Professional Documents

Culture Documents

Technical Data Sheet EP..R+MP: Type Overview

Uploaded by

Joao MoreiraOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Technical Data Sheet EP..R+MP: Type Overview

Uploaded by

Joao MoreiraCopyright:

Available Formats

Technical data sheet EP..

R+MP

Communicative characterised control

valve with sensor-operated flow

control, 2-way, internal thread (EPIV)

• Nominal voltage AC/DC 24 V

• Control Modulating

• For closed cold and warm water

systems

• For modulating control of air-

handling and heating systems on the

water side

• Communication via Belimo MP-Bus

or conventional control

• Conversion of active sensor signals

and switching contacts

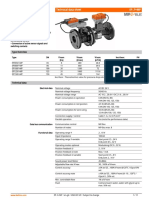

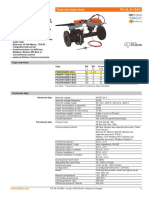

Type overview

Type DN Rp Vnom Vnom kvs theor. PN n(gl)

[ ] [“] [ l/s] [ l/min] [ m³/h] [ ] [ ]

EP015R+MP 15 1/2 0.35 21 2.9 16 3.2

EP020R+MP 20 3/4 0.65 39 4.9 16 3.2

EP025R+MP 25 1 1.15 69 8.6 16 3.2

EP032R+MP 32 1 1/4 1.8 108 14.2 16 3.2

EP040R+MP 40 1 1/2 2.5 150 21.3 16 3.2

EP050R+MP 50 2 4.8 288 32.0 16 3.2

kvs theor.: Theoretical kvs value for pressure drop calculation

Technical data

Electrical data Nominal voltage AC/DC 24 V

Nominal voltage frequency 50/60 Hz

Nominal voltage range AC 19.2...28.8 V / DC 21.6...28.8 V

Power consumption in operation DN 15...25 3.5 W / DN 32...50 4.5 W

Power consumption at rest DN 15...25 1.3 W / DN 32...50 1.4 W

Power consumption for wire sizing DN 15...25 6 VA / DN 32...50 7 VA

Connection supply / control Cable 1 m, 4 x 0.75 mm²

Parallel operation Yes (note the performance data)

Functional data Torque motor 5 Nm

10 Nm

20 Nm

Torque Motor 5 Nm (DN 15...25)

10 Nm (DN 32...40)

20 Nm (DN 50)

Positioning signal Y DC 0...10 V

Operating range Y DC 2...10 V

Operating range Y variable Start point DC 0.5...24 V

End point DC 8.5...32 V

Position feedback U DC 2...10 V

Position feedback U variable Start point DC 0.5...8 V

End point DC 2...10 V

Sound power level motor 45 dB(A)

Adjustable flow rate Vmax 30...100% of Vnom

Control accuracy ±10% (of 25...100% Vnom)

Control accuracy note ±6% (of 25...100% Vnom) at 20°C / Glykol 0%

vol.

Media Cold and warm water, water with glycol up to

max. 50% vol.

Medium temperature -10...120°C

Permissible pressure ps 1600 kPa

Closing pressure ∆ps 1400 kPa

Differential pressure ∆pmax 350 kPa

Differential pressure note 200 kPa for low-noise operation

Flow characteristic equal percentage (VDI/VDE 2178), optimised in

the opening range (switchable to linear)

Leakage rate Leakage rate A, air-bubble-tight (EN 12266-1)

Pipe connector Internal thread according to ISO 7-1

www.belimo.eu EP..R+MP • en-gb • 2015-12-03 • subject to changes 1

Communicative characterised control valve with sensor-

EP..R+MP operated flow control, 2-way, internal thread (EPIV)

Technical data

Functional data Installation position Upright to horizontal (in relation to the stem)

Maintenance Maintenance-free

Manual override Gear disengagement with push-button, can be

locked

Flow measurement Measuring principle Ultrasonic volumetric flow measurement

Measuring accuracy ±6% (of 25...100% Vnom)

Measuring accuracy note ±2% (of 25...100% Vnom) at 20°C / Glykol 0%

vol.

