Professional Documents

Culture Documents

FL Navara D

Uploaded by

Jean MoralesOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FL Navara D

Uploaded by

Jean MoralesCopyright:

Available Formats

ENGINE

SECTION

FUEL SYSTEM

FL FL

E

CONTENTS

QR PREPARATION ................................................. 13 F

Commercial Service Tool ........................................13

SERVICE INFORMATION ............................ 2

FUEL SYSTEM .................................................. 14 G

PREPARATION ................................................... 2 Checking Fuel Line ..................................................14

Commercial Service Tool .......................................... 2 General Precaution ..................................................14

FUEL SYSTEM .................................................... 3 FUEL FILTER .................................................... 15 H

Checking Fuel Line ................................................... 3 Components ............................................................15

General Precaution ................................................... 3 Removal and Installation .........................................15

FUEL TANK ......................................................... 5 I

FUEL COOLER ................................................. 16

Components .............................................................. 5 Components ............................................................16

Removal and Installation ........................................... 5 Removal and Installation .........................................16

J

FUEL LEVEL SENSOR UNIT, FUEL FILTER FUEL TANK ...................................................... 17

AND FUEL PUMP ASSEMBLY .........................10 Components ............................................................17

Components ............................................................ 10 Removal and Installation .........................................17 K

Removal and Installation ......................................... 10

FUEL LEVEL SENSOR UNIT ........................... 18

SERVICE DATA AND SPECIFICATIONS Components ............................................................18

(SDS) ..................................................................12 Removal and Installation .........................................18 L

Standard and Limit .................................................. 12

SERVICE DATA AND SPECIFICATIONS

YD

(SDS) ................................................................. 20 M

SERVICE INFORMATION ........................... 13 Standard and Limit ..................................................20

Tightening Torque ...................................................20

Revision: 2007 September FL-1 D40

PREPARATION

< SERVICE INFORMATION > [QR]

SERVICE INFORMATION

PREPARATION

Commercial Service Tool INFOID:0000000003293032

Tool name Description

Fuel tank lock ring wrench Removing and installing fuel tank lock ring

ZZA0122D

Revision: 2007 September FL-2 D40

FUEL SYSTEM

< SERVICE INFORMATION > [QR]

FUEL SYSTEM

A

Checking Fuel Line INFOID:0000000003293033

Inspect fuel lines, fuel filler cap and fuel tank for improper attach- FL

ment, leaks, cracks, damage, loose connections, chafing or deterio-

ration.

If necessary, repair or replace damaged parts.

C

SMA803A E

General Precaution INFOID:0000000003293034

WARNING: F

When replacing fuel line parts, be sure to observe the following.

• Put a “CAUTION: FLAMMABLE” sign in the workshop.

• Be sure to work in a well-ventilated area and furnish workshop with a CO2 fire extinguisher. G

• Never smoke while servicing fuel system. Keep open flames and sparks away from the work area.

CAUTION:

• Use gasoline required by the regulations for octane number. Refer to GI-4, "Precaution for Fuel".

• Before removing fuel line parts, perform the following procedures: H

- Put drained fuel in an explosion-proof container and put the lid on securely. Keep the container in

safe area.

- Release fuel pressure from the fuel lines. I

- Disconnect the battery cable from the negative terminal.

• Always replace O-rings and clamps with new ones.

• Never kink or twist hoses when they are being installed.

• Never tighten hose clamps excessively to avoid damaging hoses. J

Tighten high-pressure rubber hose clamp so that clamp end

is 3 mm (0.12 in) (a) from hose end.

K

b : 28 mm (1.10 in)

Tightening torque specifications are the same for all rubber

hose clamps. L

Fuel hose clamps tightening torque:

: 1.0 - 1.5 N·m (0.10 - 0.15 kg-m, 9 - 13 in-lb) M

JPBIA1459ZZ

Ensure that screw does not contact adjacent parts.

N

Revision: 2007 September FL-3 D40

FUEL SYSTEM

< SERVICE INFORMATION > [QR]

• After connecting the fuel tube quick connectors, check the

quick connectors are secure.

Ensure that the connector and resin tube never contact any

adjacent parts.

• After installing tubes, check there is no fuel leakage at con-

nections in the following steps.

- Apply fuel pressure to fuel lines with turning ignition switch

ON (with engine stopped). Then check for fuel leaks at con-

nections.

- Start the engine and rev it up and check for fuel leaks at con-

nections.

• Use only a Genuine NISSAN fuel filler cap as a replacement. If

an incorrect fuel filler cap is used, the “MIL” may come on.

• For servicing “Evaporative Emission System” parts.

