Professional Documents

Culture Documents

BLW 19-20

BLW 19-20

Uploaded by

M Pankaj0 ratings0% found this document useful (0 votes)

30 views37 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

30 views37 pagesBLW 19-20

BLW 19-20

Uploaded by

M PankajCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 37

1. _ Production Outturn

OverallProduction Vs Targ

310 locomotives (including 272 electric locos and 4conversion loco) manufactured in

FY 2019-20:

i, Actual production up to Mar’ 2020:

306 310

Note: No production activiti

COVID-19 pandemic.

carried out from 22.03.2020 to 31.03.2020 due

Page 1/37

[2. Quality

A) Performance vis-a-vis previous year on fi

Railways:

Diesel Loco failure within 180 days:

Fail

Period (Apr to Sep) No. of failures

T

2018-19 55

2019-20 7

eure ee cil)

Remarks

re decreased by 87%

B) Settlement of Warranty Claims made by Zonal Railways:

(No. of cases)

Period Opening | Case | Closing Remarks

(Apr- Mar) | Balance lodged | Balance

Target:

2018-19 220 2028 268 | Warranty settlement is 3

months from the date of

. lodging of ~— warranty

claim.

2019-20 268 1318 393

Page 2/37

3. i Economy Measures

A) Elect

Compara

I Energy Consumption per Equated Unit:

e energy used is given below:

[Wee

init consumption (KVAH) Remarks

pitas FPA GOEU) 12.42% saving over

18749403 previous year

2019-20

Availing Electricity in DLW through Open Access

DLW has started procurement of electric power required for non-traction

Purposethrough open access, resulting saving to the tune of approx.36 to 40 %

in monthly Electricity Billamountingto approx.Rs.5 crore/annum due to reduction

In cost of electricity.

Unit Electricity Rate (Old) Unit Electricity Rate AFTER switching

through Open Access

F Rs. 7.88 __ Rs. 4.74 (Variable)

B) Inventory Turnover Ratio:

2018-19 2019-20

Target as per FM Achieved | Target as per FM Achieved

(-) 2.25% (1.28% | (90.86% | (-)2.74%

©) Funds Booked under PH21, PH41 & PH42 as %age of Budget Grant:

| Plan 2018-19 2019-20

feed BG | Expenditure | % of BG | 8G _—_| Expenditure | % of BG

Cr.) (&Cr,) Cr.) (% Cr)

PH 2i* | 3699.63 | 2341.19 | 63.28% | 3867.95) 2962.21 76.58%

PH 41 14.77 7.64 51% 9.97 8.58) 86%

| PHaz 5.37 3.36 | 63% 3.7 | 156 | 49% |

* Plan head 21 is not operated in DLW, it is operated in Zonal Railways. Expenditure of RSP locos are

being shown in PH 7200 in DLW.

Page 3/37

[4._ Occupational Health & Safety _ oo

DLW has made integrated Quality, Health, Environment and Safety Policy. In

conformance to provision/ requirements of OHSAS Management, DLW is having

certificate of OHSAS-18001 (Occupational Health and Safety Management

System) since 2005.

A) Number of Major Accidents:

= Major Accidents

No. of Accidents

B) Average Monthly man hours lost due to IOD cases/100 stat

2018-19 2019-20

| 3.6 hrs 3.47 hrs

€) Supply and use of Personnel Protective Gears and Equipment:

‘+ DLW has formulated "Schedule of Safety Equipment

and Protective Clothing” wherein 37 safety items

(i.e. PPE’s) have been listed with their scale of issue

for the purpose of safety of workmen and the

position is reviewed regularly.

+ All 37 Personnel Protective Equipmentas per latest oe

EN/IS specificationsare made 100% available and

being used.

D) Safety seminars:

i Year Safety Seminars

2018-19 05 |

| 2019-20 13

Page 4/37

E) Safety inspections:

Sefety Inspections

es |

2018-19 163 |

164 ial

2019-20

F) Other important work executed:

* Safety awareness training is imparted to all new entrants / workman /

supervisors at shop floor and at Technical Training Centre to enhance safety

awareness. Massive training programs had been organized by safety officers,

resulted in 100% workshop staffs are trained in firefighting.

* Training imparted by safety cell amongst staff those working at height. Safety

belts & fall arresters have been provided to all the staffs working at height for

protection against fall hazard.

+ Training imparted by safety cell amongst staff those working with 25 KV OHE

and use of PPE’s resulted in 100% workshop staffs are trained.

* Mega Mock Drill on “ Industrial Disaster including Eathquack” at Cinema

Hall on dated 18.04.2019:

‘A Mega Mock Drill on " Industrial Disaster including Eathquack” at Cinema Hall

was conducted with coordination of NDRF & District Administration on 18" April

2019 for safety and crisis management prepardness. All Departments involved in

this Mock Drill

+ Release of Disaster Managemet Plan of DLW by GM/DLW:

DLW Disaster Management Plan has

been prepared and release by respected

GM/DLW on the occation of Mega Mock

Drill on * Industrial Disaster including

Eathquack" at Cinema Hall on dated

18.04.2019.

«Fire Safety awareness in Design Office on dated 09.05.2019:

Fire Safety awareness was conducted on 9" May 2019 for safety and crisis

management prepardness during Fire accident, in which staff and officers of

Design Officeare involved as participants.

Page 5/37

During this Fire Safety awareness programme detailed live presentation of fire

Extinguishers, conversation on the crisis management, prepardness and safety

measure during fire accident and rescue operation were demostrated.

+ An Environment Programme on dated 05.06.2019:

Reference to the Railway Boards guideline (letter no.2019/EnHM/10/04

dt.01.05.2019) an Environment Programme was organised on World

Environment Daydt 05.06.2019, which encourages awareness and action for

the protection of the environment in different phases by Safety cell with the

coordination of DLW Scout & Guide, St, Jone Ambulance Brigade, Civil Defence

Teachers and students of DLW inter Collage.

