Professional Documents

Culture Documents

Directions For Use of The Hazard Analysis Form

Uploaded by

Thị Thanh Ngân NguyễnOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Directions For Use of The Hazard Analysis Form

Uploaded by

Thị Thanh Ngân NguyễnCopyright:

Available Formats

Heat Treated, But Not Fully Cooked - not Shelf-Stable: cured whole muscle,

e.g. Bacon

Directions for Use of the Hazard Analysis Form

1. Make sure that every step shown on the Process Flow Diagram is

entered in the Hazard Analysis Form. Make sure that each step has

the same name and number in both the Process Flow Diagram and the

Hazard Analysis Form.

2. Check the three categories of hazard (Biological, Chemical, Physical)

shown for each step.

a. If you think a listed hazard is not reasonably likely to occur,

leave it in column 2 (Food Safety Hazard) and enter “No” in

column 3 (Reasonably likely to occur?). Then provide a reason in

column 4.

b. If you think there are no relevant hazards for a particular

category delete the listed hazard and write “none” in column 2,

write “No” in column 3, provide a reason in column 4 and cross

out any information in columns 5 and 6.

c. If you think that a relevant hazard should be added at a step,

describe the hazard in column 2 (Food Safety Hazard). Then

determine whether the hazard is reasonably likely to occur and

put the answer in column 3. Then provide, in column 4, a reason

for deciding whether or not the hazard is reasonably likely to

occur.

i. For example, following an SSOP, SOP, or approved

formulation may make a hazard unlikely to occur, or a

supplier may provide a letter of guarantee stating that

the hazard should not be present.

ii. On the other hand, a history of outbreaks or

contamination related to a hazard would mean that the

hazard IS reasonably likely to occur.

Columns 5 and 6 can be left blank if a hazard is NOT reasonably

likely to occur.

If the hazard IS reasonably likely to occur: fill in columns 5 and

6.

iii. In column 5, list measures that could be applied to

prevent, eliminate, or reduce the hazard to an acceptable

level. NOTE: at least one of these measures must be

either a Critical Control Point (CCP) at the present step,

or a CCP at a later step.

1 9/27/07 version; supersedes all previous versions

Heat Treated, But Not Fully Cooked - not Shelf-Stable: cured whole muscle,

e.g. Bacon

iv. Finally, if the hazard is controlled by a CCP at the

present step, enter the CCP number in column 6. The

accepted numbering system is to number the CCP’s in

order, followed by either B, C, or P to indicate what type

of hazard is being controlled. For example, if the 2 nd CCP

in a process controlled a physical hazard, it would be

entered as CCP -2P.

d. I f you agree that a listed hazard is relevant, no changes are

necessary.

2 9/27/07 version; supersedes all previous versions

Heat Treated, But Not Fully Cooked - not Shelf-Stable: cured whole muscle, e.g. Bacon

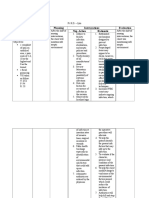

HAZARD ANALYSIS

1. Process Step 2. Food Safety 3. 4. Basis of 5. If Yes in Column 3, 6. Critical

Hazard Reasonably Reasonably What Measures Could be Control Point

likely to likely to occur Applied to Prevent,

occur Eliminate, or Reduce the

Hazard to an Acceptable

Level?

1, Receiving and 6. Biological – No Visual inspection for

Storage – Packaging Contamination with container integrity,

materials meat, other biological contamination, at

materials receiving makes

hazard unlikely. SOP

for storage makes

hazard unlikely.

Chemical – Non-food No Letters of

grade materials; guarantee are

chemical contamination. received from all

suppliers of

packaging materials.

SOP for storage

makes hazard

unlikely.

Physical – None No SOPs for receiving

and storage make

hazard unlikely.

2. Receiving – Raw Biological - Presence No Raw meat/poultry is

Meat of unacceptably high (vegetative a known source of

levels of vegetative pathogens) pathogens, but

pathogens: receiving SOP makes

Salmonella, Listeria it unlikely that

monocytogenes, unacceptably high

3 05/11/2012 version; supersedes all previous versions

Heat Treated, But Not Fully Cooked - not Shelf-Stable: cured whole muscle, e.g. Bacon

1. Process Step 2. Food Safety 3. 4. Basis of 5. If Yes in Column 3, 6. Critical

Hazard Reasonably Reasonably What Measures Could be Control Point

likely to likely to occur Applied to Prevent,

occur Eliminate, or Reduce the

Hazard to an Acceptable

Level?

Staphylococcus aureus. levels of pathogens

are present.

Product is labeled to

instruct consumers

to fully cook product

and thereby kill

pathogens.

Presence of Yes (spore- Raw meat is a known Hazard will be controlled by later

sporeforming forming source of pathogens. CCPs of smoking (prevents

pathogens: Clostridium pathogens) growth) and cooling (prevents

perfringens, germination and growth of

Clostridium botulinum. clostridial spores).

Chemical – None No SOP for receiving

makes hazard

unlikely.

Physical – None No SOP for receiving

makes hazard

unlikely.

4 05/11/2012 version; supersedes all previous versions

Heat Treated, But Not Fully Cooked - not Shelf-Stable: cured whole muscle, e.g. Bacon

1. Process Step 2. Food Safety 3. 4. Basis of 5. If Yes in Column 3, 6. Critical

Hazard Reasonably Reasonably What Measures Could be Control Point

likely to likely to occur Applied to Prevent,

occur Eliminate, or Reduce the

Hazard to an Acceptable

Level?

3. Receiving – Food Biological- None No SOP for receiving

(Non-meat) makes hazard

Ingredients: spices, unlikely.

cure mix.