PBIC1268E

Revision: 2007 September FL-4 D40

FUEL TANK

< SERVICE INFORMATION > [QR]

FUEL TANK

A

Components INFOID:0000000003293035

FL

J

PBIC4219E

1. Fuel filler cap 2. Grommet 3. Fuel filler tube K

4. EVAP tube 5. Fuel tank 6. Fuel tank band (front)

7. Fuel tank band (rear) 8. Fuel feed tube 9. Vent hose

10. Fuel filler hose L

A. To engine

Removal and Installation INFOID:0000000003293036 M

REMOVAL

WARNING: N

Be sure to read “General Precautions” when working on fuel system. Refer to FL-3, "General Precau-

tion".

• Drain fuel from fuel tank if necessary. O

• Perform work on level place.

1. Open fuel filler lid.

2. Open the fuel filler cap and release the pressure inside fuel tank. P

Revision: 2007 September FL-5 D40

FUEL TANK

< SERVICE INFORMATION > [QR]

3. Check fuel level on level place. If fuel gauge indicates more than

the level shown in figure (full or almost full), drain fuel from fuel

tank until gauge indicates level as shown in the figure or below.

NOTE:

Because fuel will be spilled when removing fuel level sensor

unit, fuel filter and fuel pump assembly for the top of the fuel is

above the fuel level sensor unit, fuel filter and fuel pump assem-

bly installation surface.

• As a guide, fuel level becomes the position as shown in the

figure or below when approximately 20 (4-3/8 lmp gal) of

fuel are drained from fuel tank. PBIC3631E

• In a case that fuel pump does not operate, perform the follow-

ing steps.

a. Insert hose of less than 15 mm (0.59 in) in diameter into fuel filler tube through fuel filler opening to draw

fuel from fuel filler tube.

b. Disconnect fuel filler hose from fuel filler tube.

c. Insert tube into fuel tank to draw fuel from fuel tank.

• As a guide, fuel level becomes the position shown in the figure or below when approximately 20 (17-

5/8 lmp qt) of fuel are drained from full tank.

NOTE:

Adjusting fuel level is to prevent fuel from spilling, when fuel level sensor unit is removed.

4. Release the fuel pressure from fuel lines.

5. Disconnect the battery cable from the negative terminal.

6. Disconnect fuel feed tube (C).

A : Harness connector

B : EVAP tube

D : Fuel filler hose

E : Vent hose

PBIC3841E

• Disconnect quick connector of fuel feed tube as follows:

- Hold the sides of the connector, push in tubs and pull out the tube.

- If the connector and the tube are stuck together, push and pull sev-

eral times until they start to move. Then disconnect them by pull-

ing.

CAUTION:

SFE562A

Revision: 2007 September FL-6 D40

FUEL TANK

< SERVICE INFORMATION > [QR]

• Quick connector can be disconnected when the tabs are com-

pletely depressed. Never twist it more than necessary. A

• Never use any tools to disconnect quick connector.

• Keep resin tube away from heat. Be especially careful when

welding near the resin tube.

FL

• Prevent acid liquid such as battery electrolyte etc. from get-

ting on resin tube.

• Never bend or twist resin tube during installation and

removal. C

• Never remove the remaining retainer on hard tube (or equiva-

lent) except when resin tube or retainer is replaced.

• When resin tube or fuel level sensor unit is replaced, also D

replace retainer with a new one. Replace same color retainer

as before replacing.

Retainer color : Green E

G

SBIA0504E

• To keep clean the connecting portion and to avoid damage

and foreign materials, cover them completely with plastic H

bags or something similar.

PBIC0163E

K

7. Using a transmission jack (A), support the bottom of fuel tank

(1).

L

CAUTION:

Support the position that fuel tank bands never engage.

PBIC3377E

8. Remove fuel tank bands, and lower the transmission jack care- O

fully until harness connector (A), EVAP tube (B), fuel filler hose

(D) and vent hose (E) can be disconnected.

P

C : Fuel feed tube

9. Disconnect harness connector, EVAP tube, fuel filler hose and

vent hose.

PBIC3841E

Revision: 2007 September FL-7 D40

FUEL TANK

< SERVICE INFORMATION > [QR]

10. Supporting with hands, lower transmission jack carefully, and remove fuel tank.

CAUTION:

• Pay attention not to fall fuel tank.

• Check that all connection points have been disconnected.

• Confirm there is no interference with vehicle.

11. Remove fuel filler tubes, fuel filler hoses and vent hoses if necessary.

INSTALLATION

Note the following, and install in the reverse order of removal.

