Professional Documents

Culture Documents

Hydrolysis Kinetics of Thifensulfuron Methyl in Aqueous Buffer Solutions

Uploaded by

梅汉Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hydrolysis Kinetics of Thifensulfuron Methyl in Aqueous Buffer Solutions

Uploaded by

梅汉Copyright:

Available Formats

J. Agric. Food Chem.

1996, 44, 333−337 333

Hydrolysis Kinetics of Thifensulfuron Methyl in Aqueous Buffer

Solutions

Jean-Pierre Cambon* and Jean Bastide

Centre de Phytopharmacie URA CNRS 461, Université de Perpignan, 52 Avenue de Villeneuve,

66860 Perpignan, France

The hydrolysis of thifensulfuron methyl and thifensulfuron were investigated in buffered aqueous

solutions with pH values of 4, 5, 9, and 10. Hydrolysis of thifensulfuron methyl was pH dependent

and relatively fast both in acidic and alkaline buffer solutions. In the case of thifensulfuron,

hydrolysis rates were of the same order of magnitude as thifensulfuron methyl at acidic pH, but

very low at alkaline pH. In acidic solutions, cleavage of the sulfonylurea bridge and O-demethylation

of the methoxy group of the triazine ring occurred concurrently. The resulting intermediates gave

two parallel reactions: cleavage of the sulfonylurea bridge and opening of the triazine ring. The

relative rates of the different hydrolysis pathways were influenced by the pKa of compounds. At

alkaline pH, thifensulfuron methyl hydrolyzed to thifensulfuron, which was slowly transformed by

cleavage of the sulfonylurea bridge and O-demethylation.

Keywords: Sulfonylurea herbicide; hydrolysis; thifensulfuron methyl

INTRODUCTION Methyl 3-[[[[(4-hydroxy-6-methyl-1,3,5-triazin-2yl)amino]-

carbonyl]amino]sulfonyl]-2-thiophene methyl carboxylate (4)

The sulfonylurea herbicides are subject to both chemi- was prepared by mixing concentrated HCl (1 mL; d ) 1.19;

cal hydrolysis and microbial degradation in the soil 37%) and anhydrous tetrahydrofuran (50 mL) at room tem-

(Harvey et al., 1985; Beyer et al., 1988). Their degrada- perature. After 2 min of stirring, thifensulfuron methyl (1, 1

tion rates are related to sulfonylurea structures. All g) was added and the mixture was allowed to stir for 2 h. The

sulfonylurea herbicides degrade relatively rapidly in white precipitate formed was collected by filtration and

soil, but half-lives (t1/2) of ∼1-8 weeks, depending on recrystallized from ethanol to afford 350 mg of a white solid

the specific compounds, have been reported (Brown, of 4 (35% yield): mp 227-228 °C; IR (Nujol) υ (cm-1) 1784,

1990). The slowly dissipating sulfonylurea herbicides 1734, 1716; 1H NMR (DMSO-d6) δ 2.23 (s, 3H, CH3), 3.85 (s,

chlorsulfuron, metsulfuron methyl, and chlorimuron 3H, CO2CH3), 7.6 (d, 1H, CH), 8.02 (d, 1H, CH), 11 (s, 1H,

were chemically hydrolyzed in acidic conditions by OH), 12.85 (s, 1H, NH), 13 (s, 1 H, NH).

cleavage of the sulfonylurea bridge and O-demethylation 1-(Methylthiophene-2-carboxylate-3 sulfonyl)-7-acetyltriuret

of triazine ring (Sabadie, 1990, 1991, 1992; Reiser et (5) was prepared by adding concentrated HCl (0.5 mL) to a

al., 1991). The more rapidly dissipating sulfonylurea solution of thifensulfuron methyl (0.5 g) in 80 mL of methanol.

The reaction mixture was stirred at room temperature for 3

herbicides have shown different pathways of chemical

days. The precipitate formed was filtered, and 5 was obtained

hydrolysis. The sulfonylurea bridge of tribenuron meth- as a white solid (0.1 g): mp 205-206 °C; IR (Nujol) υ (cm-1)

yl was easily broken in aqueous solutions (Brown, 1990), 3272, 3175, 1733, 1723, 1698; 1H NMR (DMSO-d6) δ 2.20 (s,

whereas rimsulfuron rapidly hydrolyzed in both acidic 3H, CH3), 3.9 (s, 3H, CO2CH3), 7.7 (d, 1H, CH), 8.12 (d,1H,

and alkaline conditions through contraction of the CH), 10.3 (s, 1H, NH), 11.08 (s, 1H, NH), 11.09 (s, 1H, NH).

sulfonylurea bridge (Schneiders et al., 1993). 3-(4-Hydroxy-6-methyl-1,3,5-triazin-2-ylcarbamoylsulfamoyl)-

Thifensulfuron methyl rapidly degraded in soil by a thiophene-2-carboxylic acid) (7) was prepared by dissolving a

microbial mechanism (t1/2 ) 2-3 days; Smith et al., mixture of thifensulfuron (0.5 g) in anhydrous tetrahydrofuran

1990; Cambon and Bastide, 1992) to give thifensulfuron. (50 mL) and concentrated HCl (1.5 mL) and stirring the

In this paper, we report an investigation of the chemical mixture at room temperature for 19 h. The precipitate was

hydrolysis mechanism of thifensulfuron methyl and its filtered, and 7 was obtained as a white solid (72% yield): mp

transformation products in aqueous buffer solutions (pH 285-294 °C; IR (Nujol) υ (cm-1) 3553, 1782, 1716; 1H NMR

4, 5, 9, and 10). The different reaction rate constants (DMSO-d6) δ 2.19 (s, 3H, CH3), 7.76 (d, 1H, CH), 7.41 (d, 1 H,

and pathways of hydrolysis were determined. CH), 10.4 (b, 1H, CO2H).

