100%(1)100% found this document useful (1 vote)

566 views44 pagesSwimming POOL Design Note

Uploaded by

Jin Fong KuehCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF or read online on Scribd

100%(1)100% found this document useful (1 vote)

566 views44 pagesSwimming POOL Design Note

Uploaded by

Jin Fong KuehCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF or read online on Scribd

- Design Concepts

- References

- ASHRAE Code

- Air Condition

- DUCT & OUTLET

- ESP STATIC Calculation

- Heat Pipe

- AHU

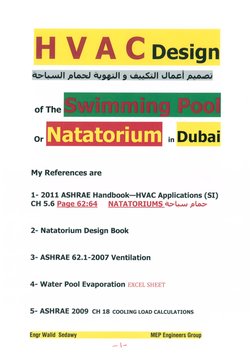

4>luw! plosd Gogil 9 Guu! Ulosi proucd

Or Natatorium in Dubai

My References are

1- 2011 ASHRAE Handbook—HVAC Applications (SI)

CH 5.6 Page 62:64 NATATORIUMS a>Lw plo>

2- Natatorium Design Book

3- ASHRAE 62.1-2007 Ventilation

4- Water Pool Evaporation £XCEL SHEET

5- ASHRAE 2009 CH 18 COOLING LOAD CALCULATIONS

ont bee

Pama! 99 OblicY) yaw élieho uy

sac 9 olSall ye asi] aL Jl lo>VI Glucd alah

Joodl cli! Ge Ugiasol Lusi dL 9 d5p>Ul 9 yyraLisel

DSO of All Ail Shou] Glus aalo] Gay Spo!

Ws uo lplu> oS pled! ahw alo

[Link]

generally from people and evaporation of water Pool surface area

Load Estimation

Loads for a natatorium include heat gains and losses from outdoor air, lighting,

walls, roof, and glass. Internal latent loads are

generally from people and evaporation.

Every building's moisture (latent) load is calculated in the same way. There are generally

three sources of moisture that are considered:

+ Internal load (pool evaporation)

+ Occupants

‘* Outdoor air load

Pool Evaporation

‘The internal load in a natatorium is the evaporation from the pool water and wet deck

surfaces. In a natatorium this represents the majority of the total dehumidification load.

Consequently, itis essential to accurately predict the pool evaporation.

There are 5 variables used to calculate the evaporation rate :

+ Pool water surface area

+ Pool water temperature

+ Room air temperature

+ Room air relative humidity

+ Pool water agitation and Activity Factor

Evaporation loads in pools

and spas are significant relative to other load elements and may vary

widely depending on pool features, areas of water and wet deck,

water temperature, and activity level in the pool.

Evaporation rate of evaporation can be estimated from

empirical Equation for pools for air velocity over water @ 10-30 fpm

= 4x 10-5A( pw - pa)Fa CHECK EXCEL SHEET

[Link] be seen from the equation that the following factors increase the evaporation rate:

« Increasing water temperature

+ Lowering air temperature

+ Lowering air relative humidity

+ High activity/agitation

aE-

1- Hap Calculation Report

(Total Load) KW) 6........(1)

2- after we get [MMB Evaporation rate (EXCEL SHEET)

USE THIS EQUATION

to get Total Latent Heat of Water Pool

Q (KW. wm * Latent Heat of Water (2260 kj/kg)

Spall Ababsth Bal Gh ( papell Gbailly GLI pa ay

a Ce Ags kata) 5 yall le Jguaally

QCKW) svenrerern(2)

Total Calculation Load =(1)+(2) kw

ASHRAE Standard 62-2007 Table 6.1

Outdoor Air ( Fresh Air )

The introduction of outdoor air is essential to maintaining good air quality in any facility.

The impact of this outdoor air ventilation on a natatorium changes with the weather and the

geographic location of the facility. Introducing outdoor air during the summer generally

adds moisture to the space and in the winter removes moisture from the space. For

maximum dehumidification load calculations the Summer Design conditions are considered.

Construction codes generally require that outdoor air be introduced into a commercial

building during occupied hours. ASHRAE Standard 62-2007 Table 6.1 recommends the

introduction of outdoor air into a natatorium at the following rates:

+ 0.48 CFM/f2 or 2.4 Lis-m2 of pool and (wet) deck area as base line

+ 7.5 CFM or 3.8 L/s per spectator added to the base line during swim meets

ASHRAE interprets the wet deck area as no more than six foot perimeter around the pool.