• Surely clamp fuel hoses and insert hose to the length below.

Fuel filler hose : 35 mm (1.38 in)

The other hose : 25 mm (0.98 in)

• Be sure hose clamp is not positioned on swelled area of fuel tube.

• Position fuel filler hose clamp (2) between paint marking (B).

1 : Fuel filler hose

3 : Fuel filler tube

A : Paint marking

PBIC4163E

• Position vent hose clamp (2) as shown in the figure.

1 : Vent hose

3 : Vent tube (part of fuel filler tube)

PBIC4162E

• Tighten fuel hose clamp so that the flange (A) of bolt head is on the

paint mark (B) on the band.

PBIC4058E

• Fit mounting band pin to the vehicle side securely.

• Before fixing the fuel tank, temporarily install the fuel filler tube.

CAUTION:

Use genuine fuel filler tube mounting bolts or equivalent. Check to tighten them to the specified

torque.

• Connect quick connector as follows.

1. Check connection for damage and foreign materials.

Revision: 2007 September FL-8 D40

FUEL TANK

< SERVICE INFORMATION > [QR]

2. Align the connector with the tube, then insert connector straight into tube until a click is heard.

3. After connecting, check that the connection is secure by following the steps below. A

• Visually confirm that the two tabs are connected to connector.

• Pull the tube and connector to check they are securely con-

nected. FL

PBIC1653E

E

INSPECTION AFTER INSTALLATION

Check there is no fuel leakage at connections in the following steps.

1. Turn ignition switch “ON” (with engine stopped), then check connections for leaks by applying fuel pres- F

sure to fuel piping.

2. Start engine and rev it up and check there is no fuel leakage at connections.

G

Revision: 2007 September FL-9 D40

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY

< SERVICE INFORMATION > [QR]

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY

Components INFOID:0000000003293037

JPBIA1568ZZ

Fuel level sensor unit, fuel filter and

1. Lock ring 2. 3. Seal packing

fuel pump assembly

4. Fuel tank

A. Refer to FL-10

• Refer to GI-7, "Component" for symbol marks in the figure.

Removal and Installation INFOID:0000000003293038

REMOVAL

WARNING:

Be sure to read “General Precautions” when working on fuel system. Refer to FL-3, "General Precau-

tion".

1. Remove fuel tank from the vehicle. Refer to FL-5, "Components".

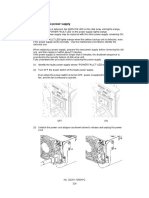

2. Using a fuel tank lock ring wrench (commercial service tool),

remove the lock ring.

PBIC0240E

3. Remove fuel level sensor unit, fuel filter and fuel pump assembly.

CAUTION:

• Never bend the float arm during removal.

• Avoid impacts such as falling when handling components.

INSPECTION AFTER REMOVAL

Check fuel level sensor unit, fuel filter and fuel pump assembly is free from foreign materials. If any are found,

remove them.

INSTALLATION

Revision: 2007 September FL-10 D40

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY

< SERVICE INFORMATION > [QR]

Note the following, and install in the reverse order of removal.

1. Install fuel level sensor unit, fuel filter and fuel pump assembly A

(1) with aligning mating marks (A) on fuel tank and fuel level

sensor unit, fuel filter and fuel pump assembly as shown in the

figure. FL

: Vehicle front

C

JPBIA1567ZZ

D

2. Install lock ring (1).

E

: Vehicle front

a. Tighten lock ring by hand.

b. Tighten lock ring with a fuel tank lock ring wrench (commercial F

service tool).

c. Align mating marks (A) as shown in the figure.

G

JPBIA1566ZZ

H

INSPECTION AFTER INSTALLATION

Check there is no fuel leakage at connections in the following steps.

• Turn ignition switch “ON” (with engine stopped), then check connections for leaks by applying fuel pressure

to fuel piping. I

• Start engine and rev it up and check there is no fuel leakage at the fuel system connections.

Revision: 2007 September FL-11 D40

SERVICE DATA AND SPECIFICATIONS (SDS)

< SERVICE INFORMATION > [QR]

SERVICE DATA AND SPECIFICATIONS (SDS)

Standard and Limit INFOID:0000000003293039

Fuel tank capacity Approx. 80 (17-5/8 Imp gal)

Fuel recommendation Refer to GI-4

Revision: 2007 September FL-12 D40

PREPARATION

< SERVICE INFORMATION > [YD]

SERVICE INFORMATION A

PREPARATION

Commercial Service Tool INFOID:0000000002978289

FL

Tool name Description

C

Fuel filter wrench Removing fuel filter

E

PBIC0519E

Fuel tank lock ring wrench Removing and installing fuel tank lock ring

ZZA0122D

Revision: 2007 September FL-13 D40

FUEL SYSTEM

< SERVICE INFORMATION > [YD]

FUEL SYSTEM

Checking Fuel Line INFOID:0000000002978290

Inspect fuel lines, fuel filler cap and fuel tank for improper attach-

ment, leaks, cracks, damage, loose connections, chafing or deterio-

ration.