Min. flow measurement 1% of Vnom

Safety Protection class IEC/EN III Safety extra-low voltage

Degree of protection IEC/EN IP54

EMC CE according to 2004/108/EC

Mode of operation Type 1

Rated impulse voltage supply / control 0.8 kV

Control pollution degree 3

Ambient temperature -30...50°C

Non-operating temperature -40...80°C

Ambient humidity 95% r.h., non-condensing

Materials Housing Brass body

Measuring pipe Brass body nickel-plated

Closing element Stainless steel

Stem Stainless steel

Stem seal O-ring EPDM

Safety notes

• This device has been designed for use in stationary heating, ventilation and air

! conditioning systems and must not be used outside the specified field of application,

especially in aircraft or in any other airborne means of transport.

• Only authorised specialists may carry out installation. All applicable legal or

institutional installation regulations must be complied during installation.

• The connection between the control valve and the measuring tube should not be

separated.

• The device contains electrical and electronic components and must not be disposed

of as household refuse. All locally valid regulations and requirements must be

observed.

2 EP..R+MP • en-gb • 2015-12-03 • subject to changes www.belimo.eu

Communicative characterised control valve with sensor-

EP..R+MP operated flow control, 2-way, internal thread (EPIV)

Product features

Mode of operation The final controlling device is comprised of three components: characterised control

valve (CCV), measuring pipe with volumetric flow sensor and the actuator itself.

The adjusted maximum flow (max) is assigned to the maximum positioning signal

(typically 10 V / 100%). The final controlling device can be controlled communicative

or analogue. The medium is detected by the sensor in the measuring pipe and is

applied as the flow value. The measured value is balanced with the setpoint. The

actuator corrects the deviation by changing the valve position. The angle of rotation α

varies according to the differential pressure through the final controlling element (see

volumetric flow curves).

Flow characteristic

Flow rate curves

∆p3

∆p1 < ∆p2 < ∆p3

∆p2

∆p1

Transmission behaviour HE Heat exchanger transmission behaviour

Depending on the construction, temperature spread, medium and hydraulic circuit,

the power Q is not proportional to the water volumetric flow (Curve 1). With the

classical type of temperature control, an attempt is made to maintain the control signal

Y proportional to the power Q (Curve 2). This is achieved by means of an equal-

percentage valve characteristic curve (Curve 3).

Y

www.belimo.eu EP..R+MP • en-gb • 2015-12-03 • subject to changes 3

Communicative characterised control valve with sensor-

EP..R+MP operated flow control, 2-way, internal thread (EPIV)

Product features

Control characteristics The velocity of the medium is measured in the measuring component (sensor

electronics) and converted to a flow rate signal.

The positioning signal Y corresponds to the power Q via the exchanger, the

volumetric flow is regulated in the EPIV. The control signal Y is converted into an

equal-percentage characteristic curve and provided with the max value as the new

reference variable w. The momentary control deviation forms the positioning signal Y1

for the actuator.

The specially configured control parameters in connection with the precise flow rate

sensor ensure a stable quality of control. They are however not suitable for rapid

control processes, i.e. for domestic water control.

U5 displays the measured volumetric flow as voltage (factory setting). As an

alternative, U5 can be used for displaying the valve opening angle. It is always in

reference to the respective nom, i.e. if max is e.g. 50% of nom, then Y = 10 V, U5

= 5 V.

1. Standard equal percentage Vmax = Vnom / 2. effect Vmax < Vnom

U5 [V] U5 [V]

1 2

nom nom

100% 100%

50% 50% max

25%

0 Y [V] 0 Y [V]

80%100% 80%100%

Block diagram

D U5

1)

A

Y

A

1)

D w

PP/MP

D

Y1

k

A

max

DN

4 EP..R+MP • en-gb • 2015-12-03 • subject to changes www.belimo.eu

Communicative characterised control valve with sensor-

EP..R+MP operated flow control, 2-way, internal thread (EPIV)

Product features

Definition nom is the maximum possible flow.

max is the maximum flow rate which has been set with the greatest positioning

signal, e.g. 10 V. max can be set to between 30% and 100% of nom.

min 0% (non-variable).

[m3/h]

100% nom

30% max

0 Y [V]

100%

Creep flow suppression Given the very low flow speed in the opening point, this can no longer be measured by

the sensor within the required tolerance. This range is overridden electronically.

Opening valve

The valve remains closed until the volumetric flow required by the positioning signal Y

corresponds to 1% of nom. The control along the valve characteristic curve is active

after this value has been exceeded.

