Professional Documents

Culture Documents

مثال ماك للدليل التشغيلي

Uploaded by

أبوهمام الحمدابيCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

مثال ماك للدليل التشغيلي

Uploaded by

أبوهمام الحمدابيCopyright:

Available Formats

Operation Steamer

625-MCD & MFY

Manual

Product Identification

On/Off Rocker Switch

(left-side of unit)

Rapid Steamer

Temperature & Celsius/Fahrenheit & Logo Button

UP Arrow Button DOWN Arrow Button

Prince Castle

Logo Button

Spatula

Product Buttons

(1 thru 4)

External Meter Plug Inlet LED Display Start Button

Control Panel (for calibration)

LIMITED WARRANTY TABLE OF CONTENTS

This product (with the exception of the water tube, part no. 625-197S) is Product Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

warranted to be free from defects in material and/or workmanship for a

period of two (2) years from date of original installation, not to exceed Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

30 months from date of shipment from our factory. P.C. Boards and Heater General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Assemblies are warranted for three (3) years from date of installation, not

to exceed 42 months from date of shipment. Any component which proves Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

to be faulty in material and/or workmanship will be replaced or repaired (at Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

the option of Prince Castle, Inc.) without cost to the customer for parts or

labor. This warranty covers on location service (i.e. trip charges and/or Temperature Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

mileage). Travel mileage is limited to 100 miles (200 kilometers) round trip View Firmware Version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

(one trip warranty) from an authorized service agency or its sub-service

agency. Manual Reset. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

This warranty is subject to the following exceptions/conditions: Programming Product Name and Water Cycle . . . . . . . . . . . . . . . . . . 4

• Use of any non-genuine Prince Castle parts voids this warranty. Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

• All labor shall be performed during regular work hours. Overtime Cleaning - Daily . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

premium will be charged to the buyer.

• Damage caused by carelessness, neglect, and/or abuse (e.g., Cleaning - Monthly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

dropping, tampering or altering parts, equipment damaged in shipment, Exploded View and Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

by fire, flood or an act of God) is not covered under this warranty.

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

SANITATION

355 East Kehoe Blvd. • Carol Stream, IL 60188 USA

Telephone: 630-462-8800 • Toll Free: 1-800-PCASTLE

Fax: 630-462-1460 • www.princecastle.com

625-505revK-EN Printed in USA 11/08 © 2008

Steamer

625-MCD & MFY

Safety Information Important

Prince Castle reserves the right to change specifications and

WARNING product design without notice. Such revisions do not entitle the

Indicates information important to the proper operation of the buyer to corresponding changes, improvements, additions or

unit. Failure to observe may result in damage to the replacements for previously purchased equipment.

equipment and/or severe bodily injury or death.

CAUTION

Indicates information important to the operation of the unit. Failure

to observe may result in damage to the equipment.

Installation

Remove the unit from the carton and inspect for signs of damage. If there NOTE: When installing this unit, the ambient temperature at the mounting

is damage to the unit: site should not exceed 37.8°C (100°F).

• notify the carrier within 24 hours of delivery

CAUTION

• save carton and packaging materials for inspection purposes

• contact your local dealer, or if purchased directly, the Prince Castle All electrical connections must be in accordance with local electrical codes

Sales Department at 800-722-7853 or 1-630-462-8800 to arrange for a and any other applicable codes.

replacement unit. Plug the unit into an applicable electrical receptacle. Connect the water

WATER CONNECTION REQUIREMENTS line to the back of the unit.

If this is a new installation, accessory - 625-104S or 625-330S Regulator CAUTION

Assembly Kit is required for the 625-MCD. The 625-MFY comes with the

625-253S Regulator Assembly. Always use area codes for determination. Water connection must provide maximum water pressure of 20 – 30 psi

(138 – 207 kPa).

This equipment is to be installed with adequate backflow protection to comply with applicable Federal, State and Local codes.

Operation

A. Turn unit power On/Off switch to ON position. The display A. When the unit reaches the setpoint temperature, display will

1 flashes all segments for 3 seconds. Then display will show 2 show the product name assigned to button 1.

PRINCE CASTLE for seven seconds. B. If 1 is the desired product to be steamed, pull out the spatula

B. After ten seconds the display will show PRE-HEAT. and place the product onto the spatula, cut side down.

NOTE: The next-to-left most decimal point appears indicating Or press product buttons 2, 3 or 4, then place product on the

power is applied to the platen. Platen will heat to the setpoint spatula, cut side down.

temperature.

Place the spatula fully into the unit and press the START button. A When steam cycle is complete, the unit will sound a tone and the

3 beep will sound and the display will start to count down the steam 4 display will flash REMOVE.

cycle. (The countdown will round down to the nearest second, e.g. Pull out the spatula and remove the finished product.

11.5 seconds will appear as 11 seconds in the display.)

Printed in USA 11/08 © 2008 2 625-505revK-EN

Steamer

625-MCD & MFY

Temperature Calibration

A. Press and hold the TEMPERATURE button. The display will The CAL TEMP Mode is used to calibrate the platen temperature

1 show the current temperature setting for Celsius (C) or 2 with an external meter connected to the meter plug inlet on the

Fahrenheit (F). bottom right side of the unit. Add ± 5°C (± 10°F).

B. While holding the TEMPERATURE button, press the C/F

A. Press and hold RAPID STEAMER LOGO button and immediately

button to change the setting between Fahrenheit and Celsius.

press and hold the TEMPERATURE button. Hold for 6 seconds.

C. Release the TEMPERATURE button to store the new value.

B. The display now shows the current calibration temperature.

C. Press the PRODUCT 2 button to zero any previous calibration offset

value. The display will now show the platen temperature without any

calibration offset.