If necessary, repair or replace damaged parts.

SMA803A

General Precaution INFOID:0000000002978291

WARNING:

When replacing fuel line parts, be sure to observe the following.

• Put a “CAUTION: FLAMMABLE” sign in workshop.

• Be sure to work in a well-ventilated area and furnish workshop with a CO2 fire extinguisher.

• Never smoke while servicing fuel system. Keep open flames and spark away from work area.

CAUTION:

• Use diesel fuel required by the regulations for cetane number. Refer to GI-4, "Precaution for Fuel".

• Before removing fuel line parts, perform the following procedures:

- Put drained fuel in an explosion-proof container and put the lid on securely. Keep the container in

safe area.

- Disconnect the battery cable from the negative terminal.

• Always replace O-ring and clamps with new ones.

• Never kink or twist tubes when they are being installed.

• Never tighten hose clamps excessively to avoid damaging hoses.

• After connecting fuel tube quick connectors, check quick con-

nectors are secure.

Ensure that connector and resin tube never contact any adja-

cent parts.

• After installing tubes, check there is no fuel leakage at con-

nections in the following steps.

- Start the engine and rev it up and check for fuel leaks at con-

nections.

SBIA0504E

Revision: 2007 September FL-14 D40

FUEL FILTER

< SERVICE INFORMATION > [YD]

FUEL FILTER

A

Components INFOID:0000000002978292

FL

G

PBIC3369E

1. Fuel filter bracket 2. Fuel filter 3. O–ring

4. Drain plug

H

A. Refer to FL-20

• Refer to GI-7, "Component" for symbol marks in the figure. I

Removal and Installation INFOID:0000000002978293

REMOVAL J

WARNING:

Be sure to read “General Precautions” when working on fuel system. Refer to FL-14, "General Precau-

tion". K

Revision: 2007 September FL-15 D40

FUEL COOLER

< SERVICE INFORMATION > [YD]

FUEL COOLER

Components INFOID:0000000002978294

PBIC4059E

1. Fuel tube (return) (to fuel tank) 2. Fuel tube (return) (to engine) 3. Bracket

4. Protector (fuel cooler) 5. Protector (fuel tube) 6. Fuel cooler assembly

7. Bracket

Removal and Installation INFOID:0000000002978295

REMOVAL

WARNING:

Be sure to read “General Precautions” when working on fuel system. Refer to FL-14, "General Precau-

tion".

Revision: 2007 September FL-16 D40

FUEL TANK

< SERVICE INFORMATION > [YD]

FUEL TANK

A

Components INFOID:0000000002978296

FL

J

PBIC4094E

1. Fuel filler cap 2. Grommet 3. Fuel filler tube (Double cab models) K

4. EVAP tube 5. Fuel tank 6. Fuel tank band

7. Fuel tank band 8. Fuel feed tube 9. Fuel return tube

10. Vent hose 11. Fuel filler hose (Double cab models) 12. Fuel filler hose (King cab models) L

13. Fuel filler tube (King cab models)

A. To fuel filter B. To fuel cooler (under floor)

M

Removal and Installation INFOID:0000000002978297

REMOVAL N

WARNING:

Be sure to read “General Precautions” when working on fuel system. Refer to FL-14, "General Precau-

tion". O

Revision: 2007 September FL-17 D40

FUEL LEVEL SENSOR UNIT

< SERVICE INFORMATION > [YD]

FUEL LEVEL SENSOR UNIT

Components INFOID:0000000002978298

PBIC3374E

1. Lock ring 2. Fuel level sensor unit 3. Seal packing

4. Fuel tank

A. Refer to FL-18

• Refer to GI-7, "Component" for symbol marks in the figure.

Removal and Installation INFOID:0000000002978299

REMOVAL

WARNING:

Be sure to read “General Precautions” when working on fuel system. Refer to FL-14, "General Precau-

tion".

INSTALLATION

Note the following, and install in the reverse order of removal.

1. Install fuel level sensor unit (1) with aligning mating marks (A) on

fuel tank and fuel level sensor unit as shown in the figure.

