Professional Documents

Culture Documents

Steel Wire Rope Handling & Maintenance

Uploaded by

RahulCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Steel Wire Rope Handling & Maintenance

Uploaded by

RahulCopyright:

Available Formats

STEEL WIRE ROPE HANDLING & MAINTENANCE

Document No: 00 95 OD 77 06 0003 0

Version: 1.0

Date: 09/04/2014

Prepared By: Rohan Kudalkar, Yogesh Akolkar

Checked By: Deepak T. Balani

Approved By: Gunter Frimmel, Vishnu Parashar

ThyssenKrupp Elevator (India)

Steel Wire Rope Handling & Maintenance 0095OD770600030-Version1.0

Contents

PURPOSE 4

SAFETY GUIDELINES 4

Basic Safety Rules to be observed 4

Signs 4

INTRODUCTION 5

What is Rope? 5

HANDLING 6

Transportation 6

Tools Required 7

Storage 7

Unrolling/Unwinding of Ropes 8

Precautions while unrolling/unwinding the ropes 8

Inspections while unrolling/unwinding the ropes 9

Ropes Installation Procedure 9

Rope Tensioning 10

Rope Tension Measurement 11

When to Tension Ropes? 12

Effects of Improper Tensioning 12

MAINTENANCE 13

When to check ropes? 13

Ropes shall be checked for? 13

How to check wire rope diameter? 14

Cleaning of Ropes 15

Checking of Lubrication 16

Lubrication of Ropes 16

Lubrication Type 16

Procedure for Lubrication 16

Relubrication of Ropes 17

Criteria for Relubrication 17

Steel Wire Rope Handling & Maintenance 0095OD770600030-Version1.0

Dispensing of Lubricant 17

Over lubrication of ropes 17

Discarding of wire ropes 18

Criteria for discarding of wire ropes 18

Disposal of Ropes 18

Wire Breaks 19

Rope Defects 19

Replacement of wire ropes 21

Rope Slip 21

Acceptable Tolerances 21

TROUBLESHOOTING 22

DOCUMENT REVISION HISTORY 23

Steel Wire Rope Handling & Maintenance 0095OD770600030-Version1.0

PURPOSE

The purpose of this document is to highlight the importance of traction rope which is a safety component and

its handling, installation and maintenance contributes to quality and life of rope.

SAFETY GUIDELINES

Basic Safety Rules to be observed

For your safety, follow the Health, Safety & Environment guidelines established.

Ensure that you are in possession of all PPE’s (Personal Protective Equipments) appropriate to the

work you are doing, as shown below

Keep all PPE’s clean and in good condition. If equipment is faulty replace it immediately.

Clear warning signs must be installed in any place where a potential hazard exists in the working

area. Labeling should be in accordance to local standards.

Signs

Following are the signs used in the document, wherever adequate.

Danger Zone

This symbol warns against imminent danger. Nonobservance can lead to physical injury

or extensive damage to property

Do Not Do

This symbol indicates not to perform or carry out the mentioned activity.

Reference

This symbol indicates reference given to a particular document.

Instructions

This symbol indicates instructions to be followed.

Steel Wire Rope Handling & Maintenance 0095OD770600030-Version1.0 Page 4 of 23

INTRODUCTION

What is Rope?

Wire rope consists of several strands of metal wire

twisted about a central axis known as core. Each

individual steel thread is known as wire. Each group

of wire twisted together forms a strand. A group of

strands twisted around a central core is known as a

wire rope.

Steel Wire Rope Handling & Maintenance 0095OD770600030-Version1.0 Page 5 of 23

HANDLING

Transportation

Adequate arrangements for loading and unloading the wooden reels (bobbins) containing rope shall be

provided.

Hoist the rope in proper way, in order to avoid damage to the package

Do not throw the rope from height

Wrong means of transportation Correct means of transportation

Steel Wire Rope Handling & Maintenance 0095OD770600030-Version1.0 Page 6 of 23

Tools Required

Steel measuring tape 3m/5m,

Spanner set Tri-square (6” & 12”)

Freeman`s make

Rope diameter measuring gauge

Brush (75mmx150mm) Wire Cutter

(metric)

Storage

The rope shall be stored in a dry environment and protected against rain, moisture and dust.

