Professional Documents

Culture Documents

Api 54

Uploaded by

kcp1986Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Api 54

Uploaded by

kcp1986Copyright:

Available Formats

API PLAN 54

ANSI PLAN 7354

DESCRIPTION: PRESSURIZED external BARRIER fluid reservoir or system supplying

clean fluid to a pressurized dual mechanical seal. Circulation is provided

by an external pump or pressure system.

PRIMARY PURPOSE: To isolate the product being pumped from the environment or to extend

seal life through better internal conditions for the seal.

This plan also guarantees virtually zero emissions to atmosphere. The pressurized barrier fluid enters the

seal and exits in a once in, once out fashion. A gauge is placed on the outlet side between the seal and

a needle valve or flow meter. The gauge measures the backpressure created by the needle valve or

flow meter. This pressure must be 20 - 30 PSI above seal chamber pressure to enable the barrier

fluid to lubricate both inboard and outboard seals. The flow meter serves also to meter the flow to a

desired rate for cooling and minimizing barrier fluid usage (usually water or a product compatible fluid).

POTENTIAL PROBLEMS:

1) This arrangement is only as reliable as its source of supply. Lose the supply, lose the

seal.

2) If the inboard seal fails, there will be significant product dilution.

3) If fluid supply is not clean, seal life may be reduced.

4) If it is part of a larger closed loop system supplying a number of pump seals and one

fails catastrophically, it could starve the other seals for liquid and possibly cause

additional failures.

5) A small reduction in system pressure could create a reverse pressure situation for an

inboard unbalanced or non-double balanced seal. This could open the inboard faces and

contaminate the barrier system with product causing numerous problems.

6) This system is excellent for cooling the seal.

7) There is no seal pot to monitor or maintain.

8) Inboard leaks can go unnoticed until dilution reaches detectable levels.

Instrumentation may be helpful in this regard.

You might also like

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryFrom EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryNo ratings yet

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingFrom EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingRating: 5 out of 5 stars5/5 (3)

- API 650 Manhole Torque Values PDFDocument2 pagesAPI 650 Manhole Torque Values PDFreynaldoNo ratings yet

- Technical Documentation: SAB 163 Screw Compressor UnitsDocument2 pagesTechnical Documentation: SAB 163 Screw Compressor UnitsHenry100% (1)

- Catalogos de Motores Electricos Eberle - DelcrosaDocument1 pageCatalogos de Motores Electricos Eberle - DelcrosaMiguel Guillermo Zelaya DamianNo ratings yet

- Operating & Maintenance Instruction NM105SY03S18V-NC 0215Document102 pagesOperating & Maintenance Instruction NM105SY03S18V-NC 0215ANo ratings yet

- Sabroe PAC Chillers: Packaged Ammonia Chillers Based On Screw Compressors, With A 100-6200 KW Capacity RangeDocument2 pagesSabroe PAC Chillers: Packaged Ammonia Chillers Based On Screw Compressors, With A 100-6200 KW Capacity RangePreeti gulati100% (1)

- 2/2-Way Valves DN 20 To DN 50Document4 pages2/2-Way Valves DN 20 To DN 50Oscar CurimanyaNo ratings yet

- Catalogo Bombas NETZSCHDocument1 pageCatalogo Bombas NETZSCHJesus BolivarNo ratings yet

- Dalamatic Insertable: Replacement Parts ListDocument20 pagesDalamatic Insertable: Replacement Parts ListWaldomiroCanoNo ratings yet

- Sabroe SMC: Reciprocating Compressor UnitsDocument2 pagesSabroe SMC: Reciprocating Compressor UnitsJerson De arcoNo ratings yet

- Bombas OBL LPDocument2 pagesBombas OBL LPJ Ferreyra LibanoNo ratings yet

- VANLT-0001-En Series 30,000 Rotary Process ValveDocument12 pagesVANLT-0001-En Series 30,000 Rotary Process ValveOneil ZárateNo ratings yet

- Gorter r100 enDocument6 pagesGorter r100 enManish SaraswatNo ratings yet

- DOME Diffusers Screen 1 PDFDocument2 pagesDOME Diffusers Screen 1 PDFzenogredina100% (1)

- Sonic Scan DatasheetDocument4 pagesSonic Scan DatasheetChandravadanNo ratings yet

- Description Materials: Cast Iron For Horizontal InstallationDocument2 pagesDescription Materials: Cast Iron For Horizontal InstallationParth GosaiNo ratings yet

- Vertical Turbine Pumps: Installation, Maintenance & Operation InstructionsDocument70 pagesVertical Turbine Pumps: Installation, Maintenance & Operation Instructionsagmibrahim5055No ratings yet

- Sundyne Gearbox Reliability Upgrade KitDocument2 pagesSundyne Gearbox Reliability Upgrade Kitjamil ahmedNo ratings yet

- Manual TB WoodsDocument92 pagesManual TB WoodsjoadNo ratings yet

- SchuF Valve Guide v6Document57 pagesSchuF Valve Guide v6Adam Chapin100% (1)

- Hydro Aluminium - AlSi7Mg0 3Document2 pagesHydro Aluminium - AlSi7Mg0 3Raj PrasanthNo ratings yet

- Shafer™ RV-Series Rotary Vane Valve ActuatorsDocument8 pagesShafer™ RV-Series Rotary Vane Valve ActuatorsarseneNo ratings yet