1-(Thiophene-2-carboxylic acid-3 sulfonyl)-7-acetyltriuret (8)

MATERIALS AND METHODS was prepared by dissolving a mixture of thifensulfuron (0.5

g) in anhydrous tetrahydrofuran (50 mL) and concentrated

Chemicals. Thifensulfuron methyl [methyl 3-[[[[(4-meth- HCl (2 mL) and stirring the mixture at room temperature for

oxy-6-methyl-1,3,5-triazin-2-yl)amino]carbonyl]amino]sulfonyl]- 6 days. The precipitate was filtered, and 8 was obtained as a

2-thiophene methyl carboxylate, 1] was a gift of Procida white solid (50% yield): mp >295 °C; IR (Nujol) υ (cm-1) 3334,

(Marseille, France). Thifensulfuron 3-[[[[(4-methoxy-6-methyl- 1714, 1694, 1682; 1H NMR (DMSO-d6) δ 2.1 (s, 3H, CH3), 7.58

1,3,5-triazin-2-yl)amino]carbonyl]amino]sulfonyl]-2 thiophene (d, 1H, CH), 7.96 (d, 1H, CH).

carboxylic acid; 2] was prepared according to the method of Buffer Solutions. Five buffer solutions were used. Buffer

Smith et al. (1990). Methyl 3-sulfamoylthiophene-2-carboxylate

A (pH 4) consisted of 33 mL of citric acid solution (0.1 M) and

(3) and 3-sulfamoylthiophene-2-carboxylic acid (6) were pre-

17 mL of Na2HPO4 solution (0.2 M) diluted to a total of 100

pared according to the method of Bastide et al. (1994).

mL. Buffer B (pH 5) consisted of 24.3 mL of citric acid solution

(0.1 M) and 25.7 mL of Na2HPO4 solution (0.2 M) diluted to a

* Author to whom correspondence should be ad- total of 100 mL. Buffer C (pH 7) consisted of 41.3 mL of KH2-

dressed (fax 3368662223; e-mail BASTIDE@UNIV- PO4 (1/15 M) and 58.7 mL of Na2HPO4‚2H2O (1/15 M). Buffer

PERP. FR). D (pH 9) consisted of 50 mL of a mixture of both KCl (0.1 M)

0021-8561/96/1444-0333$12.00/0 © 1996 American Chemical Society

334 J. Agric. Food Chem., Vol. 44, No. 1, 1996 Cambon and Bastide

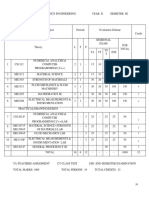

Table 1. Typical HPLC Retention Times of A, B, D, and E; 0.5 mL of 2 to buffers A and B; 0.4 mL of 2 to

Thifensulfuron Methyl and Metabolite Reference buffers D and E; 2.9 mL 4 to buffers A and B; and 2.6 mL of

Standards 7 to buffers A, B, D, and E. The solutions were maintained

HPLC retention time (Rf), min at 28 °C in the dark. Aliquots (0.5 mL) were aseptically

removed from each flask at appropriate times, depending on

compd method 1a method 2b the rate of hydrolysis. Each sample was analyzed by HPLC,

4 4.61 17.40 and each experiment was run in triplicate.

3 6.41 14.32 Analytical Methods. Herbicide and metabolite concentra-

5 7.26 64.43 tions of aqueous samples were analyzed by a Laboratory Data

1 10.93 - Control division of Milton Roy (Constametric I) high-perfor-

6 3.94 7.53 mance liquid chromatograph (HPLC) equipped with a Valco

7 3.20 9.64 injection valve, a UV detector (Monitor III), and a 250 × 4.6

8 - 20.51 mm Ultrabase 235, C8, 5 µm analytical column. The typical

2 5.45 21.94 HPLC retention times for thifensulfuron methyl and potential

a Method 1: the mobile phase consisted of water:acetonitrile: transformation products are listed in Table 1. The detection

acetic acid, 60:40:0.6 (v/v/v); flow rate, 1 mL/min; UV detector, 254 limit of each compound was between 0.05 and 0.1 mg‚L-1.

nm. b Method 2: 2, 6, 7, and 8 were analyzed with a mobile phase

of water:acetonitrile:trifluoroacetic acid (80:20:0.3, v/v/v); flow rate, RESULTS

1 mL/min; UV detector, 254 nm.

Hydrolysis Products. Products 2, 4, 5, 7, and 8

and boric acid (0.1 M) and 20.8 mL of a NaOH (0.1 M) solution were synthesized according to standard procedure and

diluted to a total of 100 mL. Buffer E (pH 10) consisted of 50

mL of both KCl (0.1 M) and boric acid (0.1 M) and 43.7 mL of

identified by IR, 1H NMR (see Materials and Methods),

solution of NaOH (0.1 M) diluted to 100 mL. and 13C NMR (Table 2). The structure of 5 was

Hydrolysis Rate Determination. The hydrolysis rates confirmed by X-ray analysis (data not shown).

were determined by monitoring the rate of disappearance of Hydrolysis Rate of Thifensulfuron Methyl at pH

thifensulfuron methyl (1), thifensulfuron (2), and 4 and 7 in 4 and 5. The hydrolysis rate of thifensulfuron methyl

aqueous buffers A, B, D, and E. All glass apparatus were heat- is pH dependent and follows pseudo-first-order kinetics

sterilized by autoclaving, and buffer solutions were sterilized (Table 3). This reaction shows two different pathways

by filtration (Sartorius Minisart NML, 0.22 µm). Aseptic (Figure 1): cleavage of the sulfonylurea bridge (path a)

techniques were used throughout the study to maintain to yield 3 and O-demethylation of the methoxy group

sterility.