The purpose of this outdoor air is to help dilute chemicals off-gassed from water. A

predictably dry portion of the deck will not factor into the IAQ issues. Additionally,

os

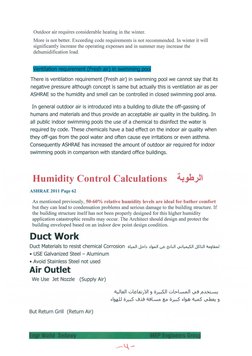

Outdoor air requires considerable heating in the winter.

More is not better. Exceeding code requirements is not recommended. In winter it will

significantly increase the operating expenses and in summer may increase the

dehumidification load.

There is ventilation requirement (Fresh air) in swimming pool we cannot say that its

negative pressure although concept is same but actually this is ventilation air as per

ASHRAE so the humidity and smell can be controlled in closed swimming pool area.

In general outdoor air is introduced into a building to dilute the off-gassing of

humans and materials and thus provide an acceptable air quality in the building. In

all public indoor swimming pools the use of a chemical to disinfect the water is

required by code. These chemicals have a bad effect on the indoor air quality when

they off-gas from the pool water and often cause eye irritations or even asthma.

Consequently ASHRAE has increased the amount of outdoor air required for indoor

‘swimming pools in comparison with standard office buildings.

Humidity Control Calculations 4:94)

ASHRAE 2011 Page 62

As mentioned previously, 50-60% relative humidity levels are ideal for bather comfort

but they can lead to condensation problems and serious damage to the building structure. If

the building structure itself has not been properly designed for this higher humidity

application catastrophic results may occur. The Architect should design and protect the

building enveloped based on an indoor dew point design condition.

Duct Work

Duct Materials to resist chemical Corrosion tall J>1> slgall ue asl! ilasSIl JSUIl aaslial

+ USE Galvanized Steel — Aluminum

* Avoid Stainless Steel not used

Air Outlet

We Use Jet Nozzle (Supply Air)

Abell lel VI 9 Bu] Ol>Luwell 98 pastas

typ byu55 GiB AdLuuo Bo dyu5S clga Aue alae 9

But Return Grill (Return Air)

Engr Walid Sedawy = MEP Engineers Group

-A\-

Project Discussion

Closed Swimming Pool Area

Gross Area = 33*20 = 660 m2

Pool Surface Area =360 m2

Average Ceiling Height = 10 m

Spectator Number = 140

HAP Program

City: Dubai

A) Outdoor Condition of the Building

Dry bulb temperature: 46°C

Wet bulb Temperature: 29°C

Dubai City Latitude: (North Latitude) 25 °N

‘Out Door Daily Range: 13.8 °C

b) Indoor Condition of the Building

Dry bulb temperature: 24°C

Relative Humidity: 50% +5 %

0.48 CFM/ft2 or 2.4 L/ssm2

7.5 CFM or 3.8 Us per spectator

Spectator Number =140

Sedentary work digit Asgee Dy Apstall Gui glal Alla of

Lightening Wattage Awlm2 Ashrae 2009 table 2 part 18.5

Type Free Hanging

The safety factor applied must be no greater than

Sensible Heat:

Latent Heat: 5%

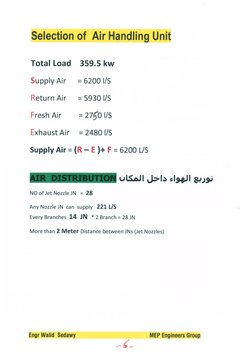

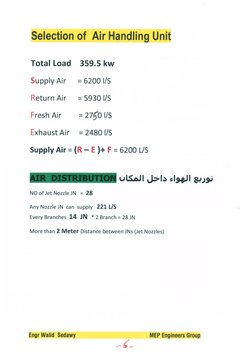

Total Load 359.5 kw

Supply Air =62001/S

Return Air =59301/S

Fresh Air = = 2760 I/S

Exhaust Air = 2480 I/S

Supply Air = (R — E )+ F = 6200 L/S

MIREDISTRIBUTION oso)! J>Is cloe)l e395

NO of Jet Nozzle JN = 28

Any Nozzle JN can supply 221 US

Every Branches 14 JN * 2 Branch = 28 JN

More than 2 Meter Distance between JNs (Jet Nozzles)