: Vehicle front

PBIC3843E

Revision: 2007 September FL-18 D40

FUEL LEVEL SENSOR UNIT

< SERVICE INFORMATION > [YD]

2. Install lock ring (1).

A

: Vehicle front

a. Tighten lock ring by hand.

FL

b. Tighten lock ring with a fuel tank lock ring wrench (commercial

service tool).

c. Align mating marks (A) as shown in the figure.

C

PBIC3632E

Revision: 2007 September FL-19 D40

SERVICE DATA AND SPECIFICATIONS (SDS)

< SERVICE INFORMATION > [YD]

SERVICE DATA AND SPECIFICATIONS (SDS)

Standard and Limit INFOID:0000000002978300

Fuel tank capacity Approx. 80 (17-5/8 Imp gal)

Fuel recommendation Refer to GI-4

Tightening Torque INFOID:0000000002978301

1): Order of tightening when tightening two or more times separately.

Unit: N·m (kg-m, ft-lb)

1) Screw until oil filter touches to the seat surface.

Method 1

Fuel filter 2) Tighten fuel filter by 2/3 turn.

Method 2 13.5 (1.4, 10)

Revision: 2007 September FL-20 D40

You might also like

- FL PDFDocument27 pagesFL PDFMontasir AlkinaniNo ratings yet

- FL PDFDocument21 pagesFL PDFOscar VillaseñorNo ratings yet

- FLDocument16 pagesFLWalter Javier MuñozNo ratings yet

- Fuel System: SectionDocument19 pagesFuel System: Sectionjorge Angel LopeNo ratings yet

- Fuel System: SectionDocument19 pagesFuel System: SectionWilthon Regalado SegoviaNo ratings yet

- Fuel System: SectionDocument24 pagesFuel System: SectionedgarNo ratings yet

- Fuel system guideDocument15 pagesFuel system guideHendrick CepedaNo ratings yet

- Fuel System Service Manual On A 2008 Infiniti G37sDocument15 pagesFuel System Service Manual On A 2008 Infiniti G37sAdel HomsiNo ratings yet

- Fuel System: SectionDocument19 pagesFuel System: Sectiongiancarlo sanchezNo ratings yet

- Fuel System: SectionDocument18 pagesFuel System: SectionZona Educación Especial ZacapaoaxtlaNo ratings yet

- Engine Lubrication System: SectionDocument16 pagesEngine Lubrication System: Sectiondmitry esaulkovNo ratings yet

- Engine Cooling SystemDocument30 pagesEngine Cooling SystemRafaelBruggemannNo ratings yet

- FL PDFDocument18 pagesFL PDFWilmer Elias Quiñonez HualpaNo ratings yet

- Engine Lubrication System: SectionDocument17 pagesEngine Lubrication System: Section801400No ratings yet

- Engine Cooling System: SectionDocument18 pagesEngine Cooling System: SectionJarden VegaNo ratings yet

- Engine Cooling System: SectionDocument21 pagesEngine Cooling System: SectionAnonymous 64HDY7IiN0No ratings yet

- Fuel System: SectionDocument17 pagesFuel System: SectionederengNo ratings yet

- Manual Combustible Infiniti Q50Document19 pagesManual Combustible Infiniti Q50David LópezNo ratings yet

- 2005 Nissan X Trail 27Document26 pages2005 Nissan X Trail 27Roberto RizzaNo ratings yet

- FL PDFDocument15 pagesFL PDFCarlos Tito AmésquitaNo ratings yet

- Engine Lubrication System: SectionDocument17 pagesEngine Lubrication System: SectionjonathanNo ratings yet

- Engine - VQ25DE and VQ35DE Lubrication SystemDocument16 pagesEngine - VQ25DE and VQ35DE Lubrication Systemscott glacken100% (1)

- Enviando LU PDFDocument15 pagesEnviando LU PDFVladimirNo ratings yet

- ENGINE COOLING SYSTEM GUIDEDocument24 pagesENGINE COOLING SYSTEM GUIDEjasleenNo ratings yet

- Engine Cooling System: SectionDocument24 pagesEngine Cooling System: Sectiongiancarlo sanchezNo ratings yet

- Fuel System: SectionDocument15 pagesFuel System: SectionDiego496No ratings yet

- 2014 Infiniti qx70 FX 15Document25 pages2014 Infiniti qx70 FX 15Henry DyNo ratings yet

- Nissan Note E11 2005-2013 Fuel SystemDocument34 pagesNissan Note E11 2005-2013 Fuel SystemDreve MariusNo ratings yet

- Sistema de Lubricación Del MotorDocument23 pagesSistema de Lubricación Del Motorastroboy2666No ratings yet

