Professional Documents

Culture Documents

Course Schedule and CA Information

Uploaded by

binukOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Course Schedule and CA Information

Uploaded by

binukCopyright:

Available Formats

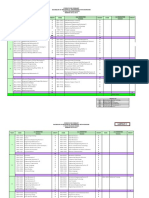

DEPARTMENT OF MECHANICAL ENGINEERING COURSE SCHEDULE

UNIVERSITY OF MORATUWA

MORATUWA 23rd Aug 2020 – 26th Nov 2021

Course B.Sc. Engineering (Hons.) Session Semester 3 (19 Batch)

Module Code ME 2023 Title Manufacturing Technology 1

Credits 04 (GPA) Hours / Week 3 hours -Lectures, 3 hours – laboratory

Module Coordinator Dr JR Gamage (JRG) [MC/L] gamagejr@uom.lk

Resource Personnel Prof. N.D. Jayaweera (NDJ) [L][L] niroshj@uom.lk

Dr. L.U. Subasinghe (LUS) [L] lihils@uom.lk

Mr Anuradha Wickramasinghenghe(AW) [PC]

MC – Module Coordinator, L – Lecturer, I – Instructor, PC– Practical Coordinator

Resource

Week Date Hrs. Topics Covered Category Remarks

Personnel

1 M 1+3 Not scheduled - -

W 2 Not scheduled L JRG

Introduction to the Module & Overview of Manufacturing

M 1+3 L JRG/AW

2 Engineering +Project

W 2 Introduction to Manufacturing Processes L JRG

3 M 1+3 Machining Operations and Machine Tools -I + Labs/Project L/P JRG/AW

W 2 Machining Operations and Machine Tools -II L JRG

M 1+3 Project proposal presentations P JRG/LUS/AW Proposal Deadline

4

W 2 Cutting Tool Materials: Applications & Selection - II L NDJ

M Holiday (20/09/2021)

5

W 2 Material Removal Processes I L JRG

M 1+3 Tool Life: Wear & Failure -I+ Labs/Project L/P NDJ/AW

6

W 2 Tool Life: Wear & Failure -II L NDJ

M 1+3 Material Removal Processes II + Labs/Project L/P JRG/AW

7

W 2 Material Removal Processes III L JRG

M 1+3 Manufacturing Materials -I+ Labs/Project L/P LUS/AW

8

W 2 Manufacturing Materials - II L LUS

M 1+3 Mechanics of Metal Cutting I + Labs/Project L/P LUS/AW

9

W Holiday (20/10/2021)

10 M 1+3 Engineering Metrology and Instrumentation-I + Labs/Project L/P NDJ/AW

W 2 Engineering Metrology and Instrumentation-II + Labs/Project L NDJ

11 M 1+3 Mechanics of Metal Cutting II + Labs/Project P/L LUS/AW

W 2 Mechanics of Metal Cutting III L LUS

12 M 1+3 Surface Treatment and Finishing - I+ Labs/Project P/L NDJ/AW

W 2 Surface Treatment and Finishing - II L NDJ

M 1+3 Reverse Engineering Project presentations -I P JRG/LUS/AW CA deadline

13

W 2 Reverse Engineering Project presentations -II P JRG/LUS/AW CA deadline

M 1+3 Introduction to NC and CAD/CAM - I L/P JRG/AW

14

W 2 Introduction to NC and CAD/CAM -II L JRG

ME2023 – Course Schedule (19 Batch) Pg. 1 Last updated 30/08/2021

Dept. of Mechanical Engineering University of Moratuwa

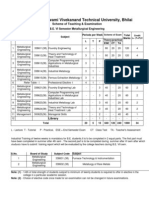

Details of Continuous Assessment – 30% (Exam 70%)

Code Title Laboratory Marks allocation

Familiarisation with basic measuring

ME2023– P1 Metrology Lab 2%

instruments

ME2023 – P2 Assessment of surface texture Metrology Lab 2%

ME2023 – P3 Familiarisation with heat treatment Production Lab 2%

Analysis of cutting parameters using Lathe

ME2023 – P4 Production Lab 2%

Tool Dynamometer

ME2023 – P5 Familiarisation with milling operations Machine Shop 2%

Familiarisation with shaping, drilling and

ME2023 – P6 Machine Shop 2%

grinding operations

ME2023 – GP Reverse Engineering project (Group) - 18%

ADDITIONAL INFORMATION ON CONTINUOUS ASSESSMENTS - 30%

• Online cover up sessions for Practicals (12%)-: There will be dedicated online sessions for each

practical with video and interactive content to present the essential elements of the traditional practical.

