Professional Documents

Culture Documents

Precautions For Flammable Liquids: Flash Point

Uploaded by

ssdxyjOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Precautions For Flammable Liquids: Flash Point

Uploaded by

ssdxyjCopyright:

Available Formats

6.

0 Safety and Health

6.1 Safety considerations

6.1.1 Personnel and the public

6.1.2 Product serviceability

6.1.3 Test validity

6.14 Safe work practices

6.2 Safety precautions

6.2.1 Explosive/implosive hazards

6.2.2 Flammability, ignitibility, combustibility hazards

Boiling Points of Flammable Liquids

The boiling point of a liquid is that temperature at which the vapor pressure of the

liquid equals the atmospheric pressure.Liquids with low boiling

points generally volatilize more readily than those with higher boiling points.

Factors Influencing Hazards of Flammable Liquids

The degree of danger depends on the following:

(1) the flash point of the liquid, (2) the concentration of vapors in the air (whether the

mixture of vapor and air is in the flammable range) and

(3) the possibility of an ignition source at or above a temperature sufficient to cause

the mixture to burst into flame

Precautions for Flammable Liquids

In the handling and use of flammable liquids, exposure of large liquid surfaces

to air should be prevented.

flammable liquids should be handled and stored in closed containers.The flash point of a

liquid is the lowest temperature at which it gives off enough vapor to form flammable

mixtures with air and to produce a flame when a source of ignition is brought close to

the surface. Other properties are factors in determining the hazards of flammable

liquids, but the flash point is the principal factor.

Auto ignition temperature is the lowest temperature at which a flammable gas or

vapor-and-air mixture will ignite under defined conditions without an external

source of ignition. Flammable vapors and gases in oxygen will spontaneously ignite at

a lower temperature than in air and their auto ignition temperature may be influenced

by the presence of catalytic substances.

Containers for Flammable Liquids

Restriction of Smoking and Lighters in Flammable Material Areas

Vapor pressure is the partial pressure (in kilopascal or in lbf·in–2) exerted by the

vapor of a volatile liquid, when in equilibrium with the surface of the liquid,

as determined by standard ASTM D 323, Test Method for Vapor Pressure of

Petroleum Products (Reid Method).9

6.2.3 Toxicity and asphyxiation hazards

Tracer gas safety aspects such as flammability, asphyxiation or specific physiological

effects as well as the possibility of pressure vessel explosions must be considered

Tracer gas safety aspects such as flammability, asphyxiation or specific physiological effects as well as the

possibility of pressure vessel explosions must be considered

The oxygen required for breathing may be accidentally removed from an area. For

example, if one of the halogenated hydrocarbons is used as a tracer gas, it

may stagnate and settle to the lowest area.

If a technician is attempting to use a detector probe in this low area, the tracer gas that

settles may eventually displace enough of the air to produce asphyxiation. To avoid

this condition, adequate ventilation must be provided. However, this ventilation must

be performed carefully.

6.2.4 Cleaning and electrical hazards

Hazards of Static Electricity with Flammable Materials

Static electricity is an accumulation of motionless charges generated by the contact and separation of

dissimilar materials. For example, static electricity is generated when a fluid flows through a pipe or from an

orifice into a vessel and may set up high voltages. The principal hazards created by static electricity are those

of fire and explosion caused by spark discharges occurring in the presence of flammable or explosive vapors,

gases or dust. A spark between two bodies occurs when there is no good electrical conductive path between

them. Hence, grounding and bonding of flammable liquid containers is necessary to prevent static electricity

from causing a spark.

A discharge of static electricity is a possible cause of ignition, so all metal parts likely to become charged should be

grounded.

When testing with gases such as hydrogen, it would also be sensible for personnel to avoid wearing clothing that

might produce static charges and for them to wear shoes with conducting soles. Another precaution is the use of reduced

sparking or nonsparking tools.

Bonding and Grounding to Prevent Electric Sparks

Bonding is done to eliminate a difference in potential between objects.

The purpose of grounding is to eliminate a difference in potential between an object and ground .

Although bonding will eliminate a difference in potential between the objects that are bonded, it will not

eliminate a difference in potential between these objects and the earth unless one of the objects possesses an adequate

conductive path to earth. Therefore, bonding will not eliminate the static charge but will only equalize the potential

between the objects bonded.

Avoidance of Sources of Ignition of Flammable Gases and Vapors

Electrical equipment may also present a problem. If there is a possibility that, in the event of leakage, such equipment

will be in an explosive environment, then either the equipment should be re positioned outside the danger

area or specifically chosen equipment should be used .

