Professional Documents

Culture Documents

Holmium Logger Installation Guide Sngrow Inverter

Holmium Logger Installation Guide Sngrow Inverter

Uploaded by

canCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Holmium Logger Installation Guide Sngrow Inverter

Holmium Logger Installation Guide Sngrow Inverter

Uploaded by

canCopyright:

Available Formats

An ISO 9001:2015

LOGGER INSTALLATION

GUIDE

For SUNGROW String Inverters (33-60kW)

Abstract

This Document refers to a brief step for datalogger installation with

SUNGROW string inverters from 33 to 60kW

Holmium Technologies Private Limited

info@holmiumtechnologies.com

Copyright © 2020 Holmium Technologies. All Rights Reserved

Logger installation guide for Sungrow String Inverter

Make: SUNGROW

Type Solar on Grid string inverter

SG33KTL-M SG40KTL-M SG49K5J SG50KTL-M SG60KU, SG60KU-M,

Available models: SG60KTL, SG60KTL-M, SG36KTL-M SG8KTL- M, SG10KTL-M, SG12KTL-

M, SG80KTL, SG80KTL-M, SG80HV, SG125HV

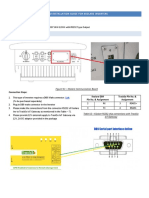

CONNECTION DAIGRAM:

Figure 1:Connection Points for SUNGROW Inverter

➢ Loose the six screws on the lower connection cabinet.

➢ The communication terminals (RS485 A/B) are located at the bottom of the inverter as shown

in Figure 1.

➢ Connect the cables to the RS485 bus terminal blocks.

➢ Please make the connections from the Terminal Block chip to D-LOG as mentioned in the

Table 1.

Figure 2: Connection diagram for D-LOG logger

Table 1: SUNGROW RS485 port connection with D-LOG pins

SUNGROW Screw SUNGROW

D-LOG Pin No. D-LOG Assignment

Terminal No. Assignment

1 A 19 A

2 B 18 B

3 GND 17 G

Copyright © 2020 Holmium Technologies. All Rights Reserved

DEFAULT CONFIGURATION IN for D-LOG Series

Inverter ID: 1, 2, 3, 4 .... Continuous numbering starting with 1, (Range: 1 to 247)

Baud Rate: 9600 (Default) (Values: 9600, 19200, 38400)

Data Bits: 8, Stop Bit: 1, Parity: None

CONFIGURATION AT THE INVERTER END

Insert password

The admin password for entering the Install

Settings is 091030 for 60kW and 111111 for

33kW inverter

Setting the BAUD RATE Set Inverter Baud rate to 9600

If you connect multiple inverters via RS485, set the same baud rate on each inverter.

Figure 3: Procedure to set Baud Rate

Setting the Inverter ID

The inverter ID is used to identify the inverter in a RS485 connection.

We set a different inverter ID for each inverter in the PV plant to identify the inverters correctly. On the last

inverter in the RS485 connection, switch on the RS485 termination resistor.

Figure 4: Procedure to set Inverter ID

Copyright © 2020 Holmium Technologies. All Rights Reserved

Set Date and Time of Inverter

Date and time have to be correct for a precise calculation of the statistics in the inverter itself and in a

monitoring system.

Figure 5: Procedure to set Date & Time

COMMUNICATION CARD SETTING

Single Inverter

Multiple

Inverter

The above details are mentioned in the Installation & Operation Manual for SUNGROW Inverter-SG60KU

on Page 99

D-LOG Installation Step

Ensure correct connections as detailed in the installation guide and verify as per following steps-

1. Daisy chaining as per shown (in case of multiple Inverters)

2. Set up Inverter ID

3. Set up Baud Rate

4. Set Communication Protocol

5. SIM card internet should be activated.

6. Plug Antenna in ANT port (supplied with D-LOG package)

7. Insert the SIM card in SIM slot.

Copyright © 2020 Holmium Technologies. All Rights Reserved

8. Connect the power supply with 12V power adaptor supplied

9. Observe LED status as per table for Internet access

10. See portal in 10 min by logging at www.holmiumtechnologies.com with username and Password.

Note: If data is not showing at portal, verify the steps again or Email us at info@holmiumtechnologies.com

Understanding LED Status:

LED NAME DETAILS

RED Supply It shows the input power supply. It should be constantly on.