Avoid contact with cement dust or sand, acid and alkaline materials

Cover ropes with adequate ventilation to avoid formation of condensation.

Do not put rope directly on the ground or under heavy object.

Apply occasional dressing of lubricant to the top layer of rope to protect the same from corrosion, if

stored for longer period of time.

Turning the wooden reel (bobbin) occasionally, about half a turn helps to prevent migration of the

rope lubricant.

Steel Wire Rope Handling & Maintenance 0095OD770600030-Version1.0 Page 7 of 23

Unrolling/Unwinding of Ropes

The ground rules for rope mounting must be observed without fail. By removing from side via the reel

(bobbin) coupling or from the coil strap, the rope is uncoiled or coiled depending on the direction of lay. This

twisting action brings about a change in the rope structure which can no longer be corrected. In the case of

ropes with steel core, this type of forced rotation creates uneven strand lengths.

Precautions while unrolling/unwinding the ropes

Wear protective gloves during the rope installation.

Wipe the rope with clean cloth in case of dust or foreign materials on the surface.

Do not clean the rope with gasoline, kerosene, water or other organic solvent.

Protect ropes from welding sparks.

The rope shall not be subjected to direct contact with fire.

Steel Wire Rope Handling & Maintenance 0095OD770600030-Version1.0 Page 8 of 23

Inspections while unrolling/unwinding the ropes

Inspect if the rope is free from dust or foreign materials.

Rope shall be free from any abnormal phenomenon, such as broken rope, extruded rope core, cage

shape distortion, squashed rope etc.

Any kind of rust observed.

Ropes Installation Procedure

Check the elevator Ensure the Release rope torsion

installation way is Unwind the rope

number correct if necessary

Wrap the other end Fasten rope & rope Make & Install the

rope socket Wrap the rope on

of the rope on the socket assembly the pulley

pulley (2:1) (counterweight side) assembly

(counterweight side)

Make & Install the

Determine the rope socket Fasten rope & rope Hang up the rope

socket assembly

rough rope length* assembly

(car side) and recheck

(car side)

Bind up the rope Cut off the extra Adjust the rope

end rope tension & rope

socket assembly

*TO DETERMINE ROUGH ROPE LENGTH, REFER THE FOLLOWING DOCUMENTS:

00 95 OD 77 00 0024 0 ‘ROPE TESTING SPECIFICATION’ &

00 95 OD 77 00 0025 0 ‘APPLICATION OF STEEL WIRE ROPE FOR ELEVATOR’

Steel Wire Rope Handling & Maintenance 0095OD770600030-Version1.0 Page 9 of 23

Rope Tensioning

All hoist ropes in an elevator installation shall carry the same tension/load. Equally tensioned ropes extend

the life of the ropes/sheaves and improve ride quality.

When ropes are installed, they must be adjusted so that each rope takes its equal share of the total load.

Adjustment of Rope Tension

Uneven rope tensions are not acceptable.

Deviation more than ± 2 kgs is not acceptable.

Spring Adjustments for Ropes

Difference between top end of

rods shall not be more than

20mm.

Difference between

compression of 2 springs shall

not be more than 2mm.

Steel Wire Rope Handling & Maintenance 0095OD770600030-Version1.0 Page 10 of 23

Rope Tension Measurement

Method I Manual Rope Tension Equalizer

Keep the car and counterweight on same

level.

Measure the rope tension at approx. 1 meter

distance above car top and counterweight

top.

The tension should be within ±2 kg for all

ropes.

Method II Henning Mobile Rope Load Meter MSM 12

FOR DETAILED USAGE INSTRUCTIONS REFER ‘HENNINGS MOBILE ROPE LOAD METER MSM

12-OPERATING INSTRUCTIONS’ DOCUMENT

Steel Wire Rope Handling & Maintenance 0095OD770600030-Version1.0 Page 11 of 23

Method III DruceGrove Rope Tensioning System

FOR DETAILED USAGE INSTRUCTIONS REFER ‘DRUCEGROVE ROPE TENSIONING SYSTEM

USER MANUAL V2’ DOCUMENT

When to Tension Ropes?

Ropes must be tensioned immediately after installation. Tensioning is especially important during the rope’s

initial constructional stretch period and during the adjustment problems when problems can still be corrected.

