Professional Documents

Culture Documents

7 Filtrationof Water

Uploaded by

sameer khan0 ratings0% found this document useful (0 votes)

23 views38 pagesfiltration

Original Title

7FiltrationofWater

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentfiltration

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

23 views38 pages7 Filtrationof Water

Uploaded by

sameer khanfiltration

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 38

FILTRATION OF WATER.

—-~1!

8-1, GENERAL:

The sedimentation tanks remove a large percentage of th

suspended solids and organic matter present in raw water. th

process of coagulation of water further assists in the removal y

impurities present in the water. But even then, the resultant wate

is not pure and may contain some very fine suspended partic,

bacteria, etc.

In order to remove or to reduce the contents of impurities

still further, the water is filtered through the beds of fine granuls

materials like sand. The process of passing the water through th

beds of such granular materials is known as the filtration.

The filtered water is potable and palatable and it is fe

from various undesirable impurities like colour, odour, turbidity

pathogenic bacteria, etc.

i i tration

In this chapter, the various aspects associated with the fi

of water will be described in brief.

8-2, THEORY OF FILTRATION: ap

5 a

The process of filtration forms the most important al

the purification of water, It usually consists in ee

pass through a thick layer of sand, It has been no!

: ; followitt

experience that during the process of filtration, the

effects occur on water:

: res

(1) The suspended and Colloidal impurities which are 4 ge

a

in water in a finely divided state are removed t0

extent,

(2) The chemical charac!

(3) The number of

reduced,

d.

teristics of water are ets e

bacteria present in water is also ©

art. 8-21 Filtration of Water

The theory of filtration to explain wh -

jg bused on the following four peraaihY Such effects take place

(1) Mechanical straining

2) Sedimentation

201

(3) Biological metabolism

(4) Electrolytic changes.

(1) Mechanical straining: The suspended particles which are

unable to pass through the voids of sand grains are arrested and

removed by the action of mechanical straining.

(2) Sedimentation: The voids between sand grains of filter

act more or less like small sedimentation tanks. The particles of

impurities, arrested in these voids, adhere to the particles of sand

grains mainly for the following two reasons:

(i) due to the presence of a gelatinous film or coating

developed on sand grains by previously caught bacteria

and colloidal matter;

(i) due to the physical attraction between the two particles of

matter.

Thus the suspended impurities are removed by filter by the

action of sedimentation.

(3) Biological metabolism: The growth and life process of

the living cells is known as the biological metabolism and the

action of filter is explained on the basis of biological metabolism.

When bacteria are caught in the voids of sand grains, a zoological

jelly or film is formed around the sand grains. This film contains

large colonies of living bacteria. The bacteria feed on the organic

impurities contained in water. They convert such impurities into

harmless compounds by the complex biochemical reactions.

(4) Electrolytic changes: The action of filter is also explained

by the ionic theory. It states that when two substances with

opposite electric charges are brought into contact with each other,

the electric charges are neutralised and in doing so, new chemical

substances are formed.

It is observed that some of the sand grains of filter are

charged with electricity of some polarity. Hence, when particles

Of suspended and dissolved matter containing electricity of opposite

polarity come into contact with such sand grains, they neutralise

ach other and it ultimately results in the alteration of chemical

Characteristics of water. After some interval of time, the eo

Power of sand grains gets exhausted. At that time, ‘% Toocti

necessary to clean the filter_and restore it with this property

202 water Supply and Sanitary Engineering

t

8-3. FILTER SAND: Shy

The cand to be used for filter should be free from ¢,

organic impurities, etc. It should also be loam

The filter sand Uniform,

H it

vegetable matter,

classified on th

e

basis 9

in nature and size.

eifective size and uniformity coefficient.

The effective size of sand indicates the size of sieve j

through which 10% of the sample of sand by weight io

Pass

“The uniformity coefficient of sand is the ratio of sieve si

mm through which 60% of the sample of sand by eigen

pass to the effective size of sand. For instance, su ight wil

Pective size of a sample of sand is 0.50 mm. If 60% oft

from the same sample passes through 0.60 mm sieve, the ween

iy

1 0.60

fi f = 9:89 = 1.20.

coefficient will be = ggg = 1:20

The anthrafilt is sometimes used instead of sand. It is

from anthracite which is a stone-coal that burns nearly ae

flame or smoke. It almost entirely consists of carbon. This mat i

rae ot enetscess many advantages such as low cost in handing

high rate of filtration, durability, better efficiency, etc. But as sa

is fteadily available, the usual practice is to recommend tel g

sand for filters.

8-4. CLASSIFICATION OF FILTERS:

The filters are classified into the following two categories:

(1) Slow sand filters

(2) Rapid sand filters.

The rapid sand filters are further sub-divided into the following

two categories:

(1) Gravity type rapid sand filter

(2) Pressure type rapid sand filter.

