Professional Documents

Culture Documents

Synthesis of Ziegler-Natta Catalyst Using Malaysian Ilmenite Derived Ticl Via Recrystallization Method: A Statistical Approach

Uploaded by

Salsa NisaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Synthesis of Ziegler-Natta Catalyst Using Malaysian Ilmenite Derived Ticl Via Recrystallization Method: A Statistical Approach

Uploaded by

Salsa NisaCopyright:

Available Formats

Available online at BCREC website: https://bcrec.

id

Bulletin of Chemical Reaction Engineering & Catalysis, 15 (3) 2020, 687-697

Research Article

Synthesis of Ziegler-Natta Catalyst using Malaysian

Ilmenite Derived TiCl4 via Recrystallization Method: A

Statistical Approach

Sanjith Udayakumar, Najwa Ibrahim, Chan Yong Chien, Shaik Abdul Rahman,

Ahmad Fauzi Mohd Noor, Sivakumar Ramakrishnan*

School of Materials and Mineral Resources Engineering, Universiti Sains Malaysia,

14300, Nibong Tebal, Penang, Malaysia

Received: 18th June 2020; Revised: 11st August 2020; Accepted: 13rd August 2020;

Available online: 19th September 2020; Published regularly: December 2020

Abstract

In the current study, Ziegler-Natta (Z-N) catalyst was synthesized via recrystallization method using MgCl2

as a support, AlCl3 as an activator and TiCl4 as a transition metal source. The TiCl4 used in the study was

derived from Malaysian ilmenite through a sequential pyrometallurgical and hydrometallurgical process of

ilmenite concentrate conversion to TiCl4. The recrystallization method of synthesis of the heterogeneous Z-N

catalyst was studied by varying the synthesis parameters, such as the combined amount of MgCl2 and AlCl3,

temperature, and amount of TiCl4, using statistical design of experiments. The investigation aimed at deter-

mining the best conditions for synthesizing the heterogeneous Z-N catalyst. The synthesis conditions posed a

significant influence on the Ti content present in the catalyst product. The morphological and elemental

analysis of SEM-EDX showed good spherical nature of the prepared catalysts. The XRD phase analysis de-

tected the peaks of MgCl2, MgCl2-Ethanol, MgCl2/TiClx, and TiO2. The IR spectra confirmed the presence of

the Mg-Cl bond at 1635 cm−1 and Ti-Cl bonds at 602 cm-1 and 498 cm-1. The produced catalyst contained a

small amount of TiO2, which could be due to the seepage of moisture during the analysis or storage of the

sample. The most favourable combination of the studied parameters was determined based on the Ti content

in the catalyst product. Therefore, the best conditions for synthesizing the heterogeneous Z-N catalyst with

high Ti content (181.1 mg/L) was at a combined amount of 2 g of MgCl 2 for 6 g of AlCl3, crystallization tem-

perature of 80 °C, and 2 mL dosage of TiCl4. Copyright © 2020 BCREC Group. All rights reserved

Keywords: Malaysian ilmenite; Ziegler-Natta catalyst; Recrystallization method; TiCl4; statistical design of

experiments

How to Cite: Udayakumar, S., Ibrahim, N., Chien, C.Y., Rahman, S.A., Noor, A.F.M., Ramakrishnan, S.

(2020). Synthesis of Ziegler-Natta Catalyst using Malaysian Ilmenite Derived TiCl4 via Recrystallization

Method: A Statistical Approach. Bulletin of Chemical Reaction Engineering & Catalysis, 15(3), 687-697

(doi:10.9767/bcrec.15.3.8195.687-697)

Permalink/DOI: https://doi.org/10.9767/bcrec.15.3.8195.687-697

1. Introduction tion of millions of tons of polyolefins annually

[1,2]. These heterogeneous catalysts enable the

The Ziegler-Natta (Z-N) catalysts have been

production of polymer materials with specific

widely used in olefin polymerization systems

tacticity and broad molecular weight distribu-

and are responsible for the industrial produc-

tion, demonstrating the presence of multiple ac-

tive sites in their structure [2]. Polypropylene

* Corresponding Author. and polyethylene, the two polymers that have

E-mail: srsivakumar@usm.my (S. Ramakrishnan)

bcrec_8195_2020 Copyright © 2020, BCREC, ISSN 1978-2993; CODEN: BCRECO

Bulletin of Chemical Reaction Engineering & Catalysis, 15 (3), 2020, 688

widespread applications, are most often pro- the TiOxCyNz at lower temperatures less than

duced with Z-N catalysts. These catalysts usu- 500 °C [26]. Preliminary studies on the reduc-

ally contain a carrier or support, such as: tion and nitridation of Malaysian ilmenite in

MgCl2, electron donors (Lewis bases), TiCl4 ac- H2-N2 and N2 have been carried out [27-28].

tive species, and a co-catalyst (alkyl alumini- Pure TiCl4 liquid was produced by chlorinating

um) [3-7]. One of the important criteria for a the TiOxCyNz after the removal of Fe in the re-

good catalyst is the surface structure of the duced ilmenite by aeration leaching (Becher’s

support component. Heterogeneous Z–N cata- process) [29,30]. Synthesizing TiCl4 or TiCl3 by

lysts with MgCl2 support have greatly im- this new method at low temperatures not only

proved the activity and stereospecificity of cata- prevents impurities from being chlorinated,

lysts, leading to substantial simplifications in but also saves on energy consumption

polyolefin production processes [8,9]. Several [27,31,32].

methods using activated MgCl2 as the support The study explores the possibility of synthe-

or carrier in the synthesis of Z-N catalyst have sizing the Z-N catalyst by utilizing the TiCl4

been proposed [4,8,10,11]. produced from ilmenite. Conventionally, TiCl 4,

Generally, MgCl2 is mechanically or chemi- the precursor for producing the catalyst, is re-

cally treated to become structurally disordered quired to be obtained of high purity after a se-

with more active centers on the surface, or may ries of intensive pyrometallurgical and separa-

remain in its crystalline state as well [3,8,11- tion processes. There is much difficulty in con-

13]. MgCl2-ethanol adducts have also been trolling the impurities, as the metallic impuri-

gaining the privilege as effective Z-N supports, ties might get chlorinated due to the high tem-

since these adducts tend to lose the alcohol perature of the chlorination process. However,

group on interacting with TiCl4, thereby result- in this study, TiCl4 derived from Malaysian il-

ing in a high surface area [14-16]. Other sup- menite through a low-temperature cost-

ports have also been used in the synthesis of Z- effective method is used for the synthesis.