Mrs. RashmiGoyal, General Manager, Planting trees Chiet Safety Omcer, OLW nagged of Prathat

In DLW ADP. Bulcing Parke ery

+ Celebrating 150" birth anniversary of Mahatma Gand

5 Community

Service Day:

On 2” October 2019, 150™birth anniversary of Mahatma Gandhi was

celebrated as Community Service Day. Cleanliness drive was carried out and

various programs were undertaken for “Swachhta Jagrukta” i.e. hygiene

awareness.

+ Release of Safety Bulletin -2019:

Safety Bulletin - 2019 DLW has been prepared by Safety Cell and release by

GM/DLW on 18.12.2019 in presence of all PHoDs.

Page 6/37

‘A mass cleaning and plastic waste collection under the banner of “Swachhta Hi

Seva” Awareness and “Shramdaan Pakhawara" conducted from 11.09.2019 to

02.10.2019.

"Swachhta Hi Seva” Awareness and "ShramdaanPaknawara”

Page 7/37

[5._ Environme'

A) Development of Alternative Sources of Energy (Solar Power):

i) Roof top Grid connected Solar Power Plant commissioned:

2018-19 ee

Total 3.86 MWp capacity Solar Power Plant has been comi

S6MWp.

ii) Renewable (Solar) energy generation:

3 2018-19 ne 2019-20 _| % improvement over

2018-19

| 17.73 Lakh units (KWHr) | 36.29 Lakh units (KWHr)_| + 104.61% ;

B) GreenCo Rating:

DLW obtained GreenCo Silver Rating under the GreenCo

Green Company Rating Systemand became the first

production unit on IR having this certification. Certificateis

valid for 3 years.

DLW is ISO 14001:2004 (Environment Management System) certified.

C) Scrap Management:

Sale of Scrap:

100% scrap disposal through E-Auction

[ 2018-19 2019-20 Pi

Target Achieved Target Achieved

i &

27 crore 710.50 crore “led @11 crore %5.3 crore

Page 8/37

D) Rain water harvesting, Water recycling,Water conservation and

management:

1) _ Rain Water Harvesting:

‘Approx 44000 sqm roof top area of has been

covered under RWH. In addition, following

actions are also taken:

© 47 deeprecharge wells in colony

© 8 nos. water bodies connected to storm

water drains

© Sabandoned tube wells converted into

recharge wells

Recharge well

Water recycling

© 1403Nillion Literwater is recycled during 2019-20 by STP.

© Recycled water is used for irrigation of road side lawns, bungalows lawn/

garden, filling of water bodies at Surya Sarovar, Tagore park and Golf

course.

Iii) Water conservation & management:

o About 3.89% savingin consumption of fresh water till Jan'2019-20 as

compared to previous year.

(April'18 - Mar’19 = 4425613 KL, April'19 — Mar'2020 = 4253266 KL)

0 Motorised Gate valve have been provided alongwith automation of Pumps.

E) Effluent treatment pollution control and

waste management

* Industrial Effluent Treatment Plant (IETP)

for treating contaminated & mixed Petroleum

oil and Lubricants (POL) of 3 MLD capacity.

Around 1,000 litres of oil and grease is

separated and sold off.

+ Sewage Treatment Plant (STP):For treatment of discharged human waste

of 12 MLD (Million Litres per day) capacity. In

STP approx. 3.85 million litres of water is

being recycled every day.

+ The treated water is released for agricultural

and gardening purposes.

+ The digested bio-manure as sludge dried is

used as fertilizer for horticultural purpose.

* One water recycling plant commissioned at

‘Surya Sarovar’ of 0.25 MLD capacity.

Page 9/37

Pollution control:

Online monitoring of STP and IETP:Performance of STP and JETP for data

pertaining to BOD, COD, pH, TSS and oil content is continuously monitored

online 24x7, round the year.

None of sewage, whether treated or untreated, is discharged into Holy

River Ganga.

DLW boasts of a green area of 40% of its total area having more than one

lakh small & big trees.

Release of CO2, CO, SO2, NO2 and particulate matters in flue gas through

different stacks is regularly monitored and kept within the limit prescribed by

Central and State Pollution Control Board

DLW has switched over to use of pictures for worship of Lord Vishwakarma on

’Vishwakarma Pooja” instead of clay idols.

Waste generated from the residential area is segregated as solid waste and

biodegradable waste. Solid waste is dumped at locations nominated by

municipality. Biodegradable waste is dumped in the pits for composting.

Debris are used to fill the low lying area.

100 kg/hour capacity incinerator is functioning to dispose off paint sludge, oil

soaked jute, oil saw dust, paint-overalll, lube & fuel cil.

4100 ka/hour capacity Incinerator

F) Tree plantation:

f

2018-19

5235 nos. (Target- 5000 nos.)

Page 10/37

6. Industrial Relations

A) Staff Council Meetings:

Staff Council meetings have been organised as per schedule and problems raised

have been solved amicably.

| Description 2018-19 2019-20)

DLW Staff Council Meeting Ce

DLW SC/ST Association Meeting 2 02

DLW OBC Association Meeting [Ree tote, a

* One meeting could not be conducted due to election of new Staff Council

members

B) Relationship of Staff with Management:

+ Relation between staff and management is very healthy and cordial.

+ Suggestions for improvement in work environment are considered for discussion

and implementation.

+ No industrial unrest took place during the financial year and not a single hour

ofwork was lost.

Transparency is given utmost importance in communication between management

‘and employees.

Special efforts were made to improve the illumination in shops and make all

drinking water purifiers and water coolers functional.

Spot awards to staff/team for motivation.

C) Staff Grievance Redressed :

Every shop/section has been provided a grievance/ feedback register for employees’

problem. Grievances are studied, monitored and tackled systematically to prevent

recurrence:

[eee No. of Grievances Disposal of Remarks |]

| Received _ Grievances s

1 78 (100%) 14% reduction

dE a | inno. of

| | 67 (100%) grievances

Page 11/37

_Certifications |

DLW is an ISO 9001, ISO 14001 and OHSAS 18001 certified Organization covering

integrated Quality, Environment, and Health & Safety Management Systems. Our

efforts for a clean and green DLW ensure that the pollution levels of water, air,

exhaust-emissions and hazardous wastes are well within the limits.