of the triazine ring (path b) giving 4. This latter

Two stock solutions containing 4 g‚L-1 of 1 or 2.1 g‚L-1 of 2

in acetonitrile were prepared. Compounds 4 and 7 are compound was transformed either into 3 by cleavage of

unstable in acetonitrile, so the stock solutions were prepared the sulfonylurea bridge (path c) or into 5 by opening of

in 0.52 and 0.58 g‚L-1 of buffer C, respectively. the triazine ring (path d). The different hydrolysis

An aliquot of each stock solution was added aseptically to products were identified on the basis of their HPLC

50 mL of each sterilized buffer solution 0.375 mL of 1 to buffers retention times compared with authentic standards

Table 2. 13C NMR Chemical Shifts in DMSO-d6 (13C Spectra Recorded on a JEOL 400 MHz)

carbon

structure group 1 2 3 4 5 6 7 8 9 10 11 12

A R ) CH3 133.1 141.4 132.1 133.1 148.5 163.8 170.1 178.4 159.3 53.12 55.22 25.07

R′ ) CH3

A R)H 135.9 140.8 131.6 131.1 149.2 163.9 170.1 178.5 160.6 55.17 25.18

R′ ) CH3

A R ) CH3 134 141.1 131.9 131.7 149.2 163.3 170.9 153.2 159.9 53.33 21.07

R′ ) H

A R)H 135.5 141.1 131.8 131.1 150 163 170.1 153.4 160.6 21.36

R′ ) H

B R ) CH3 133.3 141.3 132.1 131.6 148.1 149.5 173 150.3 159.4 53.27 23.95

B R)H 113.5 140.7 131.4 131.3 148.2 149.7 173 150.2 160.4 24.01

Table 3. First-Order Rate Constants of 1 and 4 at pH 4, 5, 9, and 10

k × 102 h-1 a

compd 1 compd 4

pH kobs k1 k2 kobs k3 k4

4 2.41 ( 0.02 1.34 ( 0.06 1.07 ( 0.08 2.37 ( 0.19 0.84 ( 0.06 1.52 ( 0.13

5 0.25 ( 0.02 0.13 ( 0.01 0.12 ( 0.01 0.40 ( 0.06 0.22 ( 0.08 0.18 ( 0.02

9 0.71 ( 0.15

10 11.55 ( 0.25

a Data are means ( SD of three replicates.

Thifensulfuron Methyl Hydrolysis J. Agric. Food Chem., Vol. 44, No. 1, 1996 335

was determined by studying the hydrolysis of 4 under

the same conditions. In this case

[3] ) [3](path a) + [3](path c)

[3](path c) k3 [3](path a) k1

and

k4 k2

) )

[5] [3](path c) + [5]

k3[5]

[3] -

k1 k4

k2 k3[5]

)

+ [5]

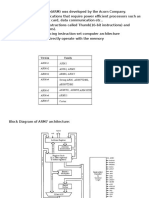

Figure 1. Proposed acidic hydrolysis pathway of thifensul-

k4

furon methyl (1) in aqueous buffer solutions (pH 4 and 5) at

28 °C (k represents reaction rate constants). A ratio k1/k2 ) 1.33 was calculated from the latter

equation. The k2 value was 1.03 × 10-2 h-1.

Method 3. Measurement of the Concentration of the

Different Products When 4 is Maximum. At the reaction

time when 4 is maximum

d[4]

)0

dt

-

) k2 (a - x) - (k3 + k4)[4]

Here (a - x) is the concentration of the product 1 at t )

48 h, and k3 + k4 ) kobs (transformation rate of 4). The

k2 value calculated according to this method is 1.0 ×

10-2 h-1.

The three different methods lead to similar k2 values

(k2 ≈ 1.0 × 10-2 h-1). The same hydrolysis pathways

were observed at pH 5, although the relative transfor-

mation rates were not affected to the same magnitude.

The different k values were calculated from the same

methods as for pH 4 and are reported in Table 3.

Hydrolysis Rate of Thifensulfuron at pH 4 and

5. Three transformation products were detected by

HPLC in these reactions and were identified as 6, 7,

and 8. In acidic aqueous solution, thifensulfuron (2) and

thifensulfuron methyl (1) hydrolysis pathways were

similar; that is cleavage of the sulfonylurea bridge (path

e) to yield 6 and conversion of the methoxy group on

the triazine ring to hydroxyl function (path f) to give 7.

Figure 2. Hydrolysis of thifensulfuron methyl (1) in pH 4 Further hydrolysis of this latter compound leading to 6

buffer solution at 28 °C.

(path g) and 8 (path h) was also observed (Figure 3).

The rate constants of the different hydrolysis reactions

(Table 1). The relative rates of these different reactions

were calculated by the method previously described for

can be estimated by three different methods.

the hydrolysis of 1 (Table 4).

Method 1. Measurement of the Initial Formation Rate

The hydrolysis rate of thifensulfuron is lower at pH

of 3 and 4. At the beginning of the reaction (pH 4), the

4 (Figure 4) and higher at pH 5 than the respective

product 5 was present at very low concentration (Figure

thifensulfuron methyl hydrolysis rates. The relation

2), which allows us to neglect this transformation. In

between pH and hydrolysis rates of chlorsulfuron and

this condition, the ratio of the concentrations of 3 and

metsulfuron methyl have been reported by Sabadie

4 and the ratio of their rate constants are the same.