Chemical –Ingredients No letter of guarantee

containing undesirable is received from

substances each supplier of

food additives,

spices, cure mix,

etc.

Physical – None No SOP for receiving

makes hazard

unlikely.

4. Storage(Frozen/ Biological - Presence No Raw meat/poultry is

Refrigerated) – Raw of unacceptably high (vegetative a known source of

Meat levels of vegetative pathogens) pathogens, but

pathogens: receiving SOP makes

Salmonella, Listeria it unlikely that

monocytogenes, unacceptably high

Staphylococcus aureus. levels of pathogens

are present.

Product is labeled to

instruct consumers

to fully cook product

5 05/11/2012 version; supersedes all previous versions

Heat Treated, But Not Fully Cooked - not Shelf-Stable: cured whole muscle, e.g. Bacon

1. Process Step 2. Food Safety 3. 4. Basis of 5. If Yes in Column 3, 6. Critical

Hazard Reasonably Reasonably What Measures Could be Control Point

likely to likely to occur Applied to Prevent,

occur Eliminate, or Reduce the

Hazard to an Acceptable

Level?

and thereby kill

pathogens.

Presence of spore- Yes (spore- Raw meat is a known Hazard will be controlled by later

forming pathogens: forming source of pathogens. CCPs of smoking (prevents

Clostridium pathogens) growth) and cooling (prevents

perfringens, germination and growth of

Clostridium botulinum. clostridial spores). Product is

labeled to instruct consumers to

fully cook product and thereby

kill pathogens.

Chemical - None No SOP for storage

makes hazard

unlikely.

Physical – None No SOP for storage

makes hazard

unlikely.

5. Storage – Food Biological – None No SOP for storage

Ingredients, both makes hazard

refrigerated and non- unlikely.

refrigerated Chemical – None No SOP for storage

makes hazard

unlikely.

Physical – None No SOP for storage

makes hazard

unlikely.

6 05/11/2012 version; supersedes all previous versions

Heat Treated, But Not Fully Cooked - not Shelf-Stable: cured whole muscle, e.g. Bacon

1. Process Step 2. Food Safety 3. 4. Basis of 5. If Yes in Column 3, 6. Critical

Hazard Reasonably Reasonably What Measures Could be Control Point

likely to likely to occur Applied to Prevent,

occur Eliminate, or Reduce the

Hazard to an Acceptable

Level?

7. Tempering of raw Biological – Presence of No Raw meat/poultry is

meat unacceptably high (Presence of a known source of

levels of vegetative vegetative pathogens, but

pathogens: pathogens) receiving SOP makes

Salmonella, Listeria it unlikely that

monocytogenes, unacceptably high

Staphylococcus aureus. levels of pathogens

are present.

Product is labeled to

instruct consumers

to fully cook product

and thereby kill

pathogens.

Growth of vegetative No Pathogen growth is

pathogens. (Growth of unlikely because

vegetative tempering is done

pathogens) according to SOP

for

Tempering/Thawing

of Frozen Materials.

Presence of spore- Yes Raw meat is a known Hazard will be controlled by later

forming pathogens: (Presence of source of pathogens. CCPs of smoking (prevents

Clostridium pathogens) growth) and cooling (prevents

perfringens, germination and growth of

7 05/11/2012 version; supersedes all previous versions

Heat Treated, But Not Fully Cooked - not Shelf-Stable: cured whole muscle, e.g. Bacon

1. Process Step 2. Food Safety 3. 4. Basis of 5. If Yes in Column 3, 6. Critical

Hazard Reasonably Reasonably What Measures Could be Control Point

likely to likely to occur Applied to Prevent,

occur Eliminate, or Reduce the

Hazard to an Acceptable

Level?

Clostridium botulinum. clostridial spores).

Growth of spore- No Pathogen growth is

forming pathogens. (Growth of unlikely because

spore- tempering is done

forming according to SOP

pathogens) for

Tempering/Thawing

of Frozen Materials.

Chemical – None No SSOP makes hazard

unlikely.

Physical - None No SSOP makes hazard

unlikely.

8. Preparing cure Biological – No Finished product

Insufficient nitrite color would be

level allowing growth of unacceptable if

spore-forming insufficient cure

pathogens added – product

would not enter

commerce

Chemical – Ingredients No Approved

not being added or (improper formulations are

used as intended; use) followed.

8 05/11/2012 version; supersedes all previous versions

Heat Treated, But Not Fully Cooked - not Shelf-Stable: cured whole muscle, e.g. Bacon

1. Process Step 2. Food Safety 3. 4. Basis of 5. If Yes in Column 3, 6. Critical

Hazard Reasonably Reasonably What Measures Could be Control Point

likely to likely to occur Applied to Prevent,

occur Eliminate, or Reduce the

Hazard to an Acceptable

Level?

cleaning/sanitizing No Pre-op SSOP makes

chemical residues; (cleaning presence of

chemicals) chemical residues

unlikely to occur.

cure-mix may contain No Application of

potential allergens; (allergens) correct label

prevents

inadvertent

consumption of

allergen by

consumer.

Operational SSOP

prevents cross-

contamination of

allergenic agents.

excess cure addition No Cure mix has highly

(excess cure) dilute concentration

of nitrite; amount

used is logged on

batch sheet.

Physical - None No SSOP makes hazard

unlikely.