Apart from above following certificates have also been obtained:

A)

B)

c)

D)

Ee)

F)

IRIS Certification

DLW has been awarded IRIS Certification for efficient and transparent

System for the activities of Design & Development and Manufacturing of

Locomotives.

5 S Certification

5 S certification has been obtained.

IS 3834 Certification

DLW has obtained certification of ISO 3834-2:2005 for Fusion Welding of

Metallic Materials.

Iso 50001

DLW has obtained certification of ISO 50001: 2011 for Energy Management

System.

GreenCo Rating:

DLW certified with GreenCo Silver Rating under the GreenCo Green Company

Rating System. Certificate is valid for 3 years.

NABL Accreditation

DLW haveNABL Accreditation for laboratory.

Page 12/37

j Welfare _

A) Staff Canteen, Toilet and Rest Rooms in factory premises inclu

separate toilet facilities for ladies:

i) Staff Canteen:

There are two modern canteens in DLW premises

ie, Staff Canteen & Workshop Canteen. Both the

canteens are running successfully as per needs of

our employees. Following facilities are available in

workshop canteen:

+ Pleasant ambience

‘+ Stainless steel dining furniture

+ Washrooms with modern fittings

+ Provision of 70” LED TV

+ Vitrified tiles flooring

+ Transparent kitchen area with modern

cooking equipment

+ Modular kitchen with fresh air cooling and

fume exhaust system

‘+ Stainless steel working table

+ Six nos. insect killer installed

view of Workshop Canteen

* Stainless steel sink for cleaning of utensils with hot and cold water facilities

and Automatic Dish Washer

+ Air tight containers and stainless steel containers for

storage of groceries etc.

+ Auto coffee and tea dispensers in shops.

* Provision of water coolers with attached purifiers

Water cooler with

attached purifier

ii) Toilets and Rest Rooms in factory

premises including separate facilities for

ladies:

+ All shops are attached with toilets |

Toilet fecitty

* Renovated lavatory blocks for hygienic

and clean environment.

Page 13/37

+ Separate toilet facilities for ladies have been constructed

+ Three change rooms/ rest rooms for female staff in different shops have been

provided.

= New water booths were provided.

ii) Staff Lockers ~ Procurement of more than 750 new lockers for workshop staff

has been done.

B) Recreational Amenities for Staff in

Colony :

Community Hall, Institute, Barat Ghars-03

nos, Kalyan Kendra, Rangshala, Employee

Club and Officers’ Club are functioning in DLW

Township for various social needs of the staff.

ema Club:

‘An air-conditioned Cinema Hall (seating

capacity of 650) with multi-channel audio

system and digital projection is functioning

in DLW.

Cinema club

+ Parks and gardens:

Two parks and one big pond named

"Surya Sarovar’ is also situated in DLW

premises where festival like Chatt Puja,

Jivitputrika Puja, Dev Depawali etc. are

organised.

C) Medical facilities:

105 bedded well-equipped Railway Hospital, a Health Unit and a First-Aid post in

workshop are functioning, taking comprehensive health care of more than 50,000

beneficiaries (around 6100 employees plus 5780 retired employees & their family

members).

Page 14/37

D)

Ee)

Facilities available:

i, Medicine, Cardiology, Paediatrics, Obstetrics & Gynaecology, Surgery, Urology,

Orthopaedics, ENT, Ophthalmology, Dentistry, Endoscopic surgery &

Physiotherapy. Diagnostics services, Pathology - Haematology &

Bio-Chemistry, X-ray- Routine & Special X-Ray, Dental X-Ray, digital X-Ray &

ECG from three private hospitals (namely Batra Hospital New Delhi, Medanta

Hospital Gurgaon and Heritage Hospital Varanasi) or so empanelled to provide

medical services.

li, Mobile based medical registration: Facility to do medical registration,

doctors’ appointment including the status of running no. of token for individual

doctor and reporting of lab investigation have been made available online and

‘on mobiles through an Android app for staff of DLW.

‘Central Hospital, DLW = as

EE a

—_r a

— =

—_—

ma ‘—

=

ne ———e,

re

Educational faciliti

One school up to Secondary Education, run by DLW administration where

more than 1000 students are being taught ~ 14 classes have been provided

with “Smart Class” for imparting education in a modern way.

One Girl's degree College in DLW premises.

Two Central Schools - KV No.4& KV, Kanchanpur.

One Sr. Secondary School (Private).

‘One Bal-Niketan (run by DLW Women's Welfare Organization).

Colony upkeep including Garden

Maintenance, Roads, _Streetlights,

Drainage etc.

DLW has a totalof3704staff quarters for about

5920 employees and officers in a lush green,

pollution free township with more than one

lakh trees. Efforts are made to keep the

colony “Clean and Green". aes ote

Glimpse of Lush Green Township

Major roads have been resurfaced. About 8.65

km road repaired in current year.

SMS based complaint management systems is working for redressal of

general electrical complaints of colony area. On an average 79 complaints per

day are attended.

Illumination in colony area is excellent.

Page 15/37

F) Other Notable Features:

More than 7600nos LED tube-lights, 50000 nos. LED bulbs distributed among

employees and 136 Solar lights have been fitted to promote eneray

conservation.

95 CCTV Cameras have been provided in DLW campus for improved safety

and monitoring of unscrupulous activities.

34 nos. CCTV cameras have been installed in Central Hospital and Associated

Health Units. aoe]

4 baggage scanners have been installed at

Administrative Building.

08 nos. Automatic Number Plate Recording

(ANPR) cameras have been installed at

entrance/exit gate of DLW Premises.

