Professional Documents

Culture Documents

Specification FOR Injection Moulded PVC Socket Fittings With Solvent Cement Joints For Water Supplies

Uploaded by

anurag singhOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Specification FOR Injection Moulded PVC Socket Fittings With Solvent Cement Joints For Water Supplies

Uploaded by

anurag singhCopyright:

Available Formats

Free Standard provided by BIS via BSB Edge Private Limited to Arihant Industries -

jaipur(anurag.srp.singh@gmail.com) 157.38.224.187 [for non-commercial use only].

(Reaffirmed 2014)

UDC 621’643~413*063’2 [ 678’743’22-46~: 623’1 IS : 7834 ( Part4)

- 1987

( Reaffirmed 1998 )

Indian Standard (Reaffirmed 2013)

(Reaffirmed 2018)

SPECIFICATION FOR

INJECTION MOULDED PVC SOCKET FITTINGS WITH SOLVENT

CEMENT JOINTS FOR WATER SUPPLIES

(Reaffirmed 2012)

PART 4 SPECIFIC REQUIREMENTS FOR 90” TEES

( First Revision )

(Reaffirmed 2011)

I. Scope - This standard ( Part 4) lays down the requirements for manufacture,

dimension, tolerance!

xrd marking for 90” tee made of injection moulded PVC for water supplies.

(Reaffirmed 2010)

C. Requirements

!.l General -The general requirements for material, manufacture, methods of test, sampling ant

njection shall conform to IS : 7834 ( Part 1 )-1987 ‘Specification for injection moulded PVC socke

‘ittings with solvent cement joints for water supplies: Part 1 General requirements (first revision )‘.

(Reaffirmed 2009)

!.2 Manufacture

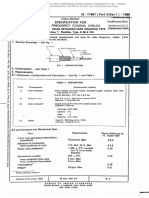

2.2.1 A typical illustration of tee is shown in Fig. 1.

(Reaffirmed 2008)

r--‘czj

(Reaffirmed 2007)

(Reaffirmed 2006)

i

(Reaffirmed 2005)

FIG. 1 90 TEE

2.2.2 Laying length -The laying length Z and the tolerance thereon shall comply with those given

1 Table 1.

2.2.3 This inside diameter of the socket and the socket length shall comply with those given in

j : 7834 ( Part 1 )-1987.

, Marking - Each tee fitting shall be marked with the following information:

a) Manufacturer’s name or identification mark, and

b) Size of the fitting and the appropriate class (working pressure ) to which the pressure rating

of the fitting corresponds.

1.1 Standard Mark - Details available with the Bureau of Indian Standard,

Adopted 25 November 1937 0 June 1966, BIS Gr 1

I I

BUREAU OF INDIAN STANDARDS

MANAK BHAVAN, 9 BAHAOUR SHAH ZAFAR MARG

NEW DELHI 119990

Free Standard provided by BIS via BSB Edge Private Limited to Arihant Industries -

jaipur(anurag.srp.singh@gmail.com) 157.38.224.187 [for non-commercial use only].

IS :‘7834 ( Part 4 ) -‘1987

TABLE 1 DIMENSIONS FOR LAYING LENGTH OF 90” TEES

( Clause 2.2.2, and Fig. 1 )

Size 90” Tee Laying

Length, Z

mm mm

16 9*1

20 11 f 1

25 13.5 + 1’2

-1

32 17 + 1’6

-1

40 21 + 2

-1

50 26 + 2.5

-1

63 32’5 + 3’2

-1

75 38’6 + 4

-1

90 46 + 5

-1

110 56 + 6

-1

125 63.5 + 6

-1

140

71 2 :

160 81 + 8

-1

180 91 + 9

-1

200 101 + 9

-1

225 114 + IO

-1

250 126 + 11

-1

280 141 + 12

-1

315 158'5 + 13

-1

EXPLANATORY NOTE

The requirements of injection moulded PVC socket fittings are covered in eight parts. The

other parts are as follows:

Part 1 General requirements

Part 2 Specific requirements for 459 elbows

.