A. Press the UP or DOWN Arrow button until the temperature Factory Presets

3 readout matches the calibration reading. Loading factory presets restores the unit to factory settings and voids

B. Press the RAPID STEAMER LOGO button to store the desired all user programmed information.

calibration and exit CAL TEMP Mode. A. During power up, press and hold both PRODUCT 1 and

NOTE: Pressing the PRODUCT 3 button at any time exits the PRODUCT 4 buttons within 3 seconds. The display will flash

Program Mode without storing the change. PRESETS LOADED.

B. Release both buttons.

625-MCD

Default Factory Presets:

ON OFF Cycles Delay

1.0 3.0 2 2.5

625-MFY

Default Factory Presets:

ON OFF Cycles Delay

0.5 1 6 2.5

View Firmware Version Manual Reset

Press and hold the RAPID STEAMER LOGO button first, then press A hi-limit thermostat will turn off electrical power to the platen and

and hold the START button. The display will show the current firmware control circuits if the unit overheats.

version. Turn the unit off and allow to cool (approximately 10 – 15 minutes).

A manual reset is located on the back of the unit. Once the unit has

cooled sufficiently, remove the cap and press the manual reset and

restart the unit. Replace the manual reset cap.

NOTE: If the unit continues to shut off due to overheating, contact your

authorized Prince Castle Service Agency.

Manual

. VERS XX.XX Reset

625-505revK-EN 3 Printed in USA 11/08 © 2008

Steamer

625-MCD & MFY

Programming Product Name and Water Cycle

The Program button menus can be changed to any of the following menu A. Press and hold the RAPID STEAMER LOGO button and a

items. 1 PRODUCT button for approximately 6 seconds. The display

PROD1 thru PROD12 can be selected to program additional product will show the current assigned product for the button pressed.

names. NOTE: A decimal point will appear and flash on the right side of

“– – – –” can be used when no product name selection is desired. the display to indicate Program Mode.

Filet Large PROD1 PROD2 PROD3

PROD4 PROD5 PROD6 PROD7 PROD8

PROD9 PROD10 PROD11 PROD12 ––––

B. Press the UP or DOWN Arrow button to scroll through the Press and hold the PRINCE CASTLE LOGO button first, then

2 product selections. 3 press and hold the RAPID STEAMER LOGO button for 6 seconds.

C. Press the RAPID STEAMER LOGO button to store the new The display will show the product name with the left-most

product name. character display or decimal point flashing.

To enter custom product names, proceed to Step 3. NOTE: Must be in Program Mode (see Step 1A).

NOTE: Pressing the PRODUCT 3 button at any time exits the

Program Mode without storing the change.

A. Press the UP or DOWN Arrow button to change the left-most The display now shows the product’s water valve ON time in

4 character. 5 seconds.

B. Press the PRODUCT 1 or PRODUCT 4 button to move the

cursor to the next character.

C. Repeat Steps 4A and 4B for each character.

D. Press the RAPID STEAMER LOGO button to store the new

product name.

NOTE: Pressing the PRODUCT 3 button at any time exits the

Program Mode without storing the change.

A. Press the UP or DOWN Arrow button to change the valve The display now shows the product’s water valve OFF time in

6 ON time. 7 seconds.

B. Press the RAPID STEAMER LOGO button to store the new

valve ON time.

NOTE: Pressing the PRODUCT 3 button at any time exits the

Program Mode without storing the change.

Printed in USA 11/08 © 2008 4 625-505revK-EN

Steamer

625-MCD & MFY

Programming Product Name and Water Cycle (continued)

A. Press the UP or DOWN Arrow button to change the valve The display now shows the product’s number of on-off water

8 OFF time. 9 valve cycles.

B. Press the RAPID STEAMER LOGO button to store the new

valve OFF time.

NOTE: Pressing the PRODUCT 3 button at any time exits the

Program Mode without storing the change.

A. Press the UP or DOWN Arrow button to change the number The display now shows the current product set temperature.

10 of water cycles. 11

B. Press the RAPID STEAMER LOGO button to store the new

water cycle number.

NOTE: Pressing the PRODUCT 3 button at any time exits the

Program Mode without storing the change.

Platen temperature can be set between 265° – 350°F The display now shows the time delay between when the

12 (129° – 176°C). 13 product is finished and when the alarm sounds.

A. Press the UP or DOWN Arrow button to scroll to the desired The delay can be set for 0.0 to 10.0 seconds.

temperature. A. Press the UP or DOWN Arrow button to scroll to the desired

B. Press the RAPID STEAMER LOGO button to store the desired time delay.

temperature. B. Press the RAPID STEAMER LOGO button to store the

NOTE: Pressing the PRODUCT 3 button at any time exits the desired time and to exit the Program Mode.

Program Mode without storing the change. NOTE: Pressing the PRODUCT 3 button at any time exits the

Program Mode without storing the change.

2.5

Factory Pre-Set Temperatures Error Messages

625-MCD Factory pre-set temperatures: Error Messages Action

Filet: 305°F (151°C) No Heat Error. Call service technician.

Large: 305°F (151°C)

PROD1 – 12: 305°F (151°C)

625-MFY Factory pre-set temperatures:

Filet: 350°F (176°C)

Large: 350°F (176°C)

PROD1 – 12: 350°F (176°C)

625-505revK-EN 5 Printed in USA 11/08 © 2008

Steamer

625-MCD & MFY

Cleaning — Daily PM Tasks

WARNING The following equipment is required:

• McD® All Purpose Super Concentrate (APSC)

Turn the unit off and unplug the power cord from the electrical

receptacle. Proceed with caution, unit is still hot! • McD® Sink Pak Sanitizer McD® APC (Australia only)

• McD® Delimer™ (as required)

CAUTION • Clean sanitized towel

This unit is not watertight. Do not clean with a water jet/jet spray. Do not • Protective (insulated) gloves

immerse the unit in water.