- Valvula para CoqueDocument12 pagesValvula para CoqueKerry DillonNo ratings yet

- Daniel Series 700 - Model V707: Spring Loaded Back Pressure ValveDocument8 pagesDaniel Series 700 - Model V707: Spring Loaded Back Pressure ValveMarcelo PinheiroNo ratings yet

- Proportional Directional ValvesDocument12 pagesProportional Directional ValvesMartinez Mauricio Martinez GomezNo ratings yet

- Product Overview - LeuschDocument32 pagesProduct Overview - Leuschprihartono_diasNo ratings yet

- Gardner Denver - GDX Modular Adsorption DryersDocument16 pagesGardner Denver - GDX Modular Adsorption DryerskuraimundNo ratings yet

- Spray Booth Manual Water BackDocument26 pagesSpray Booth Manual Water BackxiaolongNo ratings yet

- Swagelok CatalogueDocument16 pagesSwagelok CatalogueZacharia JohnNo ratings yet

- Bombas ParkerDocument6 pagesBombas ParkerDaniel ValladaresNo ratings yet

- UM10705 01 00 Screw ConveyorDocument1 pageUM10705 01 00 Screw ConveyorDADAIRESENDENo ratings yet

- Installation Equipment: Sanitary Fittings and ValvesDocument89 pagesInstallation Equipment: Sanitary Fittings and ValvesSebassde0% (1)

- Tramco: Assembly, Operation & Maintenance Instruction ManualDocument60 pagesTramco: Assembly, Operation & Maintenance Instruction ManualjurilikaNo ratings yet

- FM-GUIDE Rubber StorageDocument20 pagesFM-GUIDE Rubber StorageTeodorescu Andrei0% (1)

- Sxda/Sxwa/Syda/Sywa: Metering PumpsDocument56 pagesSxda/Sxwa/Syda/Sywa: Metering PumpsZelminha StNo ratings yet

- RCE Brochure 05 - 15Document10 pagesRCE Brochure 05 - 15Javier Alejandro Rodriguez MelgozaNo ratings yet

- Rovalve PDFDocument4 pagesRovalve PDFWilliam ValenciaNo ratings yet

- Catalogo Bomba DiafragmaDocument19 pagesCatalogo Bomba DiafragmaMaria Jose Araya CortesNo ratings yet

- AHR HPW Tech Data Sheet PDFDocument2 pagesAHR HPW Tech Data Sheet PDFLakshmi NarayanNo ratings yet

- Bombas CR, Cri, CRNDocument88 pagesBombas CR, Cri, CRNOscar Ernesto RamírezNo ratings yet

- Bombas DDDDocument3 pagesBombas DDDVladimir E. BalvinNo ratings yet

- Vacuum Pumps: The Solution To Your Water Scale ProblemsDocument4 pagesVacuum Pumps: The Solution To Your Water Scale ProblemsHugh MantaNo ratings yet

- BFP ARC Valve FunctionDocument6 pagesBFP ARC Valve FunctionVenkat ShanNo ratings yet

- Screw Pump HC 232 - 80/2 / N: 1.0 Project DataDocument1 pageScrew Pump HC 232 - 80/2 / N: 1.0 Project DataBenicio Joaquín Ferrero BrebesNo ratings yet

- NEMO Progressing Cavity PumpsDocument24 pagesNEMO Progressing Cavity PumpsPeñaloz GustavoNo ratings yet

- KSB MultitecDocument128 pagesKSB MultitecMiguel Delgado100% (1)

- STERLINGDocument8 pagesSTERLINGHummac MagañaNo ratings yet

- Block 10 Module 3Document14 pagesBlock 10 Module 3Sandra FerrellNo ratings yet

- MAKO Piping Library Catalogue - Rev CDocument28 pagesMAKO Piping Library Catalogue - Rev Celmfp7774676No ratings yet

- Fume HoodDocument16 pagesFume Hoodhans30No ratings yet

- Tabela Fator K - VAV TroxDocument2 pagesTabela Fator K - VAV TroxmquaiottiNo ratings yet

- Ahlstar: Process PumpsDocument1 pageAhlstar: Process Pumpsapi-3759223No ratings yet

- A2 - Painting Procedure PDFDocument2 pagesA2 - Painting Procedure PDFJuan Carlos Sua Sua100% (1)

- Api 53Document2 pagesApi 53andrey2509No ratings yet

- Api Plan 53Document2 pagesApi Plan 53Luis SudNo ratings yet

- Api 52Document3 pagesApi 52Sofiane HalimiNo ratings yet

- Sealing System Jun05Document2 pagesSealing System Jun05jrri16No ratings yet

- APIDocument54 pagesAPIpramod_tryNo ratings yet

- Unit 24: Applications of Pneumatics and HydraulicsDocument11 pagesUnit 24: Applications of Pneumatics and HydraulicsEmad ElsaidNo ratings yet

- Safety Relief Valve DatasheetDocument1 pageSafety Relief Valve Datasheetalmandhari330% (1)

- Air K PlotDocument1 pageAir K Plotalmandhari33No ratings yet

- PN16 Backing RingDocument1 pagePN16 Backing Ringalmandhari33No ratings yet

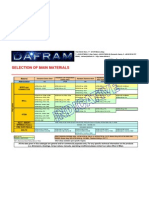

- Material Options 09 03Document1 pageMaterial Options 09 03almandhari33No ratings yet

- Pressure Drop Calculation - 6 Inch Permeate and Reject PumpDocument2 pagesPressure Drop Calculation - 6 Inch Permeate and Reject Pumpalmandhari33No ratings yet

- HDPE DesignDocument15 pagesHDPE Designalmandhari3380% (5)