2011

ASHRAE HANDBOOK

HVAC Applications

SI Edition

Supported by ASHRAE Research

4-

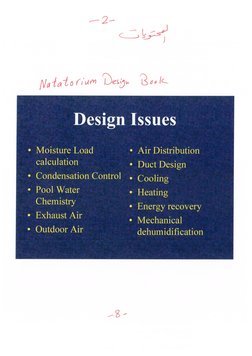

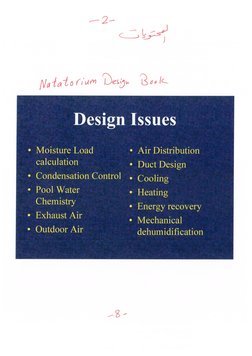

Design Issues

¢ Moisture Load « Air Distribution

EV Eveoyel * Duct Design

Condensation Control . Cerxestints

MeN EICou ¢ Heating

seen Die ounce Kony

Ua Cay Corrinne

Outdoor Air dehumidification

— 3-

ANSI/ASHRAE Standard 62.1-2007

(Supersedes ANSVASHRAE Standard 62.1-2004)

Includes ANSVASHRAE Addenda listed in Appendix I

ASHRAE STANDARD

Ventilation

for Acceptable

Indoor Air Quality

‘See Appendix fr approval dates by the ASHRAE Standards Commitee, the ASHRAE Board of Directors, andthe

‘American National Standards Insite.

“This slandardis under continuous maintenance by a Standing Standard Project Commitee (SSPC) for which the

Standards Commitee has established a documented program for regular publcaton of addenda or revisions,

Including procedures for timely, documented, consensus acton on requests for change fo any pat ofthe stan

dard. The change submittal fom, instructions, and deadlines may be oblaned in electronic frm from the ASHRAE.

‘Wb sit, hitp:/[Link], in pape form from the Manager of Standards. The lates edition ofan ASHRAE.

‘Standard may be purchased trom ASHRAE Customer Service, 1791 Tulle Circe, NE, Alanta, GA 30829-2906.

E-malt orders @[Link], Fax 404-321-5478, Telphone: 404-696-8400 (wokdwide), orto tee 1-800-527-

4723 (for orders in US and Canad),

{© Copyright 2007 ASHRAE, Inc.

ISSN 1044-2396

@

wormansLorg

American Society of Heating, Refrigerating

and Air-Conditioning Engineers, Inc.

1791 Tulle Circle NE, Atlanta, GA 30329

[Link]

-4-

oe

CHAPTER 18

Re mercial Resour

2009

NONRESIDENTIAL COOLING AND HEATING

LOAD CALCULATIONS

Cooling Load Calewaton Principles 18

Internal Heat Gains a 183

Infltration and Moishire Migration Heat Gains We.

Fenestration Heat Gain 14

Heat Balance Method 18s

Radiant Tine Series (RTS) Method 1820

‘Heating Load Caleutations 1828

System Heating and Cooling Load Efects 1832

Example Cooling and Heating Load

CaLeWatION nnn 18.36

Previous Cooling Load Calculation Methods 1849

Building Example Drawings 1856

EATING and cooling load calculations ae the primary design

basis for most heating and at-conitioning systems and com

[ponens. These calculations affect the sizeof piping, ductwork, di

fsers, ar handlers, boilers, chillers, eos, compressors, fans, and

every ther component of systems that condition indoor enviton-

‘ments. Cooling and heating load ealeulations can significantly affect,

first cost of building construction, comfort and productivity of oceu-

Pants, and operating cost and enerzy consumption

‘Simply pt, heating and cooling loads are the rates of energy in-

put (heating) or removal (cooling) required to maintain an indoor

‘environment at desired temperature and humidity condition. Hea

ing and ar conditioning systems ae designed, sized, and controlled

toaccomplish tha energy transfe. The amount of heating or cooling

required at any particular time varies widely, depending on exter

(ouside temperature) and intemal (eg, number of people oe

eupying a space) factors,

Peak design heating and cooling load caleulations which are this

chapter's focus, seck fo determine the maximum rte of heating and

cooling energy transfer needed at any point in ime. Similar princi-

pls, but with different assumptions, data, and application, can be

‘used to estimate building energy consumption, as described in

Chapter 19,

This chapter discusses common elements of cooling lod calew

lation (intemal heat gain, ventilation and infiltration, moisture

migration, fenestration heat gain) and two methods of heating and

cooling load estimation: heat balance (HB) and radiant time series

rs)