Effects of Improper Tensioning

Unequal groove wear

Unequal rope wear

Slippage

Vibration

Short rope and sheave life

Steel Wire Rope Handling & Maintenance 0095OD770600030-Version1.0 Page 12 of 23

MAINTENANCE

When to check ropes?

Under Installation In Operation

After 50,000 cycles of running time or 3 months After every 100,000 cycles of running or 6 months

(whichever is low) (whichever is low)

Ropes shall be checked for?

Check for dust or foreign particles

Dust on Ropes Foreign Particles

If dust on ropes is observed, then clean it with brush Foreign particles on ropes shall be checked and cleaned

Steel Wire Rope Handling & Maintenance 0095OD770600030-Version1.0 Page 13 of 23

Broken rope wires

Extruded wire rope

Rusted rope

Reduced diameter of rope

How to check wire rope diameter?

Method I

Measure the diameter as shown.

If the diameter is less by 6% then replace the ropes irrespective of any other defects.

Method II

Keep the lift in stop condition.

Put a scale on ropes.

Difference between any 2 ropes shall not be more

than 1mm.

Method III

Check the diameter of rope using the diameter checking

gauge as shown in the adjacent image.

Steel Wire Rope Handling & Maintenance 0095OD770600030-Version1.0 Page 14 of 23

Cleaning of Ropes

Method I Manual Cleaning of Ropes

Put the lift in Inspection mode.

Make use of wire brushes for cleaning the ropes.

Move the lift up/ down till all dust is removed.

Method II Using Rope Oiling and Cleaning Unit

Item Code Item Description UOM

0096OP029901030 ASSY_ROPE OILING AND CLEANING UNIT EA

Steel Wire Rope Handling & Maintenance 0095OD770600030-Version1.0 Page 15 of 23

Checking of Lubrication

Check the lubrication on car top or machine

room.

Rub the fingertip slightly on rope.

If you don’t find lubrication, then lubricate the

ropes with appropriate lubricant.

Lubrication of Ropes

Wires, strands and cores are important components of the rope, which are only able to interact with each

other in presence of lubrication.

Lubrication is necessary to:

Minimize wear between ropes and sheave.

Reduce friction between the wires.

Minimize corrosion due to atmospheric and/or operating conditions.

Help reducing the bending fatigue by allowing movement between the wires and strands.

Lubrication Type

Item Code Item Description Make of the lubricant Oil Type

0095OP080102030 LUBRICANT OIL_WIRE ROPE_ENKLO HLP T 32_HP Hindustan Petroleum Mineral

Procedure for Lubrication

Put the car in maintenance mode.

Keep the car on lowermost floor.

Start applying oil by brush just above counterweight from machine room.

Allow the lift to move up slowly section by section.

DO NOT TOUCH ANY OF THE MOVING PARTS OF THE LIFT

Steel Wire Rope Handling & Maintenance 0095OD770600030-Version1.0 Page 16 of 23

Relubrication of Ropes

Elevator ropes are lubricated during manufacture in order to prevent corrosion and abrasion. However, the

quantity of lubricant applied shall only be good enough to ensure that elevators operate with sufficient

traction and without slippage. The initial lubrication is hardly ever sufficient to be effective over the entire

service life of the rope. It is consequently advisable to occasionally re lubricate elevator ropes. As long as

wiping a finger over the rope shows faint smudge, there is no need for lubrication.

Criteria for Relubrication

It is not possible to provide any definitive statement in respect of re lubrication intervals, as they depend on.

The frequency of elevator use.

The environment (temperature, incidence of dust).

The sheave material and sheave wear (hardened traction sheaves require more relubrication, as no

graphite is released from the sheave as a result of wear).

Slip between the rope and sheave.

OVERSPEED GOVERNOR ROPE SHALL NEVER BE LUBRICATED

Dispensing of Lubricant

As the life of an elevator rope is closely linked to its effective rope diameter, it is essential for the fibre core to

maintain its volume for as long a period as possible. Consequently relubrication shall be performed from the

outside in such a way that lubricant also penetrates the fibre core.

Over lubrication of ropes

One of the possible causes of excessive slippage of ropes on the sheave can be over lubrication of ropes.