* Activities managed by Railway Women Welfare Organization:

Staff welfare function of DLW is also supplemented by Railway Women's

Welfare Organization who run the most popular primary school of DLW

township called ‘Bal Niketan’(@Ieee7), 2 vocational training centre for

differently-abled children called ‘Chetna’(aerT and a number of other centres

aimed at adult literacy, computer literacy, painting,

stitching, créche, etc. eo

Login Here

‘+ For obtaining pay roll information of DLW employee, a

new pay roll mobile App “DLW EMP Payroll Info" has

been launched

Page 16/37

1)

iv)

‘+ Another mobile App “Civil Complaint Management System" for various civil

related works for employees has been launched

+ eacan pie

‘onpant tag

+ Two nationalised Banks with 6 ATMs and one Co-Operative bank are

functioning within DLW campus.

Ge ne BOB ATM

Other Welfare Activities at DLW during FY 2019-20:

Ambdekar Jayanti was celebrated on 15 April 2019 at TTC Auditorium.

‘An awareness programme organised on “Investment Programme” on 24"

May 2019 at TTC.

Awareness Programme organised on “Cardio Diabetes Self-Management

Education (CDSME) on 25% May 2019 at TTC.

Lecture on Life Style Medication to Prevent Workshop Hazard was organised

on 21.01.2020 at TTC.

Page 17/37

© Golf course with 18 hole (11

fairways, 56 Acres)

+ International size standard

Swimming pool

* One synthetic Basketball court & one

cement Basketball both with flood

lights

+ One Volleyball mud court with Flood

light facility

* One Handball mud ground

* One Cricket ground with pavilion and 4 practice wicket

+ One Football ground

+ One Hockey grass ground

+ One Gym with multi-equipments.

+ Two indoor Badminton Courts with

wooden flooring

* One wrestling hall with two wrestling

mats

+ Two synthetic tennis courts with

flood lights

DLW GOLF COURSE

International size Standard Swimming Poo!

B) Achievements at Various Levels:

= Medals won in All India Railway

Championship during 2019-20:

(i) In Athletics, one athlete won Silver

Medal

(ii) Wrestling team won 6 individual

medals (Gold ~ 1, Silver-1, Bronze-4)

(iil) DLW Golf team secured Silver Medal

(iv) DLW Handball team secured Silver Medal

* _ Medals/Participation in International Championship during 2019-20:

i) Smt. Jyoti represented Indian Athletics team the XXIX International

Meeting G. Kossanov Memorial held at Almaty in Kazakhstan on 6" July,

2019 and secured 2" position in Hammer Throw event.

Page 18/37

vie

vil.

vill.

Medals/Participation in Sr. National Championship during 2019-20:

Smt. Jyoti represented Indian Railways in 59 Sr. National Athletics

Championship held at Ranchi in Sep., 2019 and won Silver Medal in Hammer

Throw event.

Sh, Arjun Yadav represented Indian Railways Wrestling team in 64"Sr. National

Wrestling (Men) Championship to be held at Jallandhar (Punjab), from 28”Nov.

to 1"Dec., 2019 and secured Bronze Medal in 74 Kg Free Style.

Sh. Deepak represented Indian Railways Wrestling team in 2"Edition of the

Traditional Senior Men Free Style National Wrestling Championship at Agra from

28""to 29"Dec, 2019,

Sh. Akash Bhashin represented Indian Railways Basketball team in 70"Senior

National Basketball Championships held at Ludhiana from 21.12.2019 to

28.12.2019 team qualified for semi-finalist.

Shri Karn Sharma represented Indian Railway Cricket team in Syed Mustsq Ali

Vijay Hazare Trophy held at Various places from 24.09.2019 to 01.12.2019.

Shri Karn Sharma, & Shri. Avinash Yadav represented Indian Railway Cricket

team in Ranji Trophy Matches held at various places in the month of December,

2019 to February, 2020.

Sh. Shushant Kumar Mishra, Vinay Kumar, Vijay Singh & Sh. Jagmeet Singh

represented Indian Railway Handball team for participation in 48"Sr. National

Handball Men Championship 2019-20 to be held at Kanpur UP from 18*to 23"

Feb, 2020 and secured 2"position in team championship.

All India Railway Golf Men and Handball Men Championship successfully

organized by DLWSA for the year 2019-20.

Page 19/37

10. Public Image & Brand Value

A) Initiatives taken:

HHP (WDG4) Conversion to 3 9 Electric Loco (WAG11: V-I):

After historical and world record conversion of 2 WDG3A locos to Twin Co-Co

Electric WAGC3 locomotive, DLW was given the responsibility of conversion of 2

WDG4 HHP Diesel locomotives to Twin Co-Co WAG11 3-phase Electric locomotive,

in view of large scale electrification over Indian Railways. This was the first time

in world history, that such a high capacity conversion was successfully done. This

conversion is also special because, traction power after conversion has been up

graded by 79%. These 2 units of loco have been permanently coupled in a Twin

Co-Co loco formation of 12,000 hp capacity. Final speed certificate was issued by

RDSO on 17.05.2019, based on oscillation and performance trials. Thereafter,

this loco was inspected by Chief Commissioner of Railway Safety (CCRS) at New

Delhi in Aug’19. He recommended for sanction of Railway Board for operation of

this loco upto a maximum speed of 95 kmph vide his letter dt.02/09/2019.

Machine Room ‘Machine Room ‘Aum. Converter (BUR ~~ FMter Cubicle

‘omer out? 2B8 ag se

Traction ‘ocuscaveneestower \\ Tron Moor

Ber ae Nh \ ae

ne nn ae

Equipment Layout Actual Loco

Page 20/37

1_| Type of Service

2. | Axle Arrangement

3

Horse power* an, 2X6000 HP ia

4 | Tractive Effort (Stall, Continuous) 2x540 KN (Stall), 2X400 KN

(Continuous)

5 | Speed Potential 95 kmph (As per final speed

2 Rs gE ecertinicatey 3

[6 | Gear Ratio 5 | PESOS wh

7 | Length over Buffer 2X21244 mm

| 8 | Overall width 3180 mm *

|9 Max, height with Pantograph locked [4255 mm

10 | Total weight 2X126 T

11 | Traction Motor 2X6 nos., 3-Phase Induction motor

12 | Power of TM(KW)* 703 (Continuous)

|.758 (One hour rating) _ at

Regenerative, Pneumatic

[14 [Braking effort 2X270 KN

| 15 | Power supply to Aux.1,2,3 Converter |415V+/-10%,0to50Hz

‘Battery voltage [ov

17 [Power supply toT™ __|2i80v a

[18 [No. of power converters 2

ii, HHP (WDG4) Conversion to 3 @ Electric Loco (WAG11: V - IT

A variant of WAG11 with new design under slung transformer and WDG4

motorized bogie has also been manufactured by DLW. In this version, one end

cab is equipped with AC, equipment layout is same as to WAG9 with both power

converters centrally placed above the transformer and battery placed on board.