Closing valve

The control along the valve characteristic curve is active up to the required flow rate of

1% of nom. Once the level falls below this value, the flow rate is maintained at 1% of

nom. If the level falls below the flow rate of 0.5% of nom required by the reference

variable Y, then the valve will close.

[m3/h]

1%

0 Y [V]

0.5% 1% 100%

Converter for sensors Connection option for a sensor (active sensor or switching contact). The MP actuator

serves as an analogue/digital converter for the transmission of the sensor signal via

MP-Bus to the higher level system.

Parameterisable actuators The factory settings cover the most common applications. Single parameters can be

modified with the Belimo Service Tools MFT-P or ZTH EU.

Positioning signal inversion This can be inverted in cases of control with an analogue positioning signal. The

inversion causes the reversal of the standard behaviour, i.e. at a positioning signal of

0%, regulation is to max, and the valve is closed at a positioning signal of 100%.

Hydraulic balancing With the Belimo tools, the maximum flow rate (equivalent to 100% requirement) can

be adjusted on-site, simply and reliably, in a few steps. If the device is integrated in the

management system, then the balancing can be handled directly by the management

system.

Manual override Manual override with push-button possible (the gear is disengaged for as long as the

button is pressed or remains locked).

High functional reliability The actuator is overload protected, requires no limit switches and automatically stops

when the end stop is reached.

www.belimo.eu EP..R+MP • en-gb • 2015-12-03 • subject to changes 5

Communicative characterised control valve with sensor-

EP..R+MP operated flow control, 2-way, internal thread (EPIV)

Product features

Home position The first time the supply voltage is switched on, i.e. at the time of commissioning,

the actuator carries out an adaption, which is when the operating range and position

feedback adjust themselves to the mechanical setting range.

After this process the actuator moves into the required position in order to ensure the

flow rate defined by the positioning signal.

Accessories

Description Type

Gateways Gateway MP for BACnet MS/TP, AC/DC 24 V UK24BAC

Gateway MP to Modbus RTU, AC/DC 24 V UK24MOD

Gateway MP to LonWorks, AC/DC 24 V, LonMark certified UK24LON

Gateway MP to KNX, AC/DC 24 V, EIBA certified UK24EIB

Description Type

Electrical accessories Connecting cable 5 m, A+B: RJ12 6/6, To ZTH/ZIP-USB-MP ZK1-GEN

Connection cable 5 m, A: RJ11 6/4, B: Free wire end, To ZTH/ZIP- ZK2-GEN

USB-MP

MP-Bus power supply for MP actuators, AC 230/24V for local power ZN230-24MP

supply

Connecting board MP bus suitable for wiring boxes EXT-WR-FP..-MP ZFP2-MP

Description Type

Service Tools Service Tool, for MF/MP/Modbus/LonWorks actuators and VAV- ZTH EU

Controller

Belimo PC-Tool, software for adjustments and diagnostics MFT-P

Adapter to Service Tool ZTH MFT-C

ZIP-USB-MP interface ZIP-USB-MP

Electrical installation

Notes • Connection via safety isolating transformer.

! • Parallel connection of other actuators possible. Observe the performance data.

Wiring diagrams

AC/DC 24 V, modulating Operation on the MP-Bus

T ~ T ~

– + – +

Y DC (0)2…10 V Y Sensor

U DC 2…10 V U MP

1 2 3 5 Cable colours: 1 2 3 5 Cable colours:

1 = black 1 = black

2 = red 2 = red

3 = white 3 = white

5 = orange 5 = orange

6 EP..R+MP • en-gb • 2015-12-03 • subject to changes www.belimo.eu

Communicative characterised control valve with sensor-

EP..R+MP operated flow control, 2-way, internal thread (EPIV)

Functions

Functions when operated on MP-Bus

Connection on the MP-Bus Network topology

T ~

– + MP

A)

There are no restrictions for the

network topology (star, ring, tree or

1 2 3 5 mixed forms are permitted).

