Professional Documents

Culture Documents

Tech Review 129 Extract

Uploaded by

Nasir JufriOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tech Review 129 Extract

Uploaded by

Nasir JufriCopyright:

Available Formats

Numerical results were subjected to statistical evaluation using Student’s t-test in order to

determine whether there was a significant difference in the change of CO2 concentration

for the bottles without spoons versus the bottles with spoons. The results showed that

there was no significant difference between the two groups. We, therefore, conclude that

the practice of putting a spoon in the bottle neck to retain CO2 almost certainly has no

scientific merit.

Peter Valente

Chemist—Industry Services

Management of various vineyard-derived moulds during

winemaking

During the past two vintages, Institute staff have had many discussions with winemakers

concerning the management of, or minimization of the loss of wine quality caused by,

various moulds. The author has also discussed these issues with leading winemaking

consultants and overseas winemakers, and as a result of these discussions the following

is a synopsis of the theory behind the management of this problem. While much of the 13

advice contained here is anecdotal, the Institute has received positive feedback from a

number of winemakers who have put the advice into practice. The author would also

welcome any extra information regarding other techniques that have been found to be of

use in minimizing the damage caused by mould.

Powdery mildew

Many winemakers consider that the taint caused by powdery mildew in white wine

results from the mycelium of the fungus itself, and thus the advice for minimizing taint is

based on minimizing the quantity of the mycelium in the juice. The application of a high

pressure, high volume water spray in the vineyard the day before harvest, assuming that

the weather conditions are such that this will not cause other mould problems, is reported

by some winemakers as having a positive effect in minimizing the concentration of

mycelium.

Whole bunch pressing of mould-affected white fruit seems to be an established practice

in parts of Europe and this is a strategy that some winemakers have reported as useful in

minimizing powdery mildew taint. The first approximately 150 L of juice per tonne is

often kept separate and is assessed for level of taint. Some feedback suggests that this

portion of juice is often far more taint-affected than further pressing fractions, possibly

because it contains the greatest concentration of mycelium, and by adopting this strategy

winemakers have the option to blend this juice into a lower value product.

December 2000 Technical Review No.129

Juice from powdery mildew-affected fruit should then be cold settled at the lowest

temperature possible to achieve rapid settling, and pectolytic enzymes should be used.

Some winemakers have reported that adding a higher concentration of enzyme than usual

aids taint minimization, but the Institute would caution against using enzymes in

concentration other than that recommended by the manufacturer. By general consensus

there is no advantage in adding bentonite at this stage. Rather, post-settling the juice

should be racked, and the heavy lees discarded or otherwise treated if heavily tainted, and

between 0.5 and 1 g/L bentonite should then be added to the racked juice. After 24 h the

juice should then be racked off the bentonite lees before fermentation is initiated.

Penicillium

During the 2000 vintage a winery contacted the Institute and reported an unusual situation,

in that it had a serious infection of white Penicillium mould without any Botrytis cinerea

being present. Clearly this situation is more common in parts of Europe, where the advice

for minimizing or removing Penicillium taint from juice is to fine with between 0.2 and

1 g/L deodorising carbon, followed by 0.01 g/L gelatine to settle the carbon. The juice

14 should then be racked off these lees before fermentation is initiated. While some

winemakers also advocate the use of bentonite, an Austrian winemaker who has experience

with this problem, who was also working in Australia during the 2000 vintage, was

adamant that bentonite has no effect on removing Penicillium taint from either juice or

wine.

Botrytis cinerea

By far the largest numbers of inquiries received by the Institute concerning moulds relate

to red fruit infected with Botrytis cinerea (botrytis). Relatively few calls relate to botrytis

in white fruit and this is one area where the author would welcome feedback. While the

fining of white juice in a manner similar to that described for powdery mildew appears to

be common, the advice given below regarding the exclusion of oxygen to minimize

oxidative damage caused by laccase also applies. Thus when attempting to minimize taint

by fining, winemakers should also aim for rapid commencement of fermentation in order

to minimize oxidative damage.

There are two winemaking issues related to botrytis-affected red fruit, namely the taint

that may be caused and the control of the laccase enzyme, and the following discussion

will focus on the second of these issues. While feedback relating to the minimization or

removal of botrytis taint from red must or wine would be welcome, the author feels that

application of the principles outlined here forms the basis of minimizing laccase damage

and taint.

