Professional Documents

Culture Documents

Temperature Controller

Temperature Controller

Uploaded by

zawmintun10 ratings0% found this document useful (0 votes)

10 views3 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

10 views3 pagesTemperature Controller

Temperature Controller

Uploaded by

zawmintun1Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 3

‘ome brewing can be a very

Hi erssrcrenccn"

itless expensive to brew wine

‘and beer at home, but depending

‘on how much time and effort one

puts into each batch, beverages of

excellent quality can be produced.

‘Al home brewers have their own

sectets to success, which they may

not be wiling to share. Two details

that most budding brewers tend fo

‘overlook have fo do with tempera-

ture and light. The bacteria responsi

ble for the fermenting process work

best at temperatures between 68°

‘and 75% Although it is a matter of

opinion as to what exact tempera-

ture is best, most brewers agree that

‘once a temperature is chosen it

should remain constant

The effect of light on fermenta-

tion has been debated among

brewers for the longest time. Itis the

author's opinion that it is best to

brew in the dark—especially for

‘wine. The obvious location for brew-

ing under those conditions is a clark

basement.

Unfortunately, most basements

are also too cod for effective fer-

mentation. Some form of controlled

One of the secrets of stc-

cessful home brewing of

wines and beers is a con-

stant temperature. Our

temperature-controlled

heater will keep the tem-

perature of your brews

precise and even!

heater would then be needed. One

method that has been tried is a

small cabinet just large enough to

hold the carboy (the é-gallon glass

jug used for brewing), a household

thermostat, ond a 60-watt light bulb.

The thermostat controls the light,

which heats the inside of the cabi-

net. Unfortunately, there are a cou-

pple of drawbacks to this. For one, the

bulb gives off light. You could wrap

the bulb in aluminum foil to cut

down on the light, but that would

decrease the bulb’s life. Even more

‘of a concen is the fact that a

household thermostat usually has a

“swing” of several degrees—per-

fectly fine for a comfortable home,

but not nearly accurate enough for

proper brewing,

The solution to those diemmas is

the Home-Brew Temperature Con-

troller presented here. This project

is relatively easy ond inexpensive

to build. The parts can be pur

chased for about $70 if you don't

have anything on hand already, The

electronics are simple enough that

the circuit can be constructed on

perfboard,

Designing a Heater. While the ci-

cuitry for a heater with temperature

feedback might seem to be on

almost trivial matter, there are sever-

al finer points fo keep in mind when

devising such a circuit, The set point

should be adjustable over a tem-

perature range of 68°-75°F. The

Tmaintained temperature should be

within 1 or 2 degrees of the set point

so that the system does not "chat-

ter” from rapid switching of the

heater’s power supply. Whatever

switching method is chosen should

be flexible enough to control differ-

ent types of loads such as fans or

lights. Choosing low-cost and read

yy-available components will help

[WON so1uoND9 ‘8661 YaveW

Electronics Now, March 1998

8

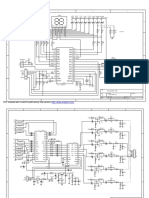

Fig. I. Although the schematic ofthe Home-Brew Temperature Controller might appear simple,

some sophisticted design work can be seen inthe temperaure-sensing portion ofthe circuit. For

safety considerations, the “hot” side ofthe supply line for the heater should be connected to RYI

and the neural is connected to R7.

4

Hy

4

B

Fig, 2. Here isan inside view ofthe author's Home Brew Temperature Controller Note the us of

{fiberglass PC board to insulate the large heating resistor from the metal case. The heating resistor

‘has also been placed near some ventilation holes and is located as far away from the rest ofthe ir

cuit as possible,

keep expenses to a reasonable

level

For the accuracy needed in this

project, a thermistor will be used to

sense temperature. That device is

inexpensive and small, and diferent

units can be selected depending

on the temperature range needed.

The one we will be using has a

negative thermal coefficient. That

means that as the temperature

increases, the thermistor’s resistance

wil decrease. The thermistor’s resis-

tances at some of the ternperatures

that we are interested in are listed in

Table 1

The thermistor will be used in a

resistor network so that the temper-

ature of the thermistor will generate

@ variable voltage. To provide the

“hysteresis” so that the circuit does

not chatter, we'll put an adaitional

resistance in parallel with the ther-

mmistor’s resistor network. That parallel

resistor will be switched so that it is

etther electrically across the thermis-

tor or across the adjustable set resis-

tor. When placed across the thermis-

fot the apparent temperature of

the thermistor will be higher be-

cause of Ohm's Law of resistors in

parallel. When placed in parallel

with the set-point resistor the appar-

ent setting will be changed in a sim-

ilar fashion. The values for the resis-

tors willbe chosen so that the circuit

wil switch off when the temperature

1s I°F above the set point and switch

‘on when the temperature drops to

1"F below the set point

With a digital signal that switches

‘when additional head Is called for,

the rest of the circuit Is smply a

relay that tums a heating element

on and off as needed.