9. Dry-rubbing Biological – Presence of No Raw meat/poultry is

9 05/11/2012 version; supersedes all previous versions

Heat Treated, But Not Fully Cooked - not Shelf-Stable: cured whole muscle, e.g. Bacon

1. Process Step 2. Food Safety 3. 4. Basis of 5. If Yes in Column 3, 6. Critical

Hazard Reasonably Reasonably What Measures Could be Control Point

likely to likely to occur Applied to Prevent,

occur Eliminate, or Reduce the

Hazard to an Acceptable

Level?

unacceptably high (Presence of a known source of

levels of vegetative vegetative pathogens, but

pathogens (see list in pathogens) receiving SOP makes

step 2 above); it unlikely that

unacceptably high

levels of pathogens

are present.

Product is labeled to

instruct consumers

to fully cook product

and thereby kill

pathogens.

Pathogen contamination No SSOP makes hazard

via equipment (Contamina- unlikely.

(contaminated at start tion)

of shift) and workers;

Presence of spore- Yes Raw meat is a known Hazard will be controlled by later

forming pathogens. (presence of source of pathogens. CCPs of smoking (prevents

spore- growth) and cooling (prevents

forming germination and growth of

pathogens) clostridial spores).

10 05/11/2012 version; supersedes all previous versions

Heat Treated, But Not Fully Cooked - not Shelf-Stable: cured whole muscle, e.g. Bacon

1. Process Step 2. Food Safety 3. 4. Basis of 5. If Yes in Column 3, 6. Critical

Hazard Reasonably Reasonably What Measures Could be Control Point

likely to likely to occur Applied to Prevent,

occur Eliminate, or Reduce the

Hazard to an Acceptable

Level?

Insufficient nitrite No Finished product

level allowing growth of (Growth of color would be

spore-forming spore- unacceptable if

pathogens forming insufficient cure

pathogens) added – product

would not enter

commerce

Growth of spore- No (Growth Duration of step is

formation pathogens of spore- short enough that

before cure acts forming growth would not

pathogens) occur.

Chemical – No Pre-op SSOP makes

cleaning/sanitizing (cleaning presence of

chemical residues; chemicals) chemical residues

excess cure addition unlikely to occur.

No Cure mix has highly

(excess cure) dilute concentration

11 05/11/2012 version; supersedes all previous versions

Heat Treated, But Not Fully Cooked - not Shelf-Stable: cured whole muscle, e.g. Bacon

1. Process Step 2. Food Safety 3. 4. Basis of 5. If Yes in Column 3, 6. Critical

Hazard Reasonably Reasonably What Measures Could be Control Point

likely to likely to occur Applied to Prevent,

occur Eliminate, or Reduce the

Hazard to an Acceptable

Level?

of nitrite; amount

used is logged on

batch sheet.

Physical – None No SSOP makes hazard

unlikely

10. Pumping Biological – Presence of No Raw meat/poultry is

unacceptably high (Presence of a known source of

levels of vegetative vegetative pathogens, but

pathogens (see list in pathogens) receiving SOP makes

step 2 above); it unlikely that

unacceptably high

levels of pathogens

are present.

Product is labeled to

instruct consumers

to fully cook product

and thereby kill

pathogens.

Pathogen contamination No SSOP makes hazard

via equipment (Contamina- unlikely.

(contaminated at start tion)

of shift) and workers;

12 05/11/2012 version; supersedes all previous versions

Heat Treated, But Not Fully Cooked - not Shelf-Stable: cured whole muscle, e.g. Bacon

1. Process Step 2. Food Safety 3. 4. Basis of 5. If Yes in Column 3, 6. Critical

Hazard Reasonably Reasonably What Measures Could be Control Point

likely to likely to occur Applied to Prevent,

occur Eliminate, or Reduce the

Hazard to an Acceptable

Level?

Presence of spore- Yes Raw meat is a known Hazard will be controlled by later

forming pathogens. (presence of source of pathogens. CCPs of smoking (prevents

spore- growth) and cooling (prevents

forming germination and growth of

pathogens) clostridial spores).

Insufficient nitrite No Finished product

level allowing growth of (Growth of color would be

spore-forming spore- unacceptable if

pathogens forming insufficient cure

pathogens) added – product

would not enter

commerce

Growth of spore- No (Growth Duration of step is

forming pathogens of spore- short enough that

before cure acts forming growth would not

pathogens) occur.

Chemical – Ingredients No Application of

may contain potential (allergens) correct label

allergens; prevents

13 05/11/2012 version; supersedes all previous versions

Heat Treated, But Not Fully Cooked - not Shelf-Stable: cured whole muscle, e.g. Bacon

1. Process Step 2. Food Safety 3. 4. Basis of 5. If Yes in Column 3, 6. Critical

Hazard Reasonably Reasonably What Measures Could be Control Point

likely to likely to occur Applied to Prevent,

occur Eliminate, or Reduce the

Hazard to an Acceptable

Level?

cleaning/sanitizing inadvertent

chemical residues; consumption of

excess cure addition allergen by

consumer.

Operational SSOP

prevents cross-

contamination of

allergenic agents.

No Pre-op SSOP makes

(cleaning presence of

chemicals) chemical residues

unlikely to occur.

No Cure mix has highly

(excess cure) dilute concentration

of nitrite; amount

used is logged on

batch sheet.

Physical – None No SSOP makes hazard

unlikely.

11. Injecting Biological – Presence of No Raw meat/poultry is

unacceptably high (Presence of a known source of

levels of vegetative vegetative pathogens, but

pathogens (see list in pathogens) receiving SOP makes

step 2 above); it unlikely that

14 05/11/2012 version; supersedes all previous versions

Heat Treated, But Not Fully Cooked - not Shelf-Stable: cured whole muscle, e.g. Bacon

1. Process Step 2. Food Safety 3. 4. Basis of 5. If Yes in Column 3, 6. Critical

Hazard Reasonably Reasonably What Measures Could be Control Point

likely to likely to occur Applied to Prevent,

occur Eliminate, or Reduce the

Hazard to an Acceptable

Level?

unacceptably high

levels of pathogens

are present.