Under no circumstances should an attempt be made to wash down ropes using cleaning agents or solvents.

Steel Wire Rope Handling & Maintenance 0095OD770600030-Version1.0 Page 17 of 23

Discarding of wire ropes

Elevator ropes are normally discarded due to wire breakage, wear and diameter reduction. However, other

discarding criteria such as corrosion or excessive elongation can also take effect.

Criteria for discarding of wire ropes

The number and distribution of externally visible wire breaks are the most important criteria when it comes to detecting

when an elevator rope shall be discarded. This is quantified by a count of maximum number of visible wire breaks over

a reference length of the rope. According to ISO 4344, the criteria for discarding ropes are:

Broken wires

Replace ropes or examine within a

specified period as stated by the Discard ropes immediately

competent person

Condition

Rope Construction

Class 6 X 19 FC Class 8 X 19 FC Class 6 X 19 FC Class 8 X 19 FC

Broken wires

randomly distributed More than 12 per More than 15 per More than 24 per More than 30 per

# # # #

among the outer rope lay rope lay rope lay rope lay

strands

Broken wires

predominating in More than 6 per rope More than 8 per rope More than 8 per rope More than 10 per

# # # #

one or two outer lay lay lay rope lay

strands

Adjacent broken

wires in one outer 4 4 More than 4 More than 4

strand

# #

More than 1 per rope More than 1 per rope

Valley breaks 1 per rope lay 1 per rope lay # #

lay lay

#

The length of one rope lay is approximately equivalent to 6 x d (where d is the nominal rope diameter)

Reduction in diameter (If rope diameter is less than 6% the desired diameter of the rope, then

replace the rope).

Disposal of Ropes

PLEASE FOLLOW THE TKEI GUIDELINES FOR DISPOSAL OF ROPES.

Steel Wire Rope Handling & Maintenance 0095OD770600030-Version1.0 Page 18 of 23

Wire Breaks

For all other elevator ropes, reference is made to the specifications of the relevant rope manufacturer. Taking

the number of wire breaks at discard as a reference, it is then possible to determine whether

The rope shall be discarded immediately

Shall be more intensively monitored in the future or

Shall continue to be monitored normally

Rope Defects

Sr. No. Defects View Remark

If the number of broken wires is

1 more than 5 or 6 or exceeds,

replace the ropes

Broken wires on surface

If more than 5 wires are broken

2 remove the broken wire sticking out

and replace the rope

3 Broken Strands Replace the rope

Try to remove the twist if it cannot

4 Deformed rope

be removed, then replace the ropes

5 Extruded rope core Replace the rope

If rope diameter is less than 6% the

6 Reduced rope diameter desired diameter of the rope, then

replace the rope

Steel Wire Rope Handling & Maintenance 0095OD770600030-Version1.0 Page 19 of 23

Sr. No. Defects View Remark

7 Squashed rope section Replace the rope

Air gap between rope

8 Replace the rope if gaps are more

strands

9 Backward distortion Replace the ropes

Replace the rope if knot cannot be

10 Knot on the rope

removed

11 Nose distortion on ropes Replace the ropes

Replacement of rope depends on its

density. For small rust it shall be

12 Rusted ropes

cleaned, for more rust replace the

ropes

If rope diameter is less than 6% the

13 Abrasion desired diameter of the rope, then

replace the rope

Increase in diameter of

14 Replace the ropes

ropes

15 Forward distortion Replace the ropes

Extended interior rope

16 Replace the ropes

strands

Steel Wire Rope Handling & Maintenance 0095OD770600030-Version1.0 Page 20 of 23

Replacement of wire ropes

When replacing suspension ropes, all ropes in a set shall be replaced. All ropes in the set

shall be from the same manufacturer and of the same material, grade, construction and

diameter and preferably be cut from the same reel (bobbin).

Rope Slip

Keep the elevator in normal mode on top most floors

Allow the lift to travel 1 full round from top to bottom and

Mark the ropes and machine at same point by chalk again bottom to top in non-stop mode, ideally the original

marks shall match, but these markings will never match

Acceptable Tolerances

For G+7 rope slip = 15 to 20mm

If the same is not observed then possible causes are

Rope tensioning not proper

Dust on ropes

Rusted ropes

Rope twist

Other defects

Defective sheave.

