Professional Documents

Culture Documents

Us 2015013696 A 1

Us 2015013696 A 1

Uploaded by

Jie990 ratings0% found this document useful (0 votes)

10 views20 pagesUs 2015013696 a 1

Original Title

Us 2015013696 a 1

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentUs 2015013696 a 1

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

10 views20 pagesUs 2015013696 A 1

Us 2015013696 A 1

Uploaded by

Jie99Us 2015013696 a 1

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 20

IMO |

US 20150013696A1

co») United States

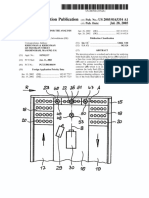

c2) Patent Application Publication (0) Pub. No.: US 2015/0013696 Al

Plojoux et al. (43) Pub, Date: Jan. 15, 2015

(64) EXTRACTOR FOR AN Publication Classification

AEROSOL-GENERATING DEVICE,

(1) Imck

(71) Applicant: Philip Morris Products S.A., Neuchatel A2iE $7400 (2006.01)

Hy (2) US.CL

cre ALE 470008 2013.01)

(72) Inventors: Julien Pajous, Geneva (CH); Olivier usPC 131/828; 131/329

Greim,Villars-Bureuin (CH); Dani

Ruselo, Cressier (CH) on ABSTRACT.

There is provided an extrcir for an aerosol-generting

(73) Assignee: Phitip Mortis Products 8.4, Neuchatel device configured to reeive a smoking article including an

cH aerosol-forming substrate and inching a heater for heating

the aeosol-forming substrate to form the aerosol. The extra

(21) Appl.No: 14/359,882 torisconfigued to extract the smoking article received inthe

device, and includes asliding receptacle configured receive

(22) PCTHiled: — Now.20,2012 tne smoking aicle, and a sleeve configured to receive the

sliding receplacle. The sliding receplale is slidable in the

(86) PCTNos —PCT/EP2012/073135 sleeve betweea a fist position in which the substate of the

$371 Xt, smoking atcleis positioned o as to be heated by the heater,

(2) Date, May 21,2014 ‘anda second position in which the substrate is substantially

separated from the heater. The sliding receptacle inches a

G0) Foreign Application Priority Data support configured to support the substrate when the sliding

receptacle and the smoking article are moved from the fist

Now. 21,2011 (EP) 11250907.0 position to the second position. There is also provided an

Feb. 13,2012 (EP) 12135245.9 electrically heated smoking system including the extractor