Do not use abrasive materials such as scrapers, steel wool, etc. to clean

the spatula or steam chamber.

While wearing protective gloves, remove the top cover by pulling While wearing protective gloves:

1 up and off the unit. 2 Top Plate

A. Remove spatula.

B. Remove the top plate

Top Cover by carefully sliding it

forward and out of the

unit.

C. Remove the venturi

plate.

Spatula

Venturi Plate

A. Wash top cover, top plate, and venturi plate in a solution of Wipe the steam chamber surface with a clean sanitized cloth.

3 McD® APSC / APC made up in the back sink. 4

B. Rinse with clean water, and then sanitize in a solution of

OPTIONAL: If the surface shows

McD® Sink Pak Sanitizer.

signs of excessive calcium and

C. Let air dry. lime buildup, dissolve two

teaspoons of McD® Delimer™ in

a small container (not a drink cup)

with 100 mI of water. Pour half on

each side. Allow to sit for

5 minutes. Using a clean sanitized

towel, thoroughly rinse and wipe

the internal surfaces of the steam

chamber.

Use brushes to clean the water tube. Dip the brush in warm water Wash all external surfaces of the steamer with a solution of

5 or deliming solution. Insert the brush about 1" into water tube and 6 McD® APSC / APC. Using the McD® APSC / APC spray bottle,

then remove. Repeat for 30 seconds. spray directly onto a clean sanitized towel and wipe the unit clean.

CAUTION

Insert brush here.

Do not spray directly on the unit or use abrasive cleaners!

Reassemble unit.

Turn the unit on. When unit is preheated, run a minimum of four

cycles to prime the unit and remove any residual cleaner.

It is recommended that the steamers go through a deliming

procedure at least once a month. Some hard water areas may

require daily, weekly, or biweekly deliming based upon actual

buildup.

Printed in USA 11/08 © 2008 6 625-505revK-EN

Steamer

625-MCD & MFY

Cleaning — Monthly PM Tasks

WARNING The following equipment is required:

• McD® All Purpose Super Concentrate (APSC)

Turn the unit off and unplug the power cord from the electrical

• McD® Sink Pak Sanitizer McD® APC (Australia only)

receptacle. Proceed with caution, unit is still hot!

• McD® Delimer™ (as required)

CAUTION • Clean sanitized towel

This unit is not watertight. Do not clean with a water jet/jet spray. Do not • Protective (insulated) gloves

immerse the unit in water.

Do not use abrasive materials such as scrapers, steel wool, etc. to clean

the spatula or steam chamber.

While wearing protective gloves, remove the top cover by pulling While wearing protective gloves:

1 up and off the unit. 2 Top Plate

A. Remove spatula.

B. Remove the top plate

Top Cover by carefully sliding it

forward and out of the

unit.

C. Remove the venturi

plate.

Spatula

Venturi Plate

A. Wash top cover, top plate, spatula, and venturi plate in a Pour a solution of McD® Delimer™ (one packet per 16 oz. of

3 solution of McD® APSC / APC made up in the back sink. 4 hot water) into the steam chamber. Let solution soak for at

B. Rinse with clean water, and then sanitize in a solution of least 15 minutes. Continue with next step while soaking.

McD® Sink Pak Sanitizer. NOTE: Use one packet for

C. Let air dry. monthly cleaning procedure and

dispose of the unused solution

once the procedure is completed.

In hard water areas that require

daily, bi-weekly or weekly

cleaning, it is possible to use

partial packets. Two teaspoons of

McD® Delimer™ can be dissolved

in a small container (not a drink

cup) with 100 ml of hot water. The

packet can be used for 4

applications. IMPORTANT: It is not recommended

to leave open packets lying around.

A. Use brushes to clean the water tube. A. Rinse with clean water.

5 B. Dip the brush in warm water or deliming solution. Insert

6 B. Wash all external surfaces of the steamer with a solution of

the brush about 1" into water tube and then remove. McD® APSC / APC. Using the McD® APSC / APC spray bottle,

C. Repeat for 30 seconds. spray directly onto a clean sanitized towel and wipe the unit

clean.

C. Reassemble the unit.

Insert brush here.

CAUTION

Do not spray directly on the unit or use abrasive cleaners!

NOTE: In areas that are affected by very hard water, a reverse

osmosis (RO) water filtration system is an option to reduce

accumulation of mineral deposits in the steamer. Contact either

Cuno, KES or Coca-Cola for recommendations.

625-505revK-EN 7 Printed in USA 11/08 © 2008

Steamer

625-MCD & MFY

Exploded View and Parts List

Ref. Part No. Description

1 625-128S Spatula Assembly

625-097S Spatula Handle Kit

2 78-233S Rocker Switch, 20A

3 625-193S Membrane Switch Assembly

625-204S Display (Control), PCB, 625-MFY

625-205S Display (Control), PCB, 625-MCD

625-222S Display (Control), PCB, 625-MCDA &

625-MCDA16

4 625-158S Top Cover

5 625-130S Silicone Gasket

6 197-232S Feet (Pkg of 4)

7 66-045S Strain Relief

8 625-357S Water Dispensing Tube Kit

9 88-497S Mini-Jack, Type K

4

10 625-064S Top Plate

11 625-207S High-Limit Thermostat

12 625-319S Water Valve Assembly

13 625-318S Water Connector Kit

14 65-059S Relay, 625-MFY

65-061S Relay, 625-MCD, 625-MCDA, 625-MCDA16

10

17 15 625-323S Main Power PCB

16 625-065S Venturi Plate

21 17 625-082S Temperature Probe, 1000 ohm RTD

18* 72-386S Line Cord Assembly, 625-MFY

5 72-392S Line Cord Assembly, 625-MFYT

72-381S Line Cord Assembly, 625-MCD

72-379S Line Cord Assembly, 625-MCDA

1

72-383S Line Cord Assembly, 625-MCDA16

19 625-253S Regulator Assembly, 625-MFY

625-330S or Regulator Assembly, 625-MCD

16

625-104S (Optional Accessory)