Technical Review No.129 December 2000

The level of oxidative damage or taint caused by botrytis appears to differ according to

the physiological stage of the botrytis when the fruit is harvested. While individual

winemakers have differing opinions as to the physiological stage at which the greatest

loss of wine quality occurs, there appears to be some consensus that the greatest laccase

activity is at the point when fresh ‘furry’ mould growth with a high number of visible

spores is present.

Minimizing the quantity of mould-affected fruit is obviously beneficial, but can be difficult

to achieve in practice. Prior to machine harvesting, sending hand-pickers through the

vineyard to remove the worst affected fruit is one option, and some callers have also

reported that in some situations machine harvesters will shake-out many botrytis-affected

berries from vines in front of the harvester, before the healthy fruit is picked. Feedback

received indicates that this strategy has been used successfully in vineyards that are

normally hand picked. Whilst the hand sorting of fruit prior to crushing is relatively

common in parts of Europe, it is clearly not a viable option in most Australian situations.

Encouraging hand-pickers, however, to discard the most badly affected fruit is desirable.

15

At all stages when handling botrytis-affected fruit, is important to consider that the

laccase enzyme can only cause oxidative damage when oxygen is present and it is,

therefore, imperative to minimize oxygen pick-up wherever possible. It is also important

to remember that a relatively high concentration of sulfur dioxide (SO2) will have little

effect on the activity of laccase. The author does advocate, however, the addition of

between 40 and 80 mg/L of SO2 (in the form of potassium metabisulfite) to botrytis

affected fruit, on the basis that a higher than normal population of other unwanted

microorganisms is likely to be present when botrytis is present.

The exclusion of oxygen pre- and post-crushing will be aided by the use of dry ice, and

by ensuring that the onset of fermentation is rapid. Larger than normal yeast additions

should be used and the yeast should be added as early as possible. If SO2 has been added

at the higher end of the rates recommended above, it might be advisable to add a small

yeast addition as a ‘sacrificial’ culture, a few minutes before the bulk of the yeast is added.

The sacrificial culture will have the effect of binding much of the free SO2.

There is strong anecdotal evidence that the addition of oenological tannin during

fermentation reduces the damage caused by laccase. If this is the case, the author considers

that the beneficial effect is more likely to be due a simple fining reaction, than to deactivation

of the enzyme. Whilst it does appear that the addition of some tannin will be beneficial in

December 2000 Technical Review No.129

most cases, winemakers should also be aware that the addition of tannin may cause a

marked change in their wine style, especially at addition rates of up to 500 mg/L, which

have reportably been advocated by some tannin suppliers.

Most winemakers choose to ferment botrytis-affected fruit in static rather than rotary

fermenters for two reasons. Firstly to minimize the ‘macerated mouldy skins’ character

that is often associated with wines made from botrytis-affected fruit and also because it

is easier to remove the fermentation lees when pressing, which is reported to be beneficial.

On the negative side, it is easier to exclude oxygen in a rotary rather than static fermenter.

There is also anecdotal evidence that there is more laccase activity in the lees than in the

fermenting wine towards the end of fermentation, and this could be considered logical if

the ‘tannin fining’ argument is accepted. Even if no tannin is added, then it is still possible

that phenolic compounds from the grapes could cause the precipitation of some laccase

during fermentation and it is, therefore, recommended that fermentation lees be separated

from the wine as quickly as possible at pressing. If it is possible to drain lees from the

fermenter or leave the lees behind in the fermenter when the wine and skins are removed,

16

then this should be done.

Pressing should take place while carbon dioxide (CO2) is still being actively produced,

which in many cases will result in a shorter fermentation than usual. It is, therefore,

important to manage the fermentation in order to obtain the required level of extraction

during this shorter fermentation time. While fermentation management techniques that

cause excessive aeration should be avoided, the oxygen dissolved during a standard

pump-over of actively fermenting must will quickly be consumed by yeast, rather than

causing oxidation via laccase. Thus pressing when fermentation is still active has the dual

advantages of the discouragement of the ingress of oxygen by the CO2 coming out of

solution, and the still-active yeast being able scavenge any oxygen that may be dissolved.

At pressing, wine should be pumped to tanks, not barrels, and inert gas cover will again

aid the exclusion of oxygen. The wine should then be racked off gross lees after 24 h,

again into tank with inert gas cover, and laccase activity should be tested at this stage.