Part 3 Specific requirements for 90” elbows

Part 5 Spec.ific requirements for 45” tees

Part 6 Specific requirements for sockets

Part 7 Specific requirements for unions

.

Part 8 Specific requirements for caps

This standard was first published in 1975 and covered sizes of fittings up to 160 mm The

present revision has been taken up to cover additional sizes of fittings up to 315 mm.

, A

2

Printed at Arcee Presq, New Delhi, India

You might also like

- EXCEL For Pump DesignDocument2 pagesEXCEL For Pump Designkad-7No ratings yet

- Goa Daman & Diu Factory Rules PDFDocument141 pagesGoa Daman & Diu Factory Rules PDFmrudang1972100% (1)

- Times Square C2C Cardigan: Finished Measurements NotionsDocument8 pagesTimes Square C2C Cardigan: Finished Measurements Notionsdiana.alyNo ratings yet

- Flow Zone Indicator Guided Workflows For PetrelDocument11 pagesFlow Zone Indicator Guided Workflows For PetrelAiwarikiaar100% (1)

- TTR TTR TTR: L:JCTTDocument6 pagesTTR TTR TTR: L:JCTTPramukh Test houseNo ratings yet

- Indian Standard: Legal Metrology - Material Measures of LengthDocument9 pagesIndian Standard: Legal Metrology - Material Measures of LengthDiptiNo ratings yet

- Dimensions For Porcelain Transformer Bushings For Use in Heavily Polluted ATMOSPHERES 12/17.5 KV, 24 KV AND 36 KVDocument12 pagesDimensions For Porcelain Transformer Bushings For Use in Heavily Polluted ATMOSPHERES 12/17.5 KV, 24 KV AND 36 KVGnanavel G100% (1)

- Indian Standard: IS: 7834 (Part 2) - l9g7Document2 pagesIndian Standard: IS: 7834 (Part 2) - l9g7CIPET TESTING - AGARTALANo ratings yet

- Specification FOR Injection Moulded PVC Socket Fittings With Solvent Cement Joints For Water SuppliesDocument3 pagesSpecification FOR Injection Moulded PVC Socket Fittings With Solvent Cement Joints For Water Suppliesanurag singhNo ratings yet

- Specification FOR Injection Moulded PVC Socket Fittings With Solvent Cement Joints For Water SuppliesDocument3 pagesSpecification FOR Injection Moulded PVC Socket Fittings With Solvent Cement Joints For Water SuppliesCIPET TESTING - AGARTALANo ratings yet

- Winding Wires For Submersible Motors - Specification: Indian StandardDocument12 pagesWinding Wires For Submersible Motors - Specification: Indian StandardShivangi BhardwajNo ratings yet

- 2008 Reff2021Document10 pages2008 Reff2021Archana ShuklaNo ratings yet

- Specification FOR Injection Moulded PVC Socket Fittings With Solvent Cement Joints For Water SuppliesDocument8 pagesSpecification FOR Injection Moulded PVC Socket Fittings With Solvent Cement Joints For Water SuppliesCIPET TESTING - AGARTALANo ratings yet

- Winding Wires For Submersible Motors - Specification: Indian StandardDocument9 pagesWinding Wires For Submersible Motors - Specification: Indian StandardkrixotNo ratings yet

- 2010 AMD3 Reff2021Document24 pages2010 AMD3 Reff2021Roushan KumarNo ratings yet

- Arrq-: Cfit1IfDocument8 pagesArrq-: Cfit1IfNikhil ShindeNo ratings yet

- 2000 Reff2021 PDFDocument7 pages2000 Reff2021 PDFocsspectroNo ratings yet

- Specification For Fittings For Rigid Non-Metallic F Second Revision) ConduitsDocument16 pagesSpecification For Fittings For Rigid Non-Metallic F Second Revision) ConduitsAvinash MishraNo ratings yet

- Insulator Telegraph and Telephone Lines - Specification: Stalks ForDocument13 pagesInsulator Telegraph and Telephone Lines - Specification: Stalks ForGnanavel GNo ratings yet