Supply and communication in one

and the same 3-wire cable

Y U A) more actuators and sensors • no shielding or twisting necessary

(max.8) • no terminating resistors required

Connection of active sensors Connection of external switching contact

T ~ T ~

– + MP – + MP

p

A) A)

A) more actuators and sensors

A) more actuators and sensors (max.8)

1 2 3 5 (max.8) 1 2 3 5 • Switching current 16 mA @ 24 V

• Supply AC/DC 24 V • Start point of the operating range

• Output signal DC 0...10 V must be parameterised on the MP

Y U (max. DC 0...32 V) Y U actuator as ≥ 0.5 V

• Resolution 30 mV

Functions for actuators with specific parameters (Parametrisation with PC-Tool necessary)

Override control and limiting with AC 24 V with relay contacts Override control and limiting with DC 24 V with relay contacts

T ~ + -

Y (DC 0 ... 10 V) Y (DC 0 ... 10 V)

e e

a b d a b

e.g. 1N 4007

a b d e

Close a b d e

1 2 3 5 1 2 3 5

max Close

T ~ Open T ~ max

Y U Y U

Y Y

www.belimo.eu EP..R+MP • en-gb • 2015-12-03 • subject to changes 7

Communicative characterised control valve with sensor-

EP..R+MP operated flow control, 2-way, internal thread (EPIV)

Operating controls and indicators

2 Push-button and LED display green

Off: No power supply or malfunction

On: In operation

Press button: Triggers angle of rotation adaptation, followed by standard mode

Adaption 2

Power 3 Push-button and LED display yellow

3 Off: Standard mode without MP-Bus

Status Flickering: MP communication active

On: Adaptation or synchronising process active

4

Press button: Confirmation of addressing

4 Gear disengagement button

Press button: Gear disengages, motor stops, manual override possible

5 Release button: Gear engages, synchronisation starts, followed by standard mode

5 Service plug

For connecting parameterisation and service tools

Check power supply connection

2 Off and 3 On: Possible wiring error in power supply

Installation notes

Recommended installation positions The ball valve can be installed upright to horizontal. The ball valve may not be installed

in a hanging position, i.e. with the stem pointing downwards.

90° 90°

Mounting position in the return Installation in the return is recommended.

Water quality requirements The water quality requirements specified in VDI 2035 must be adhered to.

Belimo valves are regulating devices. For the valves to function correctly in the long

term, they must be kept free from particle debris (e.g. welding beads during installation

work). The installation of suitable strainer is recommended.

Maintenance Ball valves, rotary actuators and sensors are maintenance-free.

In the event of any service work on the final controlling device, it is essential to isolate

the rotary actuator from the power supply (by unplugging the electrical cable). Any

pumps in the part of the piping system concerned must also be switched off and the

appropriate slide valves closed (allow everything to cool down first if necessary and

reduce the system pressure to ambient pressure level).

The system must not be returned to service until the ball valve and the rotary actuator

have been properly reassembled in accordance with the instructions and the pipeline

has been refilled in the proper manner.

Flow direction The direction of flow, specified by an arrow on the housing, is to be complied with,

since otherwise the flow rate will be measured incorrectly.

8 EP..R+MP • en-gb • 2015-12-03 • subject to changes www.belimo.eu

Communicative characterised control valve with sensor-

EP..R+MP operated flow control, 2-way, internal thread (EPIV)

Installation notes

Inlet section In order to achieve the specified measuring accuracy, a flow-calming section or inflow

section in the direction of the flow is to be provided upstream from the measuring pipe

flange. Its dimensions should be at least 5x DN.

DN L min.

15 5 x 15 mm = 75 mm

20 5 x 20 mm = 100 mm

25 5 x 25 mm = 125 mm

32 5 x 32 mm = 160 mm

40 5 x 40 mm = 200 mm

50 5 x 50 mm = 250 mm

L ≥ 5 x DN

General notes

Valve selection The valve is determined using the maximum required flow rate max.

A calculation of the kvs value is not required.

max = 30…100% of nom

If no hydraulic data are available, then the same valve DN can be selected as the heat

exchanger nominal diameter.

Minimum differential pressure The minimum required differential pressure (pressure drop through the valve) for

(pressure drop) achieving the desired volumetric flow max can be calculated with the aid of the

theoretical kvs value (see type overview) and the below-mentioned formula. The

calculated value is dependent on the required maximum volumetric flow max. Higher

differential pressures are compensated for automatically by the valve.