N catalysts, such as: MgCl2/tetrahydrofuran Since the Ti compound is originated from ni-

(THF) complexes that are reported with good trided ilmenite, it will have traces of impuri-

catalytic activity [17]. The recrystallization ties, such as FeCl3, AlCl3, VCl4, and NbCl5 af-

method of Z-N catalyst synthesis using ter the chlorination process, while most of the

TiCl4/TiCl3 has also been an industrially recog- impurities might not have chlorinated at low

nized process for the catalysis of the commer- temperatures. By examining the effect of impu-

cial polymerization process [5, 18]. This method rities on the production of the Z-N catalyst, di-

involves the solubilization of MgCl2 in organic rectly from the chlorinated product, the elimi-

media (R-OH) and the recrystallization of nation of an intensive purification process can

MgCl2 from the solution, and the newly gener- be achieved. The low-cost low-temperature

ated porous MgCl2 belongs to a γ-type MgCl2 method facilitates the production of TiCl4 from

crystal structure, which is much better in sup- local Malaysian ilmenite, which is then treated

porting TiCl4 [11,19]. Different conditions of with MgCl 2 -ethanol adduct to form

the recrystallization process, such as recrystal- TiCl4/MgCl2/Al-Et3 Z-N catalyst. This will sub-

lization temperature, amount of co-catalyst, sequently make the production of the Z-N cata-

amount of MgCl2, and the ratio of Mg/Ti have lyst more economical and energy-efficient than

been investigated so far [5,6,11,18-21]. the current industrial practices, thereby

The preparation of Z-N catalyst involves the adding more value to Malaysian ilmenite.

reaction between compounds of transition ele- Moreover, the synthesized TiCl4 based Z-N

ments of groups IV to VIII (titanium, vanadium catalyst has potential applications in the pro-

or zirconium halides) and compounds, such as duction of high-density polyethylene (HDPE)

the hydrides or alkyls of groups I-III, for in- through the Zieglar Natta process and

stance, LiEt3, BeEt3, AlEt3 or AlEt2Cl [1,22,23]. polymerization of ethylene gas into polypropyl-

TiCl4-based Z-N catalysts have been the com- ene plastics. In the study, the heterogeneous Z-

mercially preferred catalysts owing to their N catalysts were synthesized using the locally-

good catalytic performance [23-25]. The signifi- made TiCl4 and MgCl2 support by recrystalliza-

cant cost portion for producing the Ti-based Z- tion process, wherein the effects of the total

N catalyst is the production of TiCl4 itself. One amount of MgCl2 and AlCl3, recrystallization

way to tackle this problem is to synthesize tita- temperature and amount of TiCl4 were investi-

nium oxycarbonitride (TiOxCyNz), produced by gated. According to the amount of Ti in the

the carbothermal reduction-nitridation of il- catalyst synthesized for different experiments

menite as the raw material, then chlorinating considered based on the factorial design, the

Copyright © 2020, BCREC, ISSN 1978-2993

Bulletin of Chemical Reaction Engineering & Catalysis, 15 (3), 2020, 689

most favourable conditions for the synthesis of ite derived TiCl4 was added to the mixture and

the ZN catalyst were established. The effects of was stirred for 2 hours at room temperature.

the different studied parameters on the synthe- TiCl4 was added to the mixture after passing

sis outcome were evaluated. The resulting cata- through a bottle of phosphorous pentoxide

lyst was also characterized to study the surface (P2O5) in order to absorb the moisture present.

morphology, bonding nature, and phases of the The entire sequence of processes was carried

active catalytic components and the effect of out in inert conditions. The sample was washed

impurities on the synthesis of the catalyst. several times with n-heptane and filtered to ob-

tain the recrystallized sample. The wet recrys-

2. Materials and Methods tallized sample was subsequently dried in Ar

atmosphere at 70 °C.

2.1 Chemicals

The main highlight of the study is the use of 2.3 Factorial Design of Experiments -

TiCl4 produced from Malaysian ilmenite for the Recrystallization Method

preparation of the catalyst. Malaysian ilmenite A fully randomized factorial 23 design was

is converted to titanium oxycarbonitride applied for the statistical evaluation of differ-

(Fe-TiOxCyNz) in the first phase by carbother- ent factors influencing the recrystallization

mal reduction and nitridation process in the process of Z-N catalyst synthesis. The chosen

H2-N2 atmosphere, followed by the removal of factors and their levels for the study are given

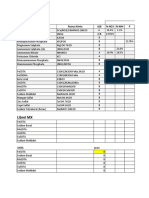

iron impurities through Becher’s process and in Table 2. The effect of the three factors on the

the chlorination of TiOxCyNz to form titanium response variable for the process, i.e. the

tetrachloride (TiCl4). All other chemical rea- amount of Ti in the catalyst was studied. Local

gents were of analytical grade. The chemicals optimization was carried out for the parame-

used in the research with information on their ters within the studied range of levels.

sources, specifications, and purposes are tabu-

lated in Table 1. 2.4 Characterization of Synthesized Catalyst

2.2 Preparation of Catalyst The elemental analysis of TiCl4 derived

from Malaysian ilmenite was conducted using

The heterogeneous Ziegler-Natta (Z-N) cata-

lyst was prepared by the recrystallization

method [6,10,11], i.e. reacting TiCl4 with

MgCl2-ethanol adduct and AlCl3. The 2 g of an- Table 2. Z-N catalyst synthesis: factors and

hydrous MgCl2 was added to 100 mL of n- their levels.

