Professional Documents

Culture Documents

Alternating Bar Sizes: Issues

Alternating Bar Sizes: Issues

Uploaded by

johnnybebadOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Alternating Bar Sizes: Issues

Alternating Bar Sizes: Issues

Uploaded by

johnnybebadCopyright:

Available Formats

Detailing Corner

Alternating

Bar Sizes

D esigners often use alternating bar sizes for reinforce-

ment in walls and slabs. While at first glance this may

seem to be a simple method to enhance design efficiency

in terms of total steel weight, it usually doesn’t optimize

the overall cost of the project. Before the decision is

made to specify alternating bar sizes, several issues

should be considered.

Issues

Which bar starts a run?

Whether to start a run of bars with the larger or

smaller bar (Fig. 1) may seem like a trivial issue, but this

Fig. 1: Should a run of bars start with the larger or smaller bar?

(Note: 1 in. = 25.4 mm)

DETAILING CORNER

Joint ACI-CRSI Committee 315-B,

Details of Concrete Reinforcement—

Constructibility, has developed forums

dealing with constructibility issues for

reinforced concrete. Staff at the Con-

crete Reinforcing Steel Institute (CRSI)

are presenting these topics in a regular

series of articles. CRSI staff will also respond to

requests for information (RFIs) regarding design,

detailing, and construction. If you’d like to suggest

an article topic or submit an RFI for this feature,

please send an e-mail to Neal Anderson, CRSI’s

Vice President of Engineering, at nanderson@crsi.org

Fig. 2: Cover thickness will vary if alternating bar sizes are used in

with the subject line “Detailing Corner.” the outside layer of wall or slab reinforcement, and the effective

depth of the section may be smaller than anticipated

48 July 2009 / Concrete international

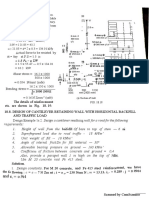

Fig. 3: The difference in splice lengths for the different bar sizes causes the location of splices to change relative to one another when

stock length bars are used

simple decision has been the root of countless

disagreements between inspectors and contractors,

especially when there are an odd number of bars.

Designers and inspectors naturally prefer to maximize

the amount of steel and tend to start with the larger

bar, while fabricators and placers prefer to minimize

steel congestion and tend to start with the smaller

bar. Consequently, the size of the starting bar in the

run becomes a matter of debate and needs to be

coordinated in advance.

Concrete cover may vary

The vertical bars in a wall are tied to the horizontal

bars. If the horizontal bars are inside the vertical bars

and the vertical bars alternate in size, the specified cover

must be met on the larger bar and the cover on the Fig. 4: Alternating bar sizes can complicate the distribution of

smaller bars will be larger (Fig. 2). If the bars differ by reinforcing steel around openings

two bar sizes, the smaller bars will have 1/4 in. (6 mm)

greater concrete cover than the larger bars. Designers

must be aware that this situation will result in a smaller

effective depth to the reinforcement and, therefore, a

smaller nominal moment capacity than would occur if

both bar sizes had the same cover.

Lap locations can shift

Alternating bar sizes can create problems with lap

locations, particularly in long runs of horizontal wall bars

or temperature reinforcement in a slab (Fig. 3). If stock

length bars are used, the difference in lap length for the

two bar sizes will cause the lap locations to move apart

relative to each other. This means the final bar in the run

is a different length for each of the bar sizes.

How are trim bars allocated?

Typically, half of the reinforcing bars interrupted by a

slab or wall opening must be placed as trim or framing

Fig. 5: The difference in hook dimensions for vertical wall bars

bars on each side of the opening. If the bar sizes alternate with different bar sizes affects the location of the outermost slab

and six bars are interrupted by an opening, for example, or beam reinforcement

Concrete international / July 2009 49

three large bars and three small bars must be distributed

at the sides of the opening. The configuration and layout

could be issues for dispute, so the “field fix” shown in

Fig. 4 could result in the need for even more bars.