COOLING LOAD CALCULATION

PRINCIPLES

Cooling loads result from many conduction, convection, and radi

ation heat transfer proceses through the building envelope and from

internal sources and system componens. Building components or

contents that may affect cooling lads include the folowing

+ External: Walls, oof, windows, skylights, doors, partitions,

ceilings, and floors

‘Air leakage and moisture mi

+ System: Outside air, duct leakage and heat gain, reheat, fan and

pump energy, and energy recovery

‘TERMINOLOGY

The variables affecting cooling load calulations are numerous,

often dificult to define precisely, and always intricately intere-

Jated, Many cooling load components vary widely in magnitude,

“The preparation ofthis chapter is assigned 19 TC 4.1, Load Calculation

181

Copytight © 2009, ASHRAE

O-

and possibly direction, during a 24h period. Because these eylic

‘changes in load components often are notin phase wit each other,

cach component must be analyzed to establish the maximum cool.

ing load fora building or zone. A zoned system (ie, one serving

Several independent areas, each with its own temperature control)

needs to provide no greater total cooling load capacity than the Tar

esthourly sum of simultaneous zone loads throughout a design day;

however, it must handle the peak cooling load for each zoe att

individual peak hour At some times of day during heating or inter-

mediate seasons, some zones may require heating while oxhers

require cooling. The zones" ventilation, humidification, or dehu-

‘midifistion nocd must also be considered.

Heat Flow Rates

In air-conditioning design, the following four related heat ow

rates each of which varies with time, must be diferentiatd

‘Space Heat Gain, This instantancousrate of hat gun the rate

at which heat enters into andr is generated within a space. Heat

san is classified by its mode of entry into the space and whether it

is sensible or latent. Entry modes include (1) solar radiation

‘through transparent surfaces; (2) heat conduction through exterior

walls and roofs; (3) heat conduction through ceilings, floors, and

interior partitions; (4) heat generated in the space by occupants,

lights, and appliances (5) energy transfer through dret-with-space

ventilation and inflation of outdoor air and (6) miscellancous

heat gains. Sensible heat is added directly othe conditioned space

by conduction, convection, and/or radiation. Latent heat gxin

‘occurs when moisture is added to the space (e.g from vaporemitied

by occupants and equipment). To maintain 3 constant humidity

ratio, water vapor must condense on the cooling apparatus snd be

emoved atthe same rate it i added tthe space. The amount of|

energy required to offset latent heat gain essentially equals the prod

uct of the condensation rate and latent heat of condensation, In

Selecting. cooling equipment, distinguish between sensible and

latent heat gain: every cooling apparatus has different maximum

‘removal eapactics fr sensible versus latent heat fr particular opet-

ating conditions. {a extremely dy climates, humidfeation may be

‘equied, rather than dehumidifcation, to maintain thermal comfor.

‘Radiant Heat Gain. Radiant energy must first be absorbed by Sut.

faces that enclose the space (walls, lor, and ceiling) and objects in

the space (furniture, et). When these surfaces and cbjects Become

‘warmer than the surrounding air, sme of ther heat transfers tothe

airby convection. The composite heat storage capacity of these su-

faces and objects determines the rate at which their respective su=

face temperatures increase for a given radiant input, and thus governs

the relationship between the radiant portion of beat gain and its cor

responding part ofthe space cooling load (Figure 1). The thermal

storage effec i critical in differentiating between instantaneous htt

sain fora given space and its cooling load at that moment. Predicting

the nature and magnitude ofthis phenomenon in order to estimate a

realistic cooling load for a particular st of circumstances has long

Software

Application Notes

The use of heat pipes for enhanced dehumidification, heat recovery and

displacement ventilation systems is discussed in detail in SPC’s range of

Application Notes. Please contact our Technical Sales Team for your copy,

or alternatively download them freely from our website.

PD Presentation

SPC are able to offer a CIBSE approved presentation on Heat Pipes

and their application in the HVAC industry. Please contact our office

for further details.