Product is labeled to

instruct consumers

to fully cook product

and thereby kill

pathogens.

Pathogen contamination No SSOP makes hazard

via equipment (Contamina- unlikely.

(contaminated at start tion)

of shift) and workers;

Presence of spore- Yes Raw meat is a known Hazard will be controlled by later

forming pathogens. (presence of source of pathogens. CCPs of smoking (prevents

spore- growth) and cooling (prevents

forming germination and growth of

pathogens) clostridial spores).

Insufficient nitrite No Finished product

level allowing growth of (Growth of color would be

spore-forming spore- unacceptable if

pathogens forming insufficient cure

15 05/11/2012 version; supersedes all previous versions

Heat Treated, But Not Fully Cooked - not Shelf-Stable: cured whole muscle, e.g. Bacon

1. Process Step 2. Food Safety 3. 4. Basis of 5. If Yes in Column 3, 6. Critical

Hazard Reasonably Reasonably What Measures Could be Control Point

likely to likely to occur Applied to Prevent,

occur Eliminate, or Reduce the

Hazard to an Acceptable

Level?

pathogens) added – product

would not enter

commerce

Growth of spore- No (Growth Duration of step is

forming pathogens of spore- short enough that

before cure acts. forming growth would not

pathogens) occur.

Chemical – Ingredients No Application of

may contain potential (allergens) correct label

allergens; prevents

cleaning/sanitizing inadvertent

chemical residues; consumption of

excess cure addition allergen by

consumer.

Operational SSOP

prevents cross-

contamination of

allergenic agents.

16 05/11/2012 version; supersedes all previous versions

Heat Treated, But Not Fully Cooked - not Shelf-Stable: cured whole muscle, e.g. Bacon

1. Process Step 2. Food Safety 3. 4. Basis of 5. If Yes in Column 3, 6. Critical

Hazard Reasonably Reasonably What Measures Could be Control Point

likely to likely to occur Applied to Prevent,

occur Eliminate, or Reduce the

Hazard to an Acceptable

Level?

No Pre-op SSOP makes

(cleaning presence of

chemicals) chemical residues

unlikely to occur.

No Cure mix has highly

(excess cure) dilute concentration

of nitrite; amount

used is logged on

batch sheet.

Physical – Metal from No No history of

injector problem (must

provide evidence).

Visual inspection of

equipment during

cleaning makes it

unlikely that hazard

enters commerce.

12. Tumbling Biological – Presence of No Raw meat/poultry is

unacceptably high (Presence of a known source of

levels of vegetative vegetative pathogens, but

pathogens (see list in pathogens) receiving SOP makes

step 2 above); it unlikely that

unacceptably high

levels of pathogens

17 05/11/2012 version; supersedes all previous versions

Heat Treated, But Not Fully Cooked - not Shelf-Stable: cured whole muscle, e.g. Bacon

1. Process Step 2. Food Safety 3. 4. Basis of 5. If Yes in Column 3, 6. Critical

Hazard Reasonably Reasonably What Measures Could be Control Point

likely to likely to occur Applied to Prevent,

occur Eliminate, or Reduce the

Hazard to an Acceptable

Level?

are present.

Product is labeled to

instruct consumers

to fully cook product

and thereby kill

pathogens.

Pathogen contamination No SSOP makes hazard

via equipment (Contamina- unlikely.

(contaminated at start tion)

of shift) and workers;

Presence of spore- Yes Raw meat is a known Hazard will be controlled by later

forming pathogens. (presence of source of pathogens. CCPs of smoking (prevents

spore- growth) and cooling (prevents

forming germination and growth of

pathogens) clostridial spores).

Insufficient nitrite No Finished product

level allowing growth of (Growth of color would be

spore-forming spore- unacceptable if

pathogens forming insufficient cure

pathogens) added – product

would not enter

18 05/11/2012 version; supersedes all previous versions

Heat Treated, But Not Fully Cooked - not Shelf-Stable: cured whole muscle, e.g. Bacon

1. Process Step 2. Food Safety 3. 4. Basis of 5. If Yes in Column 3, 6. Critical

Hazard Reasonably Reasonably What Measures Could be Control Point

likely to likely to occur Applied to Prevent,

occur Eliminate, or Reduce the

Hazard to an Acceptable

Level?

commerce

Growth of spore- No (Growth Duration of step is

forming pathogens of spore- short enough that

before cure acts. forming growth would not

pathogens) occur.

Chemical – No Pre-op SSOP makes

cleaning/sanitizing presence of

chemical residues chemical residues

unlikely to occur.

Physical - Metal No No history of

problem (must

provide evidence).

Visual observation

for foreign

materials during

processing,

inspection of

equipment during

cleaning make

hazard unlikely.

19 05/11/2012 version; supersedes all previous versions

Heat Treated, But Not Fully Cooked - not Shelf-Stable: cured whole muscle, e.g. Bacon

1. Process Step 2. Food Safety 3. 4. Basis of 5. If Yes in Column 3, 6. Critical

Hazard Reasonably Reasonably What Measures Could be Control Point

likely to likely to occur Applied to Prevent,

occur Eliminate, or Reduce the

Hazard to an Acceptable

Level?

13. Brining Biological – Presence of No Raw meat/poultry is

unacceptably high (Presence of a known source of

levels of vegetative vegetative pathogens, but

pathogens (see list in pathogens) receiving SOP makes

step 2 above); it unlikely that

unacceptably high

levels of pathogens

are present.

Product is labeled to

instruct consumers

to fully cook product

and thereby kill

pathogens.