(1990, 1991) and Dinelli et al. (1994). At pH > pKa, a

linear relation between pH and log k, with a slope of

[3] k1 ∼1 was obtained. At pH < pKa, the slope was <0.4.

and kobs ) k1 + k2

[4] k2

)

The pKa of thifensulfuron methyl is 4, and the variations

in rate constants versus pH are in agreement with the

These ratios give the values k1/k2 ) 1.24, k1 )1.34 × results reported for other sulfonylureas. The pKa of

10-2 h-1, and k2 ) 1.07 × 10-2 h-1. thifensulfuron was measured as 4.6-4.7. This value

Method 2. Analysis of Final Concentrations of Com- explains the low variation of rate constants observed

pounds. When the hydrolysis reaction is completed, the between pH 4 and 5.

products 3 and 5 are relatively stable and their concen- The hydrolysis rates of the O-demethylated compound

trations do not change. Compound 5 was obtained by 7 were measured at pH 4 and 5, and the rate constants

hydrolysis pathway d and 3 was formed by paths a and calculated followed first-order kinetics (Table 4). The

c. The amount of 3 formed by path c was related to the hydrolysis of product 7 at pH 4 was faster than thifen-

amount of 5 in solution by the ratio k3/k4. This ratio sulfuron 2 hydrolysis, although at pH 5, the hydrolysis

336 J. Agric. Food Chem., Vol. 44, No. 1, 1996 Cambon and Bastide

Table 4. First-Order Rate Constants of 2 and 7 at pH 4, 5, 9, 10

k × 102 h-1 a

compd 2 compd 7

pH k′obs k′1 k′2 k′obs k′3 k′4

4 10.7 ( 0.17 0.70 ( 0.20 0.36 ( 0.06 2.97 ( 0.12 1.55 ( 0.06 1.42 ( 0.06

5 0.45 ( 0.06 0.19 ( 0.02 0.25 ( 0.07 0.55 ( 0.04 0.35 ( 0.03 0.20 ( 0.01

9 0.032 ( 0.009 0.021 ( 0.004 0.012 ( 0.005 0.032 ( 0.004

10 0.089 ( 0.008 0.071 ( 0.005 0.049 ( 0.01

a Data are means ( SD of three replicates.

transformation product found was thifensulfuron 2

(Bastide et al., 1994). This hydrolysis pathway was

different from the methyl metsulfuron pathway and

could be explained by the difference between thiophene

ring and benzene ring activation (Bastide et al., 1994).

Hydrolysis Rate of Thifensulfuron (2) at pH 9

and 10. The two compounds 6 and 7 were obtained by

hydrolysis of 2. In the case of chlorsulfuron and met-

sulfuron methyl, only the O-demethylation reaction was

reported (Sabadie, 1991; Reiser et al., 1991). At pH 9

(Figure 5A), the most important pathway was the hy-

drolysis of the sulfonylurea bridge. At pH 10 (Figure

5B), during a reaction time of <200 h, only 7 appeared.

Figure 3. Proposed acidic hydrolysis pathway of thifensul- Compound 6 could be formed by subsequent hydrolysis

furon (2) in aqueous buffer solutions (pH 4 and 5) at 28 °C (k′ of 7. To verify this hypothesis, the hydrolysis rates of

represents reaction rate constants). 7 at pH 9 and 10 were measured, and the k values were

calculated as 3.2 × 10-4 h-1 and 4.86 × 10-4 h-1, re-

spectively. These results partially explain the formation

of 6 by hydrolysis of 7 in the hydrolytic reaction of 2.

DISCUSSION

The stability of thifensulfuron methyl (1) in aqueous

solution is markedly influenced by pH, and hydrolysis

is accelerated by acidic and, to a lesser extent, alkaline

conditions. The pH values studied are not necessarily

the best choice for correlation with agricultural soils,

but some experiments were conducted at pH 6 and 8

with thifensulfuron methyl (1), and the hydrolysis rates

were low (t1/2 ≈ 770 h at pH 8; t1/2 ≈ 2000 h at pH 6).

With these conditions, the hydrolysis pathways were

similar to those at others pHs, but it was not possible

to accurately determine the rate constant data of these

different pathways. Two hydrolysis pathways of thifen-

sulfuron methyl (1), observed with acidic conditions,

were in agreement with those reported for other sulfo-

nylureas with triazine substituted by a methoxy group

(Sabadie, 1990, 1991; Reiser et al., 1991). Two similar

hydrolysis pathways were obtained with thifensulfuron

2. The relative ratio of the two pathways is of the same

order of magnitude for the two compounds at pH 4 and

5; the breakdown of the sulfonylurea bridge is only

slightly more rapid than the O-demethylation reaction.

The hydrolysis of hydroxylated intermediates 4 and

Figure 4. Hydrolysis of thifensulfuron (2) in pH 4 buffer 7 also gives two pathways of transformation; they are,

solution at 28 °C. hydrolysis of the sulfonylurea bridge and opening of the

triazine heterocycle. The latter reaction is pH depend-

rates of these two compounds, 2 and 7, were similar. ent [k4(pH 4)/k4 (pH 5) ) 8.4; k′4 (pH 4)/k′4 (pH 5) ) 7.1

The relatively low hydrolysis rate of thifensulfuron 2 for 4 and 7, respectively], and the former is less affected

at pH 4 may be related to the pKa of this compound, as by pH [k3 (pH 4)/k3 (pH 5) ) 3.8; k′3(pH 4)/k′3 (pH 5) )

previously explained for 1 and 2. 4.4) for 4 and 7, respectively]. Moreover, the major