- 8023 1991 Reff2020Document7 pages8023 1991 Reff2020Ashish DubeyNo ratings yet

- IS: 11967 (Part 3/secl) - 1988: (Reaffirmed 20 20)Document3 pagesIS: 11967 (Part 3/secl) - 1988: (Reaffirmed 20 20)Shivangi BhardwajNo ratings yet

- 2000 Reff2021Document7 pages2000 Reff2021Ersatz IdiotaNo ratings yet

- 8262 2 1976 Reff2021Document3 pages8262 2 1976 Reff2021Shubham DhupkarNo ratings yet

- 8262 2 1976 Reff2021Document3 pages8262 2 1976 Reff2021Shubham DhupkarNo ratings yet

- Indian Standard: (Reaffirmed 2017)Document8 pagesIndian Standard: (Reaffirmed 2017)Anirban DasNo ratings yet

- 6003 2010 Reff2021 PDFDocument10 pages6003 2010 Reff2021 PDFAadarsh Kumar ShitalNo ratings yet

- Is 101 - 3 - 2Document11 pagesIs 101 - 3 - 2Ruby MalhotraNo ratings yet

- IS 906 I Specification For Fire Hose Delivery Couplings, Branch Pipe, Nozzles and Nozzle Spanner - SpecificaionDocument12 pagesIS 906 I Specification For Fire Hose Delivery Couplings, Branch Pipe, Nozzles and Nozzle Spanner - SpecificaionHemal BhagatNo ratings yet

- 1077 1992 Reff2021Document6 pages1077 1992 Reff2021Suman ChatterjeeNo ratings yet

- 3179 1990 Reff2020Document6 pages3179 1990 Reff2020Ashish DubeyNo ratings yet

- IS 2379 - Pipeline Colour CodeDocument14 pagesIS 2379 - Pipeline Colour CodeNoel Federer SarkarNo ratings yet

- Concretereinforcement-: High Strength Deformed Steel Bars and Wires ForDocument15 pagesConcretereinforcement-: High Strength Deformed Steel Bars and Wires ForMANISH VERMANo ratings yet

- IS 319 - 2007 - Reff2022Document11 pagesIS 319 - 2007 - Reff2022k27571No ratings yet

- Indian Standard': 1$:6137 - 1983 (ReaffipmedDocument4 pagesIndian Standard': 1$:6137 - 1983 (ReaffipmedAshish DubeyNo ratings yet

- Thermoplastics Pipes and Fittings - Methods of Test (: Indian StandardDocument65 pagesThermoplastics Pipes and Fittings - Methods of Test (: Indian StandardVikash MudgilNo ratings yet

- %%Wirjt'Skf%Wrfim: - RF$TFKDocument11 pages%%Wirjt'Skf%Wrfim: - RF$TFKDevesh Kumar PandeyNo ratings yet

- Dtmensions For Porcelain Transformer Bushings For Use in Lightly Polluted AtmospheresDocument12 pagesDtmensions For Porcelain Transformer Bushings For Use in Lightly Polluted AtmospheresGnanavel GNo ratings yet

- Blikr DH PKJ (Kkusnkj Iysvsa: HKKJRH EkudDocument7 pagesBlikr DH PKJ (Kkusnkj Iysvsa: HKKJRH EkudSajal DeyNo ratings yet

- 1077 PDFDocument6 pages1077 PDFPramukh Test houseNo ratings yet

- Winding Wires For Submersible Motors - Specification: Indian StandardDocument9 pagesWinding Wires For Submersible Motors - Specification: Indian StandardShivangi BhardwajNo ratings yet

- Free Cutting Brass Bars, Rods and Section - Specification: Indian StandardDocument11 pagesFree Cutting Brass Bars, Rods and Section - Specification: Indian StandardocsspectroNo ratings yet

- IS 8329 - 2000 - AMD5 - Reff 2020Document23 pagesIS 8329 - 2000 - AMD5 - Reff 2020Rishab KejriwalNo ratings yet