IV

107

«— 101

117 105b 15443

110

Patent Application Publication —_ Jan. 15, 2015 Sheet 1 of 7 US 2015/0013696 Al

Patent Application Publication —_ Jan. 15, 2015 Sheet 2 of 7 US 2015/0013696 Al

207

117 ie ae

Figure 3

403 405

103, 105

401

414 407

Figure 4

Figure 5 411b

ta

Patent Application Publication —_ Jan. 15, 2015 Sheet 3 of 7 US 2015/0013696 Al

Figure 6

701

1

aes

Figure 7B

Patent Application Publication Jan. 15, 2015 Sheet 4 of 7 US 2015/0013696 Al

Figure 8

903

101 901

Figure 9A

Patent Application Publication Jan. 15, 2015 Sheet 5 of 7 US 2015/0013696 Al

203° 991

Figure 9B

Patent Application Publication —_ Jan. 15, 2015 Sheet 6 of 7 US 2015/0013696 Al

oo d tort

(003 toot

FIGURE 10

(013

loos

Tere QV 4

iL

FIGURE It

un

wy eH 30 gis 1001

Patent Application Publication —_ Jan. 15, 2015 Sheet 7 of 7 US 2015/0013696 Al

1200

1400

1320

1300/ 1400

1410

too,

1410

FIGURE (3

US 2015/0013696 Al

EXTRACTOR FORAN

AEROSOL-GENERATING DEVICE

[0001] The present specication relates to an aeroso-gen-

‘erating device capable positioning an aerosol-forming sub

strat therein, The specification further relates to an extactor

for positioning an aeroso-forming substrate within the aero~

solgenerating device, The specification also relates 10

‘extracting a smoking article from an electrically heated

smoking system,

[0002] A numberof prior ant documents disclose aerosol-

enerting devices that includ, or example, heated smoking

systems and electrically heated smoking systems. Oneadvan-

tage of these systems is that they significantly reduce side~

stream smoke, while pemnitting the smoker to selectively

suspend and reinitate smoking. An example of & heated

smoking system is disclosed in US. Pat. No. 5,144,962,

‘which includes in one embodiment a lavour-generating

medium in contact with a heater. When the medium is

‘exhausted, both it and the heater are replaced. An aerosol-

enerating device where a substrate can be replaced without

the need to remove the heating element is desirable

[0003] The disclosure relates to an_aerosol-generating

device capable of positioning an aeroso-forming substrate,

the device comprising a heater for heating the serosol-form=

ing substrate and configured for penetrating an intemal por-

tion of the aerosol-forming substrate and an extractor,

‘wherein the extractor is capable of positioning the internal

portion ofthe substeate in contact with the heater

[0004] As used herein, the term ‘positioning’ relates the

movement of the serosol-forming substrate relative to the

heater ofthe aerosol-generating device. Thus, the extractor is

‘capable of moving the erosol-forming substrate relative to

the heater inorder to facilitate the removal of the aerosol-

forming substrate from the serosol-generating device

10005] As used herein, an ‘aerosol-generating device’

relates to a device that interacts with an aerosol- forming

substrate to generate an aerosol. The aerosol-forming sub-

strate may be part of an aerosol-generating article, for

‘example part of a smoking article. An aerosol-generating

device may comprise one or more components wsed to supply

‘energy from a power supply to an setosol-forming substrate

to generate an aerosol. For example, an aerosol-generating

‘device may bea heated aerosobgenerating device. An aero

sol-genorating dovice may bean electrically heated aeeosol-

generating device ora gas-heated erosol-generating device

‘An aerosol-generting device may be a smoking device that

interacts with an aerosol-forming substrate of an aerosol-

generating article 1 generate an aerosol that is directly inhal-

able into a user's lungs thorough the user's mouth. An aero-

sol-zenerating device may bea holder.

10006] Asusedherein, the term ‘aerosol-forming substrate’

relates toa substrate capable of releasing volatile compounds

that can form an aerosol. Such volatile compounds may be

released by heating the aerosol-forming substrate. An aero-

sol forming substrate may conveniently be part of anaeeosol-

generating anile or smoking ancl.

[0007] As used herein, the tems ‘aerosol-generating

‘antic and “smoking article‘ refer to an article comprising an

serosol-orming substrate hat iseapable of eeasing volatile

‘compounds that can form an aerosol, For example, an era

sol-genorating anile may be a smoking article that generates

snaerosol thats drwy inalable into a user's ngs through

Jan. 15, 2015

the user's mouth, An aerosol-generting article may be dis-

posable. The term ‘smoking article" is generally used hereaf=

tee

{0008} Preferably a smoking article is a heated smoking

aticle, which is a smoking article comprising an aerosol

forming substrate that is intended to be heated rather than

combusted in order to release volatile compounds that can

orm an aerosol. The aerosol formed by heating the aerosol-

forming substrate may contain fewer known harmfal cou-

stituents than would be produced by combustion or pyrolytic

degradation of the aerosol-forming substrate. A smoking

aicle may be, or may comprise, a tobacco sick.

{0009} Inoneembodiment, theextractor postions the aero

solforming substrate in. first position anda second position,

the first positon being an operating position defined by the

heater being in contact with the aerosol-orming substrate,

and the second postion being an extraction position defined

by the aerosol-forming substrate being separated from the

heater, Thus, the extrctor may be movable coupled to an

aerosol-generaing device, and may be movable between a

first postion in which the serosol-frming substrate is in

contact with a heater ofthe aerosol-generating device, and a

second position in which the aerosol-forming substrate is

separated fom the heater. Preferably the extractor remains

coupled tothe aerosol-generating device whea ia the fist

positon, the second postion and any intermediate point

between the first postion and sovond postion, The extractor

may be removably coupleable to the aerosol-generating

device.