YELLOW Fault It will glow only in case of reverse power flow.

LED NAME DETAILS

✓ RED PWR It shows the power supply connection. It should be constantly on.

✓ YELLOW STS It shows the GSM functionality. It should be constantly on.

It shows GSM network. Its blinking frequency indicates GSM network

status.

Blinking frequency GSM network status

✓ GREEN NET Glows per second Network search mode

Glows per two second GSM network is connected

Glows twice per second Internet connection is established

✓ BLUE RFS It shows that logger is trying to connect with server. It would blink.

PORTAL DETAILS IMPORTANT LINKS

Please login to 1. MODBUS Connection Guide for inverters:

//www.holmiumtechnologies.com//

using given credentials.

Support 2. Remote monitoring LOGIN address:

Please email or log complaint on

service@holmiumtechnologies.com

Or call at

8890586586

Contact us

www.holmiumtechnologies.com||service@holmiumtechnologies.com||8890586586

Copyright © 2020 Holmium Technologies. All Rights Reserved

You might also like

- StarSiege Event Horizon - Victory 2442Document25 pagesStarSiege Event Horizon - Victory 2442LenioMachadoJunior100% (1)

- Network with Practical Labs Configuration: Step by Step configuration of Router and Switch configurationFrom EverandNetwork with Practical Labs Configuration: Step by Step configuration of Router and Switch configurationNo ratings yet

- SIM900 GSM Shield Users Manual PDFDocument9 pagesSIM900 GSM Shield Users Manual PDFrotvogelNo ratings yet

- Project:: Tra Vinh Wind Farm ProjectDocument19 pagesProject:: Tra Vinh Wind Farm ProjectcanNo ratings yet

- Setting The CNC RS232Document4 pagesSetting The CNC RS232Maleš DejanNo ratings yet

- Jdsu Bert & RFC 2544 TestingDocument13 pagesJdsu Bert & RFC 2544 TestingRaviNo ratings yet

- SIM900 GSM Shield Users ManualDocument9 pagesSIM900 GSM Shield Users ManualEduardo CudiaNo ratings yet

- 5 Unit NotesDocument166 pages5 Unit NotesYokesh R100% (1)

- Steps For PCB DesignDocument6 pagesSteps For PCB DesignAnkit AgrawalNo ratings yet

- Oshmi Configuration Manual-En UsDocument47 pagesOshmi Configuration Manual-En UscanNo ratings yet

- Huong Dan Cai Dat (OMT) CombaDocument12 pagesHuong Dan Cai Dat (OMT) Combahutech2000No ratings yet

- HVDC Terminal StationDocument28 pagesHVDC Terminal Stationmaka27No ratings yet

- VHF Vehicle Roof-Top Antennas: Installation ManualDocument16 pagesVHF Vehicle Roof-Top Antennas: Installation ManualLuis MantillaNo ratings yet

- Library Management SystemDocument73 pagesLibrary Management SystemKr Sandy60% (5)

- TrackSo Connection Manual KsolareDocument6 pagesTrackSo Connection Manual KsolareBhatt DeepNo ratings yet

- GP-GC021 Ver1.0 ENDocument0 pagesGP-GC021 Ver1.0 ENSilvis PoalacinNo ratings yet

- TrackSo Connection Manual GrowattDocument6 pagesTrackSo Connection Manual Growattmarcyel Oliveira WoliveiraNo ratings yet

- Gprs Shield For ArduinoDocument7 pagesGprs Shield For ArduinoG Diego Palacios Riquelme100% (2)

- N300 HIMS+2000+Program+User+Guide (English)Document35 pagesN300 HIMS+2000+Program+User+Guide (English)faisl abdelgaffarNo ratings yet

