Professional Documents

Culture Documents

Wd-Duconite 10 15 20-gb-03

Wd-Duconite 10 15 20-gb-03

Uploaded by

Jorge Luis BriceñoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Wd-Duconite 10 15 20-gb-03

Wd-Duconite 10 15 20-gb-03

Uploaded by

Jorge Luis BriceñoCopyright:

Available Formats

Bredel

DuCoNite 10, DuCoNite 15 and

series

DuCoNite 20

Bredel Hose Pumps

FEATURES AND BENEFITS

• Robust design for aggressive chemicals or abrasives

• Pump protected against corrosive and caustic fluids and atmospheres

by its high-tech surface treatment

• Sealless, valveless pumping principle for reliable, low maintenance

metering, dosing and transfer

• Dry running and self-priming, with up to 9.5 meters (30 foot)

suctionlift capability

• Compact direct coupled design to maximise gearbox life

• Simple hose change decreases cost of ownership, downtime and

need for parts inventory

PERFORMANCE

DuCoNite 10 DuCoNite 15

Required Required

motor power kW (hp) motor power kW (hp)

0.15 (0.20hp) 0.35 (0.48hp)

) Product

i)

i) Product si

ps

s

9p si) 8p si)

09

0

8p si) temperature C (F) 0.30 (0.41hp) (5 0p

temperature C (F)

(1

(1 a (

0.125 (0.17hp) Pa (5 p

kP

a

(0 Pa

kP

a a

0

k kP kP 0 40

0 0k

75 0 0

75

40 0.25 (0.34hp) 40 (104F)

0.10 (0.14hp)

40 (104F)

0.20 (0.27hp) 50 (122F)

0.075 (0.10hp) 50 (122F)

0.15 (0.20hp) 60 (140F)

60 (140F)

70 (158F)

70 (158F) 0.10 (0.14hp)

80 (176F) 80 (176F)

Pump speed rpm 15 30 45 60 75 90 105 120 Pump speed rpm 15 30 45 60 75 90 105

Capacity L/h 20 40 60 80 100 120 140 160 Capacity L/h 75 150 225 300 375 450 525

Capacity USGPM 0.09 0.18 0.26 0.35 0.44 0.53 0.62 0.70 Capacity USGPM 0.33 0.66 0.99 1.32 1.65 1.98 2.31

Continuous Duty

Intermittent Duty*

Required DuCoNite 20 * Maximum 2 hours operation followed by minimum

motor power kW (hp) 1 hour stop

0.45 (0.61hp)

i) Product

0.40 (0.54hp) 09

ps

8p

si)

temperature C (F)

1. Flow required indicates pump speed

(1 (5

kPa k Pa

0.35 (0.48hp) 7 50 40

0

(0p

si) 2. Calculated discharge pressure

Pa 40 (104F)

0k

0.30 (0.41hp) 3. Net motor power required

50 (122F)

0.25 (0.34hp)

4. Product temperature

0.20 (0.27hp) 60 (140F)

0.15 (0.17hp)

5. Calculated discharge pressure

70 (158F)

0.10 (0.14hp) 6. Maximum recommended pump speed

80 (176F)

0.05 (0.07hp)

Note: The area of continuous operation diminishes

Pump speed rpm 15 20 30 40 50 60 70 80 90

Capacity L/h 90 180 270 365 455 545 640 730 820

with increased product temperatures. For product

Capacity USGPM 0.40 0.79 1.19 1.61 2.00 2.40 2.82 3.21 3.61 temperatures >40C, the area of continuous operation

reduces to the corresponding red temperature line.

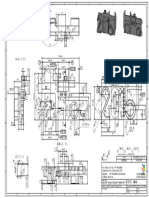

DIMENSIONS

A1

B L1 L2

H

H2

E

H1

Connector sizes ANSI 150# EN DIN JIS

4x P

C

DuCoNite 10 0.5” 10mm 10mm

F J K

DuCoNite 15 0.75” 20mm 20mm

G N M O

A L

DuCoNite 20 0.75” 20mm 20mm

Type A A1 B C D ØE F G H H1 H2max J K Lmax L1 L2max M N O ØP

DuCoNite 10 (mm) 337 311 171 62 116 16 235 265 225 127 254 78 51 501 46 378 150 65 25 12

DuCoNite 10 (inches) 13.3 12.2 6.7 2.44 4.6 16mm 9.3 10.4 8.9 5.0 10.0 3.1 2 19.7 1.8 14.9 5.9 2.6 1.0 12mm