The above classification is based on the rate of fie

On the consideration of gravity and pressure, the filters may

classified as follows: Filters

Gravity filters pressure fites

Slow sand filters Rapid sand filters

at. 831 ration of Water 203

Combining the above two classification:

Bee ines | opeatol acest ications, we will study the

(1) Slow sand filters

(2) Rapid sand filters (gravity type)

@) Pressure filters,

We will now discuss the above three types of filters in detail.

g-5. SLOW SAND FILTERS:

(1) Purpose: In case of slow sand filtration, the water is

allowed to pass slowly through a layer of sand placed above the

base material and thus the purification process aims at simultaneously

improving the biological, chemical and physical characteristics of

water. The slow sand filtration is very well suited for rural areas

in developing countries because of its simple operation and

maintenance procedures. It thus provides safe drinking water at

low recurrent cost.

(2) Essential parts: A slow sand filter consists of the following

five parts:

@ Enclosure tank

i) Underdrainage system

(iii) Base material

(iv) Filter media of sand

() Appurtenances.

i) Enclosure tank: A watertight tank is constructed either in

stone masonry or brick masonry. The sides and floor are

also coated with waterproof material. The bed slope is

about 1 in 100 to 1 in 200 towards the central drain. The

depth of tank is about 2.50 m to 3.50 m. The surface

area of a slow sand filter may vary from 30 m2 to 2000 m2

or even more.

(i) Underdrainage system: The underdrainage system consists

lateral drains as shown in fig. 8-1.

of a central drain and

The lateral drains are placed at a distance of about

2.50 m to 3.50 m and they are stopped at a distance of

about 300 mm to 800 mm from walls of the tank, The

drains may be of pipes which are laid with open joints or

they may consist of patented drain devices.

The lateral drains can also be formed by placing two

rows of bricks at right angles to each other. The first

layer of bricks is laid with the direction of its rows

Perpendicular to the central drain. The bricks in this layer

are placed about 25 mm to 40 mm apart. This space acts

water Supply and sanitary Engineering

-s The second layer is placed wj

lateral drains. TI With |

i right angles to the first layer and the bricks TO,

jayer are closely spaced. ing

— Inlet chamber Outlet chamber —

204 .

|

“Lateral drains

Plan of slow sand filter

Fic. 8-1

(iii) Base material: The base material is gravel and it is placed

on the top of underdrainage system. Its depth varies from

300 mm to 750 mm. It is usually graded and laid i

layers of 150 mm. The topmost layer should be of small

size gravel and the lowest layer should be of bigger siz

gravel. Following is a typical section of base material:

Topmost layer 150mm depth — size 3mm to 6mm

Intermediate { 150mm depth — size 6 mm to 20mm

layers: 150 mm depth — size 20 mm to 40mm

Lowest layer 150 mm depth — size 40 mm to 65mm

Total 600 mm depth

(i) Filter media of sand: A layer of sand is placed abow

gravel. The depth of sand layer varies from 600 mm

900 mm. The effective size of sand varies from 0-20 ™

fo (0.30 mm and the uniformity coefficient of sand

ahout 2 to 3. The finer the sand, the better will be *

that ent Of filter regarding removal of bacteria. Bt

oe oe the output from filter is lowered.

qpPyrtenances: The various appurtenances are to be

air pipe pascint, Working of slow sand filters.

Such pipes hae through layer of sand may b'

The devices ‘uP iP Proper functioning of filtering |

Measuring loss of head, for Com!

bove sand layer and for maintaini™

filter are to be suitably installed

an. 851 Filtration of Water 205

In order to maintain a constant discharge through the

filter, an adjustable telescopic tube as shown in fig. 8-2,

usually adopted. The difference of water level between

the filter tank and outlet chamber is known as the filter

head and it is about 100 mm to 150 mm for freshly

cleaned filter. It then goes on increasing as filter layers

get clogged and the telescopic tube is adjusted by manual

labour to maintain a uniform discharge.

Outlet chamber

“+ Filtering head

+ —}} Adjustable

telescopic

tube

Gravel

Floor:

‘Channel

‘Outlet for filtered water

Cross-section through outlet chamber

Fic. 8-2

__ (3) Working and cleaning: The water is allowed to enter the

filter through the inlet chamber. It descends through the filter

media and during this process, it gets purified. It is then collected

in the outlet chamber and taken to the clear water storage tanks.

It is to be noted that the water should not be treated with

Coagulants in sedimentation tanks. This is due to the fact that

dirty skin formed by floc and carried to the filter considerably

affects the economical working of the filter.

The depth of water on filter is to be carefully decided. It

should neither be too small nor too high. Generally it is kept as

equal to the height of filter media of sand.