- 6gk6021-0as23-3db0-Z A05+b05+c05+d05+e01+f01+g05+h05+j05+k05Document2 pages6gk6021-0as23-3db0-Z A05+b05+c05+d05+e01+f01+g05+h05+j05+k05Vinicius NadalNo ratings yet

- Anexo ACaracteristicas Tecnicas de Los EquiposDocument18 pagesAnexo ACaracteristicas Tecnicas de Los EquiposAlvaroZolaNo ratings yet

- Siemens S7 200 PPIDocument7 pagesSiemens S7 200 PPIomar alamoriNo ratings yet

- RTU5020 RTU5022 GSMSMSGPRS3G4G Remote Switch Controller V1.3Document11 pagesRTU5020 RTU5022 GSMSMSGPRS3G4G Remote Switch Controller V1.3kevin techNo ratings yet

- User Manual RUTX09 EN-v1.1Document11 pagesUser Manual RUTX09 EN-v1.1GuilhermeDeOliveiraSantosNo ratings yet

- ATC-3200 User's ManualDocument3 pagesATC-3200 User's ManualMaitry ShahNo ratings yet

- VG02L User ManualDocument11 pagesVG02L User ManualmarouenNo ratings yet

- SV-iP5A or IV5 User ManualDocument25 pagesSV-iP5A or IV5 User ManualTechnology HelperNo ratings yet

- Sim7020 Series: Simcom Nb-Iot ModuleDocument3 pagesSim7020 Series: Simcom Nb-Iot ModuleAlejandro DemitiNo ratings yet

- Ad8319 1Document19 pagesAd8319 1Игорь ЛуговскойNo ratings yet

- G70364a STD ManDocument30 pagesG70364a STD Mannyaa_joelNo ratings yet

- Siemens S7-200 PPI: HMI SettingDocument7 pagesSiemens S7-200 PPI: HMI SettingAbdullahNo ratings yet

- 2CMT001823 B3 en GSM GPRS Communication Adapter CGM 05000 Users ManualDocument14 pages2CMT001823 B3 en GSM GPRS Communication Adapter CGM 05000 Users ManualAnonymous BkmsKXzwyKNo ratings yet

- v10x B Manual Digirail-2a EnglishDocument2 pagesv10x B Manual Digirail-2a EnglishayannNo ratings yet

- DG Sync ManualDocument2 pagesDG Sync ManualdeepakNo ratings yet

- DBL1 Avr Sincro ManualDocument11 pagesDBL1 Avr Sincro ManualAnonymous vqsuRyNo ratings yet

- Opis Plytki Modbus RTU Do LG IC5 - AngDocument16 pagesOpis Plytki Modbus RTU Do LG IC5 - AngAdamNo ratings yet

- Remote Relay Switch: GSM/SMS/GPRS/3G/4GDocument11 pagesRemote Relay Switch: GSM/SMS/GPRS/3G/4GAlexander FuentesNo ratings yet

- Basic - Concepts: Opmode ConceptDocument5 pagesBasic - Concepts: Opmode ConceptChathura Shanaka De SilvaNo ratings yet

- Siemens S7 200Document6 pagesSiemens S7 200lela janNo ratings yet

- IComSatV1.1 GSM Shield Arduino - DatasheetDocument7 pagesIComSatV1.1 GSM Shield Arduino - DatasheetM Fatkhu Rizqi100% (1)

- GSM Interfacing Board: Campus Component Pvt. LTDDocument13 pagesGSM Interfacing Board: Campus Component Pvt. LTDRizal K.TNo ratings yet

- OmronDocument350 pagesOmronAdi kurniantoNo ratings yet

- GLR100 - GLR100I: Manuale D'Uso Technical ManualDocument12 pagesGLR100 - GLR100I: Manuale D'Uso Technical ManualAHATNo ratings yet

- CP2 300 User ManualDocument10 pagesCP2 300 User ManualLương Quốc ThanhNo ratings yet