heptane, and 3 mL of ethanol (95%) was added

to the mixture dropwise. This mixture was Factors Unit High Low

stirred at 400 rpm at room temperature until

MgCl2 was completely dissolved in 2 hours. Total amount of MgCl2 g 8 1

-and AlCl3 (Ratio 1:3)

Then, 6 g of anhydrous AlCl3 was added to the

prepared homogeneous solution and agitated Recrystallization tem- °C 80 100

for 2 hours at 80 °C. The hot mixture was al- perature

lowed to naturally cool down to room tempera-

ture. Thereafter, the 2 mL of Malaysian ilmen- Amount of TiCl4 mL 2 5

Table 1. Raw materials and chemicals: specifications and purpose

Materials Specifications Purpose

Titanium tetrachloride (TiCl4) 97.24% purity Source of Ti compound

from Malaysian ilmenite

Anhydrous magnesium chloride (MgCl2) Solid Catalyst support

Anhydrous aluminium chloride (AlCl3) Powder Co-catalyst feed

Ethanol 95% Organic solvent/ washing agent

n-Heptane (dry) Liquid Solvent

Phosphorous pentoxide (P2O5) Powder Moisture absorbent

Argon gas Gas Inert atmosphere

Copyright © 2020, BCREC, ISSN 1978-2993

Bulletin of Chemical Reaction Engineering & Catalysis, 15 (3), 2020, 690

Inductively Coupled Plasma-Optical Emission of titanium oxycarbonitride samples obtained

Spectroscopy (ICP-OES, Perkin Elmer). The from carbothermal reduction and nitridation

synthesized catalyst particles were character- was performed at a temperature of about 400-

ized using X-ray diffraction (XRD, Bruker D8 500 °C for 1-3 hours. The final product of this

Advance) instrument equipped with a Cu- process was a combination of TiCl4 and TiCl3.

anode and Kα radiation (λ = 154 Å) to deter- The produced TiCl4 was 97.24% pure. The ele-

mine the crystalline phases of samples. The mental analysis results from ICP-OES for the

x-ray scan was run for a 2θ range of 10-80° solution derived from Malaysian ilmenite are

operated at 40 mA and 40 kV. ICP-OES was presented in Table 3.

also used to determine the amount of Ti pre- From Table 3, the purity of the author’s

sent in the catalyst precursors. The morphology synthesized TiCl4 was lower than that of the

and elemental analysis of the solid catalyst laboratory grade TiCl4 because the synthesized

particles were examined using Scanning Elec- sample has not been run through an extensive

tron Microscopy equipped with Energy- distillation process, unlike the laboratory-

dispersive X-ray spectroscopy (SEM-EDS, grade TiCl4, which follows a sequential distilla-

Quanta FEG 450 Oxford Instruments). Fourier tion process of purification. The dominant im-

Transform Infrared (FTIR, Perkin Elmer) purities that may involve in the Z-N catalyst

analysis was also conducted with a resolution synthesis process are Fe, Va, Al, Cr, W, and

of 2 cm-1 for eight scans over a wave‐number some REEs. The study will help to understand

the efficiency of using the TiCl4 derived from

range of 4000–400 cm−1 to investigate the bond-

Malaysian ilmenite and promote the use of

ing nature of the different catalyst components.

cost-effective TiCl4 produced from the low-

temperature chlorination method for the

3. Results and Discussions heterogeneous Z-N catalyst synthesis. Addi-

3.1 Characterization of Malaysian Ilmenite tional qualitative characterization of the TiCl 4

Derived TiCl4 solution has been published elsewhere [33].

In this research, TiCl4 was prepared from 3.2 Design of Experiment (DOE) Analysis

nitrided local Malaysian ilmenite. Chlorination

The results of the factorial design for the re-

crystallization method of ZN catalyst synthesis

are shown in Table 4. Based on the results, the

Table 3. Comparison of the elemental distribu- highest content of Ti was obtained for Run 8 (2

tion of synthesized TiCl4 product with commer- g of MgCl2, 6 g of AlCl3, -crystallization temper-

cial TiCl4 ature of 80 °C, and 2 mL dosage of TiCl 4)

Concentration, ppm whereas the lowest amount of Ti was obtained

for Run 7 (4 g of MgCl2, 12 g of AlCl3,

Element Laboratory Synthesized

-crystallization temperature of 100 °C, and 5

grade TiCl4 TiCl4

mL dosage of TiCl4). The amount of Ti obtained

Ti 414,000 388,060 for different samples directly corresponds to

Fe 16.1 7.2 the Ti present in the synthesized catalysts.

Mn 0.3 0.14 There is a considerable difference in the

Al 5.3 9.6 amount of Ti between the conditions of the

Cr 1.5 2.1 highest and lowest runs. Moreover, the analy-

Mo 0.7 1.9 sis indicated a degree of favorability of the

Nb 3700 3003 studied recrystallization conditions towards

Ta 1.9 2.6 the maximum yield of the catalyst.

V - - The main effects plot helps in identifying

W - 6.5 the levels for the recrystallization process for

Zr - 0.15 which there is the most desired outcome, i.e. Ti

content in the catalyst. Figure 1 shows the dif-

Ce 0.3 0.14

ferences in the Ti content for different condi-

Dy - -

tions of process parameters evaluated in the

Gd 5.4 4.6 study. While the factors such as the total

La - 1.2 amount of MgCl2 and AlCl3, and the amount of

Lu - 0.81 TiCl4 had significant effects as denoted by the

Ge 2.5 3.4 steeper lines of the effects plot, recrystalliza-

Purity (%) 99.10 97.24 tion temperature had a relatively lesser contri-

Copyright © 2020, BCREC, ISSN 1978-2993

Bulletin of Chemical Reaction Engineering & Catalysis, 15 (3), 2020, 691

bution to the amount of Ti in the synthesized (a)

catalyst. From the main effects plot, it is evi-

dent that lower crystallization temperature

and higher amounts of MgCl2 -AlCl3 and TiCl4

feed solution favoured the increase in the

amount of Ti in the catalyst. Therefore, it can

be claimed that in the studied range of the pro-

cess parameters of recrystallization method, a

combined amount of 2 g of MgCl2 for 6 g of

AlCl3, crystallization temperature of 80 °C, and

2 mL dosage of TiCl4 is the optimal combina-

tion to synthesize a larger amount of catalyst.