RDSO has issued speed certificate for one time movement and trial route. Loco

has been dispatched from DLW for further oscillation and performance trial by

RDSO.

ii, HHP (WDG4) Conversion to 3 @ Electric Loco (WAG11: V - IIT ):

DLW has developed another variant of WAG11 (Version-3) with WAGS layout &

dual cab in association with RDSO and CLW. This was done primarily to avoid

multiple variants of spares w.r.t. WAG9 Loco and to reduce conversion cost. In

this version, a single unit can work as an independent loco, unlike the earlier

versions 1 & 2, Equipment layout same as WAG9 with under slung battery box

of WAG9/WAP7 and both end cab with AC as in WAGS.

Page 21 /37

RDSO has issued speed certificate for one time movement and trial route. Loco

has been dispatched from DLWfor further oscillation and performance trial by

RDSO.

Equipment co

Dual Mode/Traction Locomotive Project (WDAP5):

DLW in association with RDSO has developed a Dual Mode locomotive which

will be capable to work on both electrified and non-electrified section. A 4500

HP 16 cylinder 710 G3B engine will continue to power the locomotive in non-

electrified sections while in electrified sections the locomotive will draw power

from OHE (Over Head Equipment) with 4500 HP traction power delivered at

wheels. A lightweight Underframe has been completely re-designed for 21.5

ton axle load which has been validated by an internationally acclaimed rolling

stock design co. Hybrid Bogie of WDGS loco, SS Superstructure and reduced

Fuel tank capacity of 3000 L have been adopted in this loco for reducing

weight. It will be fit for passenger operations and designed to work trains up to

the speed of 135 Kmph, which would be validated during Oscillation trials by

RDSO. Both Electrical and mechanical testing has been completed by DLW.

RDSO has issued speed certificate for one-time movement of this loco for

March'2020.

oscillation and performance trials. Loco is turned out

Validation testing is done and clearance is awaited from RDSO.

Equipment Layout Actual Loco

Page 22/37

Advantages:

‘+ Increased flexibility in last mile operations in goods yard/sidings which are

non electrified.

* Increased throughput in the sections.

* Reduction in detention time at traction changing points.

+ Increased availability of locomotives by eliminating the need of stabling

additional locos at change over points.

+ During major accidents/natural calamities, where OHE gets affected, it

provides excellent operational flexibility to work on Diesel mode till OHE is

restored.

Mozambique 3000 hp AC-AC TCS Cape Gauge Loco:

Order for 05 locos for Mozambique Railway (CFM) is likely to be received soon,

through RITES. Salient features of this loco are 3000hp, 12 Cyl 710G3B

Engine, single Cab with HVAC, AC TM, AC-AC traction system tri

gauge bogie, 20t axle load, on board vacuum toilet system etc. This will be the

first loco of its type on CG having AC-AC traction system.

mount cape

Loco architecture has been finalized. Component level modelling and 2D

drafting has been completed & uploaded for E-procurement,

coounctoon —- WATERCIOSET

EQUPMENTRACK

evan FLTER mn

oe arama oxLoV-eNaNE

| Bowen

\

\ acon an cOMMREOR

surennason SOU"

reeta2 | \

noc usta

sarreny 90x

General Arrangement - 3000 HP AC-AC CG Loco

Page 23/37

B) Recognition received:

i) Public Image

Press release, write-up GM's articles and display advertisernent were published in the

National and Local Dailies as well as in magazines and house jouranal” Samvad" also.

Description and photographs of prominent events were posted / uploaded on DLW

Website as well as on social media Twitter and Facebook.

During April 2019 to March 2020 following events of DLW were prominently

highlighted and covered by media thereby creating a positive image:

Production of Electric Locomotive: DLW has successfully transformed itself from

being a diesel loco manufacturer to an electric loco manufacturer while maintaining

excellent industrial relations. From manufacturing 02 units in 2016-17, unit has scaled

in just three years, by a factor of 150.

02 locos were manufactured in 2016-17, 25 locos in 2017-18 & 145 locos in 2018-19.

Further, DLW has manufactured 272 locos in 2019-20.

272

145

indi _ cabs - ii

Si = m zi

2016-17 2017-18 2018-19 2019-20

No: of Electric Locos

This transition enables DLW to apply itself to the system engineering of electric locos.

This helped the PU to successfully convert old diesel locos to much upgraded electric

ones, a unique feat.

DLW as a brand now stands for highest level of knowledge in locomotive system

engineering.

+ Saksham-The mega mock drill: A jeiyeeeneny

mega mock drill was organized under the

joint aegis of DLW Safety Cell and

11Battalian NDRF in DLW cinema hall

premises on 18" April 2019.In this mock drill

along with DLW staffs, Civil Defence, District

Administration, Police, Fire Service, Traffic

Police, Home Guard and various NGO's and

others organizations participated. This mock

drill was organized in the gracious presence

Page 24/37

of Smt. Rashmi Goel, GM/DLW, Shri Alok Kumar Singh, DIG/NDRF, Shri Surendra

Singh, DM/Varanasi, Shri Anand Kulkarni, SSP and various dignitaries of Varanasi.

* Vendor Meet-2019: Vendor

Meet-2019 was organized in DLW

cinema hall on 22°May by Material

Management Department/DLW,

Varanasi in collaboration with North

Central —_Railway(Prayagraj), North

Eastern Railway(Gorakhpur) and

Central Organisation for Railway

Electrification (Prayagraj). The meet

was chaired by Shri V.P. Pathak,

Member/Material Management

Railway Board. Representatives of various organizations and firms concerned with

Railway participated in the meet.