Circuit Description. The schematic

of the Home-Brew Temperature

Controller is shown in Fig. 1. The tem

Perature-sensing thermistor is R8,

with R2 being the adjustment for the

temperature-set point. The values for

the combination of RI and R2 let

the set point be adjusted between

8200 ohms and 13,200 chms—cov-

eting the temperature range in

Which we are interested, Resistors

R3, Rd, and R5 make up the hystere-

sis resistance that will be switched

between RB and R2. The 640,000-

‘ohm value of the hysteresis resistors

wil change the apparent tempera-

ture being sensed by the circuit by

1*f An unusual design point is the

use of a CMOS inverter gate in its lin-

‘ear mode. The gate chosen for IC}

switches between tts logic-low and

logic-high outputs when the input

voltage is exactly one-half of the

device's supply voltage. The outputs

can also be very close to the actual

supply-voltage values.

The output of IC1-d drives Q1 so

that enough current can be sup-

plied to RY1.When the relay switch-

8 on, line current is supplied to R7.

2 100-watt power resistor, which

‘acts as the heating element. Power

for the circuit is supplied by IC2, a 5-

volt regulator,

Building the Heater. There are

many options when building any cir-

uit, even a relatively simple project

such as the Home-Brew Temp-

erature Controller, However, a few

cautions are in order. Care must

‘always be taken when using 120

volts AC in any project. With the

Home-Brew Temperature Controller,

PARTS LIST FOR THE

HOME-BREW TEMPERA-

TURE CONTROLLER

SEMICONDUCTORS

ICI—CD4049 Hex CMOS inverter,

integrated circu

1C2—7805 5-volt regulator,

circuit

D1, D2—1N4001, silicon diode

(QI-IRFZ34, MOSFET transistor

iegrated

RESISTORS

{All resistors are Ye-watt, 5% units

unless otherwise noted.)

RI—8200-ohm

R2—5000-ohm, potentiometer

3, R4—270,000-ohm,

R5—100,000-ohm

R6—3300-ohm

R7—250-ohm, 100-watt

R8—Thermistor, 10,000-ohm@25° C

(RadioShack 271-110 or similar)

CAPACITORS

CI—10-F, 25-WVDC, electrolytic

C2-4.7-uF, 25-WVDG, electrolytic

ADDITIONAL PARTS AND

MATERIALS:

RY1-—Single-pole, double-throw relay,

S-volt

9-volt DC wall adapter, case, line cord,

brackets for R7, wire, hardware, etc.

however, there is also an element

that will become hot, Take some

‘extra time to think about the place-

ment of the heating resstor within

‘the chassis, Any plastic part or wire

insulation that gets too close to the

heating resistor could melt. Also

make sure that all of the high-volt-

age connections are isolated in a

safe mannet. It is aso a good idea

that the unit’s metal chassis be

grounded and that a 1-amp fuse be

‘ited into the power line.