Formula

2 ∆pmin: kPa

max

∆pmin = 100 x max: m3/h

kvs theor. kvs theor.: m3/h

Example (DN25 with the desired maximum flow rate = 50% nom)

EP025R+MP

kvs theor. = 8.6 m 3/h

nom = 69 l/min

50% * 69 l/min = 34.5 l/min = 2.07 m3/h

2 2

max 2.07 m3/h

∆pmin = 100 x = 100 x = 6 kPa

kvs theor. 8.6 m3/h

www.belimo.eu EP..R+MP • en-gb • 2015-12-03 • subject to changes 9

Communicative characterised control valve with sensor-

EP..R+MP operated flow control, 2-way, internal thread (EPIV)

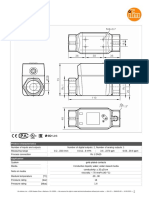

Dimensions / Weight

Dimensional drawings

min. Y

L

min. X

H

Rp

L3

B L1 L2

Type DN Rp L L1 L2 L3 B H X Y Weight

[ ] [“] [ mm] [ mm] [ mm] [ mm] [ mm] [ mm] [ mm] [ mm] [ kg]

EP015R+MP 15 1/2 275 192 81 13 75 125 195 77 1.5

EP020R+MP 20 3/4 291 211 75 14 75 125 195 77 1.8

EP025R+MP 25 1 295 230 71 16 75 127 197 77 2.0

EP032R+MP 32 1 1/4 323 255 68 19 85 131 201 77 2.8

EP040R+MP 40 1 1/2 325 267 65 19 85 141 211 77 3.3

EP050R+MP 50 2 343 288 69 22 95 142 212 77 4.4

Further documentation

• Overview MP Cooperation Partners

• Tool connections

• General notes for project planning

10 EP..R+MP • en-gb • 2015-12-03 • subject to changes www.belimo.eu

You might also like

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- EP..F+MP Datasheet en-APDocument10 pagesEP..F+MP Datasheet en-APLandz GanzonNo ratings yet

- Belimo EP..R MP Datasheet En-GbDocument11 pagesBelimo EP..R MP Datasheet En-GbNoah MusundiNo ratings yet

- Belimo Epicv 2way ValveDocument11 pagesBelimo Epicv 2way ValveAdam DharmawanNo ratings yet

- Belimo EP..F KMP Datasheet En-GbDocument13 pagesBelimo EP..F KMP Datasheet En-GbNoah MusundiNo ratings yet

- EV..F BAC Datasheet En-GbDocument12 pagesEV..F BAC Datasheet En-GbTareq JildehNo ratings yet

- PE3006 EngDocument3 pagesPE3006 EngAdolphus MashapaNo ratings yet

- Product Characteristics: Pressure SensorsDocument3 pagesProduct Characteristics: Pressure SensorsfadhlidzilNo ratings yet

- PN3000Document3 pagesPN3000A-selam IbraNo ratings yet

- RDAB20-A PRSH enDocument2 pagesRDAB20-A PRSH enMarcosNo ratings yet

- Specification - Drawing SD0523Document5 pagesSpecification - Drawing SD0523Nshmi-usNo ratings yet

- Presostato Alta Presion IFM PN4221Document3 pagesPresostato Alta Presion IFM PN4221Giovanni MorenoNo ratings yet

- Monolithic IC MM1326, 1354, 1369: Q Xpander ProcessorsDocument10 pagesMonolithic IC MM1326, 1354, 1369: Q Xpander ProcessorsrolandseNo ratings yet

- Flow Sensors: Product CharacteristicsDocument5 pagesFlow Sensors: Product CharacteristicsSoumyajit BoseNo ratings yet

- Flush Pressure Transmitter: 1 Tightening Torque 20 NMDocument3 pagesFlush Pressure Transmitter: 1 Tightening Torque 20 NMHarikrishnan DNo ratings yet

- FM/AM Tuner of Electronic Tuning Type: FunctionsDocument16 pagesFM/AM Tuner of Electronic Tuning Type: FunctionsmplennaNo ratings yet

- Pi2657 PDFDocument3 pagesPi2657 PDFDimitry TIRANo ratings yet

- RunnTech RT01 Cobra-Head Shaped Joystick ControllerDocument9 pagesRunnTech RT01 Cobra-Head Shaped Joystick ControllerRunnTechNo ratings yet

- PresostatosDocument5 pagesPresostatosOzias CruzNo ratings yet

- SM8420 00 - en UsDocument6 pagesSM8420 00 - en UsAngga SuryadarmaNo ratings yet