Over lubrication.

Steel Wire Rope Handling & Maintenance 0095OD770600030-Version1.0 Page 21 of 23

TROUBLESHOOTING

Rope Trouble Cause Solution

Severe impact/jerk Avoid overloading and jerk loads

Formation of twist during Avoid formation of twist during

Snapping of Rope (Breakage) installation/handling

installation

Severe rusting/ corrosion Store in dry environment

Overload Avoid loading beyond capacity

Prevent twisting of rope through proper

Twist

Breakage of one or more strands method of unwinding, handling at site

Prevent rusting/corrosion through proper

Rusting/Corrosion & fatigue

storage and lubrication during use

Increase in lay length and Avoid overloading by keeping load as per

Overloading

reduction in diameter capacity

Damage due to improperly Fix hoisting suspension bolts in correct

Distortion of rope.

attached hoisting suspension bolts manner.

Worn out sheaves & grooves Rectify or replace worn-out sheaves &

grooves

Abrasion wear. Misalignment Correct the alignment

Lack of lubrication Apply regular lubrication during use

Use bigger sheaves and maintain groove dia.

Undersized sheaves or grooves between 6 to 10% more than the nominal

rope diameter in case of standard rope

Wire breakage due to fatigue.

Improper selection of rope Always use rope of specification

construction recommended by OEM or rope manufacturer

Allowing rope to drag over objects Remove external objects in rope path during

during installation / operation installation / use

Spiraling.

Wrong method of handling Follow the recommended method of handling

Excessive flattening. Overload Prevent overloading beyond capacity

Steel Wire Rope Handling & Maintenance 0095OD770600030-Version1.0 Page 22 of 23

DOCUMENT REVISION HISTORY

Sr. No. Version Description Revised By Revision Date Released Date

1 1.0 New Document Released Rohan Kudalkar --- 09th April 2014

Steel Wire Rope Handling & Maintenance 0095OD770600030-Version1.0 Page 23 of 23

You might also like

- Schindler India Load Hook Testing ProcessDocument14 pagesSchindler India Load Hook Testing ProcessAli DiabNo ratings yet

- Fujitec Handrail MaintenanceDocument2 pagesFujitec Handrail Maintenancea_salehiNo ratings yet

- 0503 Geda Hoist InstructionsDocument6 pages0503 Geda Hoist InstructionsBoruida MachineryNo ratings yet

- ELEVATOR MAINTENANCE PMSDocument6 pagesELEVATOR MAINTENANCE PMSAndrie Eka saputraNo ratings yet

- Acop & UcmpDocument11 pagesAcop & Ucmpbugse100% (1)

- ESC&AWK Operation&Maintenance ManualDocument21 pagesESC&AWK Operation&Maintenance ManualWander GomesNo ratings yet

- Elevator 2003Document150 pagesElevator 2003Tita AnielaNo ratings yet

- Alimak Super Scando FC Manual Elevator Cable PDFDocument71 pagesAlimak Super Scando FC Manual Elevator Cable PDFBoruida MachineryNo ratings yet

- Elevator - Ropes Tension GaugeDocument44 pagesElevator - Ropes Tension GaugeFERNSNo ratings yet

- Thyssenkrupp Elevator: Stage 1 BDocument3 pagesThyssenkrupp Elevator: Stage 1 Bgajendrabanshiwal8905No ratings yet

- RBI Troubleshooting Guide 34 & 43kNDocument15 pagesRBI Troubleshooting Guide 34 & 43kNBartz SantosNo ratings yet

- TECH TIPS: ROPE DEFECTSDocument5 pagesTECH TIPS: ROPE DEFECTSHayder Habib100% (1)

- Mechanical Elevator Installation Safety ProceduresDocument23 pagesMechanical Elevator Installation Safety ProceduresFiorella Amer Carr100% (1)

- MRL W e Pack Electrical ManualDocument154 pagesMRL W e Pack Electrical ManualLe Huynh LongNo ratings yet

- DrakaTechTipNo.1 CompensatingChain PDFDocument2 pagesDrakaTechTipNo.1 CompensatingChain PDFKar Keong LewNo ratings yet

