Professional Documents

Culture Documents

Pages From SAES-H-001-13

Uploaded by

mohammed s fawabOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pages From SAES-H-001-13

Uploaded by

mohammed s fawabCopyright:

Available Formats

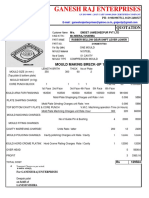

Document Responsibility: Paints and Coatings Standards Committee SAES-H-001

Issue Date: 23 May 2019 Coating Selection and Application

Next Planned Update: 23 May 2024 Requirements for Industrial Plants and Equipment

Hearing Protection

Type of Work Goggles 10000127803

Safety Impact Gloves; Leather Gloves; Rubber

to be (21-327-105)

1000129810 1000124493 1000129636

Performed 10000127807

(21-434-249) (21-432-353) (21-432-630)

(21-327-272)

Epoxy and Coal

Tar Epoxy x

Alkyd x x

x

Inorganic Zinc x x

Chlorinated x

x x

Rubber

x

Bituminous x x

x

Polyurethane x x

6 General Requirements

6.1 General

6.1.1 Blasting and coating shall not be performed if one or more of the

following conditions exist unless the coating is specifically formulated

for the averted condition (except in case novel technology applied):

a) The substrate temperature is less than 10°C or more than the

temperature limit given in the applicable Saudi Aramco Data Sheet.

b) The substrate contains oil, grease, dirt, loose coating, loose rust, or

other surface contaminants.

c) The substrate temperature is less than 3°C (5°F) above the dew

point (see Table 1).

d) Adverse weather conditions exist such as, but not restricted to

below situations. Job can only continue if proper and complete

isolation of the area are done to prevent the harmful effects of the

weather conditions.

1) Wind is strong enough to blow sand, salt spray, or other

foreign matter onto the surface being coated.

2) Wind is strong enough to cause dry spray or to otherwise

seriously disturb the spray pattern when application is by

spray gun.

6.1.2 When required, solvent cleaning shall be carried out in accordance with

SSPC-SP1. Do not use kerosene, diesel, or other degreasers that leave

an oily film unless the surface is subsequently cleaned with a non-greasy

solvent or cleaner such SAP m/n 1000186759 (s/n 26-854-642),

Saudi Aramco: Company General Use

©Saudi Aramco 2019. All rights reserved Page 13 of 122

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5806)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Drills TheoryDocument56 pagesDrills TheoryrohanNo ratings yet

- LPT ReportDocument2 pagesLPT ReportAnonymous OEUUoKHYR100% (1)

- Rancang Bangun Mesin CNC Lathe Mini 2 Axis: Eddy Kurniawan, Syaifurrahman, Bong JekkyDocument8 pagesRancang Bangun Mesin CNC Lathe Mini 2 Axis: Eddy Kurniawan, Syaifurrahman, Bong JekkyThomas RandolphNo ratings yet

- Pages From SAES-H-001-19Document1 pagePages From SAES-H-001-19mohammed s fawabNo ratings yet

- DACE Labour Norms Structural Steel V2Document6 pagesDACE Labour Norms Structural Steel V2Jose Alejandro Ruiz VargasNo ratings yet

- BS-970!3!1991-Specification For Wrought Steels For Mechanical and Allied Engineering PurposesDocument38 pagesBS-970!3!1991-Specification For Wrought Steels For Mechanical and Allied Engineering PurposesEric Mellier100% (1)

- Pages From SAES-H-001Document1 pagePages From SAES-H-001mohammed s fawabNo ratings yet

- Grades & MaterialsDocument48 pagesGrades & MaterialsgcldesignNo ratings yet

- Hani Al-Mutawa: EducationDocument1 pageHani Al-Mutawa: Educationmohammed s fawabNo ratings yet

- Pages From SAES-H-001-18Document1 pagePages From SAES-H-001-18mohammed s fawabNo ratings yet

- Pages From SAES-H-001-12Document1 pagePages From SAES-H-001-12mohammed s fawabNo ratings yet

- Pages From SAES-H-001-5Document1 pagePages From SAES-H-001-5mohammed s fawabNo ratings yet

- Pages From SAES-H-001-2Document1 pagePages From SAES-H-001-2mohammed s fawabNo ratings yet

