Professional Documents

Culture Documents

Training Note: Types of Safety Interlocks

Uploaded by

Luiz OliveiraOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Training Note: Types of Safety Interlocks

Uploaded by

Luiz OliveiraCopyright:

Available Formats

Training Note

iKnow S A F E T Y Types of Safety Interlocks

Interlock Type Safety Function Parts of System Uses

iKnow W I R E L E S S

Compact Mechanical

(plastic or metal)

Electromechanical switch with positive

opening contacts

Per Guard*:

• 2-piece construction

• Separate coded actuator

• Pivoting or sliding guards

• Hazards that stop quickly or

are far from the guard

Cat 1 or 2 = 1 switch

Cat 2 = 1 switch + safety module

Cat 2 or 3 = 2 switches

CONTACT (mechanically actuated)

Cat 3 or 4 = 2 switches + safety module

Rotary and Hinged Hinge-mounted electromechanical • 1-piece construction • Rotating or pivoting guards

switch with positive opening contacts • Hazards that stop quickly or

Per Guard*: are far from the guard

Cat 1 or 2 = 1 switch

Cat 2 = 1 switch + safety module

Cat 2 or 3 = 2 switches

Cat 3 or 4 = 2 switches + safety module

Guard Locking Key-operated interlock with solenoid • 2-piece construction • Pivoting or sliding guards

locking and positive opening contacts • Solenoid holds actuator in • Hazards that stop slowly or

place are close to the guard

Per Guard*:

Cat 1 or 2 = 1 switch

Cat 2 = 1 switch + safety module

Cat 2 or 3 = 2 switches

Cat 3 or 4 = 2 switches + safety module

Magnetic • Multiple Reed Contacts • Reed sensor • Pivoting or sliding guards

NON-CONTACT (non-mechanically actuated)

• Coded Magnet • Magnetically-coded • Washdown applications

Per Guard*: actuator • Close tolerances

Cat 1 = 1 sensor/mag • Safety module • Size limitations

Cat 3 or 4 = 1 sensor/mag + safety module

Cat 4 = 2 sensor/mag + safety module

Fiber Optic • Optics • Fiber optic cable • Use with pivoting or sliding

• Controller • Optical elements guards

Per Guard*: • Controller • Hazardous or explosive

Cat 1 = 1 optical element + photoelectric environments

Cat 4 = 1 optical element + controller • Washdown applications

• High levels of EMI/RFI noise

present

* The level of safety circuit integrity (e.g. categories per ISO13849-1/EN954-1) is dependent on each application. Extreme care should

be used in designing and installing any safety system to ensure that all instructions and relevant regulations are complied with.

Definition Interlocking Standards

An interlock switch is a means of safeguarding that monitors the position of ANSI NFPA 79 Electrical Standard for Industrial Machinery

a guard or gate. The interlocking of a guard is used to shut off power, control

access, and prevent the machine from starting when the guard is open. ANSI B11.19 Performance Criteria for Safeguarding

ANSI/RIA R15.06 Safety Requirements for Industrial Robots and Robot Systems

Advantages Limitations

• The guard contains ejected materials • Maintenance issues may be expensive IEC 60204-1 Electrical Equipment of Machines

• Provides access for maintenance • Provides limited access

and repair • Poor ergonomics ISO 14119 (EN 1088) Safety of Machinery – Interlocking Devices Associated with Guards

• Initial installation can be low-cost • Expensive to achieve higher levels of

safety IEC 60947-5 Electromechanical Switches

MS_P8_T1_E.PDF

©2005 Banner Engineering Corp., 9714 Tenth Ave. No., Minneapolis, MN USA 55441 • Phone: 763.544.3164 • www.bannerengineering.com • Email: sensors@bannerengineering.com

You might also like

- 43ff-TGard Part Number Book - DigitalDocument21 pages43ff-TGard Part Number Book - DigitalAlan David Rojo HernandezNo ratings yet

- Safety Switches BrochureDocument8 pagesSafety Switches BrochurerkponrajNo ratings yet

- BD5935 enDocument6 pagesBD5935 enaleNo ratings yet

- Dual Input Security Module: Siga-Sec2Document4 pagesDual Input Security Module: Siga-Sec2jhon bayonaNo ratings yet

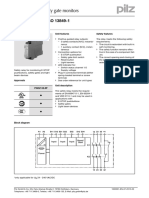

- E-STOP Relays, Safety Gate Monitors: Pnoz S5Document10 pagesE-STOP Relays, Safety Gate Monitors: Pnoz S5KAMRAN AHMEDNo ratings yet

- Monitor E-STOP and safety gatesDocument9 pagesMonitor E-STOP and safety gatesMarcos Moncunill FelipeNo ratings yet