[0010] Theextractor may comprise sliding ecepacle for

‘eceivinga smoking artele the sliding receptacle being sid-

able between the frst postion and the second position. The

entire extractor including the sliding recepacle may move to

translate the sliding receptacle between the first positon and

the second position. Alternatively only the sliding receptacle

ofthe extractor may be slidable Between the firs position and

the second position,

[011] The first position of the sliding receptacle is an

‘operating postion in which the heater ca heat the aezosol-

forming substrate of the smoking antile to form the aerosol

Asknown to those of ordinary skill i the at aa aerosl i

‘suspension of solid particles olguid droplets or both solid

particles and liquid droplets in a gas, such as air. The second

position of the sliding receptacle is an extraction positon

‘hich facilitates removal of the smoking article from the

sorosol-generating device. The upstream and downstream

ends of the serosol-generating device are defined with respect

‘o the airflow when the user takes. pul. Typically, incoming

air enters the aerosol-generating device atthe upstream end,

combines with the aerosol, and carries the aerosol ia the

sieflow towards the usee's mouth atthe downstream end

[0012] Inoneembodiment an erosol-generating device is

capable of recevingan erosol-farming substrate. The device

‘comprises heater for heating the aerosol-forming substrate,

the heater being configured for penetrating an intemal portion

ofthe erosol-forming substrate, and an extractor forextact-

ing the aerosol-fomning substrate received in the aerosol-

generating device, The extractor is movably coupled to the

erosol-generating device between a first position anda sec-

‘ond position, the first position being an operating positon

defined by the heater being in contact with the aerosol-form-

ag substrate, and the second positon being an extraction

positon defined by the aeroso-forming substrate being sep

rated fom the heater

US 2015/0013696 Al

[0013] Theextractor may comprise a sliding receptacle for

receiving the aerosol-generating article, an aperture being

defined though a wal ofthe sliding receptacle for allowing

the heater to penetrate the aerosol-forming substrate received

within the sliding receptacle when the extractors ia the fist

position.

[0014] Inone embodiment, smoking article including the

serosol-forming substrate is provided 1 the aeosol-penerat-

ing device, In this embodiment, the smoking article remains

substantially stationary relative tothe siding receptaceas the

sliding receptacle slides between the first position andl the

Second position. The term “substantially stationary” is

defined a a variation in positon on the order of millimeters

during use of the aerosol-zenerating device. The reveptacle

‘andthe smoking article move elativeto the othercomponeats

of the aeosol-generating device, including the hester. This

allows removal of the smoking anticle from the aerosol-gen-

erating device to be achieved in two phases. Ina fist phase,

‘he smoking article and siding receptacle are moved by slid-

ing, while the aerosol-forming substrate is supported, relative

'o components ofthe aerosol-generating device, in particular

the beater. ln a second phase, the smoking article, naw sepa-

rate from the heater, ean be removed from the sliding reep-

ladle,

[0015] The iavention allows the integrity of the aerosol-

forming substrate tobe substantially maintained asthe smok-

ing article is removed from the aerosol-zenerting device.

‘The risk that Joose shreds of aerosol-forming substrate are

pmxduced during removal and retained in the werosol-gener-

ating device is significantly reduced. This is advantageous,

for example, because the aerosol-generating device will need

less frequent cleaning.

[0016] Inoue embociment, the extractor further comprises

a sleeve for receiving the sliding receptacle, such that the

sliding receptacle is arranged to slide inthe sleeve between

the frst and second positions. Alternatively, the sleeve may

form par ofthe housing ofthe elececally heated smoking

system and may not comprise a separate component,

[0017] The sleeve may comprise an open ended tube. The

lubemay be cylindrical Thesliding receptacle may comprise

‘cylindrical tube, ora substantially eylindrieal shape, having

a diameter slightly smaller than the diameter ofthe sleeve,

such that the sliding receptacle canbe received in the sleeve

‘The sliding receptacle may include a flange arranged to abut

the sleeve when the sliding receptacle isin the fist position

Assuming the smoking article is correctly received in the

sliding receptacle, this allows the aerosol-forming substrate

‘ofthe smoking article to be correctly positioned so as to be

hated by the heater inthe fest position.