- Zoomlion Mobile Crane RT75 Load Chart ManualDocument49 pagesZoomlion Mobile Crane RT75 Load Chart Manualmonsieur_son100% (1)

- Calculation of Traction Sheave - محاسبات عالی و کامل WitturDocument13 pagesCalculation of Traction Sheave - محاسبات عالی و کامل WittursmsobhanNo ratings yet

- Hydraulic Car Frame WLF03 / WLF06 / WLF10 / WLF16 / WLF20Document57 pagesHydraulic Car Frame WLF03 / WLF06 / WLF10 / WLF16 / WLF20mario escottoNo ratings yet

- CalculationReport PDFDocument10 pagesCalculationReport PDFFikret DavudovNo ratings yet

- SLX SX Elevator Maintenance ManualDocument7 pagesSLX SX Elevator Maintenance ManualBahman MatouriNo ratings yet

- NOV Series Manual Part 1 EN (M368-15) PDFDocument70 pagesNOV Series Manual Part 1 EN (M368-15) PDFcarlos navarroNo ratings yet

- Installation and Operating Instructions Overspeed Governor Type 7/8/9Document16 pagesInstallation and Operating Instructions Overspeed Governor Type 7/8/9RuiNo ratings yet

- Elevator Safety SystemDocument55 pagesElevator Safety Systemapi-312620075100% (1)

- PM 5 000279 en 01Document23 pagesPM 5 000279 en 01SavoyNo ratings yet

- Material Hoist - Spare Parts ManualDocument42 pagesMaterial Hoist - Spare Parts ManualRajesh PanchalNo ratings yet

- Elevator Intercom Installation Guide 984 0012FS FULL SIZE R111407Document11 pagesElevator Intercom Installation Guide 984 0012FS FULL SIZE R111407asibrahimNo ratings yet

- ECO-FRIENDLY MRLG LIFTDocument2 pagesECO-FRIENDLY MRLG LIFTIvan Candia MariscalNo ratings yet

- 1 2005 Mistral MRL Documantation Eng PDFDocument12 pages1 2005 Mistral MRL Documantation Eng PDFTarek HareedyNo ratings yet

- Control System PLC Liebherr LHM 400Document20 pagesControl System PLC Liebherr LHM 400Liebherr33% (3)

- ALIMAK-Scando 650 Tech Desc 9104228-107 USDocument117 pagesALIMAK-Scando 650 Tech Desc 9104228-107 USramtsanNo ratings yet

- Frequency Converter Type Vacon NX For Alimak's Hoists and Lifts User's ManualDocument27 pagesFrequency Converter Type Vacon NX For Alimak's Hoists and Lifts User's Manualsulthan1975No ratings yet

- Model m25 Free Fall Service ManualDocument44 pagesModel m25 Free Fall Service ManualManuel Rodriguez100% (1)

- Lubrication and Elevator RopesDocument7 pagesLubrication and Elevator RopesRui Miguel Salvador100% (1)

- Brake Systems For Container CranesDocument105 pagesBrake Systems For Container CranesUrip S. SetyadjiNo ratings yet

- MagnubroucherDocument12 pagesMagnubroucherrmdarisaNo ratings yet

- Hydraulic Car Frame WHF35 Direct and IndirectDocument38 pagesHydraulic Car Frame WHF35 Direct and Indirectmario escottoNo ratings yet

- Elevator Check List: ControlDocument2 pagesElevator Check List: ControlENG.Tahir ThamerNo ratings yet

- IGD20 Complete ManualDocument39 pagesIGD20 Complete ManualFERNSNo ratings yet

- Insp Guide Electric Elevators PDFDocument2 pagesInsp Guide Electric Elevators PDFMoises PerelloNo ratings yet

- Omarlift Hydraulic Components Operating InstructionsDocument88 pagesOmarlift Hydraulic Components Operating Instructionsmahfoud ascenseursNo ratings yet

- Quick Reference Installation Guide: The Peelle CompanyDocument62 pagesQuick Reference Installation Guide: The Peelle CompanyRodrigo Antonio100% (1)

- S3300ap-Brochure Ascensor PDFDocument20 pagesS3300ap-Brochure Ascensor PDFStephanie García100% (1)