At the end of all sessions, there will be an online Quiz covering all practicals. Any clarifications, please

contact the Practical coordinator.

• Reverse Engineering Group Project (18%):

▪ You are required to form into groups of five (5). A Moodle self grouping link will be set.

▪ This Reverse Engineering project will be continued to S4(ME2170) as well. It is advisable to refer to

the ME2170 module descriptor too when selecting the project title.

▪ Each group is required to select a product which meets the following criteria.

o The product should be an assembly with at least 5 components. This is excluding standard

components such as nuts, bolts, washers, bearings, etc.

o There must be at least one component from each of the following categories

• Metallic component

• Plastic / Rubber component

• Any other material (e.g. Wood or Fibreglass or any other)

▪ Those components should be of significant sizes to make measurements and should be able to

manufacture with simple manufacturing processes you learn in the class and by research.

▪ You may have to take the components to laboratories for testing of materials, and/or measuring

them. As there is no access to laboratories you may find alternative research methods to find the

material types and dimensions. You may also use the measuring equipment available at home to

make approximate measurements.

▪ Evaluation criteria (Group presentations):

▪ There will be two(2) group presentations.

1. Project proposal presentations: Scheduled - 13/09/2021 08:00 (6%)

o 5 minutes per group + 5 minutes of feedback

o Your title could be “Reverse Engineering of …………..”

o Only one member or few members can present. All must be present with video ON during the

presentation.

o Present the selected product, its functions and features (5 marks)

o Identify and present 5 different components you wish to analyse further as suggested above (5

marks)

o Present a plan to reverse engineer the selected components/entire product (10 marks)

o The idea would be to guide you to successfully complete the project.

2. Final presentations : Scheduled - 15/11/2021 08:00 (12%)

o Marking scheme is given below.

o Presentation time 10 minutes (for all 5 members)+ 05 minutes for Q&A.

o Front slide should include the list of members and their individual contributions.

o Each slide should include the author's name (the person responsible) in the header.

ME2023 – Course Schedule (19 Batch) Pg. 2 Last updated 30/08/2021

Dept. of Mechanical Engineering University of Moratuwa

o All members of the group must present their section (it is advisable that one member presents

his/her contribution to the project so everyone gets a chance to present).

o Presenting group must keep their videos ON in Zoom.

o You may use same/similar headings in the marking scheme below to guide your presentation.

• A minimum of 35% of the continuous assessment marks is required to pass the module.

The marking scheme of the Group Project - Final Presentation Marks

A. Freehand sketches for measuring

Neatly done free-hand sketches of the product components, that were used to record the dimensions

05

during measurements, and assembly sketch used to record information about

assembling/dismantling the product.

B. Identification of materials

Description of standard or non-standard tests, methods, used to identify the material of each

existing component. You should explain the reason(s) for selecting a standard test/method or 15

planning a non-standard method (if you have used such). It is not required to identify the exact

material, but you must identify the material sub-class, under which the material is categorised.

C. Production drawings and assembly drawing of the existing product

Create 2D production drawings for the 5 components selected (as detailed in Section E). First angle

projection should be used for the projection views. Production drawings must be completed with all

15

dimensions, tolerances (if applicable), surface finish, material, and other technical information. You

may decide the number of assembly drawings depending on the complexity of the product. The

drawings could be done using the computer or manually.

D. Improvements & 3D model

Make some improvements to the product, mainly focusing on the selected 5 components. Limit the

improvements to the geometry, and material of the part, that affect the manufacturing process of the

part. Think in line with sustainable manufacturing. Other improvements such as automation, are not 15

relevant to this project. Create a 3D model for this modified product using any 3D modelling

software that you are familiar with. Indicate suitable views of those new designs in the presentation

(Colour pictures/animations).

E. Manufacturing processes to fabricate the current and/or modified product

1. Indicate the manufacturing methods with the sequence of manufacturing for each of

the 5 components you selected.

2. Out of the different machining processes you considered for (E.1), select at least one 50

process, and propose suitable machining tools and a work holding technique for

that.