\ ore

Beater

Ste Excel sheet

56

‘Storage areas can generally be conditioned by exhausting excess air

fiom the main exhibit hall though these spaces

4

GOP UP NATATORIUMS

Environmental Control

A eam rues yearend baniiy level beeen 40

ands coor rece nr cosungin, ad aling

Crete pesto The eget madre th fling cee

crn huni conte, rom pen onal vena reie

ina ora gly (dor td exit ha dssaon doe

{ap pool water Semi, and evaporator Ahi

nel Sc ne wil provid story ul any of

thse ems ae ovesoked Sue Chapter 2 of fe 2008 ASHIAE

Hndiok HVAC Systems ond Epes or aon huni

ier encanta den forte,

Humidity Controt

humidity

Outside the $0 to 60% range are not recommended. Sustained levels

above 60% can promote faciors that reduce indoor air quality. Rel-

ative humidity levels ificantlyinrease the facility's

energy consumption, Timits evapora

‘tion and coresponding heat loss 1s comfortable

‘without being extreme. Higher relative humidity levels can be de~

structive to building components. Mold and mildew canatack wall,

oor, and ceiling coverings, and condensation can degrade many

building materials In the worst ease, the roof structure could fa

because of eorosion from water condensing on the strctre

Loads for a natatorium include heat gains and losses from out-

or ar, ighting, walls, roof, and glass. Tntemal latent loads are

_Bencraly from people and evaporation. Evaporation loads in pools

and spa are significant relative o other load elements andmay vary

‘widely depending on pool features, areas of water and wet deck,

ind activity level in the poo!

od area of wetted

‘deck. Other pool uses may have more or less evaporation (Smith

tal. 1993).

4 (oe pgX0089-+ 0.0782 7) 0

y

where

capocton of water ks

~ are of poo sure,

Y= latent heat required io change wate to vapor at surface water

tempera, Kg

= Station vapor pos tken at surfs wale temperate,

ie

’,~ saturation pressre at oom itd poiat KPa

1 ~ air velocity over water sac. ms

‘Typical Natatorium Design Conditions

‘Ale Water

‘Typeot Poot Temperature, °C Temperature, °C

Recreational 20929 261029 —-s0%060

Thenpentic Tew 291035

Competition 261029 26102

Diving 27029 rex

Edel swinmers 291032 29032501060,

Hoel 261029 281030 01060

Whirpootpa 5019.60

SETS atmos vo ab ion

lactat

2011 ASHRAE Handbook—HVAC Applications (S1)

=

Units forthe constant 0.089 are Wi(m?-Pa). Units forthe const

(0.0782 are (W-s)(en*-Pa).

Equation (1) may be modified by multiplying it by an activity

factor Ft alter the estimate of evaporation rate based on the level

‘of ctivity supported. For Y values of shout 2400 kl kgand V values

ranging from 0.05 to 0.15 ms, Equation (1) ean be reduced 10

‘The following activity fictors should be applied to the areas of

specifi features, and not to the entire wetted are

@

Type of Poo

Baseline (pot unoccupied)

Residential poo!

CCondeminism

Therapy

Hote

Whiipoots, spas

Wavepools waterslides

The effectiveness of controling the natatorium environment

depends on cored estimation of water evaporation ates. Applying

the correct activity factors i extemely important in determining

water evaporation rates, The difference in peak evaporation rates

between private pools and active public pools of comparable size

may be more than 100%

“Actual operating temperatures and relative humidity conditions

shouldbe established before design, How the are wil be used ust

ol 5 energy conservation

through reduced evaporation and to avoid chill effects on swim-

Competition pools that hos swim meets have two distinct oper

ating profiles: (1) swim meets and (2) normal occupancy. Ii ee-

fmnmended that both be fully modeled to evaluate the facility's

needs. Although swim meets end tobe infrequent, the loads during

meets are often considerably higher than di

loads should also be designed to operate for considerable portions of

the year at part loads.