- Clutch: SectionDocument19 pagesClutch: SectionAnonymous 64HDY7IiN0No ratings yet

- Engine Lubrication System: SectionDocument28 pagesEngine Lubrication System: SectionEduardo ColinNo ratings yet

- Clutch: SectionDocument18 pagesClutch: SectionSteven AmadorNo ratings yet

- Rear Final Drive: SectionDocument31 pagesRear Final Drive: SectionAnonymous 64HDY7IiN0No ratings yet

- B ENGINE FUEL SYSTEM OVERVIEWDocument14 pagesB ENGINE FUEL SYSTEM OVERVIEWEdni OropezaNo ratings yet

- LU Motor MR20DEDocument28 pagesLU Motor MR20DEGamaliel Urbina JacNo ratings yet

- Engine Lubrication System GuideDocument17 pagesEngine Lubrication System GuideProbadorAutomotrizNo ratings yet

- Engine Lubrication System: SectionDocument17 pagesEngine Lubrication System: SectionNestor RosalesNo ratings yet

- ENGINE LUBRICATION SYSTEM GUIDEDocument18 pagesENGINE LUBRICATION SYSTEM GUIDEjasleenNo ratings yet

- Engine Lubrication System: SectionDocument21 pagesEngine Lubrication System: SectionDaniel Oliveira de ChavesNo ratings yet

- Front Final Drive: SectionDocument32 pagesFront Final Drive: SectionOscar VillaseñorNo ratings yet

- Fuel System: SectionDocument24 pagesFuel System: SectionAldo LlerenaNo ratings yet

- Fuel System: SectionDocument13 pagesFuel System: SectionDaniel Oliveira de ChavesNo ratings yet

- VQ40DE Nissan Xterra Engine Cooling System Removal and Installation GuideDocument30 pagesVQ40DE Nissan Xterra Engine Cooling System Removal and Installation GuideEuclides AdaoNo ratings yet

- Engine Lubrication System: SectionDocument10 pagesEngine Lubrication System: SectionDudu RodriguesNo ratings yet

- Engine Lubrication System: SectionDocument23 pagesEngine Lubrication System: SectionemenelikNo ratings yet

- Rear Final Drive: SectionDocument41 pagesRear Final Drive: SectionEduardo ColinNo ratings yet

- 2008 Nissan Versa 22Document14 pages2008 Nissan Versa 22Daryl TimothyNo ratings yet

- Fuel System: SectionDocument18 pagesFuel System: SectionChew LayNo ratings yet

- Engine Lubrication System GuideDocument18 pagesEngine Lubrication System Guideciro_svNo ratings yet

- B ENGINE FUEL SYSTEM OVERVIEWDocument14 pagesB ENGINE FUEL SYSTEM OVERVIEWisraelNo ratings yet

- 2007 Nissan Xterra 16Document18 pages2007 Nissan Xterra 16Roma Roma100% (1)

- Fuel System Guide for B Engine SectionDocument12 pagesFuel System Guide for B Engine SectionErickson GarciaNo ratings yet

- Clutch: SectionDocument19 pagesClutch: SectionEduardo ColinNo ratings yet

- Engine Cooling System: SectionDocument29 pagesEngine Cooling System: SectionskpppNo ratings yet

- Sistema de Refrigeración de Motor Nissan Armada 2010Document24 pagesSistema de Refrigeración de Motor Nissan Armada 2010Hendrick CepedaNo ratings yet

- Lu PDFDocument28 pagesLu PDFOscar VillaseñorNo ratings yet

- Transfer: SectionDocument42 pagesTransfer: SectionEduardo ColinNo ratings yet

- Engine Cooling System: SectionDocument25 pagesEngine Cooling System: Sectionwilder0l0pezNo ratings yet

- Fuel System: SectionDocument16 pagesFuel System: SectionSilvio ServinNo ratings yet

- Section A: Service Manual - Wheel Loading Shovel - 455ZXDocument15 pagesSection A: Service Manual - Wheel Loading Shovel - 455ZXJean MoralesNo ratings yet

- Section K: Service Manual - Wheel Loading Shovel - 455ZXDocument4 pagesSection K: Service Manual - Wheel Loading Shovel - 455ZXJean Morales0% (2)

- Ps PDFDocument21 pagesPs PDFIsaac Galvez EscuderoNo ratings yet

- El Mayor Choque de VaR en La Historia - Esta Es La Razón Detrás de Los Movimientos Locos Del Mercado en Una Tabla - Cobertura CeroDocument3 pagesEl Mayor Choque de VaR en La Historia - Esta Es La Razón Detrás de Los Movimientos Locos Del Mercado en Una Tabla - Cobertura CeroJean MoralesNo ratings yet