[0018] The serosol-generating device may further com-

prise stopper for preventing the sliding receptacle from

sliding out ofthe aerosol-generating device when the sliding

receptacle is moved to the second position. The stopper may

be arranged to cooperate with stopper receiving means, for

‘example an indent or depression for receiving the stopper

‘The stopper may be provided on the sliding receptacle. The

sopper receiving meaas may be provided on the sleve or on

another part of the aerosol-generating device. Alternatively,

the stopper may be pravided on te sleeve or on another pat

‘of the aerosol-zeneraing deviee and the stopper receiving

means may be provided on the sliding receptacle,

10019] The serosol-generating device may further com-

Drie a guide pin for guiding the shiding receptacle as the

sliding receptacle is moved between the first and second

Jan. 15, 2015

positions. The guide pin substantially prevents the sliding

receptacle from rotating in the serosol-generating device oF

sleeve. The guide pin may be arangedto cooperate witha slot

‘rgroove. Theuide pin, forexample, may beprovidedonthe

sliding receptacle. The slot or groove may be provided inthe

sleeve or in another part of the aerosol-generating device

Altematively, the guide pin may be provided onthe sleeve of

‘on another part ofthe serosol-generating device andthe slot

Dor groove may be provided in the sliding receptacle.

[0020] The sliding receptacle may comprise insulting

‘material, for proving insulation from the heat of the heater,

Alternatively or additionally the sleeve may comprise insu-

lating material, for providing insulation from the heat ofthe

heater.

[0021] ‘The aerosol-generating device may’ be an electri-

cally heated smoking system comprising an clectricheater. In

other embodiments the aerosol-generating device may be a

heater smoking system comprising a gas-burer, or some

source ofheat oer than electricity Inone embodiment, there

is provided an electrically heated smoking system for receiv-

nga smoking article including an aerosol forming substrate,

the electrically heated smoking system capable of positioning

the aerosol-forming substate and comprising: an electic

heater for heating the aerosol-forming substrate and config-

ured for penetrating an intemal portion ofthe serosol-frt-

ing substrate; and anextractorforextractinga smoking article

received inthe electrically heated smoking system, wherein

the extractor is capable of positioning the intemal portion of

the serosol-forming substrate in contact with the heater, the

extractor comprising a sliding receptacle for receiving the

smoking ancl the sliding receptacle being slidable between

‘frst position in which the aerosol-forming substrate ofthe

smoking articles positioned so as to be heated by the electric

heater, and a second position in which the aerosol forming

substrate i substantially separated from the electri heater.

[0022] The term “electric heater” refers to one or mone

electric heating elements. The electric heater may comprise

‘an internal electric heating element for at least partially

inserting into the aerosol-forming substrate of the smoking

aniele when the smoking article is received in the sliding

receptacle and the sliding receptacle i inthe frst postion. An

atenal heating element” is one which is suitable for inser-

‘ion into an aerosol-fomming material. The invention is pae-

ticularly advantageous when used in conjunction with an

internal eating element sine, in that ease, there may be a

tendency for the aerosolforming substrate to stick to the

heating element and therefore 19 break up as the aerosol-

orang substrate is separate from the heating element.

[0023] Altematvely oradationally the electric heater may

‘comprise an external heating clement. The term “external

beating element” refers to one tata east partially surounds

the aerosol-forming substrate, The eletrc heater may com-

prise one oF more intemal heating elements and one or more

external heating elements,

[0024] The electric heater may comprise a single heating

element. Alternatively, the electric heater may comprise more

than one heating element. The heating element or heating

elements may be aranged appropriately so as to most effe

tively heat the aerosol-orming substrate,

[0025] The electric heater may comprise an electrically

resistive material. Suitable electrically resistive materials

include but aze not limited to: semiconductors such as doped

ceramics, electrically “conductive” ceramies (such a5, for

example, molybdenum disilcide), carbon, graphite, metals,

US 2015/0013696 Al

metal alloys and composite materials made of a ceramic

raterial and a metallic material. Such composite materials

‘may comprise doped or uadopes ceramics, Examples of su

able doped ceramics inelude doped silicon carbides

Examples of suitable metals include titanium, zirconium,

tantalum and metals from the platinum group. Examples of

suitable metal alloys include stainless steel, nickel, cobalt,

cchromium-,sluminiumstitanium-zigcoaium-, balnium., no:

bium-, molybdenum-, tantalum, tungsten tn, galium-,

manganese- and iron-containing alloys, and superalloys

based on nickel, iron, cobalt, stainless steel, metab and

iron-manganese-aluminium based alloys. Incomposite mate-

rials, the electrically resistive material may optionally be

‘embedded in, encapsulated or coated with a insulating mate-

rialor vice-versa, depending onthekineties of energy transfer

tnd the extemal physicochemical properties required. Alter-

naively the electric heatermay compriseaninffa-redhesting

‘element, a photonic source, or an inductive heating element.