The slow sand filters are usually worked for a maximum

filtration head of 750 mm or so. But from the view point of

Safety, the maximum filtration head desired is obtained by

ultiplying the depth of filtering sand with a factor of 0.67 to

fihes Thus, when specified limit of filtration head is reached, the

ter requires cleaning.

water $upplY and Sanitary Engineering

a

ing, the top layer of tay,

e of cleaning, Of sand jg |

riemugh 2 depth of about 15 mm to 95° Scra

ed aamitted £0 the filter. But the purified ya” Th

nen mi the formation of film around Bate is at

taken ito yy require a period of about one or pyr’ Br

occurs. had been done for fy

: ning of filter had b for a numb, %s

When cleaning © titer media of sand is reduced. {n° ting

the effective depth o r :

maintain the efficiency of filter, a fresh layer of can ond .

‘ded sand is then added to the filter. At places °,™

depth of gra en a

sept of ee shortage of filtering sand, the scraped sand qy"hte

sere cleaning operations is washed and stored fo, izing

f

replacement. sl

The interval between two successive cleanings dey

Pends main,

on the nature of impurities present in water to be treated antl

on She Talering sand. It usually varies from 1 to 3 moan t

(4) Rate of filtration: The rate of filtration for a .

slow sand filter varies from 100 to 200 litres per hour

of filter area.

Rormal

per mz

(5) Efficiency of slow sand filters: The efficiency of slo

sand filters is as follows:

(@ Bacterial load: The slow sand filters are highly efficient

in the removal of hacterial load from water. It is expected

that they remove about 98 to 99 per cent of bacteria

load from raw water and this percentage may be as high

as 99.50 to 99.90 when pre-treatment has been given (0

the raw water. However, for complete removal of bacteria

the disinfection is essential.

Colour: The slow sand filters are less efficient in th

Femoval of colour of raw water. It is estimated that the

Tmove about 20 to 25 per cent colour of raw water

tte a

Turbidity: The slow sand filters can remove turbidity

ihe extent of about 50 p.p.m. For water ha Beira

idity tk i i a

weebisty than 60 p.p.m., it is necessary to give Pr

pre ppt

Problem and bring down its turbidity below 50 P-P

ani

area of slo 1@

of 15000

id per day,

Find the

2 population

tres per hea

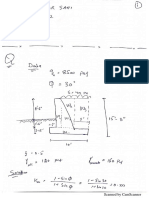

Solution:

hi

Wien’ filters required for a tow? .°

with an average rate of deman

Maxi

imum daily demand (15000 x 160 x 1-50

3600000 litres.

Assuming 2 rate of filtration as 1

of fier area, 50 litres per hour per m?

area of filter required = 3600%

% Alter required = TSpsrag ~ 1000 m2

Let the size of one unit be 16.00 mos 12.

tm % 12.50 m. Then provide

6 such units of slow sand filters including one nit ae atoneiy

The units may be arranged in series witha cei

a is on either sic

RAPID SAND FILTERS (GRAVITY TYPE):

(1) Purpose: The great disadvantage of a slow sand fiter is

that it requites considerable space for its installation. This requterment

makes it uneconomical for places where land. velues, are

high. As seen in problem 1, the area required for slow sand

fiter, only for a moderate town of 15000 population, works out

to be 1000 m2 and with future expansion, other additional equipment,

tte. the area required for water supply project would be about

3000 m? or 80.

From coagulation

eee Aiccompressor uit

Water level wile ite

‘Water level wl Washing

Boos

San

Gravel

Tarr drains ~ Wash water pipe

‘Wash water dria

To fitered water

storage tank

Lay r ind filter (gravity type)

cof a typical rapid af

of a typical rapid

ply and Sanitary Engineering

208 water Sup|

This difficulty of requiring more space for slow :

led the engineers nd scientists to find out means ee fi

the rate of filtration. It was observed that the rate of inca’

can be increased in two ways: fit

(by increasing the size of sand so that frictio

Nt

water passing through filter media is minimised. ; the

(iy. by allowing the water to pass under pressure thr "

filter media. TOURh the

The former is

and it is the most 7

water supply projects. The latter principle is aida

ed in

the working of pressure filters.

lq

achieved in rapid sand filters

leas

popular method of filtratior for

sential parts: Fig. 8-3 shows the layout of a typical rapi

cane eeee nti Pare: Hie consists of the following five. pans

(Enclosure tank ) Filter media of sand

) Underdrainage system — (v) Appurtenances.

(i) Base material

@ Enclosure tank: A watertight tank is constructed either

of masonry or concrete. The sides and floor are also

Coated with waterproof material. The depth of tank is

about 2.50 m to 3.50 m. The surface area of a unit of

rapid sand filter varies from 10 m2 to 50 m?. The units

are arranged in series.

Underdrainage system: There are various forms of under

drainage system of a rapid sand filter and most of them

are patented by the manufacturers.