6.3 Pressure precautions

6.3.1 Pressure test versus proof test

6.3.2 Preliminary leak test

6.3.3 Pressurization check

6.3.4 Design limitations

635 Equipment and setup

6.4 Safety devices

641 Pressure control valves and regulators

642 Pressure relief valves and vents

643 Flow rate of regulator and relief valves

6.5 Hazardous and tracer gas safety

6.5.1 Combustible gas detection and safely

6.5.2 Toxic gas detection and safety

6.5.3 Oxygen-deficiency detectors

6.5.4 Radioisotope detection

6.6 Types of monitoring equipment

6.6.1 Area monitors

6.6.2 Personnel monitors

Personnel Protection Badges to Warn of Excessive Exposure to Toxic Gases

Personnel protection indicators (PPIs) are plastic badges with pocket clips that have

sensors that react chemically with concentrations of various gases or vapors used as

tracers in leak testing.`

These personnel protection indicators are sensitive to the accumulated personal

exposure of the badge wearer to the concentration of gas in the leak testing area.

6.6.3 Leak-locating devices

6.7 Safety

6.7.1 State and federal regulations

6.7.2 Safety codes/standards

6.7.3 Hazardous gas standards

6.7.4 Nuclear Regulatory Commission (NRC) radiation requirements

You might also like

- QP Fire and Safety Philosophy - QP-PHL-S-0001 Rev.03 2013 16-30Document15 pagesQP Fire and Safety Philosophy - QP-PHL-S-0001 Rev.03 2013 16-30ahmed fouadNo ratings yet

- 2 Risk Assessment MethodologyDocument7 pages2 Risk Assessment MethodologyEman fatimaNo ratings yet

- Explosive Atmospheres - Classification of Hazardous Areas (Zoning) and Selection of EquipmentDocument8 pagesExplosive Atmospheres - Classification of Hazardous Areas (Zoning) and Selection of EquipmentJaggu JrzNo ratings yet

- Area ZoningDocument8 pagesArea ZoningafnakshNo ratings yet

- Explosive Atmospheres - Classification of Hazardous Areas (Zoning) and Selection of EquipmentDocument8 pagesExplosive Atmospheres - Classification of Hazardous Areas (Zoning) and Selection of EquipmentRMRE UETNo ratings yet

- CryogenicLiquidGuidelines PDFDocument15 pagesCryogenicLiquidGuidelines PDFMichel LopezNo ratings yet

- Electrical Equipment in Hazardous AreasDocument10 pagesElectrical Equipment in Hazardous Areasperumal1312No ratings yet

- Dust Explosion and Fire Prevention Handbook: A Guide to Good Industry PracticesFrom EverandDust Explosion and Fire Prevention Handbook: A Guide to Good Industry PracticesNo ratings yet

- Terminology: Administrative ControlsDocument18 pagesTerminology: Administrative ControlsAndré SantosNo ratings yet

- 2 Risk Assessment Methodology-1Document7 pages2 Risk Assessment Methodology-1Eman fatimaNo ratings yet

- ManualDocument13 pagesManualkenoly123No ratings yet

- Explosion Protection - The BasicsDocument48 pagesExplosion Protection - The BasicsJustin Gentry100% (2)

- Environmental and Safety Aspects in Process IndustriesDocument6 pagesEnvironmental and Safety Aspects in Process Industriesyadavsuyash007No ratings yet

- Design and Safety Handbook 3001.5Document51 pagesDesign and Safety Handbook 3001.5phankhoa83No ratings yet

- Msds EngDocument7 pagesMsds EngHakim YahiaouiNo ratings yet

- Msds Shell AutogasDocument9 pagesMsds Shell AutogasLe DuyetNo ratings yet

- Hydrogen - Autoignition and Leak TestingDocument3 pagesHydrogen - Autoignition and Leak TestingAhmed NagyNo ratings yet

- Is 5572 - Hazardous ClassificationDocument2 pagesIs 5572 - Hazardous ClassificationMathavaraj DharmarajNo ratings yet

- CHART CryogenicDocument47 pagesCHART Cryogenicvardarec100% (1)

- Explosion Hazards in the Process IndustriesFrom EverandExplosion Hazards in the Process IndustriesRating: 5 out of 5 stars5/5 (2)

- Jet A Fuel Pertamina InfoDocument6 pagesJet A Fuel Pertamina InfoDidi Suprayogi DanuriNo ratings yet

- Assignment No. 1Document5 pagesAssignment No. 1Muhammad YounasNo ratings yet

- Msds of Hydrocarbon GasDocument2 pagesMsds of Hydrocarbon GasQilah KamarudinNo ratings yet

- N2 OSafety Guidelines Scaled CompositesDocument4 pagesN2 OSafety Guidelines Scaled CompositesvekNo ratings yet