Further racking can be beneficial in order to remove all fermentation lees, and winemakers

applying these techniques have reported a gradual reduction in laccase activity as wines

are allowed to settle and the lees removed, even in wines made from fruit which had a

high level of laccase activity.

Technical Review No.129 December 2000

If laccase activity is still detected in the wine after several rackings, heating of the wine is

advisable, and feedback suggests that this can be performed without an immediately

apparent loss of wine quality. While a loss of wine quality due to heating may be a

reasonable concern, however, a much greater quality loss will almost certainly result if

the laccase present is not deactivated.

Peter Godden

Winemaker /Manager—Industry Services

Yeast strains available for winemaking 2000/2001

1. Yeast strains available from the Institute

The following list details the characteristics of most of the popular yeast strains available

for winemaking from the Institute’s culture collection. Yeasts are supplied as active

cultures on agar slopes for a fee of $45 per slope.

1.1 AWRI 350 Saccharomyces cerevisiae

A medium vigour, flocculating yeast, which may be used for both red and white wine 17

production. Significant amounts of esters and higher alcohols are produced, which gives

the young wine a distinct floral/aromatic character. Low volatile acidity (VA), hydrogen

sulfide (H2S) and sulfur dioxide (SO2) are produced during table wine fermentation; a

low concentration of these compounds was also observed in a laboratory-scale, botrytized

juice fermentation trial. Under cold fermentation conditions, the ferments may require

warming or agitation during the final stages to reduce premature yeast settling. Compact

lees are formed. This yeast appears suited to low nitrogen musts.

1.2 AWRI 729 S. cerevisiae

Returned to the Institute from Davis, California in 1977, but not considered identical with

the original 729. Tendency to accumulate acetic acid (VA) when fermenting some musts,

particularly at low temperature (10°C) and when some vitamin mixtures are used. Active

yeast with a fast rate of sugar catabolism at low cell numbers. Low formation of higher

alcohols and esters. Suited to both red and white wine production.

December 2000 Technical Review No.129

You might also like

- Microbiology of Soft Drinks and Fruit JuicesDocument38 pagesMicrobiology of Soft Drinks and Fruit JuicesAbdur RafeyNo ratings yet

- R&D Needs in The Industrial Production of VinasseDocument18 pagesR&D Needs in The Industrial Production of VinasseJacob ReidNo ratings yet

- Wine Storage and Bottling QCDocument12 pagesWine Storage and Bottling QCKaycee Navarro100% (1)

- Winemaking Made Easy: Learn how to create the perfect house wineFrom EverandWinemaking Made Easy: Learn how to create the perfect house wineNo ratings yet

- Final Project WINE INDDocument57 pagesFinal Project WINE INDjainnitinkumar79% (14)

- Dorff Wines ConservativeDocument24 pagesDorff Wines ConservativeAnnieCasNo ratings yet

- Nanofiltration and Reverse Osmosis in WinemakingDocument5 pagesNanofiltration and Reverse Osmosis in WinemakingfasihaNo ratings yet

- Apple Cider Vinegar in The AcetatorDocument3 pagesApple Cider Vinegar in The AcetatorAna100% (1)

- Brett Fact SheetDocument5 pagesBrett Fact SheetChris MidtunNo ratings yet

- Sparkling Wine Production: January 2011Document53 pagesSparkling Wine Production: January 2011danielNo ratings yet

- Clinically Clean Wines and The Fear of Funk at Improved WinemakingDocument4 pagesClinically Clean Wines and The Fear of Funk at Improved WinemakingAnonymous ePcnZoBENo ratings yet

- Chapter One Winemaking or Vinification Is The Production of Wine, Starting With TheDocument21 pagesChapter One Winemaking or Vinification Is The Production of Wine, Starting With TheAkinnola OluwafeyisemiireNo ratings yet

- Process Selection:: 2.1 Types of ProcessesDocument16 pagesProcess Selection:: 2.1 Types of ProcessesNabeel BhuttaNo ratings yet

- c9s12 2Document9 pagesc9s12 2Babul Kumar MishraNo ratings yet

- 1 WinemakingDocument29 pages1 WinemakingLouella Gamoso ArtatesNo ratings yet

- Experiment 1 WinemakingDocument6 pagesExperiment 1 WinemakingEllen Jane RamosNo ratings yet

- Rum PDFDocument14 pagesRum PDFJojie-Ann Alabarca100% (2)

- Generic Haccp-Document ProvidesDocument9 pagesGeneric Haccp-Document ProvidesaltempusNo ratings yet