Hook dimensions will vary

If the tops of vertical bars with different sizes are

terminated with standard hooks, the bend diameters will

be different for the two bar sizes, as shown in Fig. 5. Very

often, especially along perimeter walls, the designer

requires a continuous bar tied in the corner of the

Fig. 6: Alternating slab bar sizes can lead to broken or loose

vertical hook. The continuous bar touches only every tie wires

other vertical bar and appears to be too low, causing

concern from some inspectors. Additionally, if the or they are likely to be displaced by the concrete as

vertical bars are hooked into a continuous beam at the it is placed.

top of the wall, the different arcs of the hooks may result

in one or more bars positioned lower in the cross section Fabrication expense can increase

than expected. This may become an issue concerning the It’s more economical to cut a quantity of bars of a

effective depth of the member. single bar size than it is to cut half the quantity for

each of two different bar sizes. Furthermore, if the

Maintaining accurate installation designer used only the larger bar with a wider spacing or

is more difficult an intermediate bar size with a wider spacing, there

Slab bars are typically placed on supports known as would be fewer total bars required, thus reducing

slab bolsters. When the bottom bars are tied in place, the fabrication costs.

smaller bars are lifted off the slab bolsters and secured

against the layer of bars above, as depicted in Fig. 6. Placing expense can also increase

Later, as workers walk on the reinforcing steel to place Sorting and placing bars of alternating sizes requires

conduits, inserts, and other embedded items or during extra labor and handling. To avoid getting the alternating

concrete placement, the ties holding the small bars could bars out of sequence, ironworkers must start placing the

be stretched or broken so the bars are no longer secured reinforcing bars at a single point on a slab or wall, rather

against the reinforcing steel mat. They must be re-tied than in several locations simultaneously. The previously

mentioned tendency for lap locations to shift will also

increase labor costs.

Upcoming Total cost is more than a function

of weight

Themes

Designers should understand that what they may

perceive as cost efficiency might actually add to the

overall cost of a project. While they may be trying to

save reinforcing steel, they are increasing the potential

difficulties for the placers and the inspectors. Even better

cost efficiencies and reduced potential for placing and

August—Decorative Concrete inspection difficulties can often be achieved simply by

September—Concrete in adjusting the bar spacing and using a single size.

Extreme Environments

October—Precast/Prestressed Thanks to Joint ACI-CRSI Committee 315 member Dick

& Post-Tensioned Birley, President of Condor Rebar Consultants, Inc., in

Vancouver, BC, Canada, for providing the information in

For advertising details, contact Jeff Rhodes • Phone

this article.

(410) 584-8487 • e-mail: concrete@networkpub.com

Selected for reader interest by the editors.

50 July 2009 / Concrete international

You might also like

- Fib Bulletin 81 - ACI SP-315 - Punching Shear of Structural Concrete Slabs - Honoring Neil M. Hawkins PDFDocument396 pagesFib Bulletin 81 - ACI SP-315 - Punching Shear of Structural Concrete Slabs - Honoring Neil M. Hawkins PDFPieter MeulendijksNo ratings yet

- PCI Manual For The Design of Hollow Core Slabs and Walls 3rd Edition MNL126 15Document232 pagesPCI Manual For The Design of Hollow Core Slabs and Walls 3rd Edition MNL126 15Carlo Dizon100% (2)

- Rfis On Circular Ties, Rotating Hooks, Staggered Lap Splices, and Closure StripsDocument6 pagesRfis On Circular Ties, Rotating Hooks, Staggered Lap Splices, and Closure Stripsvelmurug_bala100% (1)

- ALIMAK SC45-30 - Technical Description - Construction HoistDocument60 pagesALIMAK SC45-30 - Technical Description - Construction HoistErick Adrian Quintero Jaramillo67% (3)

- DDM04 S310 16 SupplementDocument4 pagesDDM04 S310 16 SupplementmojeebmashalNo ratings yet

- Field Inspection of Reinforcing Bars: CTN-M-1-11Document8 pagesField Inspection of Reinforcing Bars: CTN-M-1-11pandavision76100% (1)

- Cold-Formed Steel Design: Wei-Wen Yu, PH.D., P.EDocument5 pagesCold-Formed Steel Design: Wei-Wen Yu, PH.D., P.ESaylittle PrayerNo ratings yet

- Precast Post Tentioned TanksDocument20 pagesPrecast Post Tentioned TanksMarcel SteoleaNo ratings yet

- Steel Joists - MST PDFDocument7 pagesSteel Joists - MST PDFwafikmh4No ratings yet

- Evolution of High Rise Building in VancouverDocument8 pagesEvolution of High Rise Building in VancouverTeo Peng KeatNo ratings yet