Hydrolysis Rate of Thifensulfuron Methyl at pH hydrolysis product of 4 was 5 at pH 4 and 3 at pH 5,

9 and 10. The stability of thifensulfuron methyl in whereas 6 was the major product of 7 at pH 5. At pH

alkaline aqueous solutions was pH dependent and 4, 7 gave an equal amount of 6 and 8. In the case of

followed first-order kinetics (Table 3). However, for this chlorsulfuron and metsulfuron methyl, the selectivity

product, we did not observe a contraction of the sulfo- of these different reactions was not pH dependent

nylurea bridge as in the case of rimsulfuron (Schneiders (Sabadie, 1990, 1991).

et al., 1993), but rather hydrolysis of the ester function The hydrolysis of thifensulfuron methyl (1) in alkaline

(Smith et al., 1990; Cambon et al., 1992). The sole first condition is specific to this compound, leading to the

Thifensulfuron Methyl Hydrolysis J. Agric. Food Chem., Vol. 44, No. 1, 1996 337

metabolite isolated was thifensulfuron (2), produced by

biological degradation (Smith et al., 1990; Cambon et

al., 1992). Thifensulfuron (2) was transformed by

chemical processes, and the pathway of transformation

could be the same as in aqueous solutions. However,

the sole metabolites identified in soil were 6 and 7. The

metabolite 8 was not observed. Either it was not formed

or it was easily degraded by microorganisms.

LITERATURE CITED

Bastide, J.; Badon, R.; Cambon, J. P.; Vega, D. Transformation

rates of ortho-substituted thiophene and benzene carboxylic

esters: application to thifensulfuron methyl and metsulfu-

ron methyl herbicides. Pestic. Sci. 1994, 40, 293-297.

Beyer, E. M.; Duffy, M. J.; Hay, J. V.; Schlueter, D. D.

Sulfonylurea herbicides. In Herbicides: Chemistry, degrada-

tion and mode of action. Kearney, P. C., Kaufman, D. D.,

Eds.; Dekker: New York, 1988; pp 117-189.

Brown H. M. Mode of action, crop selectivity, and soil relations

of the sulfonylurea herbicides. Pestic. Sci. 1990, 29, 263-

281.

Cambon, J. P.; Bastide, J. Chemical or microbiological degra-

dation of sulfonylurea herbicides in soil. III. Thifensulfuron

methyl. Weed Res. 1992, 32, 357-362.

Dinelli, G.; Vicari, A.; Ctizone, A. Triasulfuron, chlorsulfuron

and metsulfuron hydrolysis and triasulfuron degradation

in soil. Proceedings IX Symposium Pesticide Chemistry

Degradation and Mobility of Xenobiotics, Piacenza Oct 11-

13, 1993; Del Re, A., Capri, E., Evans, S. P., Natal, P.,

Trevisan, M., Eds.; Biagini: Piacenza, Italy, 1994; pp 411-

418.

Harvey, J., Jr.; Dulka, J. J.; Anderson, J. J. Properties of

sulfometuron methyl affecting its environmental fate: aque-

ous hydrolysis and photolysis, mobility and adsorption on

soils, and bioaccumulation potential. J. Agric. Food Chem.

1985, 33, 590.

Reiser, R. W.; Barefoot, A. C.; Dietrich, R. F.; Fogiel, A. J.;

Johnson, W. R.; Scoot, M. T. Application of microcolumn

liquid chromatography-continuous-flow fast atom bombard-

ment mass spectrometry in environmental studies sulfonyl-

urea herbicides. J. Chromatogr. 1991, 554, 91-101.

Sabadie, J. Chemical acidic hydrolysis of metsulfuron methyl.

Weed Res. 1990, 30, 413-419.

Sabadie, J. Alcoholysis and acid chemical hydrolysis of chlor-

sulfuron. Weed Res. 1991, 31, 309-316.

Sabadie, J. Degradation of the herbicide chlorsulfuron on

various dry minerals. Weed Res. 1992, 32, 429-436.

Schneiders, G. C.; Koeppe, M. K.; Naidu, M. V.; Horne, P.;

Brown, A. M.; Mucha, C. F. Fate of rimsulfuron in the

environment. J. Agric. Food Chem. 1993, 41, 2404-2410.

Smith, A. E.; Sharma, M. P.; Aubin, A. J. Soil persistence of

thiameturon (DPX M6316) and phytotoxicity of the major

degradation product. Can. J. Soil Sci. 1990, 70, 485-491.

Figure 5. Hydrolysis of thifensulfuron (2) in pH 9 (A) and

10 (B) buffer solutions at 28 °C. Received for review April 3, 1995. Revised manuscript re-

ceived October 26, 1995. Accepted October 31, 1995.X

corresponding acid. The ester function of other sulfo- JF950194F

nylurea herbicides was not easily hydrolyzable. The

resulting thifensulfuron (2) was subsequently slowly X Abstract published in Advance ACS Abstracts, De-

hydrolyzed in alkaline conditions. In soil, the first cember 15, 1995.