Inlet chamber Outlet chamber

: ( Jl n |

reheh

= Lateral drains

Plan of underdrainage system

Fic. 8-4

at, 0-61 Filtration of Water 209

following are two common types of underdrainage systems:

(a) Perforated pipe system

(b) Pipe and strainer system.

(a) Perforated pipe system: In

this system, there is a

central drain or manifold

and to this manifold, the

various lateral drains are

attached as shown in

fig. 8-4. The drains are <->

usually made of cast-iron. - *

The lateral drains are Holes 10 mm tai

placed at a distance of Perforated lateral drain

about 150 mm to 300 mm. oie

The lateral drains are provided with holes at the

bottom side and such holes make an angle of 30°

with the vertical as shown in fig. 8-5. The diameter of

holes is about 10 mm and they are sometimes

staggered on either side instead of being continuous.

The holes are drilled at a centre to centre distance of

about 75 mm to 200 mm.

(b)

In order to prevent the rusting of surfaces of holes,

the brass bushings are sometimes inserted in the holes.

For the support of the lateral drains, the concrete

blocks of thickness about 40 mm to 50 mm are placed

on the floor of filter.

The perforated pipe system is economical and

simple in operation. It however requires more quantity

of wash-water. It requires about 700 litres of water

per minute per m? of filter area for washing purpose.

This is known as the high velocity wash and the

wash-water is obtained from a wash-water overhead

tank as shown in fig. 8-3.

Pipe and strainer system: In this system also, there is

a central drain or manifold with lateral drains attached

on either side as shown in fig. 8-6. But in this system,

the strainers are placed on lateral drains instead of

drilling holes as in previous case. A strainer is a small

pipe of brass. It is closed at top and contains holes

on its surface as shown in fig. 8-7. The strainers are

either screwed or fixed on the top of lateral drains.

210 Water Supply and Sanitary Engineering teh, g

There are various forms of strainers devised 5,

different manufacturers of filter units. In some casey

the strainers are even fixed on central drain. The laters|

Grains as well as strainers are generally placed at

distance of 150 mm to 300 mm. It is desirable 19

place all the strainers at the same elevation.

‘Strainers

‘Central drain

Lateral drains

Section of underdrainage system Strainer

Fic. 8-6 Fic. 8-7

When pipe and strainer system is adopted, the

compressed air is used for the purpose of washing

the filter. This results in saving of wash-water. It requires

about 250 litres of water per minute per m? of filter

area for washing purpose. This is known as the low

velocity wash.

Following general rules should be observed in

designing the underdrainage system: —

(The ratio of length of lateral drain to its diam

should not exceed 20.

(ii) The cross sectional area of central drain heal

about twice the cross sectional areas of lateral ; aid

(iii) The total cross sectional areas of perforations s! a :

be about 0.20 per cent of the total filter hs -

(i) The cross sectional area of a lateral shoul faa

about two to four times the total cross secti

areas of perforations in it,

f

i e 0

() The perforations in the lateral drain should b

diameter 6 mm to 12 mm. | drait

() The spacing of perforations in the lateral

fe

should vary from 75 mm to 200 mm centre to Ce

)Base material: 1

on the top of

used for base

dust, silt and

at is place

he base material is gravel and it is

' 10

underdrainage system, The gravel

material should be clean

vegetable matter. The gravel particles §

wel Filtration of Water a4

be durable, hard, round and strong. Its depth varies from

450 mm to 600 mm. It is usually graded and laid in

layers of 150 mm. The topmost layer should be of small

size gravel and the lowest layer should be of big size

gravel. Following is a typical section of base material:

Topmost layer 150mm depth — size 3mm to 6mm

Intermediate { 150 mm depth — size 6 mm to 12 mm

layers 150 mm depth — size 12 mm to 20mm

Lowest layer 150 mm depth — size 20 mm to 40 mm

Total 600 mm depth

(iv Filter media of sand: A layer of sand is placed above

gravel. The depth of sand layer varies from 600 mm to

900 mm. The coarse sand is used as filter media. The

effective size of sand varies from 0.35 mm to 0.60 mm

and the uniformity coefficient of sand is between 1.20 to

1.70. Thus the space of voids between sand particles is

reased and it results in the increased rate of filtration.

() Appurtenances: In addition to the usual appurtenances

required as in case of slow sand filters, the following special

devices are to be provided in case of rapid sand filters:

(a) Air compressors: The agitation of sand grains during

washing of filters is carried out either by compressed

air or by water jet or by mechanical rakes. When air

is to be used, an air compressor of required capacity

should be installed. Generally it should have the capacity

of supplying compressed air at the rate of 0.60 to

0.80 m? per minute per m? of filter area for 5 minutes.