+ Inspection of

Member/Traction Railway Board:

Shri Ghanshyam Singh

Member/Traction Railway Board

Inspected DLW workshop on 25"

May. A meeting with HOD's presided

by Member/Traction took place

regarding production procedures,

manufacturing facilities and various

projects running in DLW.

+ Bulk Indent Meeting :To full fill

the requirements of spare parts for

Locomotives of zonal railways for the

year 2021-22 bulk indent meeting was

organized on 28" and 29" June in Hall

of Fame/DLW. Meeting was addressed

by Smt. Manju Gupta/Adal.

Member(Electrical). In this two-day re

meeting, along with the aggregation if

of demand for spare parts from the M x

Zonal Railways, various technical aspects related to the supply of parts of the

locomotives and their warranty claims were also discussed.

Page 25/37

+ Visit of Chairman/Railway Boari

Railway Board held a meeting with

the representatives of the Staff

Council and other employee unions

in the General Manager's meeting

hall on 9" July. On this occasion Shri

Rajiv Agarwal, GM, N.E. Railway and

various officers along with staff

union representatives were present.

Customer Meet-2019: Customer

Meet 2019 was organized to discuss

the issues like demands of electric

locomotives by Zonal Railways, their

maintenance and reliability on 2"

and 3" August.

©) Shri Vijay Kumar,

‘Commissioner/Railway Board flagged

off electric locomotive WAP-7 and

thereafter he held a review meeting

with concerned officers on 10”

August.

Finance

Shri Vinod Kumar Yadav, Chairman,

Page 26/37

* Loco No. 37349 DLW made electric

loco flagged off by Hon’ble MR and

Commerce & Industry Minister Shri

Piyush Goyal on 14" March 2020. Before

flagging off loco was inspected by GM/DLW

Shri Y.P, Singh.

+ Participation in Exhibitions:

With a view to promote “Brand DLW", participation in various exhititions was

undertaken. DLW stalls which displayed various products and related sub-assemlies

attracted a large number of people including various vendors and suppliers. Various

exhibitions in which DLW participated during 2019-20 were:

‘+ DLW participated in Rail Exhibition and

Fair organized at Sanatan Dharm College,

‘Ambala/Haryana on the occasion of 64"

Central rail week ceremony from 21° to

23 July 2019.In this ceremony Smt.

Rashmi Goel/GM,DLW was facilitated with

‘commendation letter Issued by Honorable

Minister of Railways by Shri Manohar Lal

Khattar, CM/Haryana in the cordial

presence of Shri Suresh Angadi, Minister of

States for Railways, Shri Vinod Kumar

Yadav Chairman, Railway Board and

various dignitary.

This commendation letter was issued for

the conversion of high horse power diesel

locomotive to electric locomotive first ever

in the world. Along with this DLW was

awarded first prize for its attractive stall

making in the category of production units.

Page 27/37

* DLW participated in 13 International

Railway Equipment Exhibition, 2019 at Aero

city New Delhi from 22 to 24 October.

+ DLW participated in two days national

vendor development program cum industrial

exhibition at Varanasi from 14 to 15

November 2019.

* DLW participated in Rail Urja

Pavilion at ELECRAMA 2020 at India

Expo Mart Greater Noida, NCR Delhi

from 18 to 22 January 2020.

+ DLW participated in Technex-20 in BHU,

Varanasi, UP from 14 to 16"” March 2020.

Page 28/37

+ DLW participated in Taj Mahotsava

in Agra from 18 to 27" February 2020.

+ 63™Electrical standards committee meeting: 63" Electrical standards

committee meeting was organized in cooperation with RDSO in Hall of fame/DLW

from 20"to 21*September 2019.

wachhata Pakhwara”: As per

the guideline issued by Ministry of

Railways Swachhata Pakhwara was

organized from 11"September to

2™October at DLW.

+ On 17"September Vishwakarma

Pujnotsava was organized in DLW.

During this Pujnotsava in place of

earthen idol only paper printed images

were used to avoid pollution in water

bodies due to idol immersion.

Page 29/37

+ 275"Electric Locomotive WAP-7 ;

was flagged off by Hon'ble Minister of

State for Railways Shri Suresh C

Angadi, Before flagging it off Shri

Angadi also inspected the driver cab

with Smt Rashmi Goel,GM/DLW.

Various programs on the occasion

Gandhi

Mahatma Gandhi's. 150th __birth.

anniversary was celebrated as

Rashtriya swachhata Diwas” on 2nd

October by all the officers, employees

and their family members. On this

occasion plantation was done in the

Premises of Surya Sarovar, by Smt.

Rashmi Goel, General Manager, DLW in

the presence of all the Heads of the Departments , officers, members of staff council

and employees.

Energy Conservation Week

Under the direction of Railway Board ,

“National Energy Conservation Day”

was organised by Electrical Department,

DLW from 9 to 14 December. On this

‘occasion the Chief guest, Smt. Rashmi

Goel, General Manager, DLW

highlighted the history and purpose of

Indian railway energy conservation.

Smt. Rashmi Goel, General Manager,

DLW rewarded and honoured the

winning participants of the competitions.

Samvidhan Diwas

Constitution day was celebrated in DLW

on 26th November on the direction of

Railway Board. On this occasion a

large number of officers and employees

sworn in by the General Manager Smt.

Rashmi Goel in the reception hall of

30/37

DLW administrative building through the Preamble of The Constitution of India.

All Indian Railway Golf Tournament

64"All Indian Railway Golf Tournament.

under the auspices of the DLW Sports

Association with the collaboration of

Railway Sports Promotion Board

organised at DLW golf course from 2 to

4 December. At the closing ceremony

Smt. Rashmi Goel, General Manager,

DLW distributed the awards to the

winning team and individual players.

Starting of 'E-Office’

‘A mission mode product (MMP) was

developed by the _ National

Informatics Centre(NIC) under the

national e-governance, Govt. Of

India. Under this e-office was

launched by Smt. Rashmi Goel,

General Manager, DLW.