- Cable Stayed BackwardDocument69 pagesCable Stayed BackwardIonut FalcescuNo ratings yet

- DetailingDocument5 pagesDetailingdavidchansm100% (1)

- Article - Bar Detailing at Wall Openings - CRSIDocument5 pagesArticle - Bar Detailing at Wall Openings - CRSIErick Adrian Quintero Jaramillo100% (1)

- Detailing Corner-Grade BeamDocument4 pagesDetailing Corner-Grade BeamProfessor Dr. Nabeel Al-Bayati-Consultant Engineer100% (2)

- Ci27 Detailing of Concrete ColumnDocument7 pagesCi27 Detailing of Concrete ColumnEgyptian Researcher100% (1)

- Aci CrsiDocument1 pageAci CrsiTos HernandoNo ratings yet

- Corner Details For Wall Horizontal BarsDocument3 pagesCorner Details For Wall Horizontal BarsProfessor Dr. Nabeel Al-Bayati-Consultant EngineerNo ratings yet

- CRSI-FAQ About RebarsDocument8 pagesCRSI-FAQ About Rebarsk_maheswari3397No ratings yet

- CRSI Notes PDFDocument8 pagesCRSI Notes PDFRajha RajeswaranNo ratings yet

- 07cb0663-d04c-4864-955d-bf609dc759c1Document6 pages07cb0663-d04c-4864-955d-bf609dc759c1x620100% (1)

- Ci3503crsi - Column Tie ConfigurationsDocument7 pagesCi3503crsi - Column Tie ConfigurationsNono_geotecNo ratings yet

- Article - Concrete Cover at Rustications, Drip Grooves, and Formliners - CRSIDocument4 pagesArticle - Concrete Cover at Rustications, Drip Grooves, and Formliners - CRSIErick Adrian Quintero JaramilloNo ratings yet

- Retaining Wall With Up To 2 Wall Segments: CRSI Example 1 9'-0" HighDocument1 pageRetaining Wall With Up To 2 Wall Segments: CRSI Example 1 9'-0" HighAnthony GravagneNo ratings yet

- Steel-Concrete Composite Coupling Beams - Behavior and DesignDocument11 pagesSteel-Concrete Composite Coupling Beams - Behavior and DesigncyrusnasiraiNo ratings yet

- Handouts - Anchor or Reinforcement HiltiDocument22 pagesHandouts - Anchor or Reinforcement HiltiAnonymous x9STa9100% (1)

- Design Provisions For Shear WallsDocument13 pagesDesign Provisions For Shear WallsRm1262No ratings yet

- Re-Bar Staggered Lap SplicesDocument4 pagesRe-Bar Staggered Lap Splicestyger089100% (2)

- Connections: Best Tips of The 21st CenturyDocument4 pagesConnections: Best Tips of The 21st Centurysymon ellimac100% (1)

- SplicesDocument2 pagesSplicesAwais Safder Malik100% (1)

- Strength of Screw Connections Subject To Shear ForceDocument34 pagesStrength of Screw Connections Subject To Shear ForceGuillermo Agustín Yáñez QuezadaNo ratings yet

- End-Plate Moment Connections-Their Use and Misuse PDFDocument3 pagesEnd-Plate Moment Connections-Their Use and Misuse PDFsaber javidNo ratings yet

- Aci MNL 1721 Aci Reinforced Concrete Design Handbook A Companion v2Document490 pagesAci MNL 1721 Aci Reinforced Concrete Design Handbook A Companion v2อัสมี่ มั่งมีNo ratings yet

- Concrete Columns PDFDocument9 pagesConcrete Columns PDFAnne Karollynne CastroNo ratings yet

- CRSI-Designers Responsibility For Rebar Design PDFDocument16 pagesCRSI-Designers Responsibility For Rebar Design PDFk_maheswari3397No ratings yet

- مخططات بناية كونكريت و حديدDocument31 pagesمخططات بناية كونكريت و حديدalaa4altaieNo ratings yet

- Steelwise PDFDocument3 pagesSteelwise PDFFourHorsemenNo ratings yet

- Rebar 101Document27 pagesRebar 101Alaym AguilarNo ratings yet

- Reinforcing Bar Layout For Two-Way SlabsDocument4 pagesReinforcing Bar Layout For Two-Way Slabsaomareltayeb100% (1)