- Nissan hr16Document28 pagesNissan hr16Oscar Jhonyffer Pereda RiscoNo ratings yet

- Driveline Axle Propeller Shaft Removal Installation GuideDocument5 pagesDriveline Axle Propeller Shaft Removal Installation GuideJean MoralesNo ratings yet

- (CHEVROLET) Manual de Taller Chevrolet Spark Sistema C3Document15 pages(CHEVROLET) Manual de Taller Chevrolet Spark Sistema C3Christian Ramos Campos100% (1)

- Instrument Panel Removal GuideDocument6 pagesInstrument Panel Removal GuideJean MoralesNo ratings yet

- GLASSES, WINDOW SYSTEM & MIRRORS SERVICE INFORMATIONDocument29 pagesGLASSES, WINDOW SYSTEM & MIRRORS SERVICE INFORMATIONChristian Ramos CamposNo ratings yet

- Spare Parts List: Hydraulic BreakersDocument20 pagesSpare Parts List: Hydraulic BreakersJean MoralesNo ratings yet

- Ex PDFDocument5 pagesEx PDFChristian Ramos CamposNo ratings yet

- WT PDFDocument4 pagesWT PDFIsaac Galvez EscuderoNo ratings yet

- Spare Parts List: Hydraulic BreakersDocument24 pagesSpare Parts List: Hydraulic BreakersJean Morales100% (2)

- A B C D e F G H I J K LDocument2 pagesA B C D e F G H I J K LChristian Ramos CamposNo ratings yet

- Spare Parts List: Hydraulic BreakersDocument36 pagesSpare Parts List: Hydraulic BreakersJean MoralesNo ratings yet

- Breaker Suspension Wear Limits2017 PDFDocument1 pageBreaker Suspension Wear Limits2017 PDFJean MoralesNo ratings yet

- Acc PDFDocument4 pagesAcc PDFIsaac Galvez EscuderoNo ratings yet

- Spare Parts List: Hydraulic BreakersDocument24 pagesSpare Parts List: Hydraulic BreakersJean MoralesNo ratings yet

- Spare Parts List: Hydraulic BreakersDocument24 pagesSpare Parts List: Hydraulic BreakersJean MoralesNo ratings yet

- Spare Parts List: Hydraulic BreakersDocument24 pagesSpare Parts List: Hydraulic BreakersJean MoralesNo ratings yet

- Spare Parts List: Hydraulic BreakersDocument20 pagesSpare Parts List: Hydraulic BreakersJean MoralesNo ratings yet

- Spare Parts List: Hydraulic BreakersDocument24 pagesSpare Parts List: Hydraulic BreakersJean Morales100% (1)

- Spare Parts List: Hydraulic BreakerDocument20 pagesSpare Parts List: Hydraulic BreakerJean Morales100% (1)

- Folleto HAT 2019 MarchDocument44 pagesFolleto HAT 2019 MarchJean MoralesNo ratings yet

- Spare Parts List: Hydraulic BreakersDocument24 pagesSpare Parts List: Hydraulic BreakersJean Morales100% (1)

- Spare Parts List: Hydraulic BreakerDocument24 pagesSpare Parts List: Hydraulic BreakerJean MoralesNo ratings yet

- Chisel Paste: United in Performance. Inspired by InnovationDocument2 pagesChisel Paste: United in Performance. Inspired by InnovationJean MoralesNo ratings yet

- Operating Manual and Spare Parts List: Pressure Accumulators On Hydraulic Hammers Design and MaintenanceDocument24 pagesOperating Manual and Spare Parts List: Pressure Accumulators On Hydraulic Hammers Design and MaintenanceJean MoralesNo ratings yet

- Instrucciones y Funcionamiento de Seguridad SB 302 Gama SBDocument36 pagesInstrucciones y Funcionamiento de Seguridad SB 302 Gama SBJean MoralesNo ratings yet

- Pressure Operated Switch Data Sheet: K-85-0524 Rev AA FeaturesDocument2 pagesPressure Operated Switch Data Sheet: K-85-0524 Rev AA FeaturesNatalia BeltránNo ratings yet

- Week 4Document29 pagesWeek 4Christine Marie A Llanera-CadalloNo ratings yet

- VYR Agriculture Irrigation 2Document6 pagesVYR Agriculture Irrigation 2Ahmed HussienNo ratings yet

- Am200-3 M5 Parts Book Rev.1.01Document27 pagesAm200-3 M5 Parts Book Rev.1.01Carlos Eugenio Lovera Velasquez100% (1)