10026] The electric heater may take any suitable form. For

‘example, the electri heater may take the form of a heating

blade. Alternatively the elecric heater may take the form of

‘a casing or substrate having different eletro-conduective por-

lions, or an electrically resistive metallic tube. iteratively,

‘one or more heating needles or rods that rua through the

‘entre of the arosol-forming substrate may be as already

described. Alternatively, the eletrc heater may be a disk

(6nd) heater or a combination ofa disk heater with beating

noedles of rods, Other alternatives inelude a heating wire oF

filament, for example a Ni—Cr (Nickel-Chromium),plat-

‘nm, tungsten o alloy wire ora heating plate, Optionally, the

heating element may be deposited in or on a rigid camer

material.

[0027] The electric heater may comprises heat sink, or heat

reservoir comprising # material capable of absorbing and

storing heat and subsequently celeasing the heat overtime to

the aerosol-forming substrate, The heatsink may be formed

‘of any suitable material, such asa suitable metal or ceramic

material. In one embodiment, the material has high heat

‘capacity’ (sensible heat storage material), or is material

‘capable of absorbing and subsequently releasing heat via 3

reversible process, such asa high temperature phase change.

Suitable sensible heat storage materials include sliea gel,

lumina, carbon, glass mat, glas fibre, minerals, a metal or

alloy suet a aluminium, silver or lead, and a cellulose mate-

rial suchas paper. Other suitable materials which release heat

via a reversible phase change include paraffin, sodium

acetate, naphthalene, wax, polyethylene oxide, ametal, metal

salt, mixture of eutectic salts or an alloy

[0028] Theheat sinkorheat reservoirmay be arranged such

thatitis dretly in contact with the seosol-forming subsrate

‘and can transfer the stored heat directly to the substrate.

Atematively the heat stored inthe heat sink o heat reservoir

may be wansferredto the aerosol-forming substate by means

‘ofa heat conductor, suchas a metallic tube.

0029] The electric heater may heat the aerosol-forming

‘substrate by means of conduction. The electric heater may be

atleast partially in contact with the substrate or the earier on

‘which the substrate is deposited. Altematively, the heat fom,

theelecitic eatermay be conducted to thesubstrateby means

‘ofa heat conductive element

[0030] iteratively the electic heater may transfereat to

the incoming ambient ae that is drawn through the electi-

cally heated smoking system during use, which in turn eats

Jan. 15, 2015

the aerosol-forming substrate by convection. The ambient ai

‘ay be heated before passing through the aerosol-forming

substrate,

[0031] In one embodiment, electric energy is supplied to

the electric heater util the heating element or elements of the

electric heater reach a temperature of between approximately

250° C. and 440° C. Any suitable temperature sensor and

‘control cireuitry may be used inorder to contro heating ofthe

heating element of elements to reach the temperature of

betwoen approximately 250° C, and 440° C. This is in con-

‘east t conventional cigarettes ia which the combustion of

tobacco and cigarette wrapper may reach 800° C.

[0032] The sliding receptacle may include a support for

supporting the aerosol-fomning substrate of the smoking

ticle as the sliding receptacle and the smoking article are

being moved from the first position tothe second postion.

{0033} In one embodiment, the support for supporting the

Aaerosal-forming substrate ofthe smoking aticle comprises a

face af the sliding receptacle, the face inchuding at least one

aperture for allowing though-flow of ai. Thesize, shape and

positon ofthe aperture can be adapted to coateol or guide the

air low, for example the direction and amount ofr flow, The

air flow can be guided towards the vienity ofthe heater, in

onder to improve the seosol generation.

[0034] The face or surice of the sliding receptacle may

provide the support which assists in maintaining the integrity

of the aerosol-forming substrate, particularly asthe sliding

receptacle is moved from the first position to the second

positon. The size and shape ofthe at least one aperture may

alfect the sr owing through the arosol-generating device.