Pathogen contamination No SSOP makes hazard

via equipment (Contamina- unlikely.

(contaminated at start tion)

of shift) and workers;

Presence of spore- Yes Raw meat is a known Hazard will be controlled by later

forming pathogens. (presence of source of pathogens. CCPs of smoking (prevents

spore- growth) and cooling (prevents

forming germination and growth of

pathogens) clostridial spores).

20 05/11/2012 version; supersedes all previous versions

Heat Treated, But Not Fully Cooked - not Shelf-Stable: cured whole muscle, e.g. Bacon

1. Process Step 2. Food Safety 3. 4. Basis of 5. If Yes in Column 3, 6. Critical

Hazard Reasonably Reasonably What Measures Could be Control Point

likely to likely to occur Applied to Prevent,

occur Eliminate, or Reduce the

Hazard to an Acceptable

Level?

Insufficient nitrite No Finished product

level allowing growth of (Growth of color would be

spore-forming spore- unacceptable if

pathogens forming insufficient cure

pathogens) added – product

would not enter

commerce

Growth of spore- No (Growth Step is done under

forming pathogens of spore- refrigeration to

forming prevent growth.

pathogens)

Chemical – No Pre-op SSOP makes

cleaning/sanitizing presence of

chemical residues chemical residues

unlikely to occur.

Physical - None No SSOP makes hazard

unlikely.

21 05/11/2012 version; supersedes all previous versions

Heat Treated, But Not Fully Cooked - not Shelf-Stable: cured whole muscle, e.g. Bacon

1. Process Step 2. Food Safety 3. 4. Basis of 5. If Yes in Column 3, 6. Critical

Hazard Reasonably Reasonably What Measures Could be Control Point

likely to likely to occur Applied to Prevent,

occur Eliminate, or Reduce the

Hazard to an Acceptable

Level?

14.Hanging in cooler Biological – Presence of No Raw meat/poultry is

unacceptably high (Presence of a known source of

levels of vegetative vegetative pathogens, but

pathogens (see list in pathogens) receiving SOP makes

step 2 above); it unlikely that

unacceptably high

levels of pathogens

are present.

Product is labeled to

instruct consumers

to fully cook product

and thereby kill

pathogens.

Pathogen contamination No SSOP makes hazard

via equipment (Contamina- unlikely.

(contaminated at start tion)

of shift) and workers;

Presence of spore- Yes Raw meat is a known Hazard will be controlled by later

forming pathogens. (presence of source of pathogens. CCPs of smoking (prevents

spore- growth) and cooling (prevents

forming germination and growth of

pathogens) clostridial spores).

22 05/11/2012 version; supersedes all previous versions

Heat Treated, But Not Fully Cooked - not Shelf-Stable: cured whole muscle, e.g. Bacon

1. Process Step 2. Food Safety 3. 4. Basis of 5. If Yes in Column 3, 6. Critical

Hazard Reasonably Reasonably What Measures Could be Control Point

likely to likely to occur Applied to Prevent,

occur Eliminate, or Reduce the

Hazard to an Acceptable

Level?

Growth of vegetative No Cooler temperature

or spore-forming (Growth of is maintained cold

pathogens spore- enough to prevent

forming pathogen growth,

pathogens) per SOP for

storage.

Chemical - None No SSOP makes hazard

unlikely.

Physical - None No SSOP makes hazard

unlikely.

15. smoking Biological – Presence of No Raw meat/poultry is

unacceptably high (Presence of a known source of

levels of vegetative vegetative pathogens, but

pathogens (see list in pathogens) receiving SOP makes

step 2 above); it unlikely that

unacceptably high

levels of pathogens

are present.

23 05/11/2012 version; supersedes all previous versions

Heat Treated, But Not Fully Cooked - not Shelf-Stable: cured whole muscle, e.g. Bacon

1. Process Step 2. Food Safety 3. 4. Basis of 5. If Yes in Column 3, 6. Critical

Hazard Reasonably Reasonably What Measures Could be Control Point

likely to likely to occur Applied to Prevent,

occur Eliminate, or Reduce the

Hazard to an Acceptable

Level?

Product is labeled to

instruct consumers

to fully cook product

and thereby kill

pathogens.

Presence of spore- Yes Raw meat is a known Hazard will be controlled by this

forming pathogens. (presence of source of pathogens. CCP of smoking (prevents growth)

spore- and the later CCP of cooling

forming (prevents germination and growth

pathogens) of clostridial spores).

Growth of spore- No Presence of nitrite,

forming pathogens (Growth of relatively short

spore- duration, and

forming relatively low

pathogens) temperature make

germination of

Production of heat- Yes spores unlikely. CCP 1-B

stable enterotoxin by Product is labeled to This step is a CCP. Time and

S. aureus instruct consumers temperature of smoking will be

to fully cook product controlled to prevent S. aureus

and thereby kill growth.

germinated cells.

S. aureus is salt-

24 05/11/2012 version; supersedes all previous versions

Heat Treated, But Not Fully Cooked - not Shelf-Stable: cured whole muscle, e.g. Bacon

1. Process Step 2. Food Safety 3. 4. Basis of 5. If Yes in Column 3, 6. Critical

Hazard Reasonably Reasonably What Measures Could be Control Point

likely to likely to occur Applied to Prevent,

occur Eliminate, or Reduce the

Hazard to an Acceptable

Level?

tolerant and forms a

toxin that may not

be destroyed during

cooking.

Chemical – None No SSOP makes hazard

unlikely.

Physical - None No SSOP makes hazard

unlikely.