- 03 - Third Party IntegrationDocument3 pages03 - Third Party IntegrationMuthumari KNo ratings yet

- 29010078A v1r6 Vector G2-G2B Installation Operation Manual AddendumDocument32 pages29010078A v1r6 Vector G2-G2B Installation Operation Manual Addendumlos hermanos ValiNo ratings yet

- 10P 2L8M D5 V3 Product SpecificationsDocument6 pages10P 2L8M D5 V3 Product SpecificationsAnkur PrasadNo ratings yet

- Manual Corto Modulo GMS 9000Document6 pagesManual Corto Modulo GMS 9000Johana GomiitaNo ratings yet

- Sim900 TTL GSM Modem OpnDocument21 pagesSim900 TTL GSM Modem OpnMohammad AliNo ratings yet

- Wavecom Modem KitDocument4 pagesWavecom Modem KitDeyaaAmayrehNo ratings yet

- NanoStation M Loco M QSGDocument24 pagesNanoStation M Loco M QSGwilson juniorNo ratings yet

- High-Power 2X2 Mimo Airmax Tdma Station: Models: Nsm2/Nsm3/Nsm365/ Nsm5/Locom2/Locom5Document24 pagesHigh-Power 2X2 Mimo Airmax Tdma Station: Models: Nsm2/Nsm3/Nsm365/ Nsm5/Locom2/Locom5Kris MilandoNo ratings yet

- Siemens S7 300 MPIDocument12 pagesSiemens S7 300 MPIbakri fattalNo ratings yet

- TL200 User ManualDocument11 pagesTL200 User ManualJulio LeijaNo ratings yet

- 2021 GDT CatalogDocument23 pages2021 GDT CatalogAdrian MartínezNo ratings yet

- Bluetooth Module DatasheetDocument5 pagesBluetooth Module Datasheetjamesgreen1010% (1)

- Installation Instruction For Smart Anti-Rejection Box: Model: SAR-100Document47 pagesInstallation Instruction For Smart Anti-Rejection Box: Model: SAR-100StipeNo ratings yet

- DZ123Document8 pagesDZ123Frank WestmeyerNo ratings yet

- Sdonglea-03 Quick Guide (4G) : Communication ScenarioDocument1 pageSdonglea-03 Quick Guide (4G) : Communication ScenarioSAEL SOLARNo ratings yet

- 6gk6021-0as23-3fc0-Z A03+b03+c01+d01+e01+f00+g01+h00+j00+k00Document2 pages6gk6021-0as23-3fc0-Z A03+b03+c01+d01+e01+f00+g01+h00+j00+k00Ivan JeremicNo ratings yet

- Comba 9122Document4 pagesComba 9122Pablo BarbozaNo ratings yet

- User's Manual: Smart IDUDocument20 pagesUser's Manual: Smart IDUJose De PinaNo ratings yet

- Easyio FG 20Document24 pagesEasyio FG 20Syed Mohammad NaveedNo ratings yet

- S7810M Modbus Module Product DataDocument20 pagesS7810M Modbus Module Product DataAnonymous zdCUbW8HfNo ratings yet

- Color Monitor: Service ManualDocument34 pagesColor Monitor: Service ManualCristian LeizzaNo ratings yet

- QSG RUTX11aDocument6 pagesQSG RUTX11aMarekKowalskiNo ratings yet

- RV3-65D-R4-V2: General SpecificationsDocument5 pagesRV3-65D-R4-V2: General SpecificationsMario Alvarez GarciaNo ratings yet

- Sungrow Blue'log Driver: Description of FunctionsDocument3 pagesSungrow Blue'log Driver: Description of FunctionscanNo ratings yet

- Modbus RS485 RTU Communication Protocol of PV Grid-Connected String Inverters SUNGROWDocument22 pagesModbus RS485 RTU Communication Protocol of PV Grid-Connected String Inverters SUNGROWcanNo ratings yet