- Wine Nano Filtration 9435Document7 pagesWine Nano Filtration 9435Dr. Vikhar KhanNo ratings yet

- Otet Din VinDocument8 pagesOtet Din Vinpixel5dNo ratings yet

- Sensors 22 06247 v2Document11 pagesSensors 22 06247 v2nimmi kumariNo ratings yet

- SCOPE AND LIMITATION SCOPE ChemistryDocument2 pagesSCOPE AND LIMITATION SCOPE Chemistryprabhat solankiNo ratings yet

- Citric Acid Production From Pineapple Waste Through Solid-State FermentationDocument6 pagesCitric Acid Production From Pineapple Waste Through Solid-State FermentationCiara DevelosNo ratings yet

- Fermentation of WineDocument5 pagesFermentation of WineskljoleNo ratings yet

- Business Case - Víctor Fiérrez - Yeast Extract Production From Beer Brewing FermentationsDocument4 pagesBusiness Case - Víctor Fiérrez - Yeast Extract Production From Beer Brewing FermentationsVíctor Fiérrez JuanNo ratings yet

- 2 1 Preparation of Wine Through Simple Fermentation Process: 3 I. Background of The ExperimentDocument5 pages2 1 Preparation of Wine Through Simple Fermentation Process: 3 I. Background of The ExperimentrickiegasparNo ratings yet

- FERMENTATION Vinegar PDFDocument22 pagesFERMENTATION Vinegar PDFJivashiniBalasupurManiam100% (1)

- B.Chap Wine 2011Document60 pagesB.Chap Wine 2011Annabelle OlgaNo ratings yet

- Flash Bio Thermo Extraction - What Can It Do For You? - by Paul BaggioDocument3 pagesFlash Bio Thermo Extraction - What Can It Do For You? - by Paul BaggioTheBeverageFoodGroupNo ratings yet

- Fermentation Process (Wine & Beer)Document39 pagesFermentation Process (Wine & Beer)Jannielle Joyce BoniaoNo ratings yet

- Use of Wine LeesDocument10 pagesUse of Wine LeesIthan Jessemar DollenteNo ratings yet

- Sấy phunDocument11 pagesSấy phuntranb2014450No ratings yet

- Nutrient RemovalDocument2 pagesNutrient RemovalChali HaineNo ratings yet

- Analysis of Old Trends in Indian Wine-Making and Need of Expert System in Wine-MakingDocument10 pagesAnalysis of Old Trends in Indian Wine-Making and Need of Expert System in Wine-MakingIJRASETPublicationsNo ratings yet

- 20 Facts You Should KnowDocument7 pages20 Facts You Should KnowDomagoj ĆosićNo ratings yet

- Vinegar Production Research Paper PDFDocument4 pagesVinegar Production Research Paper PDFefeh4a7z100% (1)

- Scott Labs HandbookDocument51 pagesScott Labs Handbookvikramreddy041302No ratings yet

- Laboratorio para Pequelas ViñasDocument4 pagesLaboratorio para Pequelas ViñasCSC-BikerNo ratings yet

- TWP-142446-Nhóm 1Document6 pagesTWP-142446-Nhóm 1Nguyễn Quang KhánhNo ratings yet

- Raju Inplant Traing Final 2Document59 pagesRaju Inplant Traing Final 2ssrcs1No ratings yet

- Martin GreeveDocument43 pagesMartin GreevemanuelNo ratings yet

- PinkDocument2 pagesPinkdaniela ratuleaNo ratings yet

- Food Science Nutrition - 2020 - Bouatenin - Organic Production of Vinegar From Mango and PapayaDocument7 pagesFood Science Nutrition - 2020 - Bouatenin - Organic Production of Vinegar From Mango and PapayakeziahNo ratings yet

- Term Paper Presentation On FermentationDocument11 pagesTerm Paper Presentation On FermentationOluwagbenga ElijahNo ratings yet

- Technology of WineDocument5 pagesTechnology of Winemawamaka90No ratings yet

- Consumption of Alcoholic Beverages 1. Exposure DataDocument130 pagesConsumption of Alcoholic Beverages 1. Exposure Databasge7414No ratings yet

- Pamantasannglungsodngmaynila: Fermentation of Jackfruit (Artocarpus Heterophyllus) To Produce Jackfruit WineDocument13 pagesPamantasannglungsodngmaynila: Fermentation of Jackfruit (Artocarpus Heterophyllus) To Produce Jackfruit WineMinjdeDios100% (1)