16. Cooling Biological – growth of Yes Spores survive This step is a CCP. Product is CCP 2-B

Clostridium (clostridial cooking and can cooled rapidly enough to prevent

perfringens or growth) germinate and grow growth of Clostridium

Clostridium botulinum; if cooling is done too perfringens (> 1 log) or

slowly. Clostridium botulinum.

Recontamination of No Pre-op and

product with pathogens (Recontamina Operational SSOPs

tion) make contamination

unlikely.

No Product is

Growth of (Growth of refrigerated or

25 05/11/2012 version; supersedes all previous versions

Heat Treated, But Not Fully Cooked - not Shelf-Stable: cured whole muscle, e.g. Bacon

1. Process Step 2. Food Safety 3. 4. Basis of 5. If Yes in Column 3, 6. Critical

Hazard Reasonably Reasonably What Measures Could be Control Point

likely to likely to occur Applied to Prevent,

occur Eliminate, or Reduce the

Hazard to an Acceptable

Level?

recontaminating L.m. or other frozen (minimizes or

pathogens. pathogens) prevents pathogen

growth)

Chemical – None No

Physical - None No

17. Slicing and 18. Biological - Growth of No Product does not

Packaging Clostridium (clostridial get warm enough for

perfringens or growth) a long enough time

Clostridium botulinum; during slicing and

packaging to result

in growth.

Recontamination with No Pre-op and

pathogens; (Presence of operational SSOP

L.m. or other make contamination

pathogens) unlikely.

Growth of No Duration of slicing is

recontaminating (Growth of short enough to

pathogens. L.m. or other prevent pathogen

pathogens) growth. Product is

kept

refrigerated/frozen

(minimizes/prevents

pathogen growth)

Chemical – improperly No Labeling SOP and

26 05/11/2012 version; supersedes all previous versions

Heat Treated, But Not Fully Cooked - not Shelf-Stable: cured whole muscle, e.g. Bacon

1. Process Step 2. Food Safety 3. 4. Basis of 5. If Yes in Column 3, 6. Critical

Hazard Reasonably Reasonably What Measures Could be Control Point

likely to likely to occur Applied to Prevent,

occur Eliminate, or Reduce the

Hazard to an Acceptable

Level?

labeled allergens SSOP make hazard

unlikely.

Physical - metal No No history of

problem (must

provide evidence).

Visual inspection of

equipment during

cleaning makes it

unlikely that hazard

enters commerce.

19. Shipping or retail Biological - None No SSOP makes hazard

sale unlikely.

Chemical - None No SSOP makes hazard

unlikely.

Physical - None No SSOP makes hazard

unlikely.

27 05/11/2012 version; supersedes all previous versions

You might also like

- Drug Testing in Child WelfareDocument49 pagesDrug Testing in Child WelfareLOLA100% (1)

- Operator Handbook Red Team Osint Blue Team Reference V10nbsped 9798605493952Document443 pagesOperator Handbook Red Team Osint Blue Team Reference V10nbsped 9798605493952harshamlNo ratings yet

- The 5 Fundamental of Fat LossDocument16 pagesThe 5 Fundamental of Fat LossAndrés Jimenez100% (2)

- Azard Nalysis and Ritical Ontrol Oint: H A C C PDocument47 pagesAzard Nalysis and Ritical Ontrol Oint: H A C C PFranz MarasiganNo ratings yet

- The Body Remembers Volume 2: Revolutionizing Trauma Treatment - Babette RothschildDocument6 pagesThe Body Remembers Volume 2: Revolutionizing Trauma Treatment - Babette Rothschildnamonomi0% (4)

- International General Certificate Assessor's Marking Sheet (2011 Specification) Igc3 - The Health and Safety Practical ApplicationDocument11 pagesInternational General Certificate Assessor's Marking Sheet (2011 Specification) Igc3 - The Health and Safety Practical ApplicationVigneshwaraNo ratings yet

- Receiving ingredients HACCP analysisDocument26 pagesReceiving ingredients HACCP analysisAYMAN ZEHRANo ratings yet

- Food Safety Management Plan SummaryDocument3 pagesFood Safety Management Plan Summarysafety officer100% (2)

- Submitted By: Lantape, Ryan Luis P. RISK 111 Balandang, Jymel Gabriel Submitted To: Mrs. Mylene Dela Cruz Palmares, Vincent RileyDocument3 pagesSubmitted By: Lantape, Ryan Luis P. RISK 111 Balandang, Jymel Gabriel Submitted To: Mrs. Mylene Dela Cruz Palmares, Vincent RileyJhon Rommel Dela Cruz-OdiamanNo ratings yet

- Manufacturing Steps of Butter ChickenDocument27 pagesManufacturing Steps of Butter ChickenAYMAN ZEHRA75% (4)

- HACCP Plan Template FermentationDocument18 pagesHACCP Plan Template FermentationAugustina AnaglateyNo ratings yet

- Summary MiasmsDocument8 pagesSummary MiasmsPranesh PeterNo ratings yet

- Lesson 2 Risk Management As Applied To Safety, SecurityDocument30 pagesLesson 2 Risk Management As Applied To Safety, SecurityMarlon AndayaNo ratings yet

- HACCP Plan for Raw Ground PizzaDocument13 pagesHACCP Plan for Raw Ground PizzaLe DioNo ratings yet

- Hazard Analysis Worksheet (Apple Juice)Document8 pagesHazard Analysis Worksheet (Apple Juice)JyShe_la100% (1)

- Pizza HaccpDocument13 pagesPizza HaccpLe Dio100% (2)

- Reading Final Qs 1 1 PDFDocument64 pagesReading Final Qs 1 1 PDFMuntaserAlawiNo ratings yet