This may, in turn, affect the characteristics of the aerosol

‘Therelore,theat least one aperture may havea sizeand shape

chosen acconing tothe desired aerosol characteristic. This

can improve air low management and hence improve overall

eliciency ofthe aerosol-generating device

[0035] ‘The size and shape of the atleast one aperture may

also be chosen depending on the properties of the arosol-

forming substate, For example ifthe erosol-forming sub-

strate comprises large pieces or shreds a large aperture may

be appropriate. However, if the aerosolforming substrate

‘comprises smaller pieces or shreds a smaller aperture may be

desired to prevent the small pieces falling through the aper-

ture

[0036] The atleast one aperture may comprise one, two,

three, four ora larger numberof apertures. In an embodiment

ofthe invention, the face of the sliding receptacle comprises

‘amesh or gauze, Ifthe sliding receptacle comprises acylin-

sical tube, the support may comprise an end face, or part of

‘an end face, ofthe eylindreal tube

[0037] Oncofthe at keastone apertures may be arranged for

the heute to extend through the aperture when the sliding

receptace isin the fist postion,

[0038] In one embodiment, the sliding receptacle com-

prises gripping means for gripping the smoking article when

the smoking article is received inthe sliding receptacle and

the sliding receptacle isin the fist position.

[0039] The gripping means ensure that the smoking article

is correctly positioned so thatthe heater can eat the aerosol-

orming substrate of the smoking article when the user pfs

In addition, the gripping means ensure that the smoking

anicle does not fill out ofthe aerosol-generating device the

smoking system is oriented away from the vertical or away

from the operating orientation. The gripping means may be

‘aranged to grip the smoking article when a smoking article is

US 2015/0013696 Al

received in the siding receptacle, whether the sliding evep-

tele iin the first positon or inthe second positon. Alterna-

tively, the gripping means may be arranged to grip the smok-

ing article when a smoking article is received inthe sliding

receptacle only when the sliding receptacle isin the fist

position.

[0040] "As mentioned above, removal ofthe smoking article

from the aerosol-generating device may be achieved in two

phases. In the frst phase, the smoking article and sliding

receptacle are moved, by sliding, relative to components of

the aerosol-generating device. In one embodiment, the grip-

ping means are arranged to gripthe smoking article during the

first phase. In the second phase, the smoking article, now

separate from the heater, can be removed from the sliding

receptacle. The gripping means may also be arranged to

release the smoking aticle during the second phase.

[0041] The gripping means may be ctvated when the slid-

ing receptacle is moved into the lst position. Alternatively,

the gripping means isactivatedoaly when a smokingaricleis

received inthe sliding receptacle, This is advantageous as it

allows user to insert asmoking atc easily int the sliding

receptacle, even when iti in the frst postion, without the

user having to overcome any fores exerted by the gripping

means. For example, the gripping means may comprise

mechanical gripping means arranged tobe in a non-aripping

positioa when no smoking article is rosived ia the sliding

receptacle and agranged to move toa gripping postion when

1 smoking article is eceved in the sliding receptacle, The

ripping means may move from the non-gripping position to

the gripping postion bya force exerted by the smoking article

itsell

[0042] The siding receptacle may comprise a face agsinst

Which the smoking article abuts when the aerosol-foming

substrate ofthe smoking aicle is correctly positioned soasto

be heated by the heater. This indicates to the user that the

smoking article is fully inserted into the sliding receptacle

‘This reduces the chance of damage to the aerosol-forming

substrate during insertion

[0043] In one embodiment, the aeosol-generating device

further comprises moving means for moving the sliding

receptacle between the first and second positions.

[0044] The moving means may comprise motorised mov

ing means The sliding receptacle may be moved between the

first and second positions automatically when the user exerts

«force on the smoking article to emove the smoking article

from the serosol-penerating device. Altematively, the si

receptacle may be moved between te first and second po

tions automaticaly when the user operates a switch Alterna-

tively, no moving means may be provided and the sliding

receptacle may be moved between the first and second pos

tions manually by 2 user.

[0045] During operation, the smoking article containing

the serosol-frming substrate may be completely contained

within the aerosol-generating device. In that ease, user may’

puff ona mouthpiece ofthe aerosol-generating device. Alter-

natively, during operation the smoking article containing the

‘serasol-forming substrate may be partially contained within

the aerosol-zenerating device. In that case the user may pull

lirectly oa the smoking article

10046] ‘The smoking article may be substantially cylindi-

‘alin shape. The smoking atcle may be substantially elon-

‘gate, The smoking article may havea length anda creunnfer-

‘ence substantially perpendicular to the ength. The aerosol-

forming substrate may be substantially eylindsical in shape.