- Thyssenkrupp: Elevator Technology Synergy Element Package. Fact SheetDocument15 pagesThyssenkrupp: Elevator Technology Synergy Element Package. Fact SheetTek tek hapNo ratings yet

- Wittur MRM W-Line Modern Lift SolutionDocument6 pagesWittur MRM W-Line Modern Lift SolutionJairo Castro FlorianNo ratings yet

- Bloc - Stop Device PDFDocument36 pagesBloc - Stop Device PDFMoises PerelloNo ratings yet

- Escalators, Travellators and EscalatorsDocument9 pagesEscalators, Travellators and EscalatorsSadiya SameeraNo ratings yet

- AscensorDocument24 pagesAscensorBlass Hernández Castro100% (1)

- Architect's and Consultant's Specification Guide: Otis Elevator CompanyDocument12 pagesArchitect's and Consultant's Specification Guide: Otis Elevator CompanyjamesNo ratings yet

- PM 7 000338 en 01Document30 pagesPM 7 000338 en 01Anonymous N57sCcpiNo ratings yet

- General Contractor's Passenger and Freight Elevator Pre-Inspection ChecklistDocument4 pagesGeneral Contractor's Passenger and Freight Elevator Pre-Inspection ChecklistEngr. Jeremiah BadanaNo ratings yet

- SOP Terminal Tractor01Document11 pagesSOP Terminal Tractor01vozefjadavNo ratings yet

- Final QualityDocument25 pagesFinal QualityAkshat BansalNo ratings yet

- Tirak: For Man-RidingDocument36 pagesTirak: For Man-RidingBismo Anggoro80% (5)

- Hydraulic Elevators Basic ComponentsDocument16 pagesHydraulic Elevators Basic ComponentsIkhwan Nasir100% (2)

- MRL W Line: Modular Machine Roomless Electric ElevatorDocument28 pagesMRL W Line: Modular Machine Roomless Electric ElevatorMohd Abu AjajNo ratings yet

- Blain Service Manual GBDocument40 pagesBlain Service Manual GBsmsobhanNo ratings yet

- Stairlift Installations Repairs and Maintenance1234scribdDocument3 pagesStairlift Installations Repairs and Maintenance1234scribdLucas Phelps0% (1)

- Rigging Safety RecommendationDocument22 pagesRigging Safety RecommendationVivekanand SinghNo ratings yet

- RIGGING SAFETY TrainingDocument43 pagesRIGGING SAFETY TrainingBG REDDYNo ratings yet

- Order Intake ProcedureDocument1 pageOrder Intake ProcedureRahulNo ratings yet

- Getting Started With OneDrive PDFDocument1 pageGetting Started With OneDrive PDFmegaNo ratings yet

- 239 Excel Shortcuts For Windows - MyOnlineTrainingHubDocument17 pages239 Excel Shortcuts For Windows - MyOnlineTrainingHubArpan Ghosh100% (1)

- 239 Excel Shortcuts For Windows - MyOnlineTrainingHubDocument17 pages239 Excel Shortcuts For Windows - MyOnlineTrainingHubArpan Ghosh100% (1)

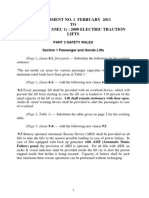

- Amendment No. 1 February 2011 TO Is 14665 (Part 3/sec 1) : 2000 Electric Traction LiftsDocument2 pagesAmendment No. 1 February 2011 TO Is 14665 (Part 3/sec 1) : 2000 Electric Traction LiftsRahulNo ratings yet

- Is 14665 5 1999 PDFDocument15 pagesIs 14665 5 1999 PDFSomnath DasNo ratings yet

- Is 14665 1 2000Document15 pagesIs 14665 1 2000Santwona ShrivastavaNo ratings yet

- Is 14665 2 1-2 2000 PDFDocument54 pagesIs 14665 2 1-2 2000 PDFBaban Patil0% (1)

- Elevator IS 3Document26 pagesElevator IS 3Sasmit RaiNo ratings yet

- Manuals TVS Star City PlusDocument69 pagesManuals TVS Star City PlusdavidNo ratings yet

- Modeling and Analysis of Dynamic Systems Using Lagrange FormalismDocument21 pagesModeling and Analysis of Dynamic Systems Using Lagrange FormalismstarykNo ratings yet