The contour plots are one way of represent-

ing the effects of the interaction of the factors (b)

on the studied response. Figures 2a-c show the

colour gradient of the variation of response, i.e.

within the range of process parameters studied.

The darkest zone of the contour indicates the

effects of the interacting parameters resulting

in the most desirable level of response. From

the contour plots for interaction in Figures 2 (a)

and 2 (c), a non-linear gradient of contour indi-

cates an intricate relationship of the interact-

ing factors. It can be noted that an increase in

the amount of Ti is more favourable with a

lower temperature, lower amount of TiCl4, and

(c)

Figure 2. Contour plots of Ti content for 2-way

interaction of three factors. (a) Ti content vs

Temperature, Total amount of MgCl2 and AlCl3,

Figure 1. Main effects plot for Ti content in the (b) TiCl4, Total amount of MgCl2 and AlCl3, (c)

synthesized catalyst Ti content (mg/L) vs TiCl4, Temperature.

Table 4. DOE table and responses: recrystallization method of Z-N synthesis

Factor A: Factor B: Tem- Factor C: Response:

Run MgCl2 AlCl3

Total amount of perature Amount of Ti content

order (g) (g)

MgCl2 and AlCl3 (g) (°C) TiCl4 (mL) (mg/L)

1 4 12 16 80 2 81.81

2 4 12 16 80 5 38.79

3 2 6 8 100 2 108

4 2 6 8 80 5 100.5

5 2 6 8 100 5 71.13

6 4 12 16 100 2 78.04

7 4 12 16 100 5 30.36

8 2 6 8 80 2 181.8

Copyright © 2020, BCREC, ISSN 1978-2993

Bulletin of Chemical Reaction Engineering & Catalysis, 15 (3), 2020, 692

lower total amount of MgCl2 and AlCl3. In ly dissolved in alcohols, and during quick pre-

Figure 2 (b), the contour exhibits a relatively cipitation, many defects are produced in MgCl 2

linear-gradient trend, also suggesting that the and lead to a porous structure [11,14]. TiCl 3

lower levels of the factors contributed towards peaks were observed as minor phases with

higher Ti amounts in the catalyst. Moreover, some peaks also corresponding to TiO2, which

additional experiments could help the study to could be due to the oxidation of TiCl4 as a re-

reveal the basis and significance behind the na- sult of moisture seepage during the synthesis

ture of the indicated interactions. or storage of samples. For a Z-N catalyst to

have a good performance, the Ti must form a

3.3 XRD Studies complex with the MgCl2-ethanol adduct. The

formation of complex favours the unstable na-

The different phases of the synthesized com-

ture of the catalysts during the polymerization

pounds were characterized using XRD analysis,

reaction. In addition, the formed complex is not

as shown in Figure 3. Since the catalyst syn-

easily washed away during washing and, as a

thesis comprised several components, it was

result, leads to higher Ti content in the synthe-

not possible to detect and identify the phases

sized catalysts. For Run 8 sample, crystalline

accurately. The XRD spectra were character-

peaks were prominent, which could be due to

ized by several reflections, which are due to the

the α- and/or β-MgCl2 dominating the composi-

formation of several complexes between the

tion of the catalyst. Nevertheless, the broad

main catalyst element Ti, co-catalyst Al, and

peaks indicate the structurally disordered

MgCl2 support with organic groups. Based on

MgCl2 undergoing titanation [35]. On the con-

previous diffraction studies of Z-N, the notable

trary, the diffraction pattern of Run 7 was

peaks in the synthesized catalyst compounds

dominated by phases of MgCl2, which means

are MgCl2, MgCl2/TiClx, MgEtOH, and uniden-

that the adduct formation is incomplete as a

tified complexes of Ti. The diffractogram of the

result of which the titanation might not occur

catalyst with the highest amount of Ti is shown

[14,21]. Also, there were no amorphous charac-

in Figure 3 (Run 8). The diffractogram has

teristics or broad peaks in the spectrum. i.e.

characteristic peaks of MgCl2 at 2θ = 15ׄ°, 30°,

the amount of disordered γ-MgCl2 is low. In

35°, 50°, and 55° [6,14,34]. The additional re-

that case, the TiCl4 remains unreacted might

flections between 11° to 30° might probably be

get oxidized due to the exposure to the OH -

due to the formation of the Ti complexes during

group of the residual alcohol, forming TiO 2.

the synthesis of the catalyst [17]. MgCl2 is easi-

Apart from the above observations, no other

impurity phases, like FeCl3, AlCl3, VCl4, and

NbCl5, were noticed in the diffraction studies.

3.4 FTIR Analysis

The synthesized Z-N catalyst using Malay-

sian ilmenite derived TiCl4 was further charac-

terized using the FTIR analysis. The FTIR

spectra obtained from two different samples,

namely Run 8 and Run 7, corresponding to the

highest and lowest amounts of Ti have been

compared in Figure 4. From Figure 4, it can be

noted that both the spectra are quite identical

except for a few positional differences in the

absorption peaks. The progress of the reaction

is possible to be tracked by observing the band

between 3000-3500 cm-1, as the band primarily

appears as a result of the -OH bond due to the

addition of ethanol for the preparation of the

MgCl2-ethanol adduct. This absorption band

arises from adsorbed H2O on the active MgCl2

carrier; therefore, the adsorbed moisture may

not favour the oxidation of the TiCl4 to form

Ti-O or Ti-O-H groups. However, the final reac-

tion product after the time of a complete reac-

Figure 3. XRD patterns of synthesized Z-N

tion may also exhibit this broad band due to

catalysts (Run 8 and Run 7).