DuCoNite 15 (mm) 427 431 230 63 195 20 285 315 304 167 294 82 61 505 46 378 150 75 25 12

DuCoNite 15 (inches) 16.8 17.0 9.1 2.5 7.7 20mm 11.2 12.4 12.0 6.6 11.6 3.2 2.4 19.9 1.8 14.9 5.9 3.0 1.0 12mm

DuCoNite 20 (mm) 427 431 230 63 195 20 285 315 304 167 294 82 61 505 46 378 150 75 25 12

DuCoNite 20 (inches) 16.8 17.0 9.1 2.5 7.7 20mm 11.2 12.4 12.0 6.6 11.6 3.2 2.4 19.9 1.8 14.9 5.9 3.0 1.0 12mm

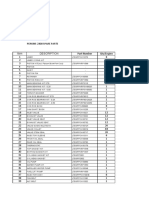

TECHNICAL SPECIFICATIONS

DuCoNite 10 DuCoNite 15 DuCoNite 20

Flow range up to 145 L/hr (0.63 USGPM) up to 525 L/hr (2.32 USGPM) up to 820 L/hr (3.62 USGPM)

Capacity 0.022 L/rev (0.006 G/rev) 0.083 L/rev (0.022 G/rev) 0.152 L/rev (0.040 G/rev)

Minimum starting torque 47Nm (416 inch-lbs) 60Nm (531 inch-lbs) 85Nm (752 inch-lbs)

Hose lubricant required 0.5 litres (0.13 USG) 1 litre (0.26 USG) 1 litre (0.26 USG)

Pumphead weight 12.2kg (26.89lbs) 18.5kg (40.79lbs) 18.5kg (40.79lbs)

Common features

Suction pressure 0.05 bar abs (0.73psia)

Product temperature range* -10C up to 80C (14F up to 176F)

Ambient temperature range** -20C up to 45C (-4F up to 113F)

Max inlet pressure 2.0 bar abs (30psia)

Max discharge pressure NR, NBR,

7.5 bar (109psi)

F-NBR, EPDM, CSM

*Please consult your Bredel representative for lower or higher temperature operation.

**Allowable ambient temperature is based on pump capabilities and may be further limited by gearbox ambient capabilities

MATERIALS OF CONSTRUCTION

DuCoNite DuCoNite DuCoNite Options DuCoNite 10/15/20

wd-duconite_10_15_20-gb-03 © Copyright 2014 Watson-Marlow Pumps Group

10 15 20 Available hose materials NR, NR Endurance, NBR, F-NBR, EPDM, CSM

Pump housing Available rotors Low pressure 0-4bar

Medium pressure 4-7.5bar

Rotor with Cast iron with DuCoNite surface

integral shoes treatment. Available port Ports left (position 1), right (position 2), up (position 3)

configurations and down (position 4). Standard configuration position 2

Cover Integrated FI for stand Factory programmable from 12-80 Hz

Brackets Standard in AISI 316 alone speed control

Support frame Standard in AISI 316 Revolution counter For maintenance and /or metering

High level float switch Max. 1A, 50 VA, IP65

Fasteners Standard in AISI 316

Insert combinations

Hose clamps AISI 316 Hose nipple AISI 316, PTFE, PVDF

Coupling bush Alloy steel Threaded nipple AISI 316 BSP, AISI 316 NPT, PP NPT, PVC NPT, AISI

Seals EPDM 316 DIN 11851

Threaded nipple and flange AISI 316 BSP nipple and Flange DIN threaded AISI

(+nut) assembly 316, AISI 316 BSP nipple and Flange ASA threaded

AISI 316

Flange and bracket Flange DIN AISI 316 + PP insert, Flange ASA AISI

assembly 316 + PP insert, Flange DIN AISI 316 + AISI 316 insert,

Flange ASA AISI 316 + AISI 316 insert

The information contained in this document is believed to be correct at the time of publication, but Watson-Marlow Bredel BV wmpg.com

accepts no liability for any error it contains, and reserves the right to alter specifications without prior notice. All mentioned

values in this document are values under controlled circumstances at our test bed. Actual flow rates achieved may vary +44 (0)1326 370 370

because of changes in temperature, viscosity, inlet and discharge pressures and/or system configuration. APEX, DuCoNite®,