625-165S Regulator Assembly, 625-MCDA & MCDA16

(Optional Accessory)

21 625-285S Platen, 625-MFY

3 625-284S Platen, 625-MCD

625-253S Regulator Parts (Not Shown)

86-359S Male Quick Disconnect Fitting

86-365S Water Strainer Assembly

** 95-1249-12S Ribbon Cable

15 11 ** 88-600-200S Fuse

7 ** 625-364S Dual Steamer Interconnect, MCD/C

19 ** 625-244 Dual Steamer Interconnect, MFY/G

18 ** 625-103S Coiled Tubing

** 88-787S Fuse Holder

2

** 86-329S Tubing

8 12

** 625-078S Panel Mount Fitting

** 524-164 Guard Switch

** 625-342S O-Ring

13 ** 625-320S Cover Backplate

6 * NOTE: From Model 625-MCDNZ, units are shipped without a plug.

9 ** Parts Not Shown

14

Printed in USA 11/08 © 2008 8 625-505revK-EN

Steamer

625-MCD & MFY

Troubleshooting Guide

PROBLEM PROBABLE CAUSE SOLUTION

Unit will not heat up; “DISPLAY” is lit. Loose connections. Check continuity wiring.

On/Off switch is ON.

Unit heats up but will not steam. Water supply is not connected or shut Disconnect water line and check if water is flowing

Display reads “REMOVE” at end of off. Regulator has pressure set too low. through main water supply. Check water pressure at

cycle. regulator to ensure unit is receiving water.

Water delivery tube clogged. Replace water tube.

Defective main PC board or water Call service technician.

solenoid.

Water supply line is pinched. Straighten water line.

Unit steams continuously. Defective main PC board or water Call service technician.

solenoid.

Unit is flooded. Water pressure too high. Turn input water regulator to between 20 and 30 psi.

Defective platen, water solenoid or Call service technician.

relay.

Bun temperature is too cold. Water pressure too low. Turn input water regulator to between 20 and 30 psi.

Not enough water CYCLES. Check for proper programming of Filet steam cycles.

Increase number of CYCLES until desired results are

reached.

Water ON cycle too short. Check for proper programming of Filet steam cycles.

Increase ON time until desired results are reached.

Partially clogged water tube. Clean/delime the water tube.

Bun temperature is too hot. Water pressure too high. Turn input water regulator to between 20 and 30 psi.

Water ON cycle too long. Check for proper programming of Filet steam cycles.

Decrease ON time until desired results are reached.

Too many water CYCLES. Check for proper programming of Filet steam cycles.

Decrease number of CYCLES until desired results are

reached.

Not enough moisture in bun. Water pressure too low. Turn input water regulator to between 20 and 30 psi.

Platen not hot enough. Increase platen temperature.

Water ON cycle too short. Check for proper programming of Filet steam cycles.

Increase ON time until desired results are reached.

Not enough water CYCLES. Check for proper programming of Filet steam cycles.

Increase number of CYCLES until desired results are

reached.

Water OFF cycle is too short/long. Check for proper programming of Filet steam cycles.

Increase/decrease OFF time until desired results are

reached.

Partially clogged water tube. Clean/delime water tube.

Out-of-date buns. Use fresh buns.

Too much moisture in bun. Water pressure too high. Turn input water regulator to between 20 and 30 psi.

Water ON cycle too long. Check for proper programming of Filet steam cycles.

Decrease ON time until desired results are reached.

Too many water CYCLES. Check for proper programming of Filet steam cycles.

Decrease number of CYCLES until desired results are

reached.

Water OFF too long/short. Check for proper programming of Filet steam cycles.

Decrease/increase OFF time until desired results are

reached.

Water is leaking from behind the unit. Water tube not properly pushed into Completely push tube into valve until you feel it click.

valve.

Faulty water valve. Call service technician.

Bun sticking to spatula. Spatula cool. Keep in steamer between uses.

Spatula surface compromised. Replace spatula, do not clean with abrasive pad or

cleaners.

625-505revK-EN 9 Printed in USA 11/08 © 2008

Steamer

625-MCD & MFY

Wiring Diagram

Printed in USA 11/08 © 2008 10 625-505revK-EN

Steamer

625-MCD & MFY

Water Tube Replacement

Stores that have harder water in their areas may experience scale buildup in their water tubes, thus clogging the tube and preventing water from being

dispensed into the steaming chamber. If the tube needs to be replaced, this sheet will illustrate how to replace the water tube.

First, turn off and unplug steamer. Let steamer cool down. To To insert the new tube, first insert the top end through the hole

1 remove the rear cover plate that shields the water tube, use a 4 that leads to the platen. The tube will fit through the insulating

Phillips head screwdriver to remove the two screws. Next, take bushing.

off the rear cover plate to access the water tube.

To pull the tube out from the water valve, push in the grey disk on Push the other end of the tube into the water valve. Ensure that

2 the water valve and then slowly slide the tube from the water 5 you feel it click into place. Gently tug on the water tube to check if

valve. it is secure. If the tube slides out, reinstall the tube. If tube is

improperly installed, water will leak at this point.

Using pliers, gently pull the tube out from the platen. You may Finally, reinstall the rear cover plate. Turn on unit and begin a

3 need to softly rock it back and forth. Replace the black insulating 6 water cycle to check for leaking at the water valve. If leaking

bushing if the original bushing pulled out with the water tube. All occurs at the back panel of the steamer, turn off unit and repeat

units must have a bushing installed. To reinstall the bushing, Step 5.

lubricate it with water and push it back into the opening.

CAUTION

Platen must be cool.