- Electrical Equipment in Hazardous Areas - Wikipedia, The Free EncyclopediaDocument12 pagesElectrical Equipment in Hazardous Areas - Wikipedia, The Free EncyclopediaMrNo ratings yet

- Fundamentos ATEXDocument20 pagesFundamentos ATEXNelson_1492No ratings yet

- MSDS Argon Compressed GasDocument6 pagesMSDS Argon Compressed Gassajid aliNo ratings yet

- Confined Safety Entry: NtroductionDocument10 pagesConfined Safety Entry: NtroductionSteve manicsicNo ratings yet

- Confined Space DangersDocument5 pagesConfined Space DangersBrian Lee BantuganNo ratings yet

- Hydrogengassafety PDFDocument23 pagesHydrogengassafety PDFmujolicoNo ratings yet

- BUS 401, ASSISSMENT 1 (Electric Bus)Document3 pagesBUS 401, ASSISSMENT 1 (Electric Bus)SantoshKumarNo ratings yet

- Grundlagen Explosionsschutz Eng WebDocument48 pagesGrundlagen Explosionsschutz Eng WebsllazicNo ratings yet

- Argon Compressed GasDocument6 pagesArgon Compressed GasAnto MaryadiNo ratings yet

- Monochlorosilane (Sih CL) : Material Safety Data Sheet ForDocument7 pagesMonochlorosilane (Sih CL) : Material Safety Data Sheet ForMohamed Farag MostafaNo ratings yet

- 1B13-Int Confined Spaces v3Document15 pages1B13-Int Confined Spaces v3AboghassanNo ratings yet

- Gaseous Hydrogen: Safetygram 4Document8 pagesGaseous Hydrogen: Safetygram 4Ahmed ReshaNo ratings yet

- Toxic and Flammable Gases in Research LabDocument7 pagesToxic and Flammable Gases in Research LabjeyalaljNo ratings yet

- Safety Data Sheet: Product Name: FCC CATALYSTDocument11 pagesSafety Data Sheet: Product Name: FCC CATALYSTLindsey BondNo ratings yet

- LPGStorage Tankand Pipe Line ReportDocument16 pagesLPGStorage Tankand Pipe Line Reportarnaud fabrice douaNo ratings yet

- GAP.8.0.1.1. Oil and Chemical Properties Loss Potential Estimation GuideDocument19 pagesGAP.8.0.1.1. Oil and Chemical Properties Loss Potential Estimation Guidemartinnovel100% (1)

- Risk Assessment Thermal Power PlantDocument24 pagesRisk Assessment Thermal Power Plantfloayzav5684No ratings yet

- Dust Explosion Hazard AssessmentDocument9 pagesDust Explosion Hazard AssessmentCarlos JiménezNo ratings yet

- Segurida ElectricaDocument4 pagesSegurida ElectricaMartin LaraNo ratings yet

- Understanding Hazardous Locations: An Ebook By: Pepperl+Fuchs, The Intrinsic Safety ExpertsDocument19 pagesUnderstanding Hazardous Locations: An Ebook By: Pepperl+Fuchs, The Intrinsic Safety Experts04422236558No ratings yet

- Gas Cilinder SafetyDocument46 pagesGas Cilinder SafetyJoshua Kirby100% (1)

- Compressed Gas Design and Safety Handbook2006Document46 pagesCompressed Gas Design and Safety Handbook2006basura12345100% (3)

- INC GasDetectionDocument28 pagesINC GasDetectionPavel ViktorNo ratings yet

- Selection and Use of ASTM Standards For The Determination of Flash Point of Chemicals by Closed Cup MethodsDocument6 pagesSelection and Use of ASTM Standards For The Determination of Flash Point of Chemicals by Closed Cup MethodsJorge ToribioNo ratings yet

- Heat Fence Inorganic MineralsDocument3 pagesHeat Fence Inorganic MineralsmeNo ratings yet

- Msds of OxygenDocument7 pagesMsds of OxygensahilchemNo ratings yet

- Material Safety Data Sheet: Section 1 - Product and Company IdentificationDocument5 pagesMaterial Safety Data Sheet: Section 1 - Product and Company IdentificationMicheal MattheyNo ratings yet

- MSA Gas Detection HandbookDocument146 pagesMSA Gas Detection HandbookVid YullNo ratings yet

- Handbook of Fire and Explosion Protection Engineering Principles: for Oil, Gas, Chemical and Related FacilitiesFrom EverandHandbook of Fire and Explosion Protection Engineering Principles: for Oil, Gas, Chemical and Related FacilitiesRating: 5 out of 5 stars5/5 (2)