Copyright © 2020, BCREC, ISSN 1978-2993

Bulletin of Chemical Reaction Engineering & Catalysis, 15 (3), 2020, 693

the presence of moisture or unreacted alcohol on the impurities which is due to their low con-

in the reaction mixture. Generally, the nature centrations (Fe, Al, Nb, Va).

of TiCl4 is relatively less reactive with alcohol

compared to the Al-Et compound in the mix- 3.5 Morphological Analysis

ture. Mild inflections were noticed in the spec-

The morphology of the synthesized catalysts

tra between 2000-2500 cm-1, usually ascribed to

based on conditions of Run 8 and Run 7 are

the absorbed CO2 and C-H bond of the

presented in Figures 5 and 6, respectively. The

n-heptane, used to dissolve the MgCl2 to form

SEM images characterize the physical nature

the adduct. Additionally, two hydrocarbon ab-

and appearance of the catalysts, as the changes

sorptions were observed at 1384 cm-1 and 1326

in the synthesis conditions of the catalyst tends

cm-1, which may also correspond to the

to cause changes in their morphology.

n-heptane. A strong peak at 1634 cm-1 is evi-

Agglomerated spherical structures (highlighted

dent, which is due to the moisture-present

in the white box) were observed in the SEM

MgCl2. Another peak at 602 cm-1, which can be

micrographs of the catalyst obtained in Run 8

corresponded to the MgCl2-TiCl3 or the MgCl2-

(Figure 5). On physical observation, the size of

EtAl(OR)2 group, was also observed. The Al-

the spherical structures was in between the

alkyl group showed weak absorption at 1173

range of 1-1.5 µm. Figures 5 (a) and (b) display

cm−1, and a mild inflection at 910 cm-1. The

masses of spherical particles, which is

main absorption peaks of Ti-Cl were identified

corresponded to the MgCl2-ethanol adducts.

at 602 cm-1 and 498 cm-1, which were weaker,

Generally, the removal of alcohol from the

but were the only possible indicators of Ti pres-

MgCl2 adducts makes the surface of the cata-

ence in the catalyst. While the spectra of Run 8

lyst porous [36]. The surface heterogeneity and

exhibited the presence of Ti, Run 7 was not ob-

porosity of the catalyst structures were not pre-

served of any notable Ti peaks, which could be

cisely observable, but on comparing the micro-

due to the lower content of Ti in the catalyst.

graphs of the synthesized catalysts in Run 8

Since the catalyst was prepared using the TiCl 4

and Run 7, the morphological differences were

derived from Malaysian ilmenite, the role of

evident. For Run 7 (Figures 6 (a) and (b)), the

impurities is expected to be influential in

surface was fragmented and composed of

affecting the synthesis process; however, the

cracks. The distribution of the spherical cata-

FTIR analysis did not reveal any information

lyst structures in the image was very sparse.

Figure 4. FTIR spectra of the synthesized catalysts: Run 8 (highest amount of Ti content) and Run 7

(lowest amount of Ti content)

Copyright © 2020, BCREC, ISSN 1978-2993

Bulletin of Chemical Reaction Engineering & Catalysis, 15 (3), 2020, 694

A good catalyst comprises a porous and smaller inert medium under vigorous stirring, spheri-

sphere of the catalyst particles, such that the cal droplets will be formed because of surface

polymers produced during the catalytic activity tension. However, the absorption of humidity

tend to replicate the shape of the catalyst parti- or poor purity of the reagents may affect the

cles [6,10]. In order to synthesize a catalyst morphology of the final adduct obtained [8,36].

with high catalytic efficiency, it is essential to The amount of ethanol added during the for-

understand the conditions underlying the for- mation of MgCl2 adducts is crucial in determin-

mation of MgCl2 support. Usually, when a ing the stability and reactive nature of the

solvate of MgCl2 in ethanol is dispersed in the catalysts as well as the polymer. Besides, the

triethyl aluminium (C2H5Al), which is the co-

catalyst, is influential in regulating the surface

area of the catalyst particles.

Elemental analysis of the solid catalyst par-

ticles complemented the morphological

findings, wherein the spherical particles

showed the presence of Ti, Cl, Mg, and Al. The

composition of the identified elements differed

between the catalyst samples; however, no

foreign elements were observed. Figure 7

shows the EDS spectra and composition at two

points of the catalyst sample Run 8 from Fig-

ure 5 (c). Thus, no impurities or impurity

Figure 5. SEM micrographs of catalyst for Run Figure 6. SEM micrographs of catalyst for

8 (highest Ti content) at different magnifications Run 7 (lowest Ti content)

Copyright © 2020, BCREC, ISSN 1978-2993

Bulletin of Chemical Reaction Engineering & Catalysis, 15 (3), 2020, 695

Figure 7. EDS analysis of the synthesized catalyst (Run 8) at (a) point A and (b) point B marked in

Figure 5 (c).

effects were observed during the morphological The spherical morphology of the catalyst parti-

analysis of the catalyst, thereby approving the cles was observed from the SEM analysis. The

successful use of TiCl4 derived from Malaysian concentrations of impurities like Fe, Va, Al,

ilmenite as a promising source of Ti for the syn- and W were undetected by EDS analysis or

thesis of Z-N catalysts. were very low to affect the synthesis process

and the output. Thus, the findings of the re-

4. Conclusions search will open gateways for using Malaysian

ilmenite derived TiCl4 as a potential replace-

Heterogeneous Ziegler-Natta catalyst was

ment to the currently imported TiCl4 for poly-

successfully synthesized via the recrystalliza-

mer-based industries.

tion method using TiCl4 derived from Malaysi-

an ilmenite. The TiCl4 produced from the chlo-

Conflict of Interest

rination of carbothermally reduced ilmenite

was found to be 97.24% pure. Using this TiCl 4 On behalf of all authors, the corresponding

as the source of Ti compound, the synthesis of author states that there is no conflict of inter-

the Z-N catalyst was studied using a factorial est.

design of experiments by varying the combined

amount of MgCl2 and AlCl3, the recrystalliza- Acknowledgments

tion temperature, and amount of TiCl4. The

The authors gratefully acknowledge the fi-

highest amount of Ti (181.1 mg/L in the synthe-

nancial support from Universiti Sains Malay-

sized catalyst was obtained for a combined

sia (USM) Bridging Special Grant 2017(No.

amount of 2 g of MgCl2 for 6 g of AlCl3, crystal-

304/PBAHAN/631693). The authors express

lization temperature of 80 °C, and 2 mL dosage

their gratitude to Dr. Sheikh Abdul Rezan,

of TiCl4. The XRD results revealed major phas-

School of Materials and Mineral Resources En-

es like MgCl2, MgCl2/TiClx compounds and Ti

gineering, USM, for his support and technical

based complexes. A broad peak was present in

advice. Special thanks to USM technicians Mr.

the spectrum of the sample with high Ti con-

Shahrul, Mr. Syafiq, and Mr. Azrul for sup-

tent, which denotes the presence of structurally

porting the experimental work.

distorted MgCl2 in the process of titanation.