- Digitalmeasuringinstrumentsfor Measurementandcontrol: Indian StandardDocument7 pagesDigitalmeasuringinstrumentsfor Measurementandcontrol: Indian StandardAshish DubeyNo ratings yet

- Specification For Gauging Members For Plain Plug Gauges Go and No Go Members (Size Range Above 120 Up To and Including 250 MM)Document3 pagesSpecification For Gauging Members For Plain Plug Gauges Go and No Go Members (Size Range Above 120 Up To and Including 250 MM)Ashish DubeyNo ratings yet

- Hot-Rolled Steel Strip For Welded Tubes and Pipes - SpecificationDocument9 pagesHot-Rolled Steel Strip For Welded Tubes and Pipes - SpecificationDip Jyoti SatiarNo ratings yet

- 3wriw: Indian StandardDocument6 pages3wriw: Indian StandardkrixotNo ratings yet

- Bitumen Based Felt - Methods of Test: Indian StandardDocument8 pagesBitumen Based Felt - Methods of Test: Indian StandardNKPCNo ratings yet

- Specification For Mechanical Bevel Protractors: Indian StandardDocument4 pagesSpecification For Mechanical Bevel Protractors: Indian StandardAshish DubeyNo ratings yet

- FT$ TV? PM% - FS!RF+ (FTT 5 R W) : Engineeringmetrology-Plainv-Blocksforinspection Purposes - SpecificationDocument13 pagesFT$ TV? PM% - FS!RF+ (FTT 5 R W) : Engineeringmetrology-Plainv-Blocksforinspection Purposes - SpecificationAshish DubeyNo ratings yet

- 1995 Reff2020Document7 pages1995 Reff2020Ashish DubeyNo ratings yet

- Methods of Sampling For Paints, Varnishes A ND Related: Indian StandardDocument6 pagesMethods of Sampling For Paints, Varnishes A ND Related: Indian StandardselvaNo ratings yet

- 1985 Reff2020Document5 pages1985 Reff2020Ashish DubeyNo ratings yet

- FT RQ:: Carbon Steel Billets, Blooms, Slabs and Bars For Forgings - SpecificationDocument9 pagesFT RQ:: Carbon Steel Billets, Blooms, Slabs and Bars For Forgings - SpecificationocsspectroNo ratings yet

- 7356 1 2002 Reff2021Document13 pages7356 1 2002 Reff2021Santhan NaniNo ratings yet

- 9483 1993 Reff2020Document7 pages9483 1993 Reff2020Ashish DubeyNo ratings yet

- 9483 1993 Reff2020Document7 pages9483 1993 Reff2020Ashish DubeyNo ratings yet

- Specification For Radio Frequency Coaxial Cables: IS: 11967 (Part 3/sec 3) - 1988Document3 pagesSpecification For Radio Frequency Coaxial Cables: IS: 11967 (Part 3/sec 3) - 1988Shivangi BhardwajNo ratings yet

- Coldrolled Steelstrips - . - # B ? (Box Strappings) - Specification .D (Document7 pagesColdrolled Steelstrips - . - # B ? (Box Strappings) - Specification .D (Sajal DeyNo ratings yet

- Specification For Crosslinked Polyethylene Insulated PVC Sheathed CablesDocument23 pagesSpecification For Crosslinked Polyethylene Insulated PVC Sheathed CablesJanavi RajaganapathyNo ratings yet

- 2 1993 Reff2020Document10 pages2 1993 Reff2020Parth PatelNo ratings yet

- Indian Standard: Mild Steel Wire For General Engineering PurposesDocument7 pagesIndian Standard: Mild Steel Wire For General Engineering PurposesDimple nirmalkarNo ratings yet

- IS-12437 Zirconium PowderDocument8 pagesIS-12437 Zirconium PowderAnuradhaPatraNo ratings yet