- DB18Document2 pagesDB18taleb 6269No ratings yet

- Cam Bien AP Suat DI PN016ADocument3 pagesCam Bien AP Suat DI PN016AĐức AnhNo ratings yet

- Fy700 Series TaieDocument9 pagesFy700 Series TaieHưng Phan HữuNo ratings yet

- LT1618 DatasheetDocument16 pagesLT1618 DatasheetkurabyqldNo ratings yet

- RunnTech RT02 Series Robust Industrial JoystickDocument10 pagesRunnTech RT02 Series Robust Industrial JoystickRunnTechNo ratings yet

- RT-100 Industrial JoystickDocument11 pagesRT-100 Industrial JoystickRunnTechNo ratings yet

- DCL400Document2 pagesDCL400taleb 6269No ratings yet

- Proportional Amplifier PV: For The Control of A Proportional SolenoidDocument8 pagesProportional Amplifier PV: For The Control of A Proportional SolenoidIvan BeljinNo ratings yet

- Panel MeterDocument10 pagesPanel MeterchaabiabdeljalilNo ratings yet

- Magnetic Inductive FlowmeterDocument5 pagesMagnetic Inductive Flowmeterarif kurniawanNo ratings yet

- Linde 7919040093 & 7919040095 JoystickDocument3 pagesLinde 7919040093 & 7919040095 JoystickRunnTechNo ratings yet

- Moog-L VDT Oscillator DemodulatorDocument2 pagesMoog-L VDT Oscillator DemodulatorLuis Jonathan Bahamaca FernandezNo ratings yet

- FY900 Temperature ControllerDocument9 pagesFY900 Temperature ControllerOlubunmi AdejugbeNo ratings yet

- 2p en Uds3v3Document2 pages2p en Uds3v3Mantenimiento Trety T2No ratings yet

- Hansaflex Senzor 400barDocument3 pagesHansaflex Senzor 400barsmomisNo ratings yet

- Linde 7919040041 & 7919040042 JoystickDocument3 pagesLinde 7919040041 & 7919040042 JoystickRunnTechNo ratings yet

- Ifm S2 CatalogDocument2 pagesIfm S2 CatalogInbanesan AkNo ratings yet

- AM/FM Tuner System of Electronic Tuning Type: FunctionsDocument11 pagesAM/FM Tuner System of Electronic Tuning Type: FunctionsGunawan AryantoNo ratings yet

- Imagen Phoenix ContactDocument7 pagesImagen Phoenix ContactRodrigo CiezaNo ratings yet

- Pressure Sensors: Product CharacteristicsDocument4 pagesPressure Sensors: Product CharacteristicsAbdellah IbrahimNo ratings yet

- IP Conveter Norgen - 100XDocument2 pagesIP Conveter Norgen - 100XAnkit RedkarNo ratings yet

- LM1578A/LM2578A/LM3578A Switching Regulator: General Description FeaturesDocument18 pagesLM1578A/LM2578A/LM3578A Switching Regulator: General Description FeaturesMauricio VillarNo ratings yet

- vc7931 HoneywellDocument4 pagesvc7931 Honeywellmohamad chaudhariNo ratings yet

- Belimo AFX24-SR-S N4 Datasheet En-UsDocument5 pagesBelimo AFX24-SR-S N4 Datasheet En-Usraul sajamaNo ratings yet

- FR150A Frequency Inverter Catalog EN 2021 V2.0Document8 pagesFR150A Frequency Inverter Catalog EN 2021 V2.0wow greatNo ratings yet

- Modicon X80 Modules - BMXAMI0810 PDFDocument5 pagesModicon X80 Modules - BMXAMI0810 PDFRahul Raj SinghNo ratings yet

- 3061-DIP30S: SANYO Electric Co.,Ltd. Semiconductor Bussiness HeadquartersDocument6 pages3061-DIP30S: SANYO Electric Co.,Ltd. Semiconductor Bussiness HeadquartersJenny VasquezNo ratings yet

- Honeywell Ds Vn8 Oct 2019Document3 pagesHoneywell Ds Vn8 Oct 2019Aiman AliNo ratings yet

- Operating Instructions: LCD Display Counters E5024C SeriesDocument20 pagesOperating Instructions: LCD Display Counters E5024C SeriesFernando BarraganNo ratings yet

- EDS601Document2 pagesEDS601Asnake SolomonNo ratings yet

- BEV Datasheet En-GbDocument12 pagesBEV Datasheet En-GblijoedasseryNo ratings yet