- Aci 355-3r11 (Ejemplos Anclajes)Document128 pagesAci 355-3r11 (Ejemplos Anclajes)dnavarrete01100% (1)

- Layering Reinforcing Bars: @seismicisolationDocument26 pagesLayering Reinforcing Bars: @seismicisolationali tahaNo ratings yet

- ACiDocument9 pagesACiMarcel SteoleaNo ratings yet

- Anchorage of Steel Building Components To ConcreteDocument7 pagesAnchorage of Steel Building Components To ConcreteGlenn Rey DomingoNo ratings yet

- SteelWise Strong Connection To HSSDocument4 pagesSteelWise Strong Connection To HSSv100% (2)

- Precast ConcreteDocument8 pagesPrecast ConcreteNeistinitoNo ratings yet

- CFT Design Guide March 2014Document44 pagesCFT Design Guide March 2014Juan Castillo100% (4)

- CCAAT55 Guide To Tilt-Up Design and ConstructionDocument54 pagesCCAAT55 Guide To Tilt-Up Design and ConstructionJose Jacobo Alvarez Saint-Hilaire100% (1)

- 2 Lateral-Load-Transfer Session-2 2perDocument56 pages2 Lateral-Load-Transfer Session-2 2perLuis CortesNo ratings yet

- Detailing Corner 2008-2009Document26 pagesDetailing Corner 2008-2009Arden PoncioNo ratings yet

- Reinforced Concrete Tilt Up Wall With Opening Panel Analysis Design ACI551Document42 pagesReinforced Concrete Tilt Up Wall With Opening Panel Analysis Design ACI551mikollimNo ratings yet

- Standard Rebar BendsDocument2 pagesStandard Rebar BendsEgyptian Researcher100% (1)

- CRSI Manual To Design RC Diaphragms - Part1Document4 pagesCRSI Manual To Design RC Diaphragms - Part1Adam Michael GreenNo ratings yet

- HHS Connection DesignDocument3 pagesHHS Connection Designwii2001No ratings yet

- Why Steel Reinforcement Is Needed in Concrete SlabsDocument2 pagesWhy Steel Reinforcement Is Needed in Concrete SlabsAuYongTheanSengNo ratings yet

- Plate Dowels: An Innovation Driven by Industrial Concrete PavingDocument6 pagesPlate Dowels: An Innovation Driven by Industrial Concrete PavingRizaam Nafiz100% (1)

- PCA - CI-Economical-Concrete-Formwork PDFDocument4 pagesPCA - CI-Economical-Concrete-Formwork PDFMIKHA2014No ratings yet

- Steel MembersDocument6 pagesSteel Membersalinaitwe shalifuNo ratings yet

- Let It Crack - tcm45-343570Document2 pagesLet It Crack - tcm45-343570Anonymous K7JMmMwNo ratings yet

- Reinforcing Steel Design GuideDocument18 pagesReinforcing Steel Design GuidewillchamNo ratings yet

- CRSI The Designer's ResponsibilityDocument16 pagesCRSI The Designer's ResponsibilityAdam Jones100% (1)

- Tesis Unvi MichiganDocument297 pagesTesis Unvi MichiganenucasNo ratings yet

- Stair DesignDocument12 pagesStair DesignErick Adrian Quintero JaramilloNo ratings yet

- Seismodynamics of An Underground Pipeline - M. Sh. Israilov PDFDocument6 pagesSeismodynamics of An Underground Pipeline - M. Sh. Israilov PDFErick Adrian Quintero JaramilloNo ratings yet

- Toyota - Prado - EBrochureDocument30 pagesToyota - Prado - EBrochureErick Adrian Quintero Jaramillo100% (1)

- Steel-Concrete Composite Coupling Beams - Behavior and DesignDocument11 pagesSteel-Concrete Composite Coupling Beams - Behavior and DesigncyrusnasiraiNo ratings yet

- Article - Concrete Cover at Rustications, Drip Grooves, and Formliners - CRSIDocument4 pagesArticle - Concrete Cover at Rustications, Drip Grooves, and Formliners - CRSIErick Adrian Quintero JaramilloNo ratings yet

- Article - Bar Detailing at Wall Openings - CRSIDocument5 pagesArticle - Bar Detailing at Wall Openings - CRSIErick Adrian Quintero Jaramillo100% (1)