625-505revK-EN 11 Printed in USA 11/08 © 2008

PREP EQUIPMENT

PR 30

Prince Castle

Prince Castle Bun Steamer Model 625-MFY

Bun Steamer

Model 625-MFY

Daily maintenance tasks Model 625-MFY

PR 30 D1 Check water

pressure and

supply line

PR 30 D2 Clean water tube

Monthly maintenance tasks

PR 30 M1 Delime bun

steamer

Hazards

These icons alert you to a possible risk of personal injury.

Equipment alerts

Look for this icon to find information about how to avoid damaging the

equipment while doing a procedure.

PR 30

Tips

Look for this icon to find helpful tips about how to do a procedure.

©McDonald’s Corporation · Planned Maintenance Manual · Revised November 2008

Check water pressure and supply line Daily PR 30 D1

Prince Castle Bun Steamer Model 625-MFY

Why To prevent water damage to internal components of steamer

Time required 0 minutes to prepare 2 minutes to complete

Time of day At equipment start-up For 24-hour restaurants: at equipment start-up

Hazard icons

Tools and supplies

Screwdriver, Phillips

Procedure

1 Turn steamer on. 3 Check water supply lines.

Look at the water supply lines

running from the ceiling to

the steamer. There should be

no kinks or bends in the lines.

To remove kinks, pull the

water line straight.

2 Check water pressure. 4 Check for water leaks.

Check the water pressure Look for puddles of water on

shown on the gauge on the or near the steamer. Puddles

water regulator. The gauge can indicate a leak. Check the

should show water pressure at toaster table shelf, the water

20 to 30 psi (1.4 to 2.1 bar). regulator, and where the

supply line attaches to the

If water pressure is below water regulator.

20 psi (1.4 bar), lift knob on

water regulator. Turn to the A leak will cause a puddle of

right. Push the knob back water near the steamer. Find

down where the puddle is.

If water pressure is above If it is behind the steamer,

30 psi (2.1 bar), lift knob on check the connection between

water regulator. Turn to the the water valve and tube.

left. Push the knob back

Daily

down. If it is under the water

regulator, check the o-ring on

the connector.

PR 30 D1

©McDonald’s Corporation · Planned Maintenance Manual · Revised November 2008 Page 1 of 1

Clean water tube Daily PR 30 D2

Prince Castle Bun Steamer Model 625-MFY

Why To extend the life of the water tube and to prevent damage to internal components

Time required 5 minutes to prepare 5 minutes to complete

Time of day At open For 24-hour restaurants: during breakfast menu

Hazard icons Chemicals Electricity Hot Surfaces

Tools and supplies

Brush, steamer Bucket, clean and Bucket, soiled towels Gastro norm metal Gloves, neoprene McD All Purpose McD DeLimer

sanitized towels pan Super Concentrate

(APSC) solution

Procedure

1 Turn off and unplug steamer. 4 Check platen for lime build-up.

Turn the steamer off. Unplug Look for excessive lime

the unit. Let the steamer cool build-up on the platen. That is

for at least 5 minutes. a sign of lime build-up in the

water tube.

Electricity

If you see excessive lime

Unplug the steamer before

build-up on that platen, mix

cleaning the water tube.

2 teaspoons (10 ml) of McD

DeLimer solution in 31/2 fluid

Hot Surfaces ounces (100 ml) of water.

Do not attempt to clean a hot Pour the solution on the

steamer. platen. Let the solution soak

for 5 minutes.

2 Remove top cover, top plate,

and venturi plate.

Put on neoprene gloves. Chemicals

Remove the top cover, top McD DeLimer

plate, and venturi plate. Take

them to the three-

5 Clean water tube.

compartment-sink for Dip the steamer brush into a

cleaning.

gastro norm metal pan filled

with warm water. Insert the

brush about 1 inch (2.5 cm)

3 Wash, rinse, and sanitize top

Daily

into the water tube. Brush the

cover, top plate, and venturi tube for 30 seconds.

plate.

continued

PR 30 D2

©McDonald’s Corporation · Planned Maintenance Manual · Revised November 2008 Page 1 of 2

Clean water tube (continued)

6 Wipe platen.

Prince Castle Bun Steamer Model 625-MFY

Wear rubber gloves if the unit

is still hot. Mop the solution

from the platen with a clean,

sanitized towel. Place the

towel in the soiled towel

bucket.

Chemicals

Chemicals

Sanitizer solution

7 Clean outside of steamer.

Wipe all outside surfaces of

the steamer with a clean,

sanitized towel saturated with

McD APSC. Place the towel

in the soiled towel bucket.

Chemicals

McD APSC

8 Reinstall top cover, top plate,

and venturi plate.

Reinstall the top cover, top

plate, and venturi plate on the

steamer.

9 Run steamer for 4 cycles.

Plug the steamer in and turn it

on. Run the steamer through

4 cycles before steaming

buns.

Daily

PR 30 D2

©McDonald’s Corporation · Planned Maintenance Manual · Revised November 2008 Page 2 of 2

Delime bun steamer Monthly PR 30 M1

Prince Castle Bun Steamer Model 625-MFY

Why To prevent lime build-up that can be deposited on buns or can damage the equipment

Time required 5 minutes to prepare 15 minutes to complete

Time of day At open For 24-hour restaurants: during breakfast menu

Hazard icons Chemicals Hot Surfaces

Tools and supplies

Brush, steamer Bucket, clean and Bucket, soiled towels Gastro norm metal Gloves, neoprene McD All Purpose McD DeLimer

sanitized towels pan Super Concentrate

(APSC) solution

Procedure

1 Turn off and unplug steamer. 4 Wash, rinse, and sanitize top

Turn the steamer off. Unplug cover, top plate, and venturi

the unit. Let the steamer cool plate.

for at least 5 minutes.

Hot Surfaces

Do not delime a hot steamer.

