Power SourceanilNo ratings yet

- TEA2018A Power Supply Control CircuitDocument8 pagesTEA2018A Power Supply Control CircuitJean Carlos RamosNo ratings yet

- Specification: Shenzhen LIZE Electronic Technology Co., LTDDocument13 pagesSpecification: Shenzhen LIZE Electronic Technology Co., LTDfrangi frangioniNo ratings yet

- Vishay Siliconix: Product SummaryDocument7 pagesVishay Siliconix: Product SummaryTango SierraNo ratings yet

- Chapter 2. TransistorsDocument69 pagesChapter 2. TransistorsAnh Ha Duy AnhNo ratings yet

- 5L0365RDocument20 pages5L0365RbounezraNo ratings yet

- A Study and Analysis of Two Stage Single Ended CMOS OP-AMPDocument9 pagesA Study and Analysis of Two Stage Single Ended CMOS OP-AMPsanjeevsoni64No ratings yet

- SEL 4283 Analog CMOS IC Design Single Stage Amplifiers: Small Signal Model 1Document52 pagesSEL 4283 Analog CMOS IC Design Single Stage Amplifiers: Small Signal Model 1jitendraNo ratings yet

- Course: Electronic Circuit Design Lab No: 08 Title: Characterization of The MOS Transistor CID: - DateDocument6 pagesCourse: Electronic Circuit Design Lab No: 08 Title: Characterization of The MOS Transistor CID: - DateAamir ChohanNo ratings yet

- Chapter 6 - Analog Integrated Circuit Design by John ChomaDocument134 pagesChapter 6 - Analog Integrated Circuit Design by John ChomaAriana Ribeiro Lameirinhas100% (1)

- Power Supply Rejection Ratio in Operational Transconductance amplifiers-FRiDocument8 pagesPower Supply Rejection Ratio in Operational Transconductance amplifiers-FRijulio perezNo ratings yet

- KA5M0365RDocument14 pagesKA5M0365RmoutsyNo ratings yet

- STP 5 NK 100 ZDocument15 pagesSTP 5 NK 100 ZJimmy LinaresNo ratings yet

- Willy Sansen CT FiltersDocument71 pagesWilly Sansen CT FiltersEugine PaulNo ratings yet

- Lec08 Ae Ms14Document34 pagesLec08 Ae Ms14Mohsin Abbas ZafarNo ratings yet

- The MOSFET AmplifierDocument135 pagesThe MOSFET AmplifierRodrigo WilliamsNo ratings yet

- Singel State TransistorDocument10 pagesSingel State Transistorkaran007_mNo ratings yet

- Chapter 7Document23 pagesChapter 7enes_ersoy_3No ratings yet

- Kamran J16Document12 pagesKamran J16Nithya VelamNo ratings yet

- A Pulse Oximeter System, OxiSense, With Embedded Signal Processing Using An Ultra-Low Power ASIC Designed For Testability PDFDocument10 pagesA Pulse Oximeter System, OxiSense, With Embedded Signal Processing Using An Ultra-Low Power ASIC Designed For Testability PDFNeyronal MelgarNo ratings yet

- Demosthenous Integrated Circuits For Medical Ultrasound Applications Imaging and BeyondDocument21 pagesDemosthenous Integrated Circuits For Medical Ultrasound Applications Imaging and BeyondHubert CordonnierNo ratings yet

- CMOS Assignment QuestionsDocument6 pagesCMOS Assignment QuestionsAkhilGovindNo ratings yet

- Resistors & Circuits: Ohm's LawDocument8 pagesResistors & Circuits: Ohm's LawH Aries OñaNo ratings yet

- SI9945Document4 pagesSI9945dreyes3773No ratings yet

- Sample and Hold CircuitsDocument16 pagesSample and Hold CircuitsPraveen AndrewNo ratings yet

- High-Power N-Channel MOSFET DatasheetDocument2 pagesHigh-Power N-Channel MOSFET DatasheetAntonNo ratings yet

- Demystifying The Operational Transconductance Amplifier: Application ReportDocument13 pagesDemystifying The Operational Transconductance Amplifier: Application ReportCarlosVillavicencioGNo ratings yet

- Bakir Chapter5Document91 pagesBakir Chapter5mehtajay1993No ratings yet

- R6020ANX - 12 Datasheet (PDF) - RohmDocument14 pagesR6020ANX - 12 Datasheet (PDF) - RohmNguyen Lan RivaretNo ratings yet

- Opa 2320 DatasheetDocument32 pagesOpa 2320 DatasheetjugalstudentNo ratings yet

- LM5170-Q1 Multiphase Bidirectional Current Controller: 1 Features 3 DescriptionDocument71 pagesLM5170-Q1 Multiphase Bidirectional Current Controller: 1 Features 3 DescriptionBorn Lion MateNo ratings yet

- Precision Instrumentation Amplifier: V P-P 0.1 HZ To 10 HZDocument16 pagesPrecision Instrumentation Amplifier: V P-P 0.1 HZ To 10 HZManojChowdaryNo ratings yet

- Differential and Multistage AmplifiersDocument30 pagesDifferential and Multistage AmplifierskhsniperNo ratings yet