The pressure of compressed air should be sufficient to

‘overcome the frictional resistance in air pipes and depth

of water above air distribution system. The compressed

air may be supplied through laterals or through a separate

Pipe system.

(0) Wash-water troughs: The dirty water after washing of

filter is collected in wash-water troughs or gutters

which are placed above sand bed level. The troughs

may be of cast-iron, concrete, steel or wrought-iron.

The troughs are placed at a distance of 1300 mm to

1800 mm edge to edge. The bottom of trough is

about 450 mm to 750 mm above sand bed. For efficient

working, the troughs should be large enough and they

should be laid at suitable slope.

ana Keay

(oO Rate control: There are various devices which may

fined at the outlet end of the filler to Control the gyre

of flow, The popular device is the venturl rate contratiee

it works on the principle of venturl mete

(a) Working and cleaning: The working of a rapid grayy

fitter can be understood by referring, to fig. 8-3. The numbed,

placed near valves indicate the following:

Valve 1 = Inlet valve,

Valve 2. — Filtered water storage tank valve,

Valve 3 = Waste-water valve to drain water from inlet chamber

Valve 4 = Wash-water storage tank valve,

Valve 5 = Wavte-water valve to drain water from main drain

Valve 6 — Compressed air valv

The valve 1 is opened and the water from coagulated

sedimentation tank is allowed to enter the filter, The valve 2

opened to carry filtered water to the filtered water storage tank

All other valves are kept in closed position, Thus, when filter is

in working condition, only valves 1 and 2 are in open position

When the filter requires cleaning or washing, it is carried out

as follows:

(i) The valves 1 and 2 are closed.

(i) The valves 4 and 6 are opencd out, The wash-water is

then forced in the upward direction through the underdrainage

system, base material and filter media of sand. The

compressed air assists the cleaning process of filter

(iid) The valve 6 is closed and the valve 3 is opened out to carty

dirty water through inlet chamber to the wash-water drain

(iv) When washing of filter is over, the valves 3 and 4 a

closed and valves 1 and 5 are opened out. Thus, wher

filter is put into use after washing, the filtered water if

the beginning is led to the wash-water drain through

main drain, This is) continued for few minutes

condition the filter,

) The valve 5 is closed and the valve 2 is opened out

put the filter in the normal working condition.

dina tate of head and negative head: When water pa

filter, it has to resist the frictional resistance:

therefore loses some of its head. Th 0

ome ad. The loss of head can easilY

ware ed by Knowing the water level in the filter and pressule

Mee et, the oullet pipe, The difference between the two he

indicates the loss of head in filter

an. 8-61 Filtration of Water 213

In the beginning, when the filter is cleaned, the loss of head

is very small, about 150 mm to 300 mm. The loss of head then

radually goes on increasing. The loss of head can be measured

fy inserting piezometer tubes in filter as shown in fig. 8-8. The

difference of water level in two tubes indicates the loss of head.

Piezometer tubes |

Sand

255 Gravel =

Underdrainage system bom) — — — —| :

cee

Outlet pipe —

Negative head

Loss of head and negative head

Fic. 8-8

A stage then comes when frictional resistance offered by filter

media exceeds the static head of water above sand bed. This is

developed due to the deposit of suspended matter in top layer of

about 100 mm to 150 mm thickness. The lower portion then acts

more or less like a vacuum and the water is sucked through the

fier media rather than filtered through it. The fall of liquid level

in the piezometer tube below the centre-line of underdrainage

System indicates the negative head.

The negative head thus formed tends to release dissolved ait

and other gases present in water. The bubbles stick to the sand

Brains and the working of filter is seriously disturbed. This pheno-

Mena is known as the air binding as air binds the filter and stops

S Working. The rate of filtration is consequently greatly reduced.

'n case of rapi i Ilowable loss of head is about

id sand filters, the allowal

1 3.50 m ord the allowable negative head is about 1200 mm.

he filter is to be washed when this limit of the allowable loss of

#d has been reached. It is usually cleaned after 2 to 3 days.

following two troubles are

5) Troubles i a

Ben ubles in operation: od and filters

a .

"ally encountered in operating ©

@

wi)

@

Water Supply and Sanitary Engineering (ch. 9

Mud balls

Cracking of filters.

Mud balls: The mud balls are generally formed near the

top of filter media. They may even be formed and distributed

throughout the filter. The mud balls are caused due to

insufficient washing of sand grains. The gelatinous film

formed during filtration is not separated out from sang

grains during washing. The mud balls interfere with the

normal working of the filter and their size is about 25

mm to 50 mm

Cracking of filters: The fine material contained in the top

layer of filter shrinks and this shrinkage tends to form

cracks in the filter. These cracks are prominent near wall

junctions.

To remove these troubles, the following remedies are

adopted:

(@) The mud balls are broken with the help of rakers or

some such equipment.

(b) The working of filter is carried out with high velocity

of water.