- Case Studies of Material Corrosion Prevention for Oil and Gas ValvesFrom EverandCase Studies of Material Corrosion Prevention for Oil and Gas ValvesNo ratings yet

- 07 Marine Diesel EnginesDocument26 pages07 Marine Diesel EnginesSurasan ThepsiriNo ratings yet

- SAU Updated6630extalarmDocument3 pagesSAU Updated6630extalarmJunaidNo ratings yet

- Start Up Procedure For Alkylation Unit WithDocument10 pagesStart Up Procedure For Alkylation Unit WithBikas SahaNo ratings yet

- Biomass Energy PDFDocument20 pagesBiomass Energy PDFhugoj98No ratings yet

- Power Plant FamiliarizationDocument33 pagesPower Plant FamiliarizationAnand Kumar100% (1)

- Turbo Generador PDFDocument20 pagesTurbo Generador PDFCarlos Humberto Velez UsecheNo ratings yet

- Karthi CVDocument4 pagesKarthi CVKarthi MarxNo ratings yet

- Stirling DK EnginesDocument2 pagesStirling DK EnginesMarius-Cristian NitaNo ratings yet

- Problemario MFCDocument80 pagesProblemario MFCBassaldua AlfreedNo ratings yet

- Check Burner Air To Fuel Ratios PDFDocument2 pagesCheck Burner Air To Fuel Ratios PDFLuz SmithNo ratings yet

- Design Guidelines For Biomedical Waste IncineratorDocument4 pagesDesign Guidelines For Biomedical Waste IncineratorJeetendra KulkarniNo ratings yet

- Vapor Compression Refrigeration System LabDocument7 pagesVapor Compression Refrigeration System LabKurtNo ratings yet

- The Modeling of Petroleum Coke Gasification Using AspenDocument85 pagesThe Modeling of Petroleum Coke Gasification Using AspenMahmud Arman KibriaNo ratings yet

- Hazop Study Action Response SheetDocument5 pagesHazop Study Action Response SheetborrowmanaNo ratings yet

- Air Cooled Condenser - A Dry Cooling TowerDocument6 pagesAir Cooled Condenser - A Dry Cooling TowerGmail44No ratings yet

- Ee8703-Res Question Bank NewDocument32 pagesEe8703-Res Question Bank NewAtharsh SNo ratings yet

- Fast Pyrolysis and Bio Oil Upgrading Presentation)Document46 pagesFast Pyrolysis and Bio Oil Upgrading Presentation)api-3799861100% (3)

- Curso. Tecnologias CaptaciónDocument51 pagesCurso. Tecnologias CaptaciónVicent CarbesNo ratings yet

- Resistance Equivalent Length FittingsDocument3 pagesResistance Equivalent Length FittingsRicardo DaclanNo ratings yet

- Jet EngineDocument43 pagesJet EnginefadyNo ratings yet

- Breif Histrory of PumpsDocument5 pagesBreif Histrory of Pumpsmfhaleem@pgesco.comNo ratings yet

- A Brief Analysis of The Physical Require-2Document3 pagesA Brief Analysis of The Physical Require-2Alok KumarNo ratings yet

- Isentropic Process PDFDocument2 pagesIsentropic Process PDFJeebee Logroño AloNo ratings yet

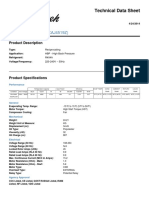

- Model:AJE4519ZFZ (CAJ4519Z) : Technical Data SheetDocument1 pageModel:AJE4519ZFZ (CAJ4519Z) : Technical Data SheetSamer ChahroukNo ratings yet

- Module 7 Exercises Problem No. 1Document3 pagesModule 7 Exercises Problem No. 1Ariel Gamboa100% (1)

- Sudhakar Vallala P. EnggDocument5 pagesSudhakar Vallala P. EnggAbo MalikNo ratings yet

- ESSC2014Document499 pagesESSC2014Aurangzaib ArshadNo ratings yet

- Types of Turbines and Its UtilizationDocument5 pagesTypes of Turbines and Its UtilizationRao SamiNo ratings yet

- Birla Institute of Technology and Science, Pilani SEMESTER I, 2011 - 2012, DATE: 05/12/2011 Comprehensive Examination (Closed Book)Document2 pagesBirla Institute of Technology and Science, Pilani SEMESTER I, 2011 - 2012, DATE: 05/12/2011 Comprehensive Examination (Closed Book)Vashistha GargNo ratings yet

- Centrifugal Compressors For CPI Plants PDFDocument4 pagesCentrifugal Compressors For CPI Plants PDFAmanda Aracely Herreria SalazarNo ratings yet