- Wine MakingDocument5 pagesWine MakingA Ba-atNo ratings yet

- Production of VinegarDocument37 pagesProduction of VinegarAhmed AliNo ratings yet

- Red Wine Is A Type ofDocument6 pagesRed Wine Is A Type ofgritchard4No ratings yet

- Estimating Economic and Environmental Impacts of Red-Wine-Making Processes in The USADocument14 pagesEstimating Economic and Environmental Impacts of Red-Wine-Making Processes in The USAVioleta IPNo ratings yet

- Fermentation OwolabiDocument9 pagesFermentation OwolabiGabrielle WhelanNo ratings yet

- Unit 13 Technological Aspects of Industrial Production of Alcoholic Beverages and Related ProductsDocument13 pagesUnit 13 Technological Aspects of Industrial Production of Alcoholic Beverages and Related Productskakinada1980No ratings yet

- BIO3215 Lab #5Document5 pagesBIO3215 Lab #5dianna dossantosNo ratings yet

- Wort SouringDocument19 pagesWort Souringgaffodio hadrienNo ratings yet

- AgustusDocument10 pagesAgustusNasir JufriNo ratings yet

- Further Developments of The Capability Maturity Model To Monitor Activities Supporting The Offshore IndustryDocument21 pagesFurther Developments of The Capability Maturity Model To Monitor Activities Supporting The Offshore IndustryNasir JufriNo ratings yet

- Free BooksDocument123 pagesFree BooksMyk Twentytwenty NBeyond100% (3)

- Part List HB 5800Document40 pagesPart List HB 5800Nasir JufriNo ratings yet

- fracCodeList 2018 PDFDocument14 pagesfracCodeList 2018 PDFLuis Angel Medrano CastilloNo ratings yet

- Material Safety Data Sheet: 1. Product and Company IdentificationDocument8 pagesMaterial Safety Data Sheet: 1. Product and Company IdentificationNasir JufriNo ratings yet

- Further Developments of The Capability Maturity Model To Monitor Activities Supporting The Offshore IndustryDocument21 pagesFurther Developments of The Capability Maturity Model To Monitor Activities Supporting The Offshore IndustryNasir JufriNo ratings yet

- fracCodeList 2018 PDFDocument14 pagesfracCodeList 2018 PDFLuis Angel Medrano CastilloNo ratings yet

- Principles of Acute Pain ManagementDocument26 pagesPrinciples of Acute Pain ManagementNasir JufriNo ratings yet

- Calcium Peroxide: Product Safety SummaryDocument5 pagesCalcium Peroxide: Product Safety SummaryNasir JufriNo ratings yet

- Sulfur Containing SaltsDocument9 pagesSulfur Containing SaltsNasir JufriNo ratings yet

- Chemicals Wine MakersDocument1 pageChemicals Wine MakersNasir JufriNo ratings yet

- 2019 Powdery MildewDocument2 pages2019 Powdery MildewNasir JufriNo ratings yet

- Studi Komunitas Rumput Laut Pada Berbagai Substrat PDFDocument6 pagesStudi Komunitas Rumput Laut Pada Berbagai Substrat PDFRatnaGumillangNo ratings yet

- Curricul Vitae Abdul Malik YusufDocument1 pageCurricul Vitae Abdul Malik YusufNasir JufriNo ratings yet

- Glossary of Wine-Tasting Terminology, Matei Alina Mihaela, MTI Anul 1Document30 pagesGlossary of Wine-Tasting Terminology, Matei Alina Mihaela, MTI Anul 1Alina-Mihaela Matei100% (2)

- Food & Wine PairingDocument37 pagesFood & Wine PairingManoj SharmaNo ratings yet

- Double Barrel Beverages Product and Price List: Item/ Description Sku (ML) Pack On Trade South African Wines DelushDocument3 pagesDouble Barrel Beverages Product and Price List: Item/ Description Sku (ML) Pack On Trade South African Wines DelushBenjamin SsematubiNo ratings yet

- QT - Case - Freemark Abbey WineryDocument7 pagesQT - Case - Freemark Abbey Wineryadirisin100% (1)

- OFERTA PRET Completa 12.06.2017Document21 pagesOFERTA PRET Completa 12.06.2017Ioana Veronica RaduNo ratings yet