- Berardi's Electronic Projects Quarterly 2016 Summer - Joseph BerardiDocument124 pagesBerardi's Electronic Projects Quarterly 2016 Summer - Joseph Berardipawasan100% (1)

- Chapter 6 ControlDocument148 pagesChapter 6 Control.ılı.Govíиð ЯäJ.ılı.No ratings yet

- A Theory of Shape by Space CarvingDocument20 pagesA Theory of Shape by Space Carvingciprian_ciucur4075No ratings yet

- Column Design With P-DeltaDocument2 pagesColumn Design With P-DeltaAKSNo ratings yet

- Engineering Materials by S K Mondal PDFDocument47 pagesEngineering Materials by S K Mondal PDFngaggu93No ratings yet

- Tension LabDocument9 pagesTension LabnehalNo ratings yet

- Lathe Serial Servo Turret With Lio-Shing Turret - Development Manual (ROT Component)Document14 pagesLathe Serial Servo Turret With Lio-Shing Turret - Development Manual (ROT Component)charlechenNo ratings yet

- I SectionDocument42 pagesI SectionAliNo ratings yet

- CCCRCxToolkit-Sequence Operation Template 2007Document6 pagesCCCRCxToolkit-Sequence Operation Template 2007Humpy DumpyNo ratings yet

- Partial Differential Equations (Week 2) First Order Pdes: Gustav Holzegel January 24, 2019Document16 pagesPartial Differential Equations (Week 2) First Order Pdes: Gustav Holzegel January 24, 2019PLeaseNo ratings yet

- Gear Pump IPHDocument13 pagesGear Pump IPHDian PramadiNo ratings yet

- 09 Introduction To Sand ControlDocument62 pages09 Introduction To Sand ControlEdgar Ordoñez100% (2)

- Introduction To Disturbance Rejection ControlDocument5 pagesIntroduction To Disturbance Rejection ControlShamsMohdNo ratings yet

- Datasheet Jinko 330WDocument2 pagesDatasheet Jinko 330WWildor Gosgot Angeles100% (1)

- Wire Diagram Switch & Circuit Prototypes The Light-House Build & BlueprintDocument8 pagesWire Diagram Switch & Circuit Prototypes The Light-House Build & BlueprintwinwonwinNo ratings yet

- 31-01-2022 - JR Iit Co SC N120 - Jee Main Model QP FinalDocument14 pages31-01-2022 - JR Iit Co SC N120 - Jee Main Model QP FinalUjib DamianNo ratings yet

- 1 Phase SpaceDocument1 page1 Phase Spaceaaditya3015No ratings yet

- HelicalDocument8 pagesHelicalAnamiya BhattacharyaNo ratings yet

- Brachistochrone Problem: Shortest Curve Between Two PointsDocument5 pagesBrachistochrone Problem: Shortest Curve Between Two PointsNinaReščičNo ratings yet

- SAGD Start-Up StrategiesDocument14 pagesSAGD Start-Up StrategiesisleepinadrawerNo ratings yet

- Cascmd enDocument369 pagesCascmd enJosé Augusto Gallegos RiveraNo ratings yet

- ADSP Course Contents in IIT MadrasDocument2 pagesADSP Course Contents in IIT MadrasabhisheknkarNo ratings yet

- Full Thesis 1Document113 pagesFull Thesis 1Murtaza SieamNo ratings yet

- Pergamon: Energy Convers. MGMTDocument12 pagesPergamon: Energy Convers. MGMThassan aliNo ratings yet

- Aerodynamics of the Airplane: The Drag Polar ChapterDocument88 pagesAerodynamics of the Airplane: The Drag Polar ChapterMuhammad Ishaq KhanNo ratings yet

- Ray Optics Practice SheetDocument14 pagesRay Optics Practice SheetyashietasethiNo ratings yet

- Origin&Evolution of MagmasDocument47 pagesOrigin&Evolution of MagmasVictor V IeNo ratings yet

- Examples Bolted ConnectionsDocument16 pagesExamples Bolted Connectionsaisha nakato100% (2)

- Mii 2012 0102Document44 pagesMii 2012 0102asblueskyNo ratings yet