- 6773 2008 Reff2021Document13 pages6773 2008 Reff2021ocsspectroNo ratings yet

- 500 TransDocument5 pages500 TransRodney WellsNo ratings yet

- 1 Circuit TheoryDocument34 pages1 Circuit TheoryLove StrikeNo ratings yet

- Carrefour-SA Shopping Center TurkeyDocument2 pagesCarrefour-SA Shopping Center TurkeyVineet JogalekarNo ratings yet

- Technical Data Sheet: LPI HVSC PlusDocument2 pagesTechnical Data Sheet: LPI HVSC PlusNguyễn TấnNo ratings yet

- Scholomance 1 GravitonDocument18 pagesScholomance 1 GravitonFabiano SaccolNo ratings yet

- W0L0XCF0866101640 (2006 Opel Corsa) PDFDocument7 pagesW0L0XCF0866101640 (2006 Opel Corsa) PDFgianyNo ratings yet

- Influence of Aesthetics Attributes of Brand Web Pages On Customer Brand EngagementDocument22 pagesInfluence of Aesthetics Attributes of Brand Web Pages On Customer Brand EngagementNOOR AKMA AIDANo ratings yet

- Adaptive Reuse Architecture Documentation and Analysis 2168 9717 1000172Document9 pagesAdaptive Reuse Architecture Documentation and Analysis 2168 9717 1000172Komal HundiaNo ratings yet

- Clocks (New) PDFDocument5 pagesClocks (New) PDFAbhay DabhadeNo ratings yet

- MSDS DowthermDocument4 pagesMSDS DowthermfebriantabbyNo ratings yet

- Data SiEMEx School SafetyPreparedness 25 26 NOVDocument81 pagesData SiEMEx School SafetyPreparedness 25 26 NOVSuraj RajuNo ratings yet

- 12-Week Off-Season Training Programme Junior Rugby (U18 - U21)Document5 pages12-Week Off-Season Training Programme Junior Rugby (U18 - U21)LeBron JamesNo ratings yet

- Asme Code Sec Ix Ma Appe 2004Document3 pagesAsme Code Sec Ix Ma Appe 2004Guillermo CamachoNo ratings yet

- ACR39U-U1: (USB Type A) Smart Card ReaderDocument8 pagesACR39U-U1: (USB Type A) Smart Card Readersuraj18in4uNo ratings yet

- End of Summer Course Test August 2021Document16 pagesEnd of Summer Course Test August 2021Thanh Nguyen vanNo ratings yet

- Chap 4 - Basic Principles of ElectricityDocument31 pagesChap 4 - Basic Principles of ElectricityAdiseshuMiddeNo ratings yet

- Asco Series 238 ASCO Pilot Operated Solenoid Valves (Floating Diaphragm)Document2 pagesAsco Series 238 ASCO Pilot Operated Solenoid Valves (Floating Diaphragm)Khyle Laurenz DuroNo ratings yet

- PANASONIC - WebCam-TQZJ402 - TY-CC20W PDFDocument188 pagesPANASONIC - WebCam-TQZJ402 - TY-CC20W PDF123anthonyNo ratings yet

- Exam 3 DynamicsDocument7 pagesExam 3 DynamicsJulioNo ratings yet

- Aquaculture Scoop May IssueDocument20 pagesAquaculture Scoop May IssueAquaculture ScoopNo ratings yet

- Esterification Oil of WintergreenDocument8 pagesEsterification Oil of WintergreenMaria MahusayNo ratings yet

- Paper-Czechowski-Slow-strain-rate Stress Corrosion Testing of Welded Joints of Al-Mg AlloysDocument4 pagesPaper-Czechowski-Slow-strain-rate Stress Corrosion Testing of Welded Joints of Al-Mg Alloysjavo0128No ratings yet

- Arts Class: Lesson 01Document24 pagesArts Class: Lesson 01Lianne BryNo ratings yet

- Javanese PeopleDocument22 pagesJavanese PeopleDenisaNo ratings yet

- ELS 06 Maret 223Document16 pagesELS 06 Maret 223Tri WinarsoNo ratings yet

- Karl MarxDocument4 pagesKarl Marxeirvine noah isidroNo ratings yet