- Workbook PDFDocument70 pagesWorkbook PDFGaudence walecNo ratings yet

- List of Processing Units in KarnatakaDocument5 pagesList of Processing Units in KarnatakaRamzad Kumble100% (1)

- BBS Book (PT 14) NeglyDocument7 pagesBBS Book (PT 14) Neglyapi-3871208No ratings yet

- MFW February Portfolio UpdateDocument43 pagesMFW February Portfolio UpdatejasonmalumedNo ratings yet

- Catalogue Wine SectorDocument2 pagesCatalogue Wine SectorIdaNo ratings yet

- Grapes Production in The PhilippinesDocument7 pagesGrapes Production in The Philippinesvpacademicpsu.edu.ph PSU100% (1)

- Foliar Boron and Zinc TurkeyDocument9 pagesFoliar Boron and Zinc TurkeyFitri AudiaNo ratings yet

- Benefit For Daryl Bagley Silent Auction ItemsDocument9 pagesBenefit For Daryl Bagley Silent Auction ItemskatschornbergNo ratings yet

- Cunard WDocument26 pagesCunard WSunnyNo ratings yet

- Complete PDFDocument80 pagesComplete PDFGCMediaNo ratings yet

- 4 Olives MenuDocument1 page4 Olives Menu4olivesNo ratings yet

- Sandlands VineyardsDocument2 pagesSandlands VineyardsAnirudh Rathore100% (2)

- 2020 Champagne AR Lenoble International Press ReviewDocument4 pages2020 Champagne AR Lenoble International Press ReviewD kingNo ratings yet

- Burgundy PDFDocument6 pagesBurgundy PDFBianca CotellessaNo ratings yet

- Wine MenuDocument24 pagesWine MenuSethdaniel HendersonNo ratings yet

- Ledo B: Name of Vine Variety in FranceDocument2 pagesLedo B: Name of Vine Variety in FranceFiderman SzabolcsNo ratings yet

- Wines - Henri FluchereDocument164 pagesWines - Henri FluchereKenneth86% (7)

- Grapevine Management Guide 2018 19Document154 pagesGrapevine Management Guide 2018 19jtempradobernalNo ratings yet

- Indigo On TRADE List January 2017Document65 pagesIndigo On TRADE List January 2017JuliaNo ratings yet

- 30 Years VIVC - Vitis International Variety CatalogueDocument8 pages30 Years VIVC - Vitis International Variety CatalogueMarina Zdravkovic Ex TodorovicNo ratings yet

- BaroloDocument33 pagesBaroloJonathan MarchatNo ratings yet

- The Oxford Companion To WinePDF - Harding, Julia Robinson OBE Mncis Thomas, Tara Q. & Jancis Robinson OBE MW & Tara Q. ThomasDocument4,061 pagesThe Oxford Companion To WinePDF - Harding, Julia Robinson OBE Mncis Thomas, Tara Q. & Jancis Robinson OBE MW & Tara Q. ThomasSergio BoggeroNo ratings yet

- Wine CatalogDocument5 pagesWine CatalogMuhammad DanishNo ratings yet

- Fine Wines - Skinner Auctions 2593B and 2592TDocument108 pagesFine Wines - Skinner Auctions 2593B and 2592TSkinnerAuctionsNo ratings yet

- Australia Wine RegionsDocument56 pagesAustralia Wine RegionsShiva ChaurasiyaNo ratings yet

- Instant Loss On a Budget: Super-Affordable Recipes for the Health-Conscious CookFrom EverandInstant Loss On a Budget: Super-Affordable Recipes for the Health-Conscious CookRating: 3.5 out of 5 stars3.5/5 (2)

- The Obesity Code: Unlocking the Secrets of Weight LossFrom EverandThe Obesity Code: Unlocking the Secrets of Weight LossRating: 4 out of 5 stars4/5 (5)

- The Encyclopedia of Spices & Herbs: An Essential Guide to the Flavors of the WorldFrom EverandThe Encyclopedia of Spices & Herbs: An Essential Guide to the Flavors of the WorldRating: 3.5 out of 5 stars3.5/5 (5)

- Waiter Rant: Thanks for the Tip—Confessions of a Cynical WaiterFrom EverandWaiter Rant: Thanks for the Tip—Confessions of a Cynical WaiterRating: 3.5 out of 5 stars3.5/5 (487)