- 05 PEXb XP650 - 1. TDS (Data Sheet)Document2 pages05 PEXb XP650 - 1. TDS (Data Sheet)Mohammad Rashad BarakatNo ratings yet

- Green University of Bangladesh Man-Made Fiber 00001 YEANDocument12 pagesGreen University of Bangladesh Man-Made Fiber 00001 YEANAbrar RomanNo ratings yet

- TDS Fosroc Solvent 102 Saudi ArabiaDocument2 pagesTDS Fosroc Solvent 102 Saudi ArabiaShaikhRizwanNo ratings yet

- Jiangsu Senolo Medical Technology Co., LTD.: NO.88 4 Road, Private Venture Park, Jianhu Contry JiangsuDocument2 pagesJiangsu Senolo Medical Technology Co., LTD.: NO.88 4 Road, Private Venture Park, Jianhu Contry JiangsuPedro Ant. Núñez UlloaNo ratings yet

- Perth CGR ExtPaintDocument6 pagesPerth CGR ExtPaintYãbeçk MâmNo ratings yet

- Cutting Tool and Cutting FluidsDocument11 pagesCutting Tool and Cutting FluidsAtif WahidNo ratings yet

- Surface Hardening of Steel: 1. Case Hardening 2. Nitriding 3. Flam Hardening 4. Induction HardeningDocument10 pagesSurface Hardening of Steel: 1. Case Hardening 2. Nitriding 3. Flam Hardening 4. Induction HardeningiurtfkuhygfjkhgjkhgjNo ratings yet

- Mould Quotation 7703 PDFDocument1 pageMould Quotation 7703 PDFdeepak patelNo ratings yet

- Product Data Sheet: Transozinc Silicate Solventborne 1.52Document2 pagesProduct Data Sheet: Transozinc Silicate Solventborne 1.52Sachin NambiarNo ratings yet

- Chris Juarez ResumeDocument1 pageChris Juarez Resumeapi-487648580No ratings yet

- Berger: Product SpecificationsDocument2 pagesBerger: Product SpecificationsAabhas UpadhyayaNo ratings yet

- Protective & Marine Coatings: Industrial Enamel Voc ComplyingDocument4 pagesProtective & Marine Coatings: Industrial Enamel Voc ComplyingAna CabreraNo ratings yet

- Machining Fundamentals Instructor's Resource 05 Layout WorkDocument8 pagesMachining Fundamentals Instructor's Resource 05 Layout WorktrollforgeNo ratings yet

- ABC Tile AdhesiveDocument1 pageABC Tile AdhesiveTeomnerCabreraNo ratings yet

- ConsumablesDocument28 pagesConsumablesadeoye_okunoyeNo ratings yet

- Lines For CPP CPE, Cast PET, Barrier and Mono-Oriented FilmDocument20 pagesLines For CPP CPE, Cast PET, Barrier and Mono-Oriented FilmAlexandra Gabriela Pacheco PrietoNo ratings yet

- Catálogo Cadenas PIAZ 2017Document256 pagesCatálogo Cadenas PIAZ 2017Eduardo Mario NuñezNo ratings yet

- Refining Processes Simulation HYSYS v.10 (PART 1)Document11 pagesRefining Processes Simulation HYSYS v.10 (PART 1)Rafael GomesNo ratings yet

- Aquarium Tank and Accessories: Create Something More Natural Than NatureDocument3 pagesAquarium Tank and Accessories: Create Something More Natural Than NatureRomon YangNo ratings yet

- Nitoflor Anti-Slip GransDocument2 pagesNitoflor Anti-Slip GransBalasubramanian AnanthNo ratings yet

- European Steel and Alloy Grades: X1Crnimocun24-22-8 (1.4652)Document2 pagesEuropean Steel and Alloy Grades: X1Crnimocun24-22-8 (1.4652)farshid KarpasandNo ratings yet

- Avk Universal Supa® Step Coupling, Pn16 602: Product DescriptionDocument3 pagesAvk Universal Supa® Step Coupling, Pn16 602: Product DescriptionArshad IqbalNo ratings yet

- Workshop Technology PDFDocument48 pagesWorkshop Technology PDFilamparithiNo ratings yet

- Casting Defects and Its Optimization Method in Centrifugal Casting Process: A ReviewDocument6 pagesCasting Defects and Its Optimization Method in Centrifugal Casting Process: A ReviewSangram ChougaleNo ratings yet