Bioprene® and Bredel are registered trademarks. info@wmpg.com

You might also like

- Ford TW5 - 15 - 25 - 35 Workshop Manual PDFDocument160 pagesFord TW5 - 15 - 25 - 35 Workshop Manual PDFFranzz50% (4)

- System Operation Testing and Adjusting 3304 Vehicular EngineDocument103 pagesSystem Operation Testing and Adjusting 3304 Vehicular EngineAbdelbagi100% (2)

- Caterpillar D11R CD Carrydozer Implement Systems ManualDocument68 pagesCaterpillar D11R CD Carrydozer Implement Systems ManualMaquinarias Pesadas100% (4)

- Engine DiagramsDocument43 pagesEngine Diagramsthetam218kjjNo ratings yet

- Seawage Treatment PDFDocument96 pagesSeawage Treatment PDFaung koko100% (1)

- 1 - PL - FEED Lvl2Document89 pages1 - PL - FEED Lvl2Gladys WilliamNo ratings yet

- Oil and Gas FacilitiesDocument11 pagesOil and Gas FacilitiesDemzy Adeniyi100% (4)

- Yuri Senkevich - Cargo System ManualDocument237 pagesYuri Senkevich - Cargo System Manualpochinkov100% (1)

- VSM Template (LEan Six Sigma)Document8 pagesVSM Template (LEan Six Sigma)DearRed FrankNo ratings yet

- SNG and LPG Systems Overview PDFDocument57 pagesSNG and LPG Systems Overview PDFMohanad100% (2)

- Doosan HP 4000II 5100II EnglishDocument20 pagesDoosan HP 4000II 5100II EnglishBow LinNo ratings yet

- Bomba Bredel CaracteristicasDocument2 pagesBomba Bredel CaracteristicasFelipe MelgarejoNo ratings yet

- WD Duconite 25 32 GB 03Document2 pagesWD Duconite 25 32 GB 03Jorge Luis BriceñoNo ratings yet

- Datasheet Bredel - 40 50Document2 pagesDatasheet Bredel - 40 50Giorgi GhambashidzeNo ratings yet

- WD Bredel 25 32 enDocument2 pagesWD Bredel 25 32 enMario CalvisiNo ratings yet

- All Terrain Hydraulic CraneDocument18 pagesAll Terrain Hydraulic CraneJulio torresNo ratings yet

- Capacitance-Resistive Model: CRMP: Producer CV: 1Document32 pagesCapacitance-Resistive Model: CRMP: Producer CV: 1Anonymous iZx83pFsOrNo ratings yet

- Figure 2Document1 pageFigure 2BubeNo ratings yet

- Monte Da Fava Herdade Da CaniceiraDocument1 pageMonte Da Fava Herdade Da CaniceiraBubeNo ratings yet

- Figure 2Document1 pageFigure 2BubeNo ratings yet

- Op Tim Ization 1Document1 pageOp Tim Ization 1Reza ArefidamghaniNo ratings yet

- Op Tim Ization 5Document1 pageOp Tim Ization 5Reza ArefidamghaniNo ratings yet

- Topic Page NoDocument49 pagesTopic Page NoUjwal JaiswalNo ratings yet

- System Design PresentationenDocument14 pagesSystem Design PresentationenVaibhav ChaudharyNo ratings yet

- Chanakya: Total Production (Units) 6400 Selling Price Per Unit (Cu.) 610Document1 pageChanakya: Total Production (Units) 6400 Selling Price Per Unit (Cu.) 610Ash Krishna RamanNo ratings yet

- Pile Diameter BOQ: 14 5 1 P5L2 2 P8R2 P13L1Document2 pagesPile Diameter BOQ: 14 5 1 P5L2 2 P8R2 P13L1Chiranjaya HulangamuwaNo ratings yet

- Ciardi - Pa (E-S) Saggi (For Viola and Electronics)Document18 pagesCiardi - Pa (E-S) Saggi (For Viola and Electronics)JamesNo ratings yet

- Pressostatos JohnsonDocument2 pagesPressostatos JohnsonLuiz Ricardo De OliveiraNo ratings yet

- August 2017Document2 pagesAugust 2017NishantNo ratings yet

- DPP 9 PDFDocument11 pagesDPP 9 PDFCharlie PuthNo ratings yet

- A Thousand Years Piano (Medium)Document1 pageA Thousand Years Piano (Medium)Original musicNo ratings yet