5 Pour Delimer solution on

2 Mix Delimer solution. platen.

Mix one packet of McD Pour the Delimer solution on

DeLimer in 473 to 600 ml the platen. Let the solution

(16 to 20 fluid ounces) of hot soak for at least 15 minutes.

water in a gastro norm metal The solution can be left to

pan. soak for several hours.

Chemicals Tip

McD DeLimer If there is a heavy build-up of

lime, more than 15 minutes of

3 Remove top cover, top plate, soaking will probably be

and venturi plate. required.

Put on neoprene gloves.

6 Clean water tube.

Monthly

Remove the top cover, top

plate, and venturi plate. Take Dip the steamer brush into a

them to the three- gastro norm metal pan filled

compartment- sink for with warm water. Insert the

cleaning. brush about 2,5 cm (1 inch)

into the water tube. Brush the

tube for 30 seconds.

PR 30 M1

©McDonald’s Corporation · Planned Maintenance Manual · Revised November 2008 Page 1 of 2

Delime bun steamer (continued)

7 Wipe platen.

Prince Castle Bun Steamer Model 625-MFY

Wear rubber gloves if the unit

is still hot. Mop the solution

from the platen with a clean,

sanitized towel. Place the

towel in the soiled towel

bucket.

Chemicals

Sanitizer solution

8 Clean outside of steamer.

Wipe all outside surfaces of

the steamer with a clean,

sanitized towel saturated with

McD APSC. Place the towel

in the soiled towel bucket.

Chemicals

McD APSC

9 Reinstall top cover, top plate,

and venturi plate.

Reinstall the top cover, top

plate, and venturi plate on the

steamer.

10 Run steamer for 4 cycles.

Plug the steamer in and turn it

on. Run the steamer through

4 cycles before steaming

buns.

Monthly

PR 30 M1

©McDonald’s Corporation · Planned Maintenance Manual · Revised November 2008 Page 2 of 2

You might also like

- AC Pro VRF GMV 72-360 HP CondenserDocument76 pagesAC Pro VRF GMV 72-360 HP CondenserSingh BaldevNo ratings yet

- ROU MT 12 2 - SPMDocument20 pagesROU MT 12 2 - SPMtissemdgh93No ratings yet

- D.C. Powered Timing Light Model 161.2158 for 12 Volt Ignition Systems Sears Owners ManualFrom EverandD.C. Powered Timing Light Model 161.2158 for 12 Volt Ignition Systems Sears Owners ManualNo ratings yet

- 2580 FlowtraMag ManualDocument20 pages2580 FlowtraMag Manualasghar khanNo ratings yet

- Kodiak Recirculating Chillers: Technical ManualDocument51 pagesKodiak Recirculating Chillers: Technical Manualcarlos gomezNo ratings yet

- Samsung Galaxy S22 Ultra User Guide For Beginners: The Complete User Manual For Getting Started And Mastering The Galaxy S22 Ultra Android PhoneFrom EverandSamsung Galaxy S22 Ultra User Guide For Beginners: The Complete User Manual For Getting Started And Mastering The Galaxy S22 Ultra Android PhoneNo ratings yet

- GF Signet 2551 Blind ManualDocument12 pagesGF Signet 2551 Blind ManualJose Luis HoraNo ratings yet

- Sub-Zero BI Service ManualDocument284 pagesSub-Zero BI Service Manualp_rizz_357% (7)

- Mrcool 13seer r410 Cond Install ManualDocument40 pagesMrcool 13seer r410 Cond Install ManualRay RavelNo ratings yet

- 01-06225-226 Manual Mezc ScottDocument26 pages01-06225-226 Manual Mezc ScottLaura MalagarrigaNo ratings yet

- Installation, Operation and Maintenance Instructions: Model 6032 Baylor Eddy Current BrakeDocument68 pagesInstallation, Operation and Maintenance Instructions: Model 6032 Baylor Eddy Current BrakeCampo Anibal Grandas100% (1)

- SM 5300 Instruccion Manual PDFDocument24 pagesSM 5300 Instruccion Manual PDFelgegoNo ratings yet

- Screw Type Air-Cooled Packages: Acdx/AudxDocument44 pagesScrew Type Air-Cooled Packages: Acdx/AudxAhmed Sofa100% (1)

- Daikin-Applied-Agz-E Da 05062015 LRDocument96 pagesDaikin-Applied-Agz-E Da 05062015 LRGustavo Fugon IglesiasNo ratings yet

- Operator'S Manual: OGSC300Document24 pagesOperator'S Manual: OGSC300Ankadi Sikari ReddyNo ratings yet

- Warranty Administration Policy and Procedures: Container RefrigerationDocument43 pagesWarranty Administration Policy and Procedures: Container RefrigerationJuan Pablo Muñoz CortezNo ratings yet

- 175 Umeng0300Document26 pages175 Umeng0300AndrewNo ratings yet

- Pub051 001 00 - 0211Document24 pagesPub051 001 00 - 0211Doc_LACNo ratings yet

- 600 2 Sub-Zero Built-In Series Refrigerator Service ManualDocument188 pages600 2 Sub-Zero Built-In Series Refrigerator Service Manual911servicetechNo ratings yet

- SM MultiV IV Air Outdoor Units 4 15 - 20150414080917Document150 pagesSM MultiV IV Air Outdoor Units 4 15 - 20150414080917Gino Waximinguirijillo Santana100% (3)

- Cutmaster A80, A120: Operating ManualDocument106 pagesCutmaster A80, A120: Operating ManualNguyễn Thị LiênNo ratings yet

- Bolens BL-100 Owners ManualDocument64 pagesBolens BL-100 Owners ManualstonedoggNo ratings yet

- A0000253468 Generac Owner S ManualDocument44 pagesA0000253468 Generac Owner S ManualKrīztīän TörrësNo ratings yet