- 85001-0527 - SIGA-SEC2 Security ModuleDocument4 pages85001-0527 - SIGA-SEC2 Security ModuleInstalaciones y Servicios 2906, C.A. Amado IbarraNo ratings yet

- E-STOP Relays, Safety Gate Monitors: Pnoz X9PDocument9 pagesE-STOP Relays, Safety Gate Monitors: Pnoz X9PEdward Erney Salas ValenzuelaNo ratings yet

- Data Sheet Ramsey Pro Line EmeaDocument5 pagesData Sheet Ramsey Pro Line Emeadekyun49No ratings yet

- PNOZ XV2 enDocument8 pagesPNOZ XV2 entmsxptoNo ratings yet

- Safetyrelayselectable 6970Document6 pagesSafetyrelayselectable 6970aguilavmNo ratings yet

- Ficha InterlockDocument2 pagesFicha InterlockLuis MartínezNo ratings yet

- ECP Safe-T-Pull SD Dissipative (2019)Document2 pagesECP Safe-T-Pull SD Dissipative (2019)Guang ChenzNo ratings yet

- Manual Relay PnozDocument8 pagesManual Relay PnozAdam Muhammad ZamanNo ratings yet

- E-STOP and safety gate monitoring relayDocument9 pagesE-STOP and safety gate monitoring relayBALDEV SINGHNo ratings yet

- E-STOP Relays, Safety Gate Monitors: Pnoz S4Document10 pagesE-STOP Relays, Safety Gate Monitors: Pnoz S4Jean ZacaríasNo ratings yet

- ECP Safe-T-Pull PBT (2019)Document2 pagesECP Safe-T-Pull PBT (2019)Guang ChenzNo ratings yet

- E-STOP Relays, Safety Gate MonitorsDocument9 pagesE-STOP Relays, Safety Gate MonitorsRuro LaudaNo ratings yet

- LG5924 enDocument4 pagesLG5924 enTOPOTRONIKNo ratings yet

- E-STOP Relays, Safety Gate Monitors: Pnoz X3PDocument9 pagesE-STOP Relays, Safety Gate Monitors: Pnoz X3PLuc DemeerssemanNo ratings yet

- Pilz Rele Segurança PNOX X10 120VCADocument8 pagesPilz Rele Segurança PNOX X10 120VCASaph SaphNo ratings yet

- Monitor E-STOP and safety gatesDocument9 pagesMonitor E-STOP and safety gatesJosito HNNo ratings yet

- Safety Technique: Emergency Stop Module BD 5987 SafemasterDocument4 pagesSafety Technique: Emergency Stop Module BD 5987 SafemasterConstantin MoldoNo ratings yet

- Installation-/ Safety Technique: Safemaster Delay Module, Release Delay BA 7924, IL 7824, IN 7824Document4 pagesInstallation-/ Safety Technique: Safemaster Delay Module, Release Delay BA 7924, IL 7824, IN 7824Михайло БирчакNo ratings yet

- E-STOP Relays, Safety Gate Monitors: Pnoz Xv3.1PDocument10 pagesE-STOP Relays, Safety Gate Monitors: Pnoz Xv3.1PJose EscobarNo ratings yet

- E-STOP Relay, Safety Gate Monitor: Pnoz 16SDocument8 pagesE-STOP Relay, Safety Gate Monitor: Pnoz 16SilarroceascribdNo ratings yet

- Relé Movimento 0Document10 pagesRelé Movimento 0Alexandre SepulvedaNo ratings yet

- Guardlink DEVICE LEVEL SAFETY LINKING TECHNOLOGYDocument6 pagesGuardlink DEVICE LEVEL SAFETY LINKING TECHNOLOGYFederico FranchinoNo ratings yet

- PNOZ X2 8P enDocument9 pagesPNOZ X2 8P enHamed MokhtariNo ratings yet

- Guard Locks Operating Instructions - March 2022 - V1.3Document14 pagesGuard Locks Operating Instructions - March 2022 - V1.3Ariel Horta LoeraNo ratings yet

- Safety Manual Vegaswing 66: Relay (2 X SPDT) With SIL QualificationDocument20 pagesSafety Manual Vegaswing 66: Relay (2 X SPDT) With SIL Qualificationduong hoang tinNo ratings yet

- SDC Catalog 6 Remote ControlsDocument16 pagesSDC Catalog 6 Remote ControlsMohamed RizkNo ratings yet

- E-STOP Relays, Safety Gate Monitors: Pnoz X2.8PDocument10 pagesE-STOP Relays, Safety Gate Monitors: Pnoz X2.8PburbujaNo ratings yet