- Transes MLSP-112Document60 pagesTranses MLSP-112Hermione GrangerNo ratings yet

- HACCP Principles Comparison TableDocument27 pagesHACCP Principles Comparison TablefushiersNo ratings yet

- HACCP Plan Template Sample ReportDocument7 pagesHACCP Plan Template Sample ReportgustasalNo ratings yet

- SITXFSA008 Food Safety Program TemplateDocument26 pagesSITXFSA008 Food Safety Program Templateshanmugam thevapriyan50% (2)

- FDC Organic Virgin Coconut Oil Hazard Analysis and Critical Control Points Plan PDFDocument3 pagesFDC Organic Virgin Coconut Oil Hazard Analysis and Critical Control Points Plan PDFWynona Basilio100% (2)

- Yogurt HACCP Plan PDFDocument38 pagesYogurt HACCP Plan PDFserenela100% (2)

- Intake and Output CalculationDocument20 pagesIntake and Output CalculationJaycee Silva100% (2)

- CSS - Hazards and RisksDocument1 pageCSS - Hazards and RisksRowell MarquinaNo ratings yet

- HACCP Sheep Goat Pork SlaughterDocument19 pagesHACCP Sheep Goat Pork SlaughterFatou Sarr100% (1)

- Essential Practices for Managing Chemical Reactivity HazardsFrom EverandEssential Practices for Managing Chemical Reactivity HazardsNo ratings yet

- Critical Control Points of Fish Longganisa ProductionDocument2 pagesCritical Control Points of Fish Longganisa Productionjezu roqNo ratings yet

- Food Safety Handbook - Part 2Document203 pagesFood Safety Handbook - Part 2Yasser MostafaNo ratings yet

- Python Cheat SheetDocument16 pagesPython Cheat Sheetphamxtien3741No ratings yet

- LC HAGroundBeefDocument2 pagesLC HAGroundBeefAnar MahmudovNo ratings yet

- Hazard Analysis Template v.2019.02.13Document2 pagesHazard Analysis Template v.2019.02.13amir ShehzadNo ratings yet

- NCP Pt. DE ASISDocument3 pagesNCP Pt. DE ASISRhea Mae Valles - ReyesNo ratings yet

- Hazard Analysis ChartDocument9 pagesHazard Analysis Chartapi-410362945No ratings yet

- RTE Hazard Analysis Review of Hot Dogs Identifies Cooking and Cooling as CCPsDocument8 pagesRTE Hazard Analysis Review of Hot Dogs Identifies Cooking and Cooling as CCPsStanislava KanjevacNo ratings yet

- ISO 22000 food safety fundamentalsDocument14 pagesISO 22000 food safety fundamentalsVineeth Kumar MishraNo ratings yet

- Bio Risk Part 1Document4 pagesBio Risk Part 1CXT EnterpriseNo ratings yet

- 07-Hazard Analysis, 007Document4 pages07-Hazard Analysis, 007sajid waqasNo ratings yet

- Biorisk Mitigation Strategies - PASMETH - PhBBA - DTRADocument66 pagesBiorisk Mitigation Strategies - PASMETH - PhBBA - DTRARyan Marañon PedregosaNo ratings yet

- SushiDocument27 pagesSushishani31No ratings yet

- 17a IM Est Process Hazard AnalysisDocument27 pages17a IM Est Process Hazard AnalysisNader SedighiNo ratings yet

- HACCP ImplementationDocument25 pagesHACCP ImplementationAronn SiamNo ratings yet

- Hazard Analysis & HACCP WorksheetsDocument3 pagesHazard Analysis & HACCP WorksheetsJohn Cedric DullaNo ratings yet

- Antimicrobial Susceptibility Test ResultsDocument7 pagesAntimicrobial Susceptibility Test Resultsangela roperezNo ratings yet

- BMS533 Practical 1Document10 pagesBMS533 Practical 1NURUL AIHAN AHMAD HILMINo ratings yet

- Lunchbox HACCP PlanDocument18 pagesLunchbox HACCP PlanFooTraGoNo ratings yet

- Hazard Analysis and Critical Control Point (Haccp)Document7 pagesHazard Analysis and Critical Control Point (Haccp)Elsadig AmnconsNo ratings yet

- Pembetulan Peta Minda SlideDocument3 pagesPembetulan Peta Minda SlideNur Husnina ZawawiNo ratings yet

- Indonesian Symposium Looks at The ABC of The Biosecurity ChallengeDocument2 pagesIndonesian Symposium Looks at The ABC of The Biosecurity ChallengeDrivailaNo ratings yet

- Managing Biosafety and Biosecurity Risks in Veterinary LabsDocument13 pagesManaging Biosafety and Biosecurity Risks in Veterinary LabsallatkertNo ratings yet

- Guidance For Environmental Sampling ProgramDocument4 pagesGuidance For Environmental Sampling Programalias brownNo ratings yet

- Haccp WsDocument11 pagesHaccp WsFreg GregNo ratings yet

- Feed Safety Basics For VeterinariansDocument4 pagesFeed Safety Basics For VeterinariansŠhâh NawazNo ratings yet

- 6 Ways To Prevent Food ContaminationDocument1 page6 Ways To Prevent Food ContaminationKriszzia Janilla ArriesgadoNo ratings yet

- Conduct a hazard analysis for food safetyDocument5 pagesConduct a hazard analysis for food safetyjujuNo ratings yet

- Taking Salmonella ProblemDocument4 pagesTaking Salmonella ProblemM.C. Ángel ArteagaNo ratings yet

- Safety Security Biosafety Laboratory Biosecurity PerspectiveDocument5 pagesSafety Security Biosafety Laboratory Biosecurity PerspectiveZabdiel Ann SavellanoNo ratings yet