- Performance Curves: Rotary Lobe Pumps SCPP 2/015Document15 pagesPerformance Curves: Rotary Lobe Pumps SCPP 2/015Angel CoesNo ratings yet

- Mathematical Logic Reconstructed: Applicable Natural DeductionDocument230 pagesMathematical Logic Reconstructed: Applicable Natural DeductionDavi PeixotoNo ratings yet

- Build Your PC Online - Customize Your PC - PC StudioDocument3 pagesBuild Your PC Online - Customize Your PC - PC StudioManas BaruaNo ratings yet

- Pilotes DescongeladosDocument1 pagePilotes DescongeladosLuis Miguel MedranoNo ratings yet

- WSC2015 TP07 at M3 Iso ADocument1 pageWSC2015 TP07 at M3 Iso ALucas SalustianoNo ratings yet

- CSE 499A Sec. 3 Spring 18 Ece, NsuDocument2 pagesCSE 499A Sec. 3 Spring 18 Ece, NsuMd SiamNo ratings yet

- Presentation 1Document13 pagesPresentation 1Anugrah Alief PNo ratings yet

- Horizontal Pump 8 MF: WPA8D52/2 WPA8D52/2 WPA8D52/2 WPA8D52/2 WPA8D52/2 WPA8D52/2 WPA8D52/2Document1 pageHorizontal Pump 8 MF: WPA8D52/2 WPA8D52/2 WPA8D52/2 WPA8D52/2 WPA8D52/2 WPA8D52/2 WPA8D52/2Dirceu ValadaresNo ratings yet

- IMG - 0094 MCQ College Algebra 179Document1 pageIMG - 0094 MCQ College Algebra 179bnqr584bNo ratings yet

- Labor DemandDocument13 pagesLabor DemandAnugrah Alief PNo ratings yet

- Earthquake - PH 5000w d1Document1 pageEarthquake - PH 5000w d1vishnu csNo ratings yet

- All Terraln Hydrau1k:: CraneDocument18 pagesAll Terraln Hydrau1k:: CraneHoward HoacNo ratings yet

- Proteus Simulation Based Pic Projects - PIC MicrocontrollerDocument30 pagesProteus Simulation Based Pic Projects - PIC MicrocontrollerElie RaffoulNo ratings yet

- Evaporador de EmbutidosDocument5 pagesEvaporador de Embutidosluisferqm10No ratings yet

- Thursday, February 29, 2024,9:04:52 PMDocument1 pageThursday, February 29, 2024,9:04:52 PMnaurahputrianindiaNo ratings yet

- Current Models: Size Type FinishesDocument10 pagesCurrent Models: Size Type FinishesQuinnNo ratings yet

- Seatwork 1Document3 pagesSeatwork 1Ellaine NacisNo ratings yet

- الأحياء السابع من أوائل الجمهوريةDocument4 pagesالأحياء السابع من أوائل الجمهوريةsaadalsamed2020No ratings yet

- Sp20 DescripcionDocument2 pagesSp20 DescripcionJuan Pablo Moreno Téllez Moreno TéllezNo ratings yet

- Comptector & Chiller (Cdu) Controller (Fx32C Series) : Precaution For UseDocument5 pagesComptector & Chiller (Cdu) Controller (Fx32C Series) : Precaution For UseFcma0903100% (1)

- Datasheet Ap4439gmt-Hf Hal4Document1 pageDatasheet Ap4439gmt-Hf Hal4Ij OooNo ratings yet

- Zany Zoo Score SampleDocument4 pagesZany Zoo Score SampleRosaNo ratings yet

- Assignment 5 - BushardDocument5 pagesAssignment 5 - Bushardapi-594060005No ratings yet

- Behriner+SMPSU18 Ground ReferenceDocument1 pageBehriner+SMPSU18 Ground ReferenceLuiz SantosNo ratings yet

- P83 OPL FinalDocument11 pagesP83 OPL FinalJorge León IllanesNo ratings yet

- Se Pvy Insem PapersDocument9 pagesSe Pvy Insem Paperseditingop2003No ratings yet

- Valisi Fata Sheet FPSH 15Document1 pageValisi Fata Sheet FPSH 15Cristian CamiloNo ratings yet

- Smart Note Taker - 2015005 - 2015038Document16 pagesSmart Note Taker - 2015005 - 2015038hrishikeshdeka18No ratings yet