Total 100

ME2023 – Course Schedule (19 Batch) Pg. 3 Last updated 30/08/2021

You might also like

- 5 Mandrels & Landing NipplesDocument34 pages5 Mandrels & Landing NipplesWaled FekryNo ratings yet

- JJ 104 Workshop Technology 1 MillingDocument44 pagesJJ 104 Workshop Technology 1 MillingHusaini Zamzury0% (1)

- Course Structure and Syllabus: For 2-Year M. Tech. Programme in Mining EngineeringDocument33 pagesCourse Structure and Syllabus: For 2-Year M. Tech. Programme in Mining Engineeringabhishek urmaliyaNo ratings yet

- Lathe MachineDocument25 pagesLathe MachineAbhimanyu SinghNo ratings yet

- Figure QW-462.1 (A) Tension - Reduced Section - Plate: ASME BPVC - IX-2019Document2 pagesFigure QW-462.1 (A) Tension - Reduced Section - Plate: ASME BPVC - IX-2019Carlos Lluen AquinoNo ratings yet

- Machines For Grinding and Polishing of Workpieces: & Co. KGDocument44 pagesMachines For Grinding and Polishing of Workpieces: & Co. KGGabriel TresNo ratings yet

- MechanicalDocument191 pagesMechanicalbolanNo ratings yet

- DBATU BTech Civil Syllabus 2017Document66 pagesDBATU BTech Civil Syllabus 2017Abhishek DhangarNo ratings yet

- Btech Syallabus 2019 20Document61 pagesBtech Syallabus 2019 20Archana GuptaNo ratings yet

- Latest Mechanical Engineering Course Structure 2022Document36 pagesLatest Mechanical Engineering Course Structure 2022rahulprakashjiNo ratings yet

- BTech Civil Syllabus Revised July2019Document73 pagesBTech Civil Syllabus Revised July2019Darpan P JainNo ratings yet

- BTech Civil Syllabus Revised July2019 PDFDocument73 pagesBTech Civil Syllabus Revised July2019 PDFShweta KulkarniNo ratings yet

- M. Tech Machine Design EngineeringDocument73 pagesM. Tech Machine Design Engineeringsaurabh salviNo ratings yet

- UG 4-1 R19 Civil SyllabusDocument42 pagesUG 4-1 R19 Civil SyllabusMasimukkala SunithaNo ratings yet

- MTech MEDocument110 pagesMTech MEGangadhar TallaNo ratings yet

- Syllabus BTech Civil 2019 1Document72 pagesSyllabus BTech Civil 2019 1ravi maskeNo ratings yet

- Production-Third - Structure 29 March 2008Document1 pageProduction-Third - Structure 29 March 2008VikrantNo ratings yet

- 31 R20 IIMid Nov-December 2023Document7 pages31 R20 IIMid Nov-December 2023palivelasrinu12No ratings yet

- Mech Engg 1 2 ME Syllabus - UG - R20Document25 pagesMech Engg 1 2 ME Syllabus - UG - R20alietmatt37No ratings yet

- Pdil NotificationDocument14 pagesPdil NotificationNDTVNo ratings yet

- TY B.Tech. Mechanical - Final - Revised - 24 June 2021Document79 pagesTY B.Tech. Mechanical - Final - Revised - 24 June 2021Nihar ApteNo ratings yet

- Mech Engg 2-1 CS & Syllabus - UG - R20Document22 pagesMech Engg 2-1 CS & Syllabus - UG - R20Syam RajuNo ratings yet

- ME119 Schedule Course Contents Policies PDFDocument7 pagesME119 Schedule Course Contents Policies PDFPriyanshu MeshramNo ratings yet

- R22M Tech AdvancedManufacturingSystemsSyllabusDocument60 pagesR22M Tech AdvancedManufacturingSystemsSyllabusSivaNo ratings yet

- Nit Scheme IV SemesterDocument10 pagesNit Scheme IV SemesterSai KiranNo ratings yet

- Jawaharlal Nehru Technological University Gurajada VizianagaramDocument5 pagesJawaharlal Nehru Technological University Gurajada VizianagarambmkmanicNo ratings yet

- Syllabus With ReportDocument44 pagesSyllabus With ReportrajeshNo ratings yet

- Mech Engg 1 1 ME Syllabus - UG - R20Document24 pagesMech Engg 1 1 ME Syllabus - UG - R20alietmatt37No ratings yet

- Final Project Management Spring 2021Document2 pagesFinal Project Management Spring 2021Syed MoizNo ratings yet

- Subjek Semua SemDocument10 pagesSubjek Semua SemMuhammad Amirul Haziq Bin ZawawiNo ratings yet

