Professional Documents

Culture Documents

1

Uploaded by

Abhushan NeupaneCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1

Uploaded by

Abhushan NeupaneCopyright:

Available Formats

A drain pipe should be incorporated so that the forebay tank can be fully emptied for maintenance

work, especially if it is not possible to do so from the penstock pipe. 6. Flushing arrangement should be

provided to flush the sediment deposited in the basin. The flushing arrangement should be such that

when the flushing gate or cone is fully opened, the water level in the basin should decrease even with

the incoming design flow (i.e. rapid draw-down). 7. A spillway should be incorporated and sized to spill

the design flow (or flood flow if the system conveys flood flows to this point) without undermining

structures or causing ground erosion along its route. This is essential since when the turbine is suddenly

shut down and flow through the penstock is stopped, the flow will spill over from the forebay. 8. A fine

trash rack should be provided at the entrance of the penstock. The trash rack should be laid at a vertical-

horizontal slope of 3:1 slope for optimum hydraulic efficiency and ease of operation. The velocity

through the trash rack should be 0.6–1.0 m/s. The forebay should have walls of RCC or 1:4 c/s mortar

masonry and an RCC base slab in order to reduce the problem of partial settlement. The water-retaining

surfaces of the forebay should be plastered to 12 mm thickness using 1:4 c/s mortar with punning. In

case of multipurpose projects that need to accommodate additional flows for secondary uses till the

forebay, this structure should be sized accordingly. However, if possible, additional flows for secondary

uses should be diverted upstream of the forebay or settling basin so that the size of these structures

need not be increased.

You might also like

- Sanima - Course Topics - ANDocument5 pagesSanima - Course Topics - ANAbhushan NeupaneNo ratings yet

- Sanima Course Topics AnDocument5 pagesSanima Course Topics AnAbhushan NeupaneNo ratings yet

- Risk Assessment: San Luis Hydropower ProjectDocument12 pagesRisk Assessment: San Luis Hydropower ProjectAbhushan NeupaneNo ratings yet

- Operation and Maintenance of Hydro Tunnels 13th December 2018 Kathmandu, NepalDocument99 pagesOperation and Maintenance of Hydro Tunnels 13th December 2018 Kathmandu, NepalAbhushan NeupaneNo ratings yet

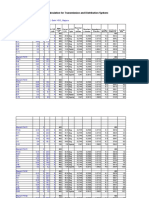

- Voltage Drop Calculation For Transmission and Distribution SystemDocument4 pagesVoltage Drop Calculation For Transmission and Distribution SystemAbhushan NeupaneNo ratings yet

- Operation and Maintenance of Hydro Tunnels 13th December 2018 Kathmandu, NepalDocument28 pagesOperation and Maintenance of Hydro Tunnels 13th December 2018 Kathmandu, NepalAbhushan NeupaneNo ratings yet

- Nepal Water For Health (Newah) : G) Kfn:Jf:Yosf) Nflu KFGL - G) JFDocument11 pagesNepal Water For Health (Newah) : G) Kfn:Jf:Yosf) Nflu KFGL - G) JFAbhushan NeupaneNo ratings yet

- Operation and Maintenance of Hydro TunnelsDocument49 pagesOperation and Maintenance of Hydro TunnelsAbhushan NeupaneNo ratings yet

- ICH Annual Report 2020 75dpi FDocument26 pagesICH Annual Report 2020 75dpi FAbhushan NeupaneNo ratings yet

- P3165 Â Geotechnical Baseline Reporting - v5Document2 pagesP3165 Â Geotechnical Baseline Reporting - v5Abhushan NeupaneNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5796)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)