- 4th Module 1Document18 pages4th Module 1Mha RizNo ratings yet

- HACCP Exercise Assignment Wheat Flour MatterhornDocument10 pagesHACCP Exercise Assignment Wheat Flour MatterhornZigiju ZelekeNo ratings yet

- Laboratory Biosafety and Biosecurity ConceptsDocument6 pagesLaboratory Biosafety and Biosecurity ConceptsCXT EnterpriseNo ratings yet

- Work Activity Inventory Sheet Word TemplateDocument7 pagesWork Activity Inventory Sheet Word TemplateHendrawan ChandraNo ratings yet

- Shrimp DriedDocument5 pagesShrimp DriedbinchooknationNo ratings yet

- Manage food safety with HACCPDocument10 pagesManage food safety with HACCPCamille AlberichNo ratings yet

- Risk Managemnt ReviewerDocument4 pagesRisk Managemnt ReviewerHaru CutieNo ratings yet

- BMS533 Lab Practical 1Document13 pagesBMS533 Lab Practical 1Nur NazirahNo ratings yet

- Risk ManagementDocument5 pagesRisk ManagementTrisha Anne MorionesNo ratings yet

- Icheme Symposium Series No. 124Document8 pagesIcheme Symposium Series No. 124Amarnath Reddy RagipindiNo ratings yet

- CXS 192eDocument490 pagesCXS 192eRosita handrianaNo ratings yet

- Appetite: Jordan E. Lyerly, Charlie L. ReeveDocument9 pagesAppetite: Jordan E. Lyerly, Charlie L. ReeveHanh PhamNo ratings yet

- Willingness To Try InsectsDocument58 pagesWillingness To Try InsectsThị Thanh Ngân NguyễnNo ratings yet

- Guerrero2010 PDFDocument9 pagesGuerrero2010 PDFRomi Lycantrophe DieorliveNo ratings yet

- Guerrero2009 PDFDocument10 pagesGuerrero2009 PDFRomi Lycantrophe DieorliveNo ratings yet

- Nutrients 09 00088Document17 pagesNutrients 09 00088Familia Uribe-fuentesNo ratings yet

- Association between traditional food consumption and motivesDocument8 pagesAssociation between traditional food consumption and motivesdaneunbiNo ratings yet

- Guerrero2010 PDFDocument9 pagesGuerrero2010 PDFRomi Lycantrophe DieorliveNo ratings yet

- Willingness To Try InsectsDocument58 pagesWillingness To Try InsectsThị Thanh Ngân NguyễnNo ratings yet

- RCP y PH ArterialDocument2 pagesRCP y PH ArterialPaola LizarzabalNo ratings yet

- Putnam Voice - 1/11/12Document10 pagesPutnam Voice - 1/11/12The Lima NewsNo ratings yet

- Research EthicsDocument2 pagesResearch EthicsCarla HAHAHAHANo ratings yet

- Soal Kuis 7 Ppu - Bahasa Inggris: Text 1Document3 pagesSoal Kuis 7 Ppu - Bahasa Inggris: Text 1rayhan taufikNo ratings yet

- Date: 9/10/15 Week of 9/07/15Document4 pagesDate: 9/10/15 Week of 9/07/15api-296922357No ratings yet

- Is It Better To Do Cardio Before or After Weight Training?Document4 pagesIs It Better To Do Cardio Before or After Weight Training?Radhakrishnan SreerekhaNo ratings yet

- Marketing challenges at St. Margaret's HospitalDocument2 pagesMarketing challenges at St. Margaret's HospitalMihaela Papusica0% (1)

- Ignatavicius TOCDocument9 pagesIgnatavicius TOCjennaaahhhNo ratings yet

- Product Safety Data Sheet: Moringa Body LotionDocument2 pagesProduct Safety Data Sheet: Moringa Body LotionemyNo ratings yet

- LeprosyDocument22 pagesLeprosyvisweswar030406No ratings yet

- Professional Services, Inc. vs. Natividad and AganaDocument2 pagesProfessional Services, Inc. vs. Natividad and AganaBryan Albert SuerteNo ratings yet

- AMDLI COVID-19 Test ResultDocument2 pagesAMDLI COVID-19 Test ResultMarco Dela CruzNo ratings yet

- Intensivist To Patient RatioDocument8 pagesIntensivist To Patient RatioroykelumendekNo ratings yet

- NetworkList (NAS)Document70 pagesNetworkList (NAS)Fahad MohammadNo ratings yet

- Perioperative Nursing Cesarean SectionDocument13 pagesPerioperative Nursing Cesarean Sectionmark OrpillaNo ratings yet

- Department of Education: Republic of The PhilippinesDocument4 pagesDepartment of Education: Republic of The PhilippinesJESSIELYNE LA ROSANo ratings yet

- Main Match Results and Data 2017Document124 pagesMain Match Results and Data 2017Tǻɲ ṦħǻNo ratings yet

- Documentation in Colorectal and Stoma Care Nursing RCN 2013Document24 pagesDocumentation in Colorectal and Stoma Care Nursing RCN 2013Bhie BhieNo ratings yet

- Module 6 - Sexual SelfDocument14 pagesModule 6 - Sexual SelfFlorence de LeonNo ratings yet

- Kidney Treatment Guidelines For HyponatremiaDocument7 pagesKidney Treatment Guidelines For HyponatremialguerreroNo ratings yet

- Sample Question PaperDocument3 pagesSample Question Paperamar_deshmukh713710No ratings yet

- 3M 9105 Wear It Right Poster PDFDocument2 pages3M 9105 Wear It Right Poster PDFScott KramerNo ratings yet