- The Food Lover's Cleanse: 140 Delicious, Nourishing Recipes That Will Tempt You Back into Healthful EatingFrom EverandThe Food Lover's Cleanse: 140 Delicious, Nourishing Recipes That Will Tempt You Back into Healthful EatingRating: 4 out of 5 stars4/5 (3)

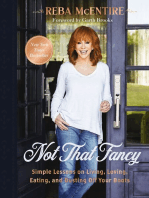

- Not That Fancy: Simple Lessons on Living, Loving, Eating, and Dusting Off Your BootsFrom EverandNot That Fancy: Simple Lessons on Living, Loving, Eating, and Dusting Off Your BootsNo ratings yet

- Surprise-Inside Cakes: Amazing Cakes for Every Occasion—with a Little Something Extra InsideFrom EverandSurprise-Inside Cakes: Amazing Cakes for Every Occasion—with a Little Something Extra InsideRating: 4 out of 5 stars4/5 (6)

- Mostly Plants: 101 Delicious Flexitarian Recipes from the Pollan FamilyFrom EverandMostly Plants: 101 Delicious Flexitarian Recipes from the Pollan FamilyRating: 4 out of 5 stars4/5 (11)

- Instant Pot Miracle 6 Ingredients Or Less: 100 No-Fuss Recipes for Easy Meals Every DayFrom EverandInstant Pot Miracle 6 Ingredients Or Less: 100 No-Fuss Recipes for Easy Meals Every DayRating: 4 out of 5 stars4/5 (4)

- Saved By Soup: More Than 100 Delicious Low-Fat Soups To Eat And Enjoy Every DayFrom EverandSaved By Soup: More Than 100 Delicious Low-Fat Soups To Eat And Enjoy Every DayRating: 4 out of 5 stars4/5 (10)

- Body Love Every Day: Choose Your Life-Changing 21-Day Path to Food FreedomFrom EverandBody Love Every Day: Choose Your Life-Changing 21-Day Path to Food FreedomRating: 4 out of 5 stars4/5 (1)

- Pati's Mexican Table: The Secrets of Real Mexican Home CookingFrom EverandPati's Mexican Table: The Secrets of Real Mexican Home CookingRating: 4 out of 5 stars4/5 (9)

- The Blue Apron Cookbook: 165 Essential Recipes & Lessons for a Lifetime of Home CookingFrom EverandThe Blue Apron Cookbook: 165 Essential Recipes & Lessons for a Lifetime of Home CookingNo ratings yet

- The Stark Naked 21-Day Metabolic Reset: Effortless Weight Loss, Rejuvenating Sleep, Limitless Energy, More MojoFrom EverandThe Stark Naked 21-Day Metabolic Reset: Effortless Weight Loss, Rejuvenating Sleep, Limitless Energy, More MojoNo ratings yet

- Eating Clean: The 21-Day Plan to Detox, Fight Inflammation, and Reset Your BodyFrom EverandEating Clean: The 21-Day Plan to Detox, Fight Inflammation, and Reset Your BodyRating: 4 out of 5 stars4/5 (1)

- Waiting: The True Confessions of a WaitressFrom EverandWaiting: The True Confessions of a WaitressRating: 3 out of 5 stars3/5 (7)

- Binging with Babish: 100 Recipes Recreated from Your Favorite Movies and TV ShowsFrom EverandBinging with Babish: 100 Recipes Recreated from Your Favorite Movies and TV ShowsNo ratings yet

- Eat Complete: The 21 Nutrients That Fuel Brainpower, Boost Weight Loss, and Transform Your HealthFrom EverandEat Complete: The 21 Nutrients That Fuel Brainpower, Boost Weight Loss, and Transform Your HealthRating: 2 out of 5 stars2/5 (1)

- Grape, Olive, Pig: Deep Travels Through Spain's Food CultureFrom EverandGrape, Olive, Pig: Deep Travels Through Spain's Food CultureRating: 4.5 out of 5 stars4.5/5 (15)

- The Volumetrics Eating Plan: Techniques and Recipes for Feeling Full on Fewer CaloriesFrom EverandThe Volumetrics Eating Plan: Techniques and Recipes for Feeling Full on Fewer CaloriesNo ratings yet

- Heirloom Kitchen: Heritage Recipes & Family Stories from the Tables of Immigrant WomenFrom EverandHeirloom Kitchen: Heritage Recipes & Family Stories from the Tables of Immigrant WomenRating: 4.5 out of 5 stars4.5/5 (3)