- Models:: Recovery/Recycling/Recharging UnitDocument134 pagesModels:: Recovery/Recycling/Recharging UnitJULIAN VALDERRAMANo ratings yet

- Duet ManualDocument68 pagesDuet ManualhydrasearchNo ratings yet

- Delfield Fridge Dm6000xlDocument20 pagesDelfield Fridge Dm6000xlRomankoNo ratings yet

- Nidek Co., Ltd. (Manufacturer) Nidek Co., LTD (Tokyo Office)Document99 pagesNidek Co., Ltd. (Manufacturer) Nidek Co., LTD (Tokyo Office)Lyn Rose Garcia100% (1)

- 369 Motor Management Relay - MULTILIN PDFDocument280 pages369 Motor Management Relay - MULTILIN PDFMario Guzman100% (1)

- Fluke 789 ManualDocument50 pagesFluke 789 Manualfu yuNo ratings yet

- Milk Coolers: Installation and Operations ManualDocument20 pagesMilk Coolers: Installation and Operations ManualsandyNo ratings yet

- MODEL G0841 18" Double-Sided Planer W/Spiral Cutterheads: Owner'S ManualDocument84 pagesMODEL G0841 18" Double-Sided Planer W/Spiral Cutterheads: Owner'S ManualAlfred TsuiNo ratings yet

- MODEL G0484 Gearhead Mill/Drill With Stand: Owner'S ManualDocument48 pagesMODEL G0484 Gearhead Mill/Drill With Stand: Owner'S Manualcmperes49No ratings yet

- Dartmoor Mk2 Log Conventional Flue Installation & User InstructionsDocument36 pagesDartmoor Mk2 Log Conventional Flue Installation & User InstructionsClementineNo ratings yet

- User Manual Precision Circulating Water BathDocument32 pagesUser Manual Precision Circulating Water BathService BlockNo ratings yet

- Bar Equipment: Installation and Operations ManualDocument28 pagesBar Equipment: Installation and Operations ManualsandyNo ratings yet

- g0440 MDocument56 pagesg0440 MJhony MedranoNo ratings yet

- HEBT-5V - Manual Serviço (EN) (2016.11)Document24 pagesHEBT-5V - Manual Serviço (EN) (2016.11)Thiago AzevedoNo ratings yet

- The Red Jacket Submersible Turbine Pump FE Petro Conversion KitDocument18 pagesThe Red Jacket Submersible Turbine Pump FE Petro Conversion KitsyahabdulrizalNo ratings yet

- Horno de Porcelana Jelrus VIP Vision 300 Exclusive 500Document36 pagesHorno de Porcelana Jelrus VIP Vision 300 Exclusive 500Brevas CuchoNo ratings yet

- 1EM GEN 4 Ducted IndoorUnitsDocument130 pages1EM GEN 4 Ducted IndoorUnitsTim WorkmanNo ratings yet

- Installation Instructions 99232Document24 pagesInstallation Instructions 99232richesNo ratings yet

- FGRC AD 21W - SPMDocument22 pagesFGRC AD 21W - SPMPedro Pablo Ferreiro GonzalezNo ratings yet

- Air-to-water Heat Pump Split Versati Owner's ManualDocument61 pagesAir-to-water Heat Pump Split Versati Owner's ManualsaleNo ratings yet

- Ren o Thin Repair ManualDocument37 pagesRen o Thin Repair ManualArcom Power EquipNo ratings yet

- Frozen MachineDocument37 pagesFrozen MachineatereñoneNo ratings yet

- JT2720 Mach 1: All Terrain Tier 2Document316 pagesJT2720 Mach 1: All Terrain Tier 2krunoNo ratings yet

- Service Manual For WAB-WYB 16-20 SEER Inverter SystemsDocument120 pagesService Manual For WAB-WYB 16-20 SEER Inverter SystemsDalton SingletonNo ratings yet

- Quickjack: Installation and Operation ManualDocument52 pagesQuickjack: Installation and Operation ManualPeter StanleyNo ratings yet

- Mxd-K+an Ahu+Kit Installatin+Manual Db68-03711a-04 English 160706Document40 pagesMxd-K+an Ahu+Kit Installatin+Manual Db68-03711a-04 English 160706El Ajiaco BikeNo ratings yet

- Bizhub - c360 Service ManualDocument1,150 pagesBizhub - c360 Service ManualRudyNo ratings yet

- Single Function Timers Model No. 740Document6 pagesSingle Function Timers Model No. 740jose marcanoNo ratings yet

- R-22gv R-22gt R-23gt R-24gt R-25jt Operation ManualDocument24 pagesR-22gv R-22gt R-23gt R-24gt R-25jt Operation Manualjason.orchard.5341No ratings yet

- Cut 120Document128 pagesCut 120Jimmy MyNo ratings yet

- KEA MG 2 MG 4 E - SPMDocument15 pagesKEA MG 2 MG 4 E - SPMAdelAlcebaiNo ratings yet

- Sterlco Royal Series TCU OI ManualDocument64 pagesSterlco Royal Series TCU OI ManualLuis Villafana.SanchezNo ratings yet

- Multilin™ 9450/9650: Instruction ManualDocument152 pagesMultilin™ 9450/9650: Instruction ManualAnonymous sLRlLluNo ratings yet

- 2018 Dairy Dream Employee ManualDocument23 pages2018 Dairy Dream Employee Manualأبوهمام الحمدابيNo ratings yet

- Restaurant OPS Manual Chapter 8 PDFDocument8 pagesRestaurant OPS Manual Chapter 8 PDFAamir RawaNo ratings yet

- 2015 03 Biz4Document67 pages2015 03 Biz4Anonymous 01ieJ2No ratings yet

- Mcdonalds Employee Handbook PDFDocument17 pagesMcdonalds Employee Handbook PDFErick Rodríguez LujánNo ratings yet