(©) The damaged portion of filter media is replaced.

(6) Rate of filtration: The chief advantage of a rapid sand

filter is that its rate of filtration is very high. It is about 3000

to 6000 litres per hour/m? of filter area. The high rate of filtration

results in considerable saving of space for the installation of filter.

(7) Efficiency of rapid sand filters: The efficiency of rapid

sand filters is as follows:

(@) Bacterial load: The rapid sand filters are less effective in

the removal of bacterial load. It is expected that they

remove about 80 to 90 per cent of bacterial impurity

present in water.

Gi) Colour: The rapid sand filters are highly efficient in colour

removal and the intensity of colour can be brought down

below 10 on cobalt scale.

Turbidity: The rapid sand filters can remove turbidity to

the extent of 35 to 40 p.p.m. As water entering rapid

sand filter is invariably given the treatment in coagulation

sedimentation tank, it possesses less turbidity. This turbidity

is easily brought down to the permissible limits by rapi

sand filters.

at 86 Fiteation of Water me

oblem 8

Fin oO ean wand filters required for a town having

Jistation oF 80000 with ar averses ea

ep or day We rate of demand ae 200 hires

solution:

Maximum daily demand

(80000 x 200 x 1.50)

= 24000000 titres.

Assuming @ rate of filtration as 5000 litres per hour per m?

of filter area, e re

24000000

5000 x 24

Let the size of one unit be 8 m x 5 m. Then provide 6 such

unis of rapid sand filters including one unit as standby. The units

may be arranged in series with 3 units on elther side.

area of filter required 200 m?.

Problem 8-3.

‘A rapid sand filter is required to treat a flow of 0.50 m per

second. The filtration rate is 120 m3 per day per m? of filter

trea and it is provided that the filtration rate with one filter

washing Is not to exceed 150 m? per day per m? of filter area.

Determine the number of units and the area of each unit to

satisfy these conditions.

Each filter is washed for 5 minutes every 24 hours at a wash

rate of 10 mm per second per m? of filter area. The filter remains

out of operation for a total interval of 30 minutes per day. Calculate

the percentage of filter output used for washing.

Solution:

Maximum flow rate = (0.5 x 60 x 60 x 24) m3 per day

= 43200 m? per day.

Note: The rate of filtration can also be expressed as m? per day per m?

Of filter area. because of the relation 1m? = 1000 litres.

Thus 120 m? per day per m? of filter area is equivalent to

(22x 1000

28 =

Filter area on the basis) _ 4:

maximum filtration rate! ~

Filter area on the basis} _ 43200 0 mi,

©f minimum filtration rate} “120, ~ 360 ™

Hence, maximum filter area = 360 m?

5000 litres per hour per m® of filter area,

= 208 m2.

:200

50

a6 Water Supply and Sanitary Engineering. ten

‘Area of one filter unit = (360 - 288) = 72 m2 ‘

Maximum filter area

‘Area of one unit

360

=" 75

Total numbers of filters =

Now, each unit of filter is working at the filtration rate

120 mn’ per day per m2 of filter area and the operation of fic

is out of order for a period of 30 minutes. a

Hence, the total working period per day of each filter is

(24 = 0.5) = 23.5 hours.

utput of ex Working per

ouput of ech area x Filtration Rate x WOME pois

2

23s

24

(72 x 120 x 23:5

U

8460 m?.

Wash rate = 10 mm per second per m? of filter area

(10 x 10-3 x 60) m per minute per

m? of filter area.

Washing period = 5 minutes

_ Wastewater teguted) yea x Wash rate Washing peri

ped ay

72 x (10 x 103 x 60) x 5

216 m’.

Percentage of filterout- | __ Wash- water required

put used for washing |“ “Guipat af each unit * 100

216

- BS x 100

= 2.55%.

6-7. COMPARISON BETWEEN SLOW SAND FILTERS

AND RAPID SAND FILTERS (GRAVITY TYPE):

We have so far discussed at length slow sand filters at

rapid sand fiers (gravity type) separately, In order to bring OH

the points of differences between similar items of slow sand ‘ie

and “rapid sand filters, is tabulated tn table 8-1

wen Filtration of water a7

Taste a

DIFFERENCE BETWEEN TWO TYPES OF FILTERS

3] tem Slow sand fiters | Rapid sand fiers

N Teraity type)

Base material of

gravel

‘Coagulation

Compactness

Cost of operation

Depreciation of

plant

Economy

Efficiency

Filter media of

and

Flexibility

Loss of head

Method of

disaning.

Period of cleaning |

Rate of filtration

Skilea

Supervision

Suttabiity,

Varies from 3 to 65

mm in'size and’ 300

{0°750 mim indepth

Not required

Requires large, area

femoval of bacteria

Be saab Siar

age is ates

untae

in“Gemand

{50 me 70 mm

Seapcg. Sh ae

1 to 3 months.