Jan. 15, 2015

‘The aerosol-forming substrate may be substantially elongate

“The aerosol-fomming substrate may also have a length and a

circumnfereace substantially perpendicular to th length. The

serosol-fomning substrate may be received in the sliding

receptacle of the serosol-generating device such that the

length ofthe aeroso-forming substrates substantially paral-

[elo the airflow direction in the aerosol-generating device.

[0047] Thesmoking article may havea otal length between

approximately 30 mm and approximately 100 mm, The

smoking article may have an external diameter between

approximately § mm and approximately 12 mm. The smok-

ing article may comprise a iter plug. The filter plug may be

located at the dowastream end of the smoking article. The

fiterplog may bea cellulose cette ilterplug. The filter plug

is approximately 7mm in leagth in one embodiment, but may

have a length of between approximately § mm to approx:

‘mately 10mm,

[0048] In one embodiment, dhe smoking article has total

length of approximately 45 mm. The smoking article may

hhavean extemal diameter of approximately 7.2 mm. Further,

the aerosol-forming substrate may have a length of approxi=

mately 10 mm. Altematively, the aerosol-forming substrate

‘may have a length of approximately 12 mm. Further, the

siameter of the aerosol-forming substrate may be between

approximately § mum and approximately 12 am, The smok-

ing aniele may comprise an ovter paper wrapper. Further, the

smoking atcle may comprisea separation between the aer-

solsforming substrate andthe fter plug. The separation may

beapproximately 18 mm, but may'be in the range of appeox

‘mately $ mm to appeoximately 25 mum,

{0049} The aerosolforming substrate may be a solid ero

solforming substrate. Alternatively, the aerosol-fomning,

substrate may comprise both solid and liquid components,

“The aerosol-forming substrate may comprise atobacco-con-

taining material containing volalile tobacco favour com-

pounds whieh are released from the substrate upon heating

Alternatively, che aerosolforming subsieate may comprise a

no-lobaceo material. The aerosol-forming substrate may

rer comprise an aerosol former, Examples af suitable

aorosol formers are glycerine and propylene glycol

[0050] If die serosol-forming substrate is solid aerosal-

orming substrate, the solid aerosol-forming substrate may

comprise, for example, one or more of: powder, granules,

pellets, shreds, spaghetti, strips or sheets containing one oF

more of: herb laf, tobaceo leaf, fragments of tobacco ribs,

reconstituted tobacco, homogenised tobacco, extruded

tobacco and expanded tobacco, The solid aerosol-forming

substrate may be in Teose form, or may be provided in a

suitable container or cancidge. Optionally, the slid aerosol-

Torming substrate may contain additioal tobacco oF nox

tobacco volatile favour compounds, obo released uponheat-

ing of the substate. The solid aerosol-forming substrate may

also contain capsules that, fr example, include the additional

tobacco or non-tobacco volatile flavour compounds and such

capsules may melt during heating ofthe solid aerosol-frm-

ing substrate

[0051] Optionally, the sold aeosol-forming substrate may

be provided on or embeslded ina thermally stable carrie. The

cater may take the form of powder, granules, pellets, shreds,

spaghotis strips or sheets, Alteratively, the carrier may be a

tubular carrer having athin layer ofthe solid substrate depos

ited on its inner surface, or on is outer surface, oF on both its

mer andoouter surfaces. Such a tubular carrier may be formed

of for example. paper or paper like material, non-woven

US 2015/0013696 Al

‘carbon fre mat, alow mass open mesh metallic screen, oa

perforated metallic fil orany other thetmally stable polymer

matrix

10052] ‘The solid aeroso-forming substrate may be depos

ited on the surface ofthe carrer in the form of, for example,

1 sheet, foam, gel or slurry. The sold aerosol-forming sub-

strate may be deposited on the entre surface ofthe carrier, or

alternatively, may be deposited in patter in onder o provide

‘8 non-uniform favour delivery during use,

[0053] Although reference is made to solid serosol-form-

ing substrates above, it will beclearo one of ordinary kil in