Copyright © 2020, BCREC, ISSN 1978-2993

Bulletin of Chemical Reaction Engineering & Catalysis, 15 (3), 2020, 696

References crystallites: synthesis and characterization.

Iranian Polymer Journal, 25(4), 321-337.

[1] Vaughan, A., Davis, D., Hagadorn, J., Sal-

wani, M. (2017). Industrial catalysts for al- [12] Huang, R., Malizia, F., Pennini, G., Koning,

kene polymerization. In Polymer Science: A C.E., Chadwick, J.C. (2008). Effects of MgCl2

Comprehensive Reference (Vol. 3, pp. 657-672): crystallographic structure on active centre

Elsevier. formation in immobilized single‐centre and

Ziegler–Natta catalysts for ethylene

[2] Galli, P., Vecellio, G. (2001). Technology: driv-

ing force behind innovation and growth of pol- polymerization. Macromolecular Rapid Com-

yolefins. Progress in Polymer Science, 26(8), munications, 29(21), 1732-1738.

1287-1336. [13] Makwana, U., Naik, D.G., Singh, G., Patel,

[3] Correa, A., Credendino, R., Pater, J.T., Mori- V., Patil, H.R., Gupta, V.K. (2009). Nature of

ni, G., Cavallo, L. (2012). Theoretical Investi- phthalates as internal donors in high perfor-

gation of Active Sites at the Corners of MgCl2 mance MgCl2 supported titanium catalysts.

Crystallites in Supported Ziegler–Natta Cata- Catalysis letters, 131(3-4), 624-631.

lysts. Macromolecules, 45(9), 3695-3701. [14] Thushara, K., Ajithkumar, T., Rajamohanan,

[4] Chen, Y.-P., Fan, Z.-Q. (2006). Ethylene/1- P., Gopinath, C.S. (2014). Structural investi-

hexene copolymerization with gations of porous MgCl2–2-butanol molecular

TiCl4/MgCl2/AlCl3 catalyst in the presence of adduct as support for olefin polymerization.

hydrogen. European Polymer Journal, 42(10), Applied Catalysis A: General, 469, 267-274.

2441-2449. [15] Thushara, K., Gnanakumar, E.S., Mathew,

[5] Parada, A., Rajmankina, T., Chirinos, J., Mo- R., Jha, R.K., Ajithkumar, T., Rajamohanan,

rillo, A. (2002). Influence of support recrystal- P., Sarma, K., Padmanabhan, S., Bhaduri, S.,

lization techniques on catalyst performance in Gopinath, C.S. (2010). Toward an Under-

olefin polymerization. European Polymer standing of the Molecular Level Properties of

Ziegler−Natta Catalyst Support with and

Journal, 38(10), 2093-2099.

without the Internal Electron Donor. The

[6] Pokasermsong, P., Praserthdam, P. (2009). Journal of Physical Chemistry C, 115(5),

Comparison of activity of Ziegler-Natta cata- 1952-1960.

lysts prepared by recrystallization and chemi-

cal reaction methods towards polymerization [16] Czaja, K., Bialek, M. (2000). The role of mag-

of ethylene. Engineering Journal, 13(1), 57- nesium chloride as support for Ziegler-Natta

64. catalysts. Polimery, 45(9), 608-613.

[7] Tornqvist, E., Richardson, J., Wilchinsky, Z., [17] Pirinen, S., Jayaratne, K., Denifl, P., Pak-

Looney, R. (1967). Solid solution formation in kanen, T.T. (2014). Ziegler–Natta catalysts

the TiCl3-AlCl3 system. Journal of Catalysis, supported on crystalline and amorphous

8(2), 189-196. MgCl2/THF complexes. Journal of Molecular

Catalysis A: Chemical, 395, 434-439.

[8] Ye, Z.Y., Wang, L., Feng, L.F., Gu, X.P., Chen,

H.H., Zhang, P.Y., Pan, J., Jiang, S., Feng, [18] Parada, A., Rajmankina, T., Chirinos, J.

L.X. (2002). Novel spherical Ziegler–Natta (1999). Study of the MgCl2 recrystallization

catalyst for polymerization and copolymeriza- conditions on Ziegler-Natta catalyst proper-

tion. I. Spherical MgCl2 support. Journal of ties. Polymer Bulletin, 43(2-3), 231-238.

Polymer Science Part A: Polymer Chemistry, [19] Coutinho, F.M., Costa, M.A., Santos, A.L.,

40(18), 3112-3119. Costa, T.H., Santa Maria, L.C., Pereira, R.A.

[9] Sinthusai, L., Trakarnpruk, W., Strauss, R. (1992). Characterization of Ziegler-Natta cat-

(2017). Ziegler-Natta catalyst with high activ- alysts based on TiCl3 synthesized by different

ity and good hydrogen response. Journal of methods. Fresenius' Journal of Analytical

Metals, Materials and Minerals, 19(2). 27-32. Chemistry, 344(10-11), 514-516.

[10] Almeida, L.A., Marques, M.d.F.V. (2012). [20] Ahmadjo, S., Jamjah, R., Zohuri, G.H., Dama-

vandi, S., Haghighi, M.N., Javaheri, M.

Synthesis of a TiCl4 Ziegler‐Natta Catalyst

(2007). Preparation of highly active heteroge-

Supported on Spherical MgCl2·nEtOH for neous Ziegler-Natta catalyst for polymeriza-

the Polymerization of Ethylene and Propyl- tion of ethylene. Iranian Polymer Journal,

ene. Macromolecular Reaction Engineering, 16(1), 31.