400 to 200 litres

our per mf

Not essential.

The filter, can, be

fgnstructed of local

tes" suitable for mal

{ovens and sillages

ehere land’ is cheaply

ivaiiable

Raion eae

ean

a a

its installation,

Senate ts

and constructed:

area for

Sconomieat WE

Less efficient in the

removal of bacteria But

Fore eihcieat in: the

Femoval of colour and

Sorority,

Efective size varies from

SENS Qled"men ad

about 172 t0 1-7

ite flexible for reaso-

iets aeeteRons tn

Semand

3'm to 3.50 m

Agitation and.” back:

sens Faith or without

Sir, Shore and speedy

method.

Pto 3 days

44000 to 6009 liters per

hour perme of tier

Eseential.

It is. suitable for i

Eltgs Where land, coat

In detnand of water 13

Considerable.

218 Water Supply and Sanitary Engineering i;

ha

8-8. PRESSURE FILTERS:

These filters are more Or less similar to the rapid sand filter,

(gravity type) except with the following differences: Ss

(1) Meaning of the term — pressure filter: The term pressy

filter does not indicate that the water is pumped through rl

filter under a high pressure loss. But it indicates that a filter :

enclosed in space and the water passes under pressure gene

than atmospheric pressure. This pressure can be developed by

pumping and it may vary from 0.3 to 0.7 N/mm?, Y

(2) Construction: The pressure filters are closed steel cylinders

either riveted or welded. They may be of horizontal type as shown

in fig. 8-9 or of vertical type as shown in fig. 8-10. The diameter

of pressure filters varies from 1.50 m to 3.00 m and their length

or height varies from 3.50 m to 8.00 m. The manholes are

provided at top for inspection.

Inlet valve for

fae oe

me Water ——-

i Sand ‘

q Gavel )

oe ,

. + To wash

So a

7 lateral drains

To fitered water

storage tank

-Inlet valve for wash water

Pressure filter — horizontal type

Fic. 8-9

(3) Working: The water mixed with coagulant is directly admitted

to the pressure filter. Thus the flocculation takes place inside

Pressure filter itself. In normal working condition, all valves

closed except those for raw water and filtered water. The “4

is admitted through inlet and after it is filtered, it is collected |"

the central drain and conveyed to the filtered water storage

{2 Cleaning: The compressed air may be used to 8g

sand grains. The valves for raw water and filtered water ait

closed position and those for wash-water and wash-watel 2,

are in open posi i

Filtration of Water

219

ning of pressure filters may

i 'Y be required more frequently.

pressure filters are

available in which washing of

ig done automatically at a predetermined interval of time or

fite ‘i

f head.

tae Inlet valve for Manhole

raw water,

To wash

water drain

ee — Concrete filling

wash water

| Central drain with

c ateral drains

To filtered water lateral dr

storage tank ;

Pressure filter — vertical type

Fic. 8-10

(6) Rate of filtration: The rate of filtration of pressure filters

's high as compared to that of rapid sand filters. It is about

6000 to 15000 litres per hour per m? of filter area as compared

‘0 that of 3000 to 6000 litres per hour per m? of rapid sand filters.

(6) Efficiency: The pressure filters are found to be less efficient

‘han the rapid sand filters in terms of bacterial load, colour and

luridity,

a) Suitability: The pressure filters are not suitable for public

spe SUPPIY projects. But they can be installed for small water

Pol projects such as colonies of a few houses, industrial plants,

® estates, swimming pools, railway stations, etc.

inal Advantages: The advantages of the pressure filters can be

Merated as follows:

: dern automatic pressure

These ar ,

i e com nits and the mo! a

resigned way that it does not

fier unit is designed in such a wa

i i ision.

{i “ire manual operation or supervisi

These filters are flexible in operation because the rate of

iltration can be altered by changing the compressed’ 2

Pressure,

water Supply and Sanitary Engineering

Ich,

(iii) They do not require further pumping as the filtered y,.

tomes out under pressure: er

{yy They prove to be ideal for small estates.

(They require less number of fittings.

(They require very small space for their installation,

(viiy When these filters are employed, the sediment,

coagulant tanks are not required:

(9) Disadvantages: The pressure filters possess the follo

disadvantages: Win,

{) It becomes difficult to keep close watch on the perform,

of these filters because the process of filtration and ro

washing are done in the closed tank. ack

It is difficult to repair these filters.

The overall capacity of these filters is small.

They are costly and hence, they cannot b

for treating large quantity otvater ommended

() They possess poor efficien

and turbidity. p ciency in the removal of bacteria

(vi) They require additional i

They req itional pumps for pumping the water in

220

Nang

8-9. DOUBLE FILTRATION:

Sometimes the water is filtered twice to achieve better results.