- M.Tech Curriculam - Document 2020 05 01 8 52 AmDocument29 pagesM.Tech Curriculam - Document 2020 05 01 8 52 AmVARAD DIXITNo ratings yet

- Itm University Naya Raipur, Raipur: Bachelor of Technology)Document21 pagesItm University Naya Raipur, Raipur: Bachelor of Technology)Mufaddal ZakaviNo ratings yet

- 00 Narrative Report P11 - Rev.0 15-4-2023Document15 pages00 Narrative Report P11 - Rev.0 15-4-2023Masoud OsamyNo ratings yet

- The Maharaja Sayajirao University of Baroda, VadodaraDocument2 pagesThe Maharaja Sayajirao University of Baroda, VadodaraWhatsApp statusNo ratings yet

- Corrected Final Year Btech Mech Syllabus Effective 2014-15Document43 pagesCorrected Final Year Btech Mech Syllabus Effective 2014-15Bhushan RaneNo ratings yet

- BTech Civil Syllabus Revised July2019Document78 pagesBTech Civil Syllabus Revised July2019Anil JadhavNo ratings yet

- Notification MECON Various VacancyDocument20 pagesNotification MECON Various VacancySipak SatapathyNo ratings yet

- Mining EngineeringDocument37 pagesMining EngineeringSoumithNo ratings yet

- Civil - Engineering Syllabus (n22)Document64 pagesCivil - Engineering Syllabus (n22)vatsalupadhyay199No ratings yet

- Robotics SyllabusDocument52 pagesRobotics SyllabusManoj Kumar100% (1)

- MWM MicroprojectDocument22 pagesMWM MicroprojectAsaduddin pattewaleNo ratings yet

- Vishwakarma Institute of TechnologyDocument32 pagesVishwakarma Institute of TechnologyVaibhav MandhareNo ratings yet

- MECH Lab ManualDocument64 pagesMECH Lab ManualDiksha PadiyarNo ratings yet

- 6th Sem MetallurgyDocument13 pages6th Sem Metallurgymtnit07No ratings yet

- Mech Engg 3-1 CS & Syllabus - UG - R20Document102 pagesMech Engg 3-1 CS & Syllabus - UG - R20PavaniNo ratings yet

- DesignDocument45 pagesDesignedris farahNo ratings yet

- ECE (2022) 5th Sem SyllabusDocument31 pagesECE (2022) 5th Sem SyllabusYaman VermaNo ratings yet

- R18 B.Tech Mining Engg. Iii YearDocument32 pagesR18 B.Tech Mining Engg. Iii YearVamshiNo ratings yet

- Maulana Abul Kalam Azad University of Technology, West BengalDocument45 pagesMaulana Abul Kalam Azad University of Technology, West BengalDebarshi GhoshNo ratings yet

- UG 4-2 R19 Mech SyllabusDocument35 pagesUG 4-2 R19 Mech SyllabusBrahmaiah ThanniruNo ratings yet

- Computer SyllabusDocument226 pagesComputer Syllabus2132 CO Rohit TandelNo ratings yet

- Syllabus M.Tech Design and Manufacturing - 2Document23 pagesSyllabus M.Tech Design and Manufacturing - 2Sudeep Kumar SinghNo ratings yet

- M.Tech. (Full Time) Construction Engineering and Management Curriculum & Syllabus 2015 - 2016Document48 pagesM.Tech. (Full Time) Construction Engineering and Management Curriculum & Syllabus 2015 - 2016SumanNo ratings yet

- West Bengal State Council of Technical & Vocational Education and Skill Development (Technical Education Division)Document44 pagesWest Bengal State Council of Technical & Vocational Education and Skill Development (Technical Education Division)Biswadeep Roy ChoudhuryNo ratings yet

- DKTE Society's Textile & Engineering Institute Rajwada, Ichalkaranji 416115 (An Autonomous Institute)Document45 pagesDKTE Society's Textile & Engineering Institute Rajwada, Ichalkaranji 416115 (An Autonomous Institute)Sam MhettarNo ratings yet

- Experimental Investigation of Microdrilling Operation of Printed Circuit BoardDocument37 pagesExperimental Investigation of Microdrilling Operation of Printed Circuit BoardSUMANTH n vNo ratings yet

- Course Registration FormDocument1 pageCourse Registration Formabdulghaniyu obaroNo ratings yet

- R19 PG Machine Design CS SyllabusDocument56 pagesR19 PG Machine Design CS SyllabusRaju LaxmanNo ratings yet