- 2015 03 Biz4Document67 pages2015 03 Biz4Anonymous 01ieJ2No ratings yet

- دليل تشغيل ماكينة الايسكريمDocument24 pagesدليل تشغيل ماكينة الايسكريمأبوهمام الحمدابيNo ratings yet

- Mcdonalds Employee Handbook PDFDocument17 pagesMcdonalds Employee Handbook PDFErick Rodríguez LujánNo ratings yet

- Operations Manual: September 2008Document53 pagesOperations Manual: September 2008mohammedelrabeiNo ratings yet

- Coffee & Cafe Service & Training Manual: Last Edited January 30, 2019Document27 pagesCoffee & Cafe Service & Training Manual: Last Edited January 30, 2019Syrian syrNo ratings yet

- Sub Zero Operations ManualDocument57 pagesSub Zero Operations Manualpascal rosasNo ratings yet

- OTECO RRV 3 In. 131380 Installation ManualDocument25 pagesOTECO RRV 3 In. 131380 Installation ManualMogrin Ogisi75% (4)

- Handling Tools WebDocument88 pagesHandling Tools WebyelmustafaaliNo ratings yet

- Auto 2Document10 pagesAuto 2Thao NguyenNo ratings yet

- 250-C20 Illustrated Parts CatalogDocument468 pages250-C20 Illustrated Parts CatalogJose Luis Avendaño95% (21)

- Dokumen - Tips - JCB 422zx Wheeled Loader Service Repair Manual SN From 2320169 To 2320669 1594970576Document25 pagesDokumen - Tips - JCB 422zx Wheeled Loader Service Repair Manual SN From 2320169 To 2320669 1594970576charnight 2100% (1)

- Hillmar Thruster Disc Brakes PowerPoint for Sales and MarketingDocument11 pagesHillmar Thruster Disc Brakes PowerPoint for Sales and MarketingJose Luis Vivanco MontenegroNo ratings yet

- Nissan Pickup D22 PROPELLER SHAFT & DIFFERENTIAL CARRIERDocument6 pagesNissan Pickup D22 PROPELLER SHAFT & DIFFERENTIAL CARRIERTE ST1No ratings yet

- Guidelines for Erection, Testing and Commissioning of Small Hydro Power PlantsDocument80 pagesGuidelines for Erection, Testing and Commissioning of Small Hydro Power PlantsRenato Nicoli Mendes83% (6)

- Durco IOM Big MX Butterfly Valve V-380-E PDFDocument28 pagesDurco IOM Big MX Butterfly Valve V-380-E PDFUtku Kepcen100% (1)

- Engineering Tribology SyllabusDocument2 pagesEngineering Tribology SyllabusDevendar YadavNo ratings yet

- Syllabus Vjti Structural EnggDocument276 pagesSyllabus Vjti Structural EnggPravin AwalkondeNo ratings yet

- Hendrickson Suspension Systems Maintenance l578Document16 pagesHendrickson Suspension Systems Maintenance l578Gabriel ZardoNo ratings yet

- Rotordynamic Stability Case StudiesDocument9 pagesRotordynamic Stability Case StudiesYong LiNo ratings yet

- RC-62K Im20160630eDocument127 pagesRC-62K Im20160630eHumberto CervantesNo ratings yet

- Catalogo BujesDocument120 pagesCatalogo BujesJason BurtonNo ratings yet

- Plain Bearings and Special Turned Parts CAROBRONZEDocument9 pagesPlain Bearings and Special Turned Parts CAROBRONZEmaria_bustelo_2100% (1)

- Listino Est 2012Document338 pagesListino Est 2012mikeNo ratings yet

- CTS Carrier PDFDocument786 pagesCTS Carrier PDFGarcia Jihoo ReneNo ratings yet

- JOHN DEERE PRICE MandaDocument17 pagesJOHN DEERE PRICE MandajakagastrusNo ratings yet

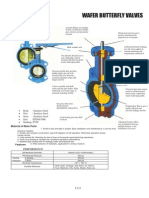

- Wafer Butterfly ValvesDocument2 pagesWafer Butterfly ValvesSandi AslanNo ratings yet

- External Gear PumpDocument4 pagesExternal Gear PumpingenieroNo ratings yet

- Chumaceras DodgeDocument1,302 pagesChumaceras DodgeMonica AquinoNo ratings yet

- Operating Manual: Gilson Economy 8in Sieve Shakers SS-15 & SS-15DDocument13 pagesOperating Manual: Gilson Economy 8in Sieve Shakers SS-15 & SS-15DRafael Fernández ConcepciónNo ratings yet

- Manual de Máquina de Coser JukiDocument243 pagesManual de Máquina de Coser JukiDavid Jesus Ludewig OrtegaNo ratings yet

- 9852 2619 01a Maintenance Instructions COP 1238KDocument44 pages9852 2619 01a Maintenance Instructions COP 1238KOsscar HerreraNo ratings yet

- Yale FIGURE 500 & 500R Closure Installation Instructions: Important InformationDocument12 pagesYale FIGURE 500 & 500R Closure Installation Instructions: Important InformationAnonymous bHh1L1No ratings yet

- Build a Soap Box Derby RacerDocument54 pagesBuild a Soap Box Derby RacerJohn Paul JonesNo ratings yet

- Aramco Engineering - Evaluating Motor SpecificationsDocument161 pagesAramco Engineering - Evaluating Motor Specificationsdeepu220100% (1)

- Milwaukee Cylinder Series H Hydraulic CylindersDocument32 pagesMilwaukee Cylinder Series H Hydraulic Cylindersnvkjayanth100% (1)

- 1.8t Oil Pressure Survival Guide and Troubleshooting DIYDocument89 pages1.8t Oil Pressure Survival Guide and Troubleshooting DIYPatrascu GabrielNo ratings yet