You might also like

- A Rapid, High-Yield Conversion of Codeine To MorphineDocument2 pagesA Rapid, High-Yield Conversion of Codeine To Morphinegeovani250% (2)

- Addition of Hydrohalogenic Acids To Alkenes in Aqueous-Organic, Two-Phase Systems in The Presence of Catalytic Amounts of Onium Salts PDFDocument3 pagesAddition of Hydrohalogenic Acids To Alkenes in Aqueous-Organic, Two-Phase Systems in The Presence of Catalytic Amounts of Onium Salts PDFatomoscoNo ratings yet

- Molecules: New 3H-Indole Synthesis by Fischer's Method. Part IDocument8 pagesMolecules: New 3H-Indole Synthesis by Fischer's Method. Part ILEONETTILENCINANo ratings yet

- 55846202 a Rapid High Yield Conversion of Codeine to MorphineDocument7 pages55846202 a Rapid High Yield Conversion of Codeine to Morphinemehdighorbani2002No ratings yet

- c3dt52013g TerpiDocument15 pagesc3dt52013g TerpiBrem BalazsNo ratings yet

- Facile Synthesis of 4-HydroxycoumarinDocument3 pagesFacile Synthesis of 4-HydroxycoumarinSolomon EricksonNo ratings yet

- Synthesis and Characterization of Potential Impurities in LevothyroxineDocument8 pagesSynthesis and Characterization of Potential Impurities in LevothyroxineEsti Rossa Larasati0% (1)

- Li, 2020 - Metodologia Cloração 2,3-Dihidroxiquinoxalina - SupInfDocument211 pagesLi, 2020 - Metodologia Cloração 2,3-Dihidroxiquinoxalina - SupInfBruna LispectorNo ratings yet

- Top Catal (2011) 54 561-567Document7 pagesTop Catal (2011) 54 561-567pedrojrsNo ratings yet

- 2,3-Trans-3,4-Trans-3,4-Dihydroxy-L-proline An Amino Acid in Toxic Peptides of Amanita Virosa MushroomsDocument2 pages2,3-Trans-3,4-Trans-3,4-Dihydroxy-L-proline An Amino Acid in Toxic Peptides of Amanita Virosa MushroomsArmando BetancourthNo ratings yet

- Synthesis and Antimicrobial Evaluation of 1, 2, 4 Triazole Derivatives Containing ThiazolidinoneDocument6 pagesSynthesis and Antimicrobial Evaluation of 1, 2, 4 Triazole Derivatives Containing ThiazolidinoneViviana TorresNo ratings yet

- Improved Etherification Procedure For The Preparation of Dibenz (B, F) (1,4) OxazepineDocument3 pagesImproved Etherification Procedure For The Preparation of Dibenz (B, F) (1,4) Oxazepineebi1364No ratings yet

- Phase Transfer Catalysis Converts Haloethanes to OlefinsDocument5 pagesPhase Transfer Catalysis Converts Haloethanes to OlefinsSuresh IyerNo ratings yet

- An Efficient Synthesis of Racemic TolterodineDocument2 pagesAn Efficient Synthesis of Racemic TolterodineJignesh TrivediNo ratings yet

- Ma 8012477Document7 pagesMa 8012477Friska SiamiNo ratings yet

- (F) - 5-Fluoro-5-Deoxyribose, An Efficient Peptide Bioconjugation Ligand For Positron Emission Tomography (PET) ImagingDocument17 pages(F) - 5-Fluoro-5-Deoxyribose, An Efficient Peptide Bioconjugation Ligand For Positron Emission Tomography (PET) ImagingSilvio PignottiNo ratings yet

- Camphorsultam CleavageDocument3 pagesCamphorsultam Cleavageleda_prandiNo ratings yet

- Interference of Phenoxyacetic Acid Derivatives in The Estimation of Monochloroacetic Acid by The Thioindigo MethodDocument6 pagesInterference of Phenoxyacetic Acid Derivatives in The Estimation of Monochloroacetic Acid by The Thioindigo MethodSh1vaNo ratings yet

- Rhodium-Catalyzed Triarylphosphine Synthesis Via Cross-Coupling ofDocument43 pagesRhodium-Catalyzed Triarylphosphine Synthesis Via Cross-Coupling ofGabriela ArequipaNo ratings yet

- 295491Document7 pages295491khaliddarwish1962No ratings yet

- Demethylation With LiCl-DMF (JMolCatA-Chemical2007)Document8 pagesDemethylation With LiCl-DMF (JMolCatA-Chemical2007)Archawin_mooNo ratings yet

- Synthesis of Menthofuran from Pulegone and Isopulegol via ChloroisopulegonesDocument3 pagesSynthesis of Menthofuran from Pulegone and Isopulegol via ChloroisopulegonesPrashant SinghNo ratings yet

- GM - Synth Commun - Aza - 2008Document8 pagesGM - Synth Commun - Aza - 2008Rudraksha BhattacharyaNo ratings yet

- Anti-Markonikov Hydrobromination paper-SIDocument26 pagesAnti-Markonikov Hydrobromination paper-SIArvindMoreNo ratings yet

- Synthesis of Carboxylic Acids, Esters, Alcohols and Ethers Containing A Tetrahydropyran Ring Derived From 6-Methyl-5-Hepten-2-OneDocument10 pagesSynthesis of Carboxylic Acids, Esters, Alcohols and Ethers Containing A Tetrahydropyran Ring Derived From 6-Methyl-5-Hepten-2-OnebiologiNo ratings yet

- Topal 1993Document7 pagesTopal 1993IlijanaNo ratings yet

- New Substituted 1,3,4-Oxadiazole-2-Thiols Synthesized and EvaluatedDocument15 pagesNew Substituted 1,3,4-Oxadiazole-2-Thiols Synthesized and EvaluatedIonut DumistrascuNo ratings yet

- Synthesis of (+) - Camptothecin: Organic Chemistry: Technology: National Chemical Laboratory, Pune 411008, India E-MailDocument5 pagesSynthesis of (+) - Camptothecin: Organic Chemistry: Technology: National Chemical Laboratory, Pune 411008, India E-Mailevsgoud_goudNo ratings yet

- Damian L 1994Document6 pagesDamian L 1994yosyNo ratings yet

- Bulk Phosphinidene Effects on Diiron ComplexDocument7 pagesBulk Phosphinidene Effects on Diiron ComplexParico PalotesNo ratings yet