‘Water parks and water feature (slides, spray cannons, arches, ef.)

loads are not uly covered by ths chapter It is ecommended that the

‘dehumidifcaion load generated by each water feature be calculated

individually. The water toys’ manufacturers shouldbe contacted to

Provide specifications tallow fr proper load determination Due to

the concentrated nature ofthe loads in these Facilites, tis recom

mended that more supply air and outdoor ar be used in these fcli-

ties compared t what is recommended for traditional pools

Venttaion Requirements —> ste R15 Ashe

‘Ale Qual. Outdoor air setlain ral’ by

AShttal Suton 2 we incoted pode etl

auiy sno rhe vege poo wig cle pay

Jencton The vealaton rte ey be scat ep

wn peaplleeenee aon cn eiey ainemeiat

pat righ cceapuncy pico wc pat aeons

SRN Ona usta Dae peer aay

quay potcen singly incenlgvetaton res ey pve

Srnec ed ative Wacoal eatin es ce

hedt sf water 22297 Ky] Ie

faye 62.

yeahdhion

Wie 6-1

Places of Assembly

function of po! use and the type and effectiveness of water isin

Feetion used

‘Because indoor pools usually have high esilings, temperature

stratification and stack effect (see Chapter 16 ofthe 2009 ASHRAE

Handbook—Fundamentals) can have a detvimental eect on indoor

air quality. Careful duct layout must ensure that the space receives

proper air changes and homogeneous air quality thoughout. Some

Airmovement atthe deck and pool water level is esential to ensure

acceptable ar quality. Complains from swimmers indicate that the

‘reatest chloramine (se the section on Pool Water Chemisty) con

‘centrations occur atthe water surface, Children ate especially vul-

‘erable to the il effects of chloramine inhalation,

"Exhaust air from pools is rich in moisture and may contain high

levels of corrosive chioramine compounds. Although most codes

allow pool iro be used as makeup for showers, toilets, and locker

rooms, these spaces should be provided with separate ventilation

and maintained ata positive pressure with respect othe pool

‘Pool and pa areas shouldbe maintained ata nepative pressure of

15040 Parelative tothe outdoors and adjacent areas ofthe building

to prevent chloramine odor migration. Active methods of pressure

control may prove more effective than static balancing and may be

reessary where outdoor sir is used as a part ofan ative humidity

control strategy: Openings from the pool to other areas should be

minimized and controled. Passageways should be equipped with

doors with automatic closers and sweeps to inhibit migration of|

moisture and

Id be located as close as posible to

th 3 fity. Warmer waters and thse

with high agitation level of gas chemicals at higher rates compared

to traditional pools. This also allows body oils to become airborne,

Ideally these pollutants should be removed from close tothe source

before they have a chance to diffuse and negatively impact the air

Installations with intakes directly above whirlpools have

resulted in ality

“Most codes require a minimum of sx air

‘changes per hour, except where mechanical cooling is used. This

rate may prove inadequate for some occupancy and use.

‘Where mechanical dehumidifcation is provided, air delivery

rates should be established to maintain appropiate conditions of

Aemperture and humidity, The following rates are tpially

lesired

Pools with no spectator areas

Spectator areas

“Therapeutic pools

(Outdoor air detivery rates may be constant or variable, depend-

ing on design. Minimum rates, however, must provide adequate

dilution of contaminants generated by pool water and must m

sceeplabe ventilation for occupancy,

‘Where a minimum outdoor at ventilation rate is established to

protect agains! condensation ina building's structural elements the

Fates are typically used for 100% outdoor air systems. These rates

usualy result in excessive humidity levels under most operating

conditions and are generally not adequate t0 produce acceptable

indoor air quality, especially in public facilities subject to heavy use

410 6 ar changes per hour

6 0 8 air changes per hour

410 6 ar changes per hour

Proper duct design and installation in a natatorium is ete.

Failure to effectively deliver air where neded can result in ae qual-

ity problems, condensation, stratifiaton, and poor equipment pe

formance, Ductwork that fils to deliver airflow a the pool deck and

\watr surface, for example, ca lead oar quality problems in those

axeas. The following duct construction practices apply to natatori=

fase

axe realy atacked by chlorides and are prone to pitting. They

requi ‘ewiron

vanized doct is used, steps shou

i adequately protect the metal from corrosion. Is recom

‘mended that, a a minimum, th galvanized ducts be properly pre-

pared and painted with epoxy-based or other durable paint suitable

fo protect metal surfaces in anatatoriam environment. Noe that

salvannealed ductwork is easier to weld and pain than ot-ipgal-

‘anized, but galvannaled is more susceptible to corrosion i left

bare. Certain types of fabric duct aitigh) with appropriate giles

sewn in are also a good choice. Buried ductwork should be con-

structed ffom nonmetallic fiberglass reinforeed or PVC materials

hecause of the more demanding environment.