This is known as the double filtration and it may be carried out

in different ways as follows:

(1) The water is allowed to pass through two or more slow

sand filters arranged one after the other.

The water is allowed to pass through two or more rapid

sand filters arranged one after the other.

The water is allowed to pass through a rapid sand filter

before it is sent to a slow sand filter.

incr Practice, the last alternative is most commonly adopted t0

increase the rat fil

@)

3)

in such a case is known as a roughing filter. The

coarse materials nstruction of a roughing

ai sequently, Itration is as high as 7000 litres

hot require ine, Of filter area. The roughing filters generally

ee ‘ated with the coagulant. J

e double filtrati i inatl i

above, is adopted ust” especially of last combination as sta

places where |. i instal

of slow sand filters is restricted o instanton of

filters practically

its rate of fil

of

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Forces Acting On DamsDocument12 pagesForces Acting On Damssameer khanNo ratings yet

- Reservoir Sedimentation: Slide #1Document15 pagesReservoir Sedimentation: Slide #1sameer khanNo ratings yet

- Sundholm 1998Document17 pagesSundholm 1998sameer khanNo ratings yet

- 206-Sheet - S 100 C - Excavation Layout-Layout1Document1 page206-Sheet - S 100 C - Excavation Layout-Layout1sameer khanNo ratings yet

- 125 Keep Public Non-Existing Misleading Designation. ReplyingDocument9 pages125 Keep Public Non-Existing Misleading Designation. Replyingsameer khanNo ratings yet

- Civil Engineering Materials Lecture 15 & 16 Steel, Alloy Steel Composition and ClassificationDocument21 pagesCivil Engineering Materials Lecture 15 & 16 Steel, Alloy Steel Composition and Classificationsameer khanNo ratings yet

- Owner: Sajid Naeem Arch-01: 1/8" 1'-0" 1 Ground FloorDocument1 pageOwner: Sajid Naeem Arch-01: 1/8" 1'-0" 1 Ground Floorsameer khanNo ratings yet

- 5 Marla House 5 Marla House 5 Marla House: Preliminary Works Preliminary Works Preliminary WorksDocument22 pages5 Marla House 5 Marla House 5 Marla House: Preliminary Works Preliminary Works Preliminary Workssameer khanNo ratings yet

- 10 Marla House Plan Owner Arh 01: 1/8" 1'-0" 1 Ground FloorDocument1 page10 Marla House Plan Owner Arh 01: 1/8" 1'-0" 1 Ground Floorsameer khanNo ratings yet

- Lecture 13 & 14 Metals, Alloys, Types of Iron and Mechanical PropertiesDocument20 pagesLecture 13 & 14 Metals, Alloys, Types of Iron and Mechanical Propertiessameer khanNo ratings yet

- Cost Expense ReportDocument1 pageCost Expense Reportsameer khanNo ratings yet

- New Doc 2020-08-21 17.35.23Document12 pagesNew Doc 2020-08-21 17.35.23sameer khanNo ratings yet

- Activities Report: Activity ID Activity Name Activity Status Original Duration Early Start Early Finish Longest PathDocument2 pagesActivities Report: Activity ID Activity Name Activity Status Original Duration Early Start Early Finish Longest Pathsameer khanNo ratings yet

- Assignment #02 Irrigation Engineering2020Document2 pagesAssignment #02 Irrigation Engineering2020sameer khan100% (1)

- Title PageDocument1 pageTitle Pagesameer khanNo ratings yet

- New Doc 2020-10-08 12.53.45Document5 pagesNew Doc 2020-10-08 12.53.45sameer khanNo ratings yet

- Tuition CentreDocument1 pageTuition Centresameer khanNo ratings yet

- Title Page APA Style and Parts of AbstractDocument3 pagesTitle Page APA Style and Parts of Abstractsameer khanNo ratings yet

- Fa16 CVE 052Document4 pagesFa16 CVE 052sameer khanNo ratings yet

- Highway Drainage Part-2Document13 pagesHighway Drainage Part-2sameer khanNo ratings yet

- Total 45000 Column1 Column2 Column3 Column4 Column5 Abbu Sameer Adeel Awais&inshal Fruit/veg 900 40 130 80 300 1000 150 1000 150Document3 pagesTotal 45000 Column1 Column2 Column3 Column4 Column5 Abbu Sameer Adeel Awais&inshal Fruit/veg 900 40 130 80 300 1000 150 1000 150sameer khanNo ratings yet

- Aashto Design Method: (Merican Ssociation of Tate Ighway and Ransportation Fficials)Document46 pagesAashto Design Method: (Merican Ssociation of Tate Ighway and Ransportation Fficials)sameer khanNo ratings yet

- Ex 9 3 FSC Part1 Ver3Document1 pageEx 9 3 FSC Part1 Ver3sameer khanNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)