Safety Conference

Shri Arun kumar (IPS) General

Director, Railway Protection Force,

Railway Board inspected DLW on 3rd

December. On this occasion he

participated in the "Safety Conference”

organized by Railway protection Force,

DLW at Technical Training Centre for

the Railway Protection Force of NE

Page 31/37

railway, Northern Railway and DLW.

13All India Railway Handball

Championship

13®All India handball championship was

‘organized by DLW Sports Association at

the handball court of DLW stadium from

13th to 15th January, in a thrilling

contest of the final match North-eastern

railway won the title by defeating host

team of DLW. Both teams are equipped

with the national and international

players. Western Railway stood at third position,

Brand Value:

Over the last 50 years, DLW has established unbeatable “Brand Equity” in respect

of locomotive sales to Non-Railway Customers (NRCs). This is backed and

supported by impressive after-sales service and spares-support to all customers.

This is manifesting in repeat orders from the clients. Moreover, DLW also gets

tough competition from open markets viz BHEL, SAN/Bangaluru et al for getting

WDS6ADT supply orders.

‘Our pro-active initiatives for “Make in

India” campaign have brought forth

rewarding dividends in terms of

proliferating our foot-prints not only

inland but also on foreign shores.

Despite adversities, DLW recently

bagged orders for 06 WDG3A from

Harduaganj, NALCO/ Angul, NALCO/

Damanjodi, NTPC/ Korba, 02 WOS6ADT

from RES/RITES during FY 2019-20 and 05 nos. 3000 HP HHP based Cape Gauge ,

AC-AC loco for Mozambique. During FY 2019-20 total order for 11 locos (worth

2119.93 Cr.) has been received till date.

Further, DLW is expecting orders for 9 WDS6ADT loco from SAIL/ Bokaro,

JSW/Raigad & RCF Mumbai, 06 WDG3A loco from MAHAGENCO, NTPC/ Talcher,

Page 32/37

LANCO/Anapara and 100 nos. 4500 HP Standard Gauge (SG) AC-AC locos from

Egypt under deliberation.

DLW has delivered 27 locomotives to NRCs including 7 nos. 3000 HP, BG, AC-AC

locomotives exported to Srilanka. Apart from this, DLW has also supplied

locomotive spares to NRC worth 25.35 Cr. Hence, total sale of loco & spares worth

309 Cr. during this FY 2019-20.

‘The above have achieved by continuous interaction with prospective customers and

endeavouring to meet their expectations within overarching government

framework with backend support of production division. A rigorous follow-up with

NRCs by Marketing Division ensures redressel of requirements of our valued

customers.

€) There is no pending audit cases more than one year

Page 33/37

| 11. Training and S$

Development of Employees |

A. Training Facilities

Technical Training Centre (TTC) of Diesel

Locomotive Works, Varanasi is functional since

1959 to impart training for new recruits, working

staff and supervisor, Act Apprentices and

Vocational training to Under Graduate Engineering/

Management students. There is also one more

training centre -Indian Railway Welding Research

Institute (IRWRI)which functions as ‘Apex Body’ of

Indian Railways for improving welding quality and

research. Techoleal Training Centre

Facilities in Technical Training Centre:

* Basic Training Workshop: Fitting and Machine

shop equipped with conventional and CNC

machines.

* Electrical & Electronics lab equipped with cut

models and wiring diagrams.

* Computer Lab for computer training viz.

Computer awareness, advanced computer

training, ORACLE, Hindi Kunjiyan / Unicode and

AutoCAD training.

+ Library: TTC is having library of more than 1000 technical and management books

for the knowledge upgradation of trainees and faculty members in various

branches i.e. Mechanical, _ Electrical,

Management and Computer Applications.

* Classroom facilities: There are ten classrooms

(including six AC rooms) with 25 seats

equipped with LCD projectors, computerised

interactive boards are available for in-house

training.

* Auditorium / Conference Hall: One Air-

conditioned Conference hall & one other Auditorium is available at TTC for

seminars & workshop with audio-visual facilities with 180 and 100 seating

capacity respectively.

|. Main Activities of Technical Training Centre (TTC):

+ In-house and outside Institutional training for DLW supervisors & staff,

Probationers and Zonal Rallway’s supervisors and staff

+ Initial training for newly recruited supervisors, artisans (RRB/promotions / New

appointees)

‘+ Training of Act. Apprentices (Non-ITI andITI) as per Apprentices Act.

Page 34/37

+ Degree & Diploma Apprentices training as allotted by Board Of Apprenticeship

Training (BOAT), Kanpur

* Vocational training for Under Graduate Engineering Students

+ ‘Kaushal Vikas’ (PMKVY) training for local youth

+ TTC regularly organizes Seminar/Talk/Meeting in Auditorium / Seminar hall.

Indian Railway Welding Research Institute (IRWRI)

IRWRI is well equipped with all the required

welding facilities i.e. MIG, TIG, SMAW,

Stainless Steel welding etc. Plasma cutting

facility and Weld Research _Lab.Main

activities are -

+ Training of DLW, NER, ECR, ER, CR&

NFR welding professionals. &

co-ordinate between _—Regional

Welding Institutes and function as

Apex Body of Indian Railways for Indian Railway Welding Researchinstitute

Welding training

+ Conducts different modules of Welding Courses for welders, supervisors & trainers

+ Conducts Welder Qualification Test as per 1S0:9606-1 for DLW & other Rly

Workshop welders

+ Research & Quality Improvement Activities

+ Welding related problems of DLW

+ Quality audit of Regional Welding Institutes

Weld Lab of RWRE

Page 35/37

Hil, Training data:

‘Special efforts were made to impart increased training to staff and also increase skill

development of local youth. Training performance of TTC and IRWRI (up to Feb'2020)

as compared to 2018-19 is as under, indicates increase in man-days by 24.78%.

iE 2018-19(up to Feb'2019) 2019-20(up to Feb'2020)

raining | NO. oF Trainee | Man Days Ne. ofTeainess [Man Daye

Imparted | |

Ee 2 he is ae

o {Es 2 p |z

Elz /2 2 (8 Peo eae

[Refresher | 2786 [900 | 3686 5934 | 19169 2553 | 16045 | 5973 | 239:

lother courses | |

| |

24.78% Increase in Training Man Days over Last Year

23918

i

=

&

2

2

=

Fe

2018-19 2019-20

B. System for ensuring proper training to employees:

For ensuring proper training to the employees/trainees following system is in place at

TTC and IRWRI:

+ Well qualified Teachers are posted in TTC. In-charge of IRWRI is having P.hd in

Welding.