6(1), 57-64.

[21] Dil, E.J., Pourmahdian, S., Vatankhah, M.,

[11] Redzic, E., Garoff, T., Mardare, C.C., List, M., Taromi, F.A. (2010). Effect of dealcoholation

Hesser, G., Mayrhofer, L., Hassel, A.W., of support in MgCl2-supported Ziegler–Natta

Paulik, C. (2016). Heterogeneous Ziegler– catalysts on catalyst activity and polypropyl-

Natta catalysts with various sizes of MgCl2 ene powder morphology. Polymer Bulletin,

64(5), 445-457.

Copyright © 2020, BCREC, ISSN 1978-2993

Bulletin of Chemical Reaction Engineering & Catalysis, 15 (3), 2020, 697

[22] Hoff, R., Mathers, R.T. (2010). Handbook of [31] Ahmadi, E., Rezan, S.A., Baharun, N., Rama-

Transition Metal Polymerization Catalysts: krishnan, S., Fauzi, A., Zhang, G. (2017).

John Wiley & Sons. Chlorination kinetics of titanium nitride for

production of titanium tetrachloride from ni-

[23] Kaminsky, W. (2013). Polyolefins: 50 years af-

trided ilmenite. Metallurgical and Materials

ter Ziegler and Natta II (1 ed.): Springer-

Transactions B, 48(5), 2354-2366.

Verlag Berlin Heidelberg.

[32] Ibrahim, N., Ahmadi, E., Rahman, S.A.,

[24] Böhm, L.L. (2003). The ethylene polymeriza-

Fauzi, M.A., Rezan, S.A. (2017). Extraction of

tion with Ziegler catalysts: fifty years after

titanium from low-iron nitrided Malaysian il-

the discovery. Angewandte Chemie Interna-

menite by chlorination. Paper presented at

tional Edition, 42(41), 5010-5030. the AIP Conference Proceedings.

[25] Klaue, A., Kruck, M., Friederichs, N., Bertola,

[33] Ahmadi, E. (2018). Synthesis of titanium tet-

F., Wu, H., Morbidelli, M. (2018). Insight into

rachloride through arbothermal reduction

the synthesis process of an industrial Ziegler–

and chlorination of ilmenite concentrate.

Natta catalyst. Industrial & Engineering

(Doctor of Philosophy), Universiti Sains Ma-

Chemistry Research, 58(2), 886-896. laysia, Malaysia. (875008031)

[26] Ahmadi, E., Fauzi, A., Hussin, H., Baharun,

[34] Gnanakumar, E.S., Gowda, R.R., Kunjir, S.,

N., Ariffin, K.S., Rezan, S.A. (2017). Synthesis

Ajithkumar, T., Rajamohanan, P.,

of titanium oxycarbonitride by carbothermal

Chakraborty, D., Gopinath, C.S. (2013).

reduction and nitridation of ilmenite with re-

MgCl2.6CH3OH: a simple molecular adduct

cycling of polyethylene terephthalate (PET).

and its influence as a porous support for ole-

International Journal of Minerals, Metallur-

fin polymerization. ACS Catalysis, 3(3), 303-

gy, and Materials, 24(4), 444-454. 311.

[27] Ahmadi, E., Sereiratana, E., Rezan, S.A.,

[35] Thushara, K., Gnanakumar, E.S., Mathew,

Yeoh, F., Fauzi, A., Zhang, G. (2016). Assess-

R., Ajithkumar, T., Rajamohanan, P., Bha-

ment of titanium carbide chlorination by sta-

duri, S., Gopinath, C.S. (2012).

tistical design. Paper presented at the Materi-

MgCl2·4((CH3)2CHCH2OH): A new molecular

als Science Forum.

adduct for the preparation of TiClx/MgCl2 cat-

[28] Rezan, S.A., Zhang, G., Ostrovski, O. (2007). alyst for olefin polymerization. Dalton Trans-

Synthesis of titanium oxycarbonitride by car- actions, 41(37), 11311-11318.

bothermal reduction of titania in nitrogen

[36] Jamjah, R., Zohuri, G., Vaezi, J., Ahmadjo, S.,

containing gas mixtures. Paper presented at

Nekomanesh, M., Pouryari, M. (2006). Mor-

the The 11th World Conference on Titanium,

phological study of spherical MgCl2.nEtOH

Kyoto, Japan.

supported TiCl4 Ziegler‐Natta catalyst for

[29] Yaraghi, A., Sapri, M.H.A., Baharun, N., Re- polymerization of ethylene. Journal of Ap-

zan, S.A., Shoparwe, N.I., Ramakrishnan, S., plied Polymer Science, 101(6), 3829-3834.

Ariffin, K.S., Fauzi, M.A., Ismail, H., Seli,

H.H. (2016). Aeration leaching of iron from ni-

trided Malaysian ilmenite reduced by polysty-

rene-coal reductant. Procedia Chemistry, 19,

715-720.

[30] Ahmadi, E., Shoparwe, N.I., Ibrahim, N., Ha-

mid, S.A.R.S.A., Baharun, N., Ariffin, K.S.,

Hussin, H., Fauzi, M.A. (2018). The Effects of

Experimental Variables on Iron Removal

from Nitrided Malaysian Ilmenite by Becher

Process. In Extraction 2018 (pp. 1383-1396):

Springer.