‘An example of the author's

arrangement is shown in Fig. 2. A

ventilated metal chassis that mea-

sures 17 inches by 11 inches by 3

inches houses the circuit. Heating

resistor R7 Is located on one side of

the cabinet, with the rest of the ci

cuitry located on the other side. The

resistoris also mounted on a sheet of

single-sided PC board material, The

board's fiberglass is a. good insulator

for both electricity and heat. The

heat insulation helps prevent the

top of the case from getting too hot

TABLE 1

‘Temperature

oF

oF

70°F

We

RF

73

wr

‘and becoming a bum hazard. ttcan

be seen that R7 is also mounted with

brackets that let air circulate all

round the resistor,

The temperatute-set resistor, R2, is

a PC-mounted trimpot. However,

it can also be a ponel-mounted

potentiometer on the outside of the

case. With that arrangement, ad-

justing the temperature becomes

much easier. Unfortunately, acc

dentally bumping the control can

just as easly change the tempera-

ture setting, so some type of protec-

tion or “lock-out” method would be

needed

Electrical power for the circuit is

provided by a 9-volt, 500-mA wall

adapter that has been tucked into

one corner of the case. Using a sur-

plus adapter can be less expensive

In terms of cost and construction

time over using a standard trans-

former, bridge rectifier, and fitter

capacitor,

The thermistor probe is best

made by soldering a pair of twisted

ites onto the device and shielding

the connections and thermistor

leads with two pieces of heat-shrink

tubing. suitable connector on the

other end of the wires should mate

with a jack mounted on the case,

‘One way to do that is to use spade

lugs on the probe wires and a dual

screw terminal on the case

To set up the Home-Brew Temp-

erature Controller fil a carboy with

water and place an accurate ther-

mometer in i. Set the corboy on the

heater in a room where the temper-

ature fs always lower than the tem-

peratures you will be needing—an

Unheated basement will do. Turn on

the heater. Over a period of several

days, the water will stabilize at a

particular temperature. Small

changes in the setting of R2 will

change the temperature that the

heater will maintain. If you used a

‘Thermistor Resistance

12,100 ohms

11,900 ohms

14,600 ohms

11,400 ohms

11,200 ohms

10,900 ohms

10,700 ohms

panel-mounted potentiometer for

2, you could mark the settings for

various temperatures. Once you

have set R2 for a particular temper-

ture you'd like to brew at, you're

ready fo mix your first batch of tem-

Perature-contioled brew.

With the adaition of the Home-

Brew Temperature Controller, the

quality and consistency of your

batches might improve. It will also

give you a warm feeling to know

that the heater is faithfully doing its

job! Q

4 SAVINGS

ERSere0. BONDS

Ee da

===] YOU CAN WIND

==" | your own coms?

‘There's no trick to it except

knowing what you are do-

ing. Ina unique, 106-page

book you can become ex-

pert in winding RF, IF

audio and power coils, chokes and trans

formers. Practically every type of col is dis-

‘cussed and necessary calculations are given

with the mathematical data simplified for

use by anyone. Get your copy today!

a |

Electronics Technology Today, nc.

P.O. Box 240

‘Massapequa Park, NY 11762-0240

Pease send me my copy of Col Desgn and

I

!

Woreocton Mara (0, ence a uckr

| etme oa coe feb co

!

!

I

J

‘and shipping-andhanding expenses. NY sate

residerts must ad local sales tx. I

tae as

seins maceinal

oy__ ao

Aorist be pa in US. ud ny. So

nord screed xe of san Canect.

Lrorlon ocr

‘MON sotompera ‘8664 YEW

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Introduction To Logic Circuits & Logic Design With VHDL, Second EditionDocument503 pagesIntroduction To Logic Circuits & Logic Design With VHDL, Second Editionzawmintun1100% (1)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- 1001 Solved Engineering Fundamentals Problems 3rd Edition by Michael R. LindeburgDocument901 pages1001 Solved Engineering Fundamentals Problems 3rd Edition by Michael R. Lindeburgzawmintun1No ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- DC Components Co., LTD.: Rectifier SpecialistsDocument2 pagesDC Components Co., LTD.: Rectifier Specialistszawmintun1No ratings yet

- Edm Psu Tl494 PCB BottomDocument1 pageEdm Psu Tl494 PCB Bottomzawmintun1No ratings yet

- Automotive Design and Production - January 2016Document52 pagesAutomotive Design and Production - January 2016zawmintun1No ratings yet

- Automotive Design and Production - April 2016Document60 pagesAutomotive Design and Production - April 2016zawmintun1No ratings yet

- X5ii X10iiDocument3 pagesX5ii X10iizawmintun1No ratings yet

- Automotive Design and Production - May 2016 PDFDocument60 pagesAutomotive Design and Production - May 2016 PDFzawmintun1No ratings yet

- Радиоконструктор 2017 06 PDFDocument48 pagesРадиоконструктор 2017 06 PDFzawmintun1No ratings yet

- Grigorash o V I DR Novaya Elementnaya Baza VozobnovlyaemykhDocument204 pagesGrigorash o V I DR Novaya Elementnaya Baza Vozobnovlyaemykhzawmintun1No ratings yet

- Circuit Collections 001-030Document30 pagesCircuit Collections 001-030zawmintun1No ratings yet

- Schematic Diagram Comparison To Find A Burnt Component Value PDFDocument5 pagesSchematic Diagram Comparison To Find A Burnt Component Value PDFzawmintun1No ratings yet

- Arduino TIAN Development Workshop - Agus Kurniawan PDFDocument121 pagesArduino TIAN Development Workshop - Agus Kurniawan PDFzawmintun1No ratings yet

- Test Flyback TransformerDocument8 pagesTest Flyback TransformerKailash RaoNo ratings yet

- Wzmacniacz Mocy Hifi 250W (Sinus) : Nowy Elektronik 107-KDocument3 pagesWzmacniacz Mocy Hifi 250W (Sinus) : Nowy Elektronik 107-Kzawmintun1No ratings yet

- 119 - ก.10200 TEL.02-22159995,02-2253282 Fax:02-2257682 WebsiteDocument2 pages119 - ก.10200 TEL.02-22159995,02-2253282 Fax:02-2257682 Websitezawmintun1No ratings yet

- Linear Opto IsolatorsDocument105 pagesLinear Opto Isolatorszawmintun1No ratings yet