- Materials and Methods: 2.1 ReagentsDocument15 pagesMaterials and Methods: 2.1 Reagentsgemma_vixNo ratings yet

- Bioresources: Estimation of Hardwood Lignin Concentrations by Uv Spectroscopy and Chlorine DemethylationDocument13 pagesBioresources: Estimation of Hardwood Lignin Concentrations by Uv Spectroscopy and Chlorine DemethylationThiago SantosNo ratings yet

- Research Article: Synthesis of New Benzofuran-2-Carboxylic Acid DerivativesDocument8 pagesResearch Article: Synthesis of New Benzofuran-2-Carboxylic Acid Derivativesfatriani smakNo ratings yet

- Supporting Information ForDocument24 pagesSupporting Information ForSumanta PadhiNo ratings yet

- He Ravi 2007Document4 pagesHe Ravi 2007Vivek ShewaleNo ratings yet

- Leuckart ReactionDocument3 pagesLeuckart ReactionKybernetikum100% (1)

- Synthesis of Glycerol Based Hyperbranched - 5HDONDocument6 pagesSynthesis of Glycerol Based Hyperbranched - 5HDONkarinagcarvalhoNo ratings yet

- Jo 01323 A 048Document3 pagesJo 01323 A 048conker4No ratings yet

- Hagens 1982Document3 pagesHagens 1982Hiorrana Cássia FariaNo ratings yet

- Hydroporphyrins of The Meso-Tetra (Hydroxyphenyl) Porphyrin PhotosensitizersDocument4 pagesHydroporphyrins of The Meso-Tetra (Hydroxyphenyl) Porphyrin PhotosensitizersMariaNo ratings yet

- Isolation and Purification of Deoxynivalenol and A New Trichothecene by High Pressure Liquid ChromatographyDocument4 pagesIsolation and Purification of Deoxynivalenol and A New Trichothecene by High Pressure Liquid ChromatographyfennypermatasariNo ratings yet

- New Synthesis of DiazepamDocument7 pagesNew Synthesis of DiazepamAntônio Neto MachadoNo ratings yet

- Ja971400y Si 001Document14 pagesJa971400y Si 001mike van dorsselaerNo ratings yet

- Convenient Reduction of Carbonyl Compounds To Their Corresponding Alcohols With Nabh / (NH) C O SystemDocument7 pagesConvenient Reduction of Carbonyl Compounds To Their Corresponding Alcohols With Nabh / (NH) C O SystemHawra JawadNo ratings yet

- LB 2003 Refrew 08 EvDocument9 pagesLB 2003 Refrew 08 EvRama Krishna AdityaNo ratings yet

- Factors Affecting Captopril Stability in Aqueous SolutionDocument8 pagesFactors Affecting Captopril Stability in Aqueous SolutionTuấn HoàngNo ratings yet

- 1 s2.0 S0014827X01011892 MainDocument5 pages1 s2.0 S0014827X01011892 Mainjipir64332No ratings yet

- ) - 6a-Hydroxy - ) - 6b-Hydroxycarvotanacetone ) - CarvoneDocument3 pages) - 6a-Hydroxy - ) - 6b-Hydroxycarvotanacetone ) - CarvoneРусланNo ratings yet

- In Vitro Studies of Lanthanide Complexes For The Treatment of OsteoporosisDocument37 pagesIn Vitro Studies of Lanthanide Complexes For The Treatment of OsteoporosisLinh TrươngNo ratings yet

- Org Let. Sauropunol - SupportingDocument63 pagesOrg Let. Sauropunol - SupportingDebanjan DasNo ratings yet

- Synthesis of New Metal-Free and Metal-Containing Phthalocyanines With Tertiary or Quaternary Aminoethyl SubstituentsDocument7 pagesSynthesis of New Metal-Free and Metal-Containing Phthalocyanines With Tertiary or Quaternary Aminoethyl SubstituentsFrancisco Batista Do NascimentoNo ratings yet

- Dendrimetos de PTDocument16 pagesDendrimetos de PTJose Miguel PalomoNo ratings yet

- Direct Continuous Fluorometric Assay For Monoamine Oxidase BDocument4 pagesDirect Continuous Fluorometric Assay For Monoamine Oxidase BMichmich90No ratings yet

- Heterocyclization and Functionalization of 1,2-Bis - (4-Amino-5-Mercapto-1,2,4-Triazol-3-Yl) BenzeneDocument14 pagesHeterocyclization and Functionalization of 1,2-Bis - (4-Amino-5-Mercapto-1,2,4-Triazol-3-Yl) BenzeneViviana TorresNo ratings yet

- A Colorimetric Assay For Detecting Haloalkane Dehalogenase ActivityDocument6 pagesA Colorimetric Assay For Detecting Haloalkane Dehalogenase ActivityshuklagNo ratings yet

- Synthesis of 1-Amino-2 - (4 - Methoxycarbonyl Ethyl-2 - Methyl) - Phenoxy-4-Hydroxy AnthraquinoneDocument4 pagesSynthesis of 1-Amino-2 - (4 - Methoxycarbonyl Ethyl-2 - Methyl) - Phenoxy-4-Hydroxy AnthraquinoneGhulam MurtazaNo ratings yet

- EpscDocument6 pagesEpscVohinh NgoNo ratings yet

- Application of IC-MS and IC-ICP-MS in Environmental ResearchFrom EverandApplication of IC-MS and IC-ICP-MS in Environmental ResearchRajmund MichalskiNo ratings yet