- Modicon X80 Modules - BMXAMI0410Document5 pagesModicon X80 Modules - BMXAMI0410Reibi VillarrealNo ratings yet

- RunnTech F100 Proportional Accelerator PedalDocument3 pagesRunnTech F100 Proportional Accelerator PedalRunnTechNo ratings yet

- Electric and Electronic Rotary Gear Motor Series AR2..., AR2... EDocument4 pagesElectric and Electronic Rotary Gear Motor Series AR2..., AR2... EanassNo ratings yet

- Technical Data Sheet 22UTH-510..: Type OverviewDocument5 pagesTechnical Data Sheet 22UTH-510..: Type OverviewJNo ratings yet

- Honeywell N34010Document8 pagesHoneywell N34010WeimannNo ratings yet

- Flow Sensors: Product CharacteristicsDocument5 pagesFlow Sensors: Product CharacteristicsLuis A PoaquizaNo ratings yet

- SD6800 00 - en GBDocument6 pagesSD6800 00 - en GBgoofflineNo ratings yet

- Electronic Dual Level Switch: FeaturesDocument2 pagesElectronic Dual Level Switch: FeaturesvinodNo ratings yet

- Modicon X80 Modules - BMXAMI0800 - Modulo Entradas AnalogicasDocument5 pagesModicon X80 Modules - BMXAMI0800 - Modulo Entradas AnalogicasEdwin RincónNo ratings yet

- Why Do I Always Wake Up After 5 Hours of Sleep?Document35 pagesWhy Do I Always Wake Up After 5 Hours of Sleep?Joao MoreiraNo ratings yet

- Macrogen GT Duo: Taking Small Steps Together, Always Ahead, Towards A Better WorldDocument8 pagesMacrogen GT Duo: Taking Small Steps Together, Always Ahead, Towards A Better WorldJoao MoreiraNo ratings yet

- Comfort Requirements and Sustainability in Housing Construction in AngolaDocument6 pagesComfort Requirements and Sustainability in Housing Construction in AngolaJoao MoreiraNo ratings yet

- Mangrove Jack's Craft Series Beer Pouch InstructionsDocument2 pagesMangrove Jack's Craft Series Beer Pouch InstructionsJoao MoreiraNo ratings yet

- Zrxxma / Zrxxxfa: 4-Way Rotary Valves PN 6Document4 pagesZrxxma / Zrxxxfa: 4-Way Rotary Valves PN 6Joao MoreiraNo ratings yet

- Zrxxma / Zrxxxfa: 4-Way Rotary Valves PN 6Document4 pagesZrxxma / Zrxxxfa: 4-Way Rotary Valves PN 6Joao MoreiraNo ratings yet

- Admapn038en 0910 PDFDocument8 pagesAdmapn038en 0910 PDFTan Kang YaoNo ratings yet

- Zrxxma / Zrxxxfa: 4-Way Rotary Valves PN 6Document4 pagesZrxxma / Zrxxxfa: 4-Way Rotary Valves PN 6Joao MoreiraNo ratings yet

- 61WG/30WG: Water-Sourced Liquid Chillers/Heat Pumps With or Without Integrated Hydronic ModuleDocument31 pages61WG/30WG: Water-Sourced Liquid Chillers/Heat Pumps With or Without Integrated Hydronic ModuleJoao MoreiraNo ratings yet

- Ashrae Ashraejournal 2020.12Document135 pagesAshrae Ashraejournal 2020.12Joao MoreiraNo ratings yet

- Qaist d3.6-7 HWC MethodDocument20 pagesQaist d3.6-7 HWC MethodFilip KovacevicNo ratings yet

- Conductors Total QTY Remarks HP OR KVA Volts "FROM" END " TO " END From TO Load Gland Type RUN ConduitsDocument1 pageConductors Total QTY Remarks HP OR KVA Volts "FROM" END " TO " END From TO Load Gland Type RUN ConduitsJohn Philip BuntalesNo ratings yet

- MVH 300ex 2 Installation ManualDocument7 pagesMVH 300ex 2 Installation ManualbugboyeeeNo ratings yet

- New HBPowerwall Price List PublicDocument2 pagesNew HBPowerwall Price List PublicmusliminmuhammadNo ratings yet