+ TTC arranges training to the trainers to upgrade their teaching skill by training in

Out-side Institutions.

+ Standardisation of lesson plan for all courses to ensure uniformity in content and

coverage of various topics in training module.

Different cut models and circuit diagrams of Locomotive equipment/parts in

finished/manufactured form are available in TTC/IRWRI. Practical demonstration is

also being done for better understanding of trainees.

+ Interactive digital boards with LCD projector and visual presenter is provided in

the classrooms for better understanding and display of teaching materials.

Page 36/37

Grading system for all faculty members is in place for continuous evaluation of

teaching faculty through trainees’ feedback.

Digital database is being maintained for continuous monitoring of mandatory

training courses. Any shortfall is promptly reported to concerned Unit In-charge to

ensure compliance.

Kaushal Vikas Yojna:In keeping with the PM's vision of skill development of local

youth, programme of “stir fara asa’ has been started and so far 521 local

youths have been trained free of cost in different trades vis Electrician, Welder,

Carpenter, Fitter etc.

Other highlights and achievements:

134% (cumulative) capacity utilised till date

605 DLW staff has been trained till Feb’2020 under * wa ‘scheme as directed by

CRB

20 employees have been imparted through outside Institutional Training

1637 undergraduates engineering students have been given vocational/internship

training

TTC officers and staff along with trainees participate in cleanliness drive at their

own premises as a part of ‘era sre afirar’on every Saturday.

The book ‘Guide on Welding Technology’ written/compiled by Dr Bipin Kumar

Srivastava, AME/Training of TTC has been awarded 3° prize by Railway Board

under ‘ate sarge areft arte atfire gers aaa greene otra

MCQ Question Bank prepared for conduction promotional examination in

‘machining, fitting, welding, electrician, painter and carpentry trade for technical

staff of DLW and also uploaded it on DLW official website

So far 159 courses have been conducted against 158 course planned/ target

Page 37/37

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Code - Aster: FORMA11 - Practical Works of The Formation "Analyzes Dynamic": Modal AnalysisDocument16 pagesCode - Aster: FORMA11 - Practical Works of The Formation "Analyzes Dynamic": Modal AnalysisM PankajNo ratings yet

- Code - Aster: FORMA12 - Practical Works of The Formation "Introduction To The Linear & Non-Linear Dynamic Analysis"Document22 pagesCode - Aster: FORMA12 - Practical Works of The Formation "Introduction To The Linear & Non-Linear Dynamic Analysis"M PankajNo ratings yet

- Code - Aster: A Simple Example of UseDocument6 pagesCode - Aster: A Simple Example of UseM PankajNo ratings yet

- Mechanical Assembly!: - Goals of This Class:!Document41 pagesMechanical Assembly!: - Goals of This Class:!M PankajNo ratings yet

- Limits, Fits and Tolerances: Prof. S. S. PandeDocument31 pagesLimits, Fits and Tolerances: Prof. S. S. PandeM PankajNo ratings yet

- Steel BridgeDocument9 pagesSteel BridgeM PankajNo ratings yet

- Braithwaite & Co LimitedDocument4 pagesBraithwaite & Co LimitedM PankajNo ratings yet

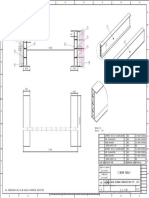

- WD 01 Bosths 04 PDFDocument13 pagesWD 01 Bosths 04 PDFM PankajNo ratings yet

- Trade GRDocument14 pagesTrade GRM PankajNo ratings yet

- Quartz (Sio) : Ceramic Oxide Silicon OxideDocument1 pageQuartz (Sio) : Ceramic Oxide Silicon OxideM PankajNo ratings yet

- Block 3 MS 53 Unit 1Document13 pagesBlock 3 MS 53 Unit 1M PankajNo ratings yet

- Details of Files/keys/Other Material Handed Over Souvik Das: SL No. Description RemarksDocument1 pageDetails of Files/keys/Other Material Handed Over Souvik Das: SL No. Description RemarksM PankajNo ratings yet

- I Beam AsslyDocument1 pageI Beam AsslyM PankajNo ratings yet

- VV Galli LucaDocument3 pagesVV Galli LucaM PankajNo ratings yet

- Nest Cal v1Document2 pagesNest Cal v1M PankajNo ratings yet

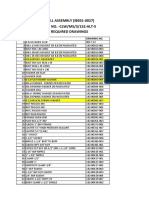

- Wap-7 Drawing DrequiredDocument8 pagesWap-7 Drawing DrequiredM PankajNo ratings yet

- MDTS 213 Rev 02Document12 pagesMDTS 213 Rev 02M PankajNo ratings yet

- MCF Usd M41 4MM 1250 6300 2locoDocument1 pageMCF Usd M41 4MM 1250 6300 2locoM PankajNo ratings yet

- Upsc 2019 Prelims Paper 1 Set D: AIIB-97 Members, Open To Accepting Other Members, ChinaDocument2 pagesUpsc 2019 Prelims Paper 1 Set D: AIIB-97 Members, Open To Accepting Other Members, ChinaM PankajNo ratings yet

- Insight:: Ductile Iron, Green Sand CastingDocument4 pagesInsight:: Ductile Iron, Green Sand CastingM PankajNo ratings yet

- Jayant Test SievesDocument2 pagesJayant Test SievesM PankajNo ratings yet

- 9081spec PDFDocument143 pages9081spec PDFM PankajNo ratings yet

- Plasma Reporting FormatDocument1 pagePlasma Reporting FormatM PankajNo ratings yet