- US8242315Document19 pagesUS8242315梅汉No ratings yet

- Viper+ADV 000000000030575388 SDS CPA US en 5-0Document13 pagesViper+ADV 000000000030575388 SDS CPA US en 5-0梅汉No ratings yet

- CoA Purasolv BLDocument1 pageCoA Purasolv BL梅汉No ratings yet

- United States: (12) Patent Application Publication (10) Pub. No.: US 2011/0086848 A1Document14 pagesUnited States: (12) Patent Application Publication (10) Pub. No.: US 2011/0086848 A1梅汉No ratings yet

- Safety Data Sheet: Section 1: Identification of The Substance/Mixture and of The Company/UndertakingDocument10 pagesSafety Data Sheet: Section 1: Identification of The Substance/Mixture and of The Company/Undertaking梅汉No ratings yet

- Safety Data Sheet for Geropon SC/213 DispersantDocument12 pagesSafety Data Sheet for Geropon SC/213 Dispersant梅汉No ratings yet

- Safety Data Sheet: Section 1: Identification of The Substance/Mixture and of The Company/UndertakingDocument11 pagesSafety Data Sheet: Section 1: Identification of The Substance/Mixture and of The Company/Undertaking梅汉No ratings yet

- Freyssinet Webinar Introduction To Passive Control System For Seismic Damage Mitigation - Tri SuryadiDocument62 pagesFreyssinet Webinar Introduction To Passive Control System For Seismic Damage Mitigation - Tri SuryadiAnto Destianto100% (1)

- Catalogo 312DDocument24 pagesCatalogo 312DMarioNo ratings yet

- Splunk Ot Security Solution Technical Guide and DocumentationDocument101 pagesSplunk Ot Security Solution Technical Guide and DocumentationDr. Sanaz TehraniNo ratings yet

- T&D UK Hazardous Area Electrical Equipment DistributorDocument8 pagesT&D UK Hazardous Area Electrical Equipment DistributorJayadevDamodaranNo ratings yet

- ALEJDocument6 pagesALEJAlejandro OdinNo ratings yet

- Chemistry Paper (12 TH New Pattern)Document2 pagesChemistry Paper (12 TH New Pattern)Suyog TekamNo ratings yet

- Long QuizDocument2 pagesLong QuizDavid Mikael Nava TaclinoNo ratings yet

- Course Caterpillar c6 6 Engines Acert Technology BenefitsDocument34 pagesCourse Caterpillar c6 6 Engines Acert Technology BenefitsGanapati Hegde100% (9)

- ARM ArchitectureDocument26 pagesARM ArchitectureKiran KumarNo ratings yet

- AngE Solutions EN WEBDocument12 pagesAngE Solutions EN WEBSayed El-MaadawyNo ratings yet

- Chapter 19 - Decision-Making Under RiskDocument29 pagesChapter 19 - Decision-Making Under RiskBich Lien PhamNo ratings yet

- Oracle Fusion Middle Ware Installation Guide For Oracle WebLogic Server 11g Release 1Document86 pagesOracle Fusion Middle Ware Installation Guide For Oracle WebLogic Server 11g Release 1EttoreNo ratings yet

- AntennasDocument5 pagesAntennasMiguel Ferrando Rocher100% (1)

- Database Administration AssessmentDocument10 pagesDatabase Administration AssessmentEsubalewNo ratings yet

- AMETANK REPORT: Roof design calculationsDocument41 pagesAMETANK REPORT: Roof design calculationsHasan arif KısaalioğluNo ratings yet

- 20a Solar Power Controller ManualDocument8 pages20a Solar Power Controller ManualVeilleur De ConscienceNo ratings yet

- Qliphothic Gestalt 2.odtDocument13 pagesQliphothic Gestalt 2.odtRobert Podgurski100% (1)

- MTH302 - Business Mathematics & Statistics - Solved - MID Term Paper - 05Document5 pagesMTH302 - Business Mathematics & Statistics - Solved - MID Term Paper - 05ehtasham shakeelNo ratings yet

- Adjustment Computation Notes by UotilaDocument59 pagesAdjustment Computation Notes by Uotilatangdc99No ratings yet

- Arithmetic Questions: Correct Answer: 14Document9 pagesArithmetic Questions: Correct Answer: 14Akash BhoiNo ratings yet

- Chem 123 Problem Set 1Document4 pagesChem 123 Problem Set 1Stuart BrookesNo ratings yet

- Feature Scope Description For SAP HANA 2.0 SPS 07 enDocument44 pagesFeature Scope Description For SAP HANA 2.0 SPS 07 enrvinNo ratings yet

- Electrical & Electronics Engineering Syllabus-Sem III To Sem VIIIDocument64 pagesElectrical & Electronics Engineering Syllabus-Sem III To Sem VIIISaroj Kumar RajakNo ratings yet

- Trabajo Fisica IDocument5 pagesTrabajo Fisica IMVAZ233No ratings yet

- Chemistry Webquest Introduction to AtomsDocument3 pagesChemistry Webquest Introduction to AtomsMarx GomesNo ratings yet

- Mineral-Insulated Thermocouples According To DIN 43710 and DIN EN 60584Document11 pagesMineral-Insulated Thermocouples According To DIN 43710 and DIN EN 60584Veryco BudiantoNo ratings yet

- MVC Architecture and Sales Order Entry (P42101)Document10 pagesMVC Architecture and Sales Order Entry (P42101)ashish007d100% (1)

- MEcDocument12 pagesMEcBinduMishraNo ratings yet

- NotepadDocument9 pagesNotepadteenapalNo ratings yet

- IBM System x3250 M3: IBM Redbooks Product GuideDocument29 pagesIBM System x3250 M3: IBM Redbooks Product Guidegopi_hcNo ratings yet