- Jawaharlal Nehru Technological University HyderabadDocument229 pagesJawaharlal Nehru Technological University Hyderabadbhukyasupraja43No ratings yet

- Biju Patnaik University of Technology, OdishaDocument2 pagesBiju Patnaik University of Technology, OdishaMd Taslim Kausar khanNo ratings yet

- 32 BT R20-July-2023Document8 pages32 BT R20-July-2023Rajiya ShaikNo ratings yet

- ApprasialDocument2 pagesApprasialkumareshNo ratings yet

- 2 IPE 3 and 4 Sem Scheme and Syllabus Academic Year 2020-2021 PDFDocument46 pages2 IPE 3 and 4 Sem Scheme and Syllabus Academic Year 2020-2021 PDFSanjay SanjuNo ratings yet

- Cad Cam SyllabusDocument4 pagesCad Cam SyllabuskrishrathoreNo ratings yet

- Lathe MachineMP IDocument44 pagesLathe MachineMP IMetalAnand ChelliahNo ratings yet

- 1 Smith Addison Hss Pricelist 19-09-2017Document36 pages1 Smith Addison Hss Pricelist 19-09-2017Aliakbar Ismail KathanawalaNo ratings yet

- 7.2 Log de Recepción de Materiales 1860 OkDocument10 pages7.2 Log de Recepción de Materiales 1860 OkAndrea VilcaNo ratings yet

- Energy Conservation in Industries. Applications and Techniques.Document456 pagesEnergy Conservation in Industries. Applications and Techniques.Hemanth Siva KumarNo ratings yet

- Mastercam Drilling Operations - MindworksDocument6 pagesMastercam Drilling Operations - MindworksAntónio JesusNo ratings yet

- Chapter 3 Process PlanningDocument21 pagesChapter 3 Process PlanninganiketNo ratings yet

- Modified Johnson CookDocument64 pagesModified Johnson CookwircexdjNo ratings yet

- Iare MTM Lecture Notes 0Document133 pagesIare MTM Lecture Notes 0Soumya KeshireddyNo ratings yet

- Fitter MCQDocument10 pagesFitter MCQRahul RawatNo ratings yet

- Centre of Excellent KKTM Ku (Terkini)Document14 pagesCentre of Excellent KKTM Ku (Terkini)Mohd Syukri AbdullahNo ratings yet

- ARMCO Iron BrochureDocument12 pagesARMCO Iron BrochureprincedrdoNo ratings yet

- Slotting PDFDocument6 pagesSlotting PDFVignesh NayakNo ratings yet

- IC348 Yuen Wai Ying Individual ReportDocument12 pagesIC348 Yuen Wai Ying Individual ReportEunice YuenNo ratings yet

- FMS Tool Library PDFDocument17 pagesFMS Tool Library PDFflytoanilNo ratings yet

- Metal Cutting QnsDocument8 pagesMetal Cutting QnsAsha DashNo ratings yet

- Surface Finish MeasurementDocument12 pagesSurface Finish MeasurementShyam SenthilNo ratings yet

- Module 1Document21 pagesModule 1AzizNo ratings yet

- Automotive Transmission-ShaftDocument7 pagesAutomotive Transmission-Shaftfileuse.fNo ratings yet

- Sachin Solanki CNC/IPC/13 Summary SupportDocument61 pagesSachin Solanki CNC/IPC/13 Summary Supportshivam modanwalNo ratings yet

- Rodney Katz - Prototype Design and Manufacturing ManualDocument64 pagesRodney Katz - Prototype Design and Manufacturing Manualenascimento32No ratings yet

- Drylin - Lead Screw Technology - Product RangeDocument4 pagesDrylin - Lead Screw Technology - Product RangeLeandro SoaresNo ratings yet

- ASME B 18.6.5M - 2000 (R2010) Metric Type IA Cross-Recessed Flat Countersunk Head Tapping Screws (Table 10)Document1 pageASME B 18.6.5M - 2000 (R2010) Metric Type IA Cross-Recessed Flat Countersunk Head Tapping Screws (Table 10)Mahmut ErdönmezNo ratings yet

- 5 Machinability and Machining EconomicsDocument48 pages5 Machinability and Machining Economicssakali aliNo ratings yet

- Basic Fundamentals of CNC Machine OperationDocument20 pagesBasic Fundamentals of CNC Machine Operationnandusp1No ratings yet

- SCM Cyflex f900 h810 en 2013Document20 pagesSCM Cyflex f900 h810 en 2013erolnaz93No ratings yet