+ Supply air shouldbe directed against envelope surface prone to

condensation (lass end door). Some suply ai should be di

‘ected over the water surfice to move contaminated ait oward an

{hast pint and condo chloaines release te wae su

irmavement ove the pool wate sirface mas not

[as per the evaporation rat wn Equation (1).

+ Retum irines shouldbe loeaedto recover war bur aiand

‘etumittthe ventilation system frtretment, 0 prevent spy

Sir fom shoring ano miinizeocrulto of eles:

+ Exhaust ir ines shouldbe located to maximize capt fe

tiveness and minimize rectulaton of ehoramines. Existing

from desl above winpools so desirable Exhaust a

should be taken ciety tothe outdoors, trough heat covery

devices where provided.

+ Fiation shouldbe selected w provide 45 065% ficiencies as

defined in ASHIRAE Standard 3.1) and be installed in locations

Selected to prevent condensation in the iter bank, Filter media

nd support materials shouldbe resistant o moist degradation

"mys miei a tc

ayo

wich re or val oe od

cng bated bets oasis at

and speech intelligibility.

Envelope Design

Glazing in exterior walls becomes susceptible to condensation

‘when the outdoor temperatute drops below the pool room dew

point. The design goa is to maintain the surface temperature ofthe

floss and the window frames a minimum of 3 K above the pool

oom dew point. Windows must allow unobstructed air movement

fn inside surfaces, and thermal break frames should be used 10

raise the indoor temperature ofthe fame. Avoid recessed win-

‘dows and protrading window frames. Skylights are especialy vul-

fnerable, and require attention to contol condensation. Wall and

roof vapor retarder designs should be carefully reviewed, espe-

lly at wall-to-wall and wall-to-roof junctures and at window,

skylight, and duct penetrations, The pool enclosure must be

Suitable for year-round operation at $0 to 60% relative humidity

‘A vapor retarder analysis (as in Figure 12 in Chapter 27 of the

2009°ASHRAE Handbook Fundamentals) should be prepare.

Failure to install an effective vapor retarder will result in conden~

sation forming inthe structure, and potentially serious envelope

damage.

Pool Water Chemistry

Failure to maintain proper chemistry in the pool water causes

serious air quality problems and deterioration of mechanical

systems and building components. Water treatment equipment

-\3-

58

and chemicals should be located in a separate, dedicated, well-

ventilated space that is under negative pressure, Pool water teat

‘ment consists of primary disinfection, pl contol, water filtration

and purging, and water heating. For futher information, refer to

Kowalsky (1990)

Air quality problems are usually caused bythe reaction of chlo-

Fine with biological wastes, and particularly with ammonia, which

isaby-product ofthe breakdown of urine and perspiration. Chlorine

reacts With these wastes, creating chloramines(menochiocamine,

chloramine, and nitogen trichloride) that are commonly me

sured as combined chlorine. Adding chemicals to pool water

increases total contaminant levels. In high-occupancy pools, water

contaminant levels can double in a single day of operation

CCilorine’s efficiency t reducing ammonia is affected by several

factors, including water temperature, water pH, (ta chlorine con-

centration, and level of dissolved solids inthe water. Because of|

their higher operating temperature and higher ratio of occupancy

per unit water volume, spas produce greater quantities of at cone

taminans than pools.

‘The following measures have demonstrated a potential to reduce

cfsloramine concentrations inthe air and water:

+ Ozonation. In low concentrations, ozone has. substantially

reduced the concentration of combined chlorine in the water. [a

high concentrations, ozone can replace chlorine as the primary

sisinfection process: however, ozone is unable to maintain sufi=

cent residual levels inthe water to maintain a latent biocidal

effect. This necessitates maintenance of chlorine as residual

process at concentrations of 05 to 1.5 mp,

+ Water Exchange Rates. High concentrations of dissolved sol-

{ds in water have been shown to directly eontribute to high com-

bined chlorine (chloramine) levels. Adequate water exchange

les are necessary to prevent the buildup of biological wastes

and their oxidized components in pool and spa water. Conduc-

tivity measurement is an effective method to control the ex-

change rate of water in pools and spas to effectively maintain

‘water quality and minimize water use. In high-occupancy pools,

heat recovery may prove useful in reducing water heating en:

eray requirements

Energy Considerations

"Natatorium can be a major energy burden on facilities, so they

representa significant opportunity for energy conservation and

recovery. ASHIRAE Standard 90.1 offers some recommendations

Several design solutions are possible using both dchumidifcation

and ventilation strategies. When evaluating a system, the seasonal

space conditions and energy consumed by all elements should be

considered, including primary heating and cooling systems, fan

motors, water heater, and pumps

Operating conditions factor significantly in the total energy

‘requirements ofa natatorium. Although occupant comfort isa pr

‘mary concer, the impact of low space temperatures and relative

‘humidity leveis below 50% (especially in winter) should be dis-

cussed withthe owner/operator. Reductions in either room ar tem-

perature or relative humidity inerease evaporation from the pools,

‘hus increasing the dehunsidiieation requirements and increasing

ool water heating costs,

[Natatoriums with Fixed outdoor ait ventilation rates without

‘dchumiification generally have seasonally Nuetuating space tem-

perature and humidity levels. Systems designed to provide mi

‘mur ventilation rates without dehumidifcation are unable ‘0

‘maintain relative humidity conditions within prescribed limits,

Those systems may facilitate mold and mildew growth and may be

‘unable to provide accepable indoor air quality. Peak dehumidifca-

tion loads vary with activity levels and during the cooling season

‘when ventilation air becomes an additional dehumidieatonloadto|

the space

2011 ASHRAE Handbook—HVAC Applications (S1)

FAIRS AND OTHER TEMPORARY

EXHIBITS

Occasionally, large-scale exhibits ae constructed t stimulate

business, present new ideas, and provide cultural exchanges. Firs

ofthis type take years to construct, are open fom several months 19

several years, and are sometimes designed considering future use of|

some buildings. Fairs, carnivals, or exhibits, which may consist of|

prefabricated shelters and tents that are moved frm place to place

and remain ina given location fr only afew days or Weeks, ae not,

covered here because they seldom require the involvement of achi-

tects and engineers

Design Concepts

‘One consultant or agency shouldbe responsible for setting uni-

form utility service regulations and practices to ensure proper oea-

nization and operation ofall exhibits, Exhibits that are open only

You might also like

- Heating and Ventilating Indoor Swimming Pool100% (1)Heating and Ventilating Indoor Swimming Pool4 pages

- Swimming Pool Evaporation Loss Calculation VERY IMPORTANTNo ratings yetSwimming Pool Evaporation Loss Calculation VERY IMPORTANT5 pages

- Pool Balancing Tank Calculation: A) Bathing Load - Equation 1No ratings yetPool Balancing Tank Calculation: A) Bathing Load - Equation 11 page

- Project Standard Specification: Jacuzzi 15491 - Page 1/5100% (1)Project Standard Specification: Jacuzzi 15491 - Page 1/55 pages

- J-Heat Cool Pump Calculations - Mercedes BenzNo ratings yetJ-Heat Cool Pump Calculations - Mercedes Benz8 pages

- Swimming Pool Calculation: To Calculate Pipe Sizing100% (4)Swimming Pool Calculation: To Calculate Pipe Sizing21 pages

- Natatorium Design & Humidity Control GuideNo ratings yetNatatorium Design & Humidity Control Guide12 pages

- Natatorium Design Webinar Presentation For Reps PDF100% (1)Natatorium Design Webinar Presentation For Reps PDF101 pages

- Thsi I P Le I T The Swimming Pool Environment The NatatoriumNo ratings yetThsi I P Le I T The Swimming Pool Environment The Natatorium34 pages

- Ashrae Swimming Pools Summary 1718855647No ratings yetAshrae Swimming Pools Summary 17188556473 pages

- ASHRAE Journal Article July 2017 Pool Ventilation100% (1)ASHRAE Journal Article July 2017 Pool Ventilation9 pages

- Dehumidification Strategies for NatatoriumsNo ratings yetDehumidification Strategies for Natatoriums8 pages

- 2025.08.18 - Reconfirmation of Accident Date (1) - SignedNo ratings yet2025.08.18 - Reconfirmation of Accident Date (1) - Signed1 page

- 2025.08.18 - Reconfirmation of Accident DateNo ratings yet2025.08.18 - Reconfirmation of Accident Date1 page