Copyright © 2020, BCREC, ISSN 1978-2993

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Niyomthai 2016Document10 pagesNiyomthai 2016Salsa NisaNo ratings yet

- Things To Think About Ch.13 (Process Control A)Document21 pagesThings To Think About Ch.13 (Process Control A)Salsa NisaNo ratings yet

- Textile Fabrics As Thermal Insulators: Zeinab S. Abdel-Rehim, M. M. Saad, M. El-Shakankery and I. HanafyDocument14 pagesTextile Fabrics As Thermal Insulators: Zeinab S. Abdel-Rehim, M. M. Saad, M. El-Shakankery and I. HanafySalsa NisaNo ratings yet

- Nama NIM Kelompok:: Salsabila Ainun Nisa: I 05180: VDocument4 pagesNama NIM Kelompok:: Salsabila Ainun Nisa: I 05180: VSalsa NisaNo ratings yet

- Preparation of Insulating Material From Rice Husk and Saw DustDocument6 pagesPreparation of Insulating Material From Rice Husk and Saw DustSalsa NisaNo ratings yet

- Distilasi Ekstraksi PDFDocument45 pagesDistilasi Ekstraksi PDFSalsa NisaNo ratings yet

- Kelompok Game Hari Ke-2 SekderDocument4 pagesKelompok Game Hari Ke-2 SekderSalsa NisaNo ratings yet

- 08-2 Kinetika - Reaksi - Gas-Cair - Tanpa - Katalis - PadatDocument10 pages08-2 Kinetika - Reaksi - Gas-Cair - Tanpa - Katalis - PadatSalsa NisaNo ratings yet

- Microbial Degradation of Vegetable Oils: A Review: Malaysian Journal of Biochemistry & Molecular BiologyDocument11 pagesMicrobial Degradation of Vegetable Oils: A Review: Malaysian Journal of Biochemistry & Molecular BiologySalsa NisaNo ratings yet

- Studi Karakterisasi Pencampuran Biodiesel Dengan Minyak SolarDocument6 pagesStudi Karakterisasi Pencampuran Biodiesel Dengan Minyak SolarSalsa NisaNo ratings yet

- The Sintering Temperature Effect On Electrochemical Properties of Limn ODocument7 pagesThe Sintering Temperature Effect On Electrochemical Properties of Limn OSalsa NisaNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Lab 7 - BioeactorDocument43 pagesLab 7 - Bioeactornur athilahNo ratings yet

- Fire Sprinkler Systems#Document8 pagesFire Sprinkler Systems#aimiza50% (2)

- Florafelt Vertical Garden GuideDocument27 pagesFlorafelt Vertical Garden Guidelarguedas100% (1)

- Electrical Design and Aspects of Hvac: Unit - 4: Heating Control DevicesDocument49 pagesElectrical Design and Aspects of Hvac: Unit - 4: Heating Control DevicesRakesh MoparthiNo ratings yet

- Material Data Sheet NC 259 Sn100c Solder Paste Rev 1Document3 pagesMaterial Data Sheet NC 259 Sn100c Solder Paste Rev 1vkmsNo ratings yet

- 1.0 Reaction Kinetic 22 - 23 (REVIEWED)Document115 pages1.0 Reaction Kinetic 22 - 23 (REVIEWED)alyaainsyirah04No ratings yet

- United States Patent (10) Patent No.: US 7,806,945 B2: The To In... TDocument21 pagesUnited States Patent (10) Patent No.: US 7,806,945 B2: The To In... TesiNo ratings yet

- Wolfson Eup3 Ch15 Test BankDocument16 pagesWolfson Eup3 Ch15 Test Bankifghelpdesk100% (1)

- AAMA 620-02 Voluntary Specfications For High Performance...Document9 pagesAAMA 620-02 Voluntary Specfications For High Performance...zaheerahmed77No ratings yet

- Chapter 10Document42 pagesChapter 10Teddy Matthew AudleyNo ratings yet

- Ball Valve - Weight ReferenceDocument19 pagesBall Valve - Weight ReferenceSigmaNo ratings yet

- Excel Meracik Nutrisi Bandung 11 Feb 2018Document30 pagesExcel Meracik Nutrisi Bandung 11 Feb 2018Ariev WahyuNo ratings yet

- Tribhuvan University Institute of Science and Technology B.Sc. Entrance Examination 2074Document11 pagesTribhuvan University Institute of Science and Technology B.Sc. Entrance Examination 2074Vijay GalamiNo ratings yet

- Homework Chapter 22 Solutions PDFDocument16 pagesHomework Chapter 22 Solutions PDFbidinNo ratings yet

- Aci y Sus NormasDocument14 pagesAci y Sus NormasJUAN AGUILARNo ratings yet

- ISMP High Alert MedicationsDocument1 pageISMP High Alert MedicationsOki TursinawatyNo ratings yet

- 010 - Permit To Work Procedure Feb 2013Document61 pages010 - Permit To Work Procedure Feb 2013vdeviv100% (1)

- bw-G1030 USDocument24 pagesbw-G1030 USEuojrNo ratings yet

- IncroquatBehenylTMS 50DataSheetDocument7 pagesIncroquatBehenylTMS 50DataSheetKirk BorromeoNo ratings yet

- Clariant SDS AddWorks IBC 760 Australia EnglishDocument10 pagesClariant SDS AddWorks IBC 760 Australia EnglishRafi UdeenNo ratings yet

- Marchs Advanced Organic Chemistry Reactions Mechanisms and Structure 8Th Edition Michael B Smith Full ChapterDocument67 pagesMarchs Advanced Organic Chemistry Reactions Mechanisms and Structure 8Th Edition Michael B Smith Full Chapterjames.modesto652100% (6)

- Amol Raj PDFDocument10 pagesAmol Raj PDFGaurav SinghNo ratings yet

- TID00019 Manual Acople Falk FLDDocument7 pagesTID00019 Manual Acople Falk FLDNatalia BeltránNo ratings yet

- Tarnish & CorrosionDocument48 pagesTarnish & CorrosionmujtabaNo ratings yet

- Applications Assignment 2Document7 pagesApplications Assignment 2Chrystal BrownNo ratings yet

- Unit 1, 2 and 8Document71 pagesUnit 1, 2 and 8Noor SaleemNo ratings yet

- Copper CorrosionDocument2 pagesCopper CorrosionDonatas BertasiusNo ratings yet

- SK Duggal Construction Materials LectureDocument19 pagesSK Duggal Construction Materials LectureTaimoor SarfarazNo ratings yet

- Effects of Caffeine and Aspirin On Daphnia MagnaDocument2 pagesEffects of Caffeine and Aspirin On Daphnia MagnazoujasonNo ratings yet

- Purlin LysaghtDocument6 pagesPurlin LysaghtAnonymous MHMqCrzgTNo ratings yet