- MiCOM P139 TechnicalManual1Document806 pagesMiCOM P139 TechnicalManual1VanBan NguyenNo ratings yet

- CPU Modules CPU001 and CPU002: Product Revision HistoryDocument4 pagesCPU Modules CPU001 and CPU002: Product Revision HistoryJuan RodríguezNo ratings yet

- Separable Screened Connector SystemsDocument20 pagesSeparable Screened Connector SystemsJesusNo ratings yet

- Inex User ManualDocument132 pagesInex User Manualduck dvdNo ratings yet

- ACB Battery Expansion 2G+3G ATP Document 3GDocument16 pagesACB Battery Expansion 2G+3G ATP Document 3GAmjad shNo ratings yet

- Manual - GT1-3K-SS - LivoltekDocument52 pagesManual - GT1-3K-SS - LivoltekPatrick FerreiraNo ratings yet

- Hilti Fire Stop 08-09 PrintDocument68 pagesHilti Fire Stop 08-09 PrintHenry MalinisNo ratings yet

- TLE-TE-9 Q3 ICT-CSS Mod8 For StudentsDocument9 pagesTLE-TE-9 Q3 ICT-CSS Mod8 For StudentsGallardo GarlanNo ratings yet

- Instruction Manual: Fundus CameraDocument37 pagesInstruction Manual: Fundus Camerashakil ahmadNo ratings yet

- Marking Smart PrintDocument84 pagesMarking Smart PrintJavier MiramontesNo ratings yet

- 8-Acti 9 Catalogue 2012 For Gulf and KSADocument36 pages8-Acti 9 Catalogue 2012 For Gulf and KSAnooruddinkhan1No ratings yet

- Earthing BasementDocument1 pageEarthing BasementNad EemNo ratings yet

- VSR 150 Installation and ServiceDocument49 pagesVSR 150 Installation and ServiceJurisĶigursNo ratings yet

- Tech Gss & TssDocument218 pagesTech Gss & Tsser.ras.ma100% (1)

- Full Pickup Catalog CompressedDocument24 pagesFull Pickup Catalog CompressedKarthikeyan LNo ratings yet

- LPG Installation - Guide PDFDocument36 pagesLPG Installation - Guide PDFFebous WambuaNo ratings yet

- 7/8" Coaxial Feeder Cable: Cl-Cf78CfrDocument5 pages7/8" Coaxial Feeder Cable: Cl-Cf78CfrRael OrtizNo ratings yet

- Technical Specification (Medium Voltage) Aaa Covered Conductor & AccesoriesDocument36 pagesTechnical Specification (Medium Voltage) Aaa Covered Conductor & AccesoriesCabcon India100% (1)

- NetCol500 Variable Speed Outdoor Unit User ManualDocument86 pagesNetCol500 Variable Speed Outdoor Unit User ManualGustavo GomezNo ratings yet

- ABB Kabeldon 2011 Cat HV Cable Joints, Terminations, ConnectorsDocument131 pagesABB Kabeldon 2011 Cat HV Cable Joints, Terminations, ConnectorsistenicNo ratings yet

- Product Data Sheet: Closed Toroid A Type, For Vigirex and Vigilhom, SA200, Inner Diameter 200 MM, Rated Current 400 ADocument2 pagesProduct Data Sheet: Closed Toroid A Type, For Vigirex and Vigilhom, SA200, Inner Diameter 200 MM, Rated Current 400 ARolando LazarteNo ratings yet

- Network CablingDocument4 pagesNetwork CablingRomeo T. Navarro Jr.No ratings yet

- Color Echo Sounder: Operation ManualDocument41 pagesColor Echo Sounder: Operation ManualtchepssilveiraNo ratings yet

- Instructions MH6S-10 PDFDocument73 pagesInstructions MH6S-10 PDFEvandro PavesiNo ratings yet

- Attachment 1 Dry Dock Specs 2019Document51 pagesAttachment 1 Dry Dock Specs 2019GabrielNo ratings yet

- Arcadis Orbic: System Maintenance InstructionsDocument42 pagesArcadis Orbic: System Maintenance InstructionsHomeroPerezNo ratings yet

- As 48117 KV-H20S H40S Um - GB WW 0025-1Document202 pagesAs 48117 KV-H20S H40S Um - GB WW 0025-1Tuấn NguyễnNo ratings yet