- Types FootingsDocument9 pagesTypes Footingsivan bolañosNo ratings yet

- Retrofitting of Building Project ReportDocument144 pagesRetrofitting of Building Project ReportNisanth Thulasidas100% (1)

- PCI Bridge ManualDocument1,355 pagesPCI Bridge Manualsergio95% (21)

- Chequered DesignDocument2 pagesChequered DesignSaravana N100% (2)

- Bill of Quantity: PIU Name & No:-Project Implementation Unit 01, PRADHAN MANTRI GRAM SADAK YOJNA DANTEWADADocument5 pagesBill of Quantity: PIU Name & No:-Project Implementation Unit 01, PRADHAN MANTRI GRAM SADAK YOJNA DANTEWADALucky TraderNo ratings yet

- Under Reamed Piles - 1-10-09Document20 pagesUnder Reamed Piles - 1-10-09f100% (1)

- Neuro Solution For Damage Detection and Categorisation of Earthquake-Affected BuildingsDocument6 pagesNeuro Solution For Damage Detection and Categorisation of Earthquake-Affected BuildingsVinay PuraniNo ratings yet

- Variable Stress AnalysisDocument43 pagesVariable Stress AnalysisCayle MalitNo ratings yet

- Presentationfinal 181109153810 PDFDocument46 pagesPresentationfinal 181109153810 PDFZohaibShoukatBalochNo ratings yet

- HILTI ANALYSIS Based On Tensile and Shear (Hitungan Manual Sendiri)Document3 pagesHILTI ANALYSIS Based On Tensile and Shear (Hitungan Manual Sendiri)inti lestariNo ratings yet

- 100'x32' 3-Storeyed RCC BuildingDocument50 pages100'x32' 3-Storeyed RCC BuildingTu AungNo ratings yet

- Self Consolidating ConcreteDocument16 pagesSelf Consolidating ConcreteMikhaelo Alberti Dela CruzNo ratings yet

- Riyang Khola at 26.12.13Document8 pagesRiyang Khola at 26.12.13psycinNo ratings yet

- Bill of Materials Date:: Praject OwnerDocument1 pageBill of Materials Date:: Praject Ownerkenneth molina100% (1)

- Bridge Bearing & Expansion Joint PDFDocument222 pagesBridge Bearing & Expansion Joint PDFjageshwari100% (3)

- 101 Nozzle SlabDocument10 pages101 Nozzle SlabkarthiNo ratings yet

- AbutmentDocument8 pagesAbutmentuchennaNo ratings yet

- Unit 15 - Stability of Cantilever Retaining WallsDocument24 pagesUnit 15 - Stability of Cantilever Retaining WallsShahid KhanNo ratings yet

- TT - Key at F.S. 1.5 Is: Actual Force To Be Resisted byDocument25 pagesTT - Key at F.S. 1.5 Is: Actual Force To Be Resisted byGajula PavanNo ratings yet

- Structural Gen Notes and SpecsDocument1 pageStructural Gen Notes and SpecsMartin GragasinNo ratings yet

- Method of Construction Joint: Position of Casting ConnectionDocument4 pagesMethod of Construction Joint: Position of Casting ConnectioneviNo ratings yet

- Eccentric FootingDocument6 pagesEccentric FootingDhimas Surya NegaraNo ratings yet

- 1.3 Pit Excavation For Isolated Footing in Oridinary Soil: A-Substructure 1. Excavation and Earth WorkDocument65 pages1.3 Pit Excavation For Isolated Footing in Oridinary Soil: A-Substructure 1. Excavation and Earth Workmamuka kassaNo ratings yet

- Boq Minor BridgeDocument19 pagesBoq Minor Bridgechanakya0% (1)

- MOS For Demolition & Pile Extraction PDFDocument7 pagesMOS For Demolition & Pile Extraction PDFMin KhantNo ratings yet

- Steel Purlin DesignDocument5 pagesSteel Purlin DesigngelonocheNo ratings yet

- Final Project ALAPAN - Nabigh Nabiyl (25515305)Document50 pagesFinal Project ALAPAN - Nabigh Nabiyl (25515305)Nabigh NabiylNo ratings yet

- Construction Progress Report TemplateDocument11 pagesConstruction Progress Report TemplateJalil AhmedNo ratings yet