the ar that other forms of aecosol-forming substrate may be

include in other embodiments ofthe invention. For example,

the aerosol-forming substrate may bea liquid serosol-form=

ing substrate. Ifa liquid acrosol-forming substrate is pro-

Vided, the aerosol-generting device preferably comprises

means for retaining the liquid. For example, the liquid aero-

solsformning substrate may be retained in a container. Alter-

natively or in addition, the liquid aerosol-forming substrate

may be absorbed into a porous carrier material. The porous

‘carrier material may be made from any suitable absorbent,

plug or body, for example, a foamed metal or plates mate-

rial, polypropylene, terylene, nylon fibres or ceramic. The

liquid aerosol-forming’ substrate may be retained in the

porous carrer material price to use of the aerosol-generating

‘device or alternatively the liquid aerosol-orming substrate

material may be released into the porous carrer material

‘uring, or immediately prior to use. For example, the liquid

serosol-forming substrate may be provided in a capsule. The

shell of the capsule preferably melts upon heating and

releases the liquid aerosol-forming substrate into the porous

‘carrier material. The capsule may optionally contain asolidin,

‘combination with the Tiguid

10054] Alternatively the carier may bea non-woven fabric

‘or fibee bundle into Which tobacoo componeals have been

incorporated. The non-woven fabric or flbrebundle may com-

prise, for example, carbon flres, natural cellulose fbres, oF

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- A Unified Approach To The Design of Resonant Power Factor CorrecDocument8 pagesA Unified Approach To The Design of Resonant Power Factor CorrecJie99No ratings yet

- Current-Source Resonant Converter in Power Factor CorrectionDocument7 pagesCurrent-Source Resonant Converter in Power Factor CorrectionJie99No ratings yet

- Control Strategy of An Interleaved Boost Power Factor CorrectionDocument6 pagesControl Strategy of An Interleaved Boost Power Factor CorrectionJie99No ratings yet

- A Novel Tri-State Boost Converter With Fast DynamicsDocument7 pagesA Novel Tri-State Boost Converter With Fast DynamicsJie99No ratings yet

- CN GN 203098171uDocument10 pagesCN GN 203098171uJie99No ratings yet

- LM3525 Single Port USB Power Switch and Over-Current ProtectionDocument12 pagesLM3525 Single Port USB Power Switch and Over-Current ProtectionJie99No ratings yet

- Unity Power Factor Boost Converter With Phase Shifted Parallel Operation For Medium Power ApplicationsDocument8 pagesUnity Power Factor Boost Converter With Phase Shifted Parallel Operation For Medium Power ApplicationsJie99No ratings yet

- AU9510 USB Smart Card Reader Chip Technical Reference ManualDocument30 pagesAU9510 USB Smart Card Reader Chip Technical Reference ManualJie99No ratings yet

- Patent Application Publication (10) Pub. No.: US 2005/0163354 A1Document15 pagesPatent Application Publication (10) Pub. No.: US 2005/0163354 A1Jie99No ratings yet

- United States Patent (10) Patent No.: US 6,599,476 B1: Watson Et Al. (45) Date of Patent: Jul. 29, 2003Document38 pagesUnited States Patent (10) Patent No.: US 6,599,476 B1: Watson Et Al. (45) Date of Patent: Jul. 29, 2003Jie99No ratings yet

- TEPZZ - 8 7 - B - T: European Patent SpecificationDocument85 pagesTEPZZ - 8 7 - B - T: European Patent SpecificationJie99No ratings yet

- NCP1200: PWM Controller, Fixed Frequency, Flyback, Current ModeDocument2 pagesNCP1200: PWM Controller, Fixed Frequency, Flyback, Current ModeJie99No ratings yet

- Intel 430Vx Pciset Design Guide: June, 1997Document92 pagesIntel 430Vx Pciset Design Guide: June, 1997Jie99No ratings yet

- Polyswitch Resettable Fuses: Short-Form Catalog April 2001Document12 pagesPolyswitch Resettable Fuses: Short-Form Catalog April 2001Jie99No ratings yet

- Polyswitch Telecom and Network Resettable Fuses: FeaturesDocument20 pagesPolyswitch Telecom and Network Resettable Fuses: FeaturesJie99No ratings yet

- DU-H4 ManualDocument8 pagesDU-H4 ManualJie99No ratings yet

- Switch-Mode Lithium-Ion Battery-Charger: General Description - FeaturesDocument8 pagesSwitch-Mode Lithium-Ion Battery-Charger: General Description - FeaturesJie99No ratings yet