- QuatDocument8 pagesQuatThanh Do DucNo ratings yet

- Be - Computer Engineering - Semester 3 - 2018 - May - Digital Electronics and Logical Design Deld Pattern 2015Document3 pagesBe - Computer Engineering - Semester 3 - 2018 - May - Digital Electronics and Logical Design Deld Pattern 2015ShivamNo ratings yet

- cb7624bd 1606188484489Document51 pagescb7624bd 1606188484489Rajesh KandhwayNo ratings yet

- 04 - Simple Trig EquationsDocument4 pages04 - Simple Trig EquationsUganda Williams Jr.No ratings yet

- 04 - Simple Trig Equations PDFDocument4 pages04 - Simple Trig Equations PDFMark Abion ValladolidNo ratings yet

- 04 - 5 - Simple Trig EquationsDocument4 pages04 - 5 - Simple Trig EquationsSUNGMIN CHOINo ratings yet

- 04 - Simple Trig EquationsDocument4 pages04 - Simple Trig EquationsUganda Williams Jr.No ratings yet

- 04 - Simple Trig Equations PDFDocument4 pages04 - Simple Trig Equations PDFoceanolive2No ratings yet

- How To Use This Severity Chart: Example Fan 625 Um (25 Mils)Document2 pagesHow To Use This Severity Chart: Example Fan 625 Um (25 Mils)Aminul Haque SaikiaNo ratings yet

- Drillmec HH 300 SummaryDocument2 pagesDrillmec HH 300 Summaryleo100% (1)

- SINAMICS Drives D23 1 Complete English 2020Document170 pagesSINAMICS Drives D23 1 Complete English 2020Руслан СафиуллинNo ratings yet

- Checklist Pre-Start Checks Pre Take-Off Checks: TmpfischDocument2 pagesChecklist Pre-Start Checks Pre Take-Off Checks: Tmpfischdick headNo ratings yet

- Abu Dhabi Sew, SWD Irr Specsc Design CriteriaDocument30 pagesAbu Dhabi Sew, SWD Irr Specsc Design Criteriamalgendy0No ratings yet

- Oil SaverDocument4 pagesOil Saverjuan mosqueraNo ratings yet

- Catalogo Completo OhioDocument52 pagesCatalogo Completo OhioGalargaAlfaNo ratings yet

- Oil & Grease PumpsDocument6 pagesOil & Grease PumpsAbass BilaNo ratings yet

- Caterpillar Cat 225 EXCAVATOR (Prefix 76U) Service Repair Manual (76U00001-00693)Document28 pagesCaterpillar Cat 225 EXCAVATOR (Prefix 76U) Service Repair Manual (76U00001-00693)rpoy9396615No ratings yet

- Fluent-Adv-rm 14.5 L01 IntroDocument12 pagesFluent-Adv-rm 14.5 L01 Introlegend guraraNo ratings yet

- 18 Dismental and Assemble Distributer Type Diesel Fuel PumpDocument3 pages18 Dismental and Assemble Distributer Type Diesel Fuel Pumpmaliksawan376116No ratings yet

- Svmfsvaf Manual 1Document102 pagesSvmfsvaf Manual 1omar farukNo ratings yet

- Grundfos SEG IOMDocument42 pagesGrundfos SEG IOMCarlos MNo ratings yet

- Fuel Priming Pump - Remove and Install - Electric Fuel Priming PumpDocument5 pagesFuel Priming Pump - Remove and Install - Electric Fuel Priming PumpOdai AlsaafinNo ratings yet

- KSB Valves - For - Water-Data PDFDocument16 pagesKSB Valves - For - Water-Data PDFPaul MaposaNo ratings yet

- Simple Preventive Maintenance ChecklistDocument3 pagesSimple Preventive Maintenance Checklistceline lamNo ratings yet

- 2300 Perkins PDFDocument1 page2300 Perkins PDFOdy Christian ViryaNo ratings yet

- P105576-IC-IDF-204 - Rev01Document10 pagesP105576-IC-IDF-204 - Rev01bmanojkumar16No ratings yet

- نقشه خوانی p&Id Poorata IranPipingDocument24 pagesنقشه خوانی p&Id Poorata IranPipingBabak Hosseini100% (1)

- Model MS-RV: Workshop ContainerDocument6 pagesModel MS-RV: Workshop Containerjose ocanaNo ratings yet

- API STANDARDS BY Dr. ABDELKADER BELHADJDocument3 pagesAPI STANDARDS BY Dr. ABDELKADER BELHADJmohamed bachir mohamedNo ratings yet