- Torres Bolt-OnDocument9 pagesTorres Bolt-OnProf. Alvarado CarlosNo ratings yet

- Maintenance Schedule For BOP - 5131086 - 01Document4 pagesMaintenance Schedule For BOP - 5131086 - 01franko guddiNo ratings yet

- EPSON Stylus D88 Plus Parts ListDocument7 pagesEPSON Stylus D88 Plus Parts ListDeniskoffNo ratings yet

- Protection and Relay SchemesDocument44 pagesProtection and Relay SchemesSaeed Mahmood Gul Khan67% (6)

- ZT - Survival GunsDocument3 pagesZT - Survival GunsJonathan AllenNo ratings yet

- Electrical Wiring Assignments SolutionsDocument12 pagesElectrical Wiring Assignments Solutionsvipul unagarNo ratings yet

- G. Bharathi Lecturer Mechanical Engg. MRAGR Govt. Polytechnic, Vizianagaram V Semester Fluid Power Systems M-503 Oil Power Hydraulics 50 Minutes Hydraulic Circuits Diagrams and ChartsDocument35 pagesG. Bharathi Lecturer Mechanical Engg. MRAGR Govt. Polytechnic, Vizianagaram V Semester Fluid Power Systems M-503 Oil Power Hydraulics 50 Minutes Hydraulic Circuits Diagrams and ChartsviranmecNo ratings yet

- EB-530P Operation Manual - 1.Document52 pagesEB-530P Operation Manual - 1.keng suttisangchanNo ratings yet

- Kyocera Kd240 245gx-LpbDocument2 pagesKyocera Kd240 245gx-LpbRenatolcNo ratings yet

- 25D-CCS-33AR2 Parts Bigott CaracasDocument10 pages25D-CCS-33AR2 Parts Bigott Caracasre diezNo ratings yet

- New Referensi NSX MCCB SchneiderDocument22 pagesNew Referensi NSX MCCB SchneiderAlfiansyah Dharma Setia DjaketraNo ratings yet

- RDD EngDocument33 pagesRDD EngTony KNo ratings yet

- Watt Gearboxes-CatalogueDocument18 pagesWatt Gearboxes-CataloguecakhokheNo ratings yet

- American Dryer SL20/CG20 Parts ManualDocument29 pagesAmerican Dryer SL20/CG20 Parts Manualnaokito AkemiNo ratings yet

- Inyector D6RDocument2 pagesInyector D6RAlberto BastidasNo ratings yet

- Reciprocating Compressor: Semi-HermeticDocument12 pagesReciprocating Compressor: Semi-HermeticGosai MohamedNo ratings yet

- L010976 - EMJ-04 Servo MotorDocument3 pagesL010976 - EMJ-04 Servo Motor許駿瑋No ratings yet

- 30ALayerPicker Zwijak CascadeDocument42 pages30ALayerPicker Zwijak CascadeLakiNo ratings yet

- Product Classification: SL110 Series Modular Jack, RJ45, Category 6, T568A/T568B, Unshielded, Without Dust Cover, BlackDocument2 pagesProduct Classification: SL110 Series Modular Jack, RJ45, Category 6, T568A/T568B, Unshielded, Without Dust Cover, BlackDWVIZCARRANo ratings yet

- ATA 32-Landing Gear DIFF R26Document81 pagesATA 32-Landing Gear DIFF R26NadirNo ratings yet

- Customer-Production List Per BMK: INTERSCHALT Maritime Systems AG 22869 Schenefeld Tel.:+49 40 830330 Page 1 From 31Document31 pagesCustomer-Production List Per BMK: INTERSCHALT Maritime Systems AG 22869 Schenefeld Tel.:+49 40 830330 Page 1 From 31Богдан КендзерNo ratings yet

- 80-Character Liquid Crystal Display Fire AnnunciatorDocument2 pages80-Character Liquid Crystal Display Fire AnnunciatorNurdin Sudrajat SasrabahuNo ratings yet

- Tx-00 Sand Rammer: Service, Operation Parts ManualDocument4 pagesTx-00 Sand Rammer: Service, Operation Parts Manualorangel anayaNo ratings yet

- (I) Gsu 14C Ultrasonic Label Fork: Easyteach FunctionDocument8 pages(I) Gsu 14C Ultrasonic Label Fork: Easyteach Functionrogerio barbosa comamNo ratings yet

- Honeywell S8600HDocument29 pagesHoneywell S8600HmariopilarNo ratings yet

- Bucyrus: Parts CatalogDocument342 pagesBucyrus: Parts CatalogSHANENo ratings yet