- NST 8Document2 pagesNST 8freedom213062No ratings yet

- PNOZ s6.1: Safety RelaysDocument18 pagesPNOZ s6.1: Safety RelaysRafael CarmoNo ratings yet

- Opinstr Euchner ESM-BA3Document4 pagesOpinstr Euchner ESM-BA3Jardas FernandesNo ratings yet

- KLM KLM RR Data Sheet Jan 19Document2 pagesKLM KLM RR Data Sheet Jan 19Marius ClavacNo ratings yet

- Pnoz x11p enDocument9 pagesPnoz x11p enBigappleNo ratings yet

- PNOZ X2 7P enDocument9 pagesPNOZ X2 7P enA.V. KomovNo ratings yet

- Products: PNOZ m1p Coated VersionDocument9 pagesProducts: PNOZ m1p Coated VersionSV100% (1)

- Arc-Flash Safety Handbook: Remote Racking SolutionsDocument78 pagesArc-Flash Safety Handbook: Remote Racking SolutionsAbraham RodriguezNo ratings yet

- KLP Data Sheet Jan 19Document2 pagesKLP Data Sheet Jan 19Alan GonzalezNo ratings yet

- E-STOP Relays, Safety Gate Monitors: Pnoz X5Document8 pagesE-STOP Relays, Safety Gate Monitors: Pnoz X5muaadh100% (1)

- ECP Safe-T-Pull SSB Stainless (2019)Document2 pagesECP Safe-T-Pull SSB Stainless (2019)Guang ChenzNo ratings yet

- Power CAGE CLAMP 60369122Document12 pagesPower CAGE CLAMP 60369122Rafael GermanoNo ratings yet

- Pg05f05te PDFDocument8 pagesPg05f05te PDFa_salehiNo ratings yet

- PY600AC Sliding Gate Opener User ManualDocument20 pagesPY600AC Sliding Gate Opener User ManualJose Gregorio Pantaleon Anaya0% (1)

- MVS AcbDocument55 pagesMVS AcbJohn JeromeNo ratings yet

- E-STOP Relays, Safety Gate Monitors: Pnoz X6Document8 pagesE-STOP Relays, Safety Gate Monitors: Pnoz X6muaadhNo ratings yet

- BG5912 enDocument6 pagesBG5912 endavidk8No ratings yet

- Preventa Safety Detection XCSE7313Document2 pagesPreventa Safety Detection XCSE7313Alex SkanderNo ratings yet

- PNOZ s4 1 Operat Man 21890-EN-05Document20 pagesPNOZ s4 1 Operat Man 21890-EN-05aaronNo ratings yet

- Automatic Transfer Switches Instruction ManualDocument46 pagesAutomatic Transfer Switches Instruction ManualNguyễn Tấn TrưởngNo ratings yet

- Socomec CosDocument5 pagesSocomec CosMahidhar TalapaneniNo ratings yet

- Safety Relay - EUCHNERDocument4 pagesSafety Relay - EUCHNERClaudio AlmiciNo ratings yet

- Eaton PKZM0 0-2.5Document4 pagesEaton PKZM0 0-2.5AbelToledoFuentes0% (1)

- E-STOP Relays, Safety Gate Monitors: PNOZ X3.10PDocument8 pagesE-STOP Relays, Safety Gate Monitors: PNOZ X3.10PRafael CarmoNo ratings yet

- E-STOP Relays, Safety Gate Monitors: Pnoz X7PDocument8 pagesE-STOP Relays, Safety Gate Monitors: Pnoz X7Pandreas bahdaNo ratings yet

- Hornet 732t InstallDocument22 pagesHornet 732t InstallNicky DragutescuNo ratings yet

- Manual XGB Analog 10310000920 Eng V1.6Document515 pagesManual XGB Analog 10310000920 Eng V1.6Luiz OliveiraNo ratings yet

- C.T. Jones - Step 7 in 7 Steps PDFDocument468 pagesC.T. Jones - Step 7 in 7 Steps PDFmitrosNo ratings yet

- Guide to TCP/IP Connections Between PCs and PLCsDocument11 pagesGuide to TCP/IP Connections Between PCs and PLCsCamilo BlanquivNo ratings yet

- WhitePaper SQL The Next Big Thing in SCADADocument7 pagesWhitePaper SQL The Next Big Thing in SCADAInduAutomationNo ratings yet

- WeldSensorSolutionBrochure WEBDocument28 pagesWeldSensorSolutionBrochure WEBLuiz OliveiraNo ratings yet

- Training Note: Types of Safety InterlocksDocument1 pageTraining Note: Types of Safety InterlocksLuiz OliveiraNo ratings yet