- 1416217428S3 D000030718 - C - en - ZMD402xT Techincal DataDocument6 pages1416217428S3 D000030718 - C - en - ZMD402xT Techincal DatacanNo ratings yet

- ReadMe IEC101 Development BundleDocument2 pagesReadMe IEC101 Development BundlecanNo ratings yet

- DS SG110CX Datasheet V14 en PDFDocument2 pagesDS SG110CX Datasheet V14 en PDFcanNo ratings yet

- Multi-Protocol Substation Demonstration: DNP3 Key Manager DNP3 ForgeDocument2 pagesMulti-Protocol Substation Demonstration: DNP3 Key Manager DNP3 ForgecanNo ratings yet

- Ba Tim1531 76Document168 pagesBa Tim1531 76canNo ratings yet

- Retrofitting of Denford TRIAC CNC Milling MachineDocument25 pagesRetrofitting of Denford TRIAC CNC Milling MachineDivyanshNo ratings yet

- REPUESTO LTM230HL07-SamsungDocument35 pagesREPUESTO LTM230HL07-SamsungElias Morales100% (1)

- Synchronous Optical Network: Sonet Standard For Synchronous Data Transmission On Optical MediaDocument19 pagesSynchronous Optical Network: Sonet Standard For Synchronous Data Transmission On Optical Mediamohammed draeyNo ratings yet

- MCQDocument51 pagesMCQWaqas AslamNo ratings yet

- Laptop Price Prediction Using Machine Learning (Abstract)Document3 pagesLaptop Price Prediction Using Machine Learning (Abstract)Vikas Bankar0% (1)

- Noise Reduction in Images Using AutoencodersDocument7 pagesNoise Reduction in Images Using AutoencodersIJRASETPublicationsNo ratings yet

- 200series Console ManualDocument59 pages200series Console ManualcharleschyipNo ratings yet

- Enterprise Resource Planning: The Rising: Organizational Value SystemsDocument6 pagesEnterprise Resource Planning: The Rising: Organizational Value SystemsSudhaNo ratings yet

- 100 Page Python Intro v1p0Document114 pages100 Page Python Intro v1p0ArunghishNo ratings yet

- Kyocera FS-C8520MFP ManualDocument387 pagesKyocera FS-C8520MFP ManualJuan R Martinez100% (2)

- E BillingDocument10 pagesE BillingGokul KrishnanNo ratings yet

- Loto ProcedureDocument3 pagesLoto Procedurepatrick ruwonaNo ratings yet

- Navigational PaperDocument25 pagesNavigational PaperDEVENDRA KISHORENo ratings yet

- Garage Electical Plan Smoke Alarm Notes:: WH AC Bedroom 1Document1 pageGarage Electical Plan Smoke Alarm Notes:: WH AC Bedroom 1IamJace C.No ratings yet

- Uploading.comDocument7 pagesUploading.comfabristancoNo ratings yet

- BBA Business Information System Module 3 MISDocument23 pagesBBA Business Information System Module 3 MISPriya SinghNo ratings yet

- Infineon XDPS2201 DataSheet v01 - 10 ENDocument75 pagesInfineon XDPS2201 DataSheet v01 - 10 EN偉誠曾No ratings yet

- RDPENDocument2 pagesRDPENVodeNo ratings yet

- Botswana Parliament Ict Master PlanDocument88 pagesBotswana Parliament Ict Master Planabey.mulugetaNo ratings yet

- Zafar-Ali RESUMEDocument1 pageZafar-Ali RESUMEWajid AliNo ratings yet

- NSR Neb-2000c Eb212175Document1 pageNSR Neb-2000c Eb212175Sooraj SudhakarNo ratings yet

- 09 Req480 06 Define SystemDocument32 pages09 Req480 06 Define SystemjoycmercadoNo ratings yet

- Bapuji Institute of Engineering and Technology: Topic:-Artificial IntelligenceDocument12 pagesBapuji Institute of Engineering and Technology: Topic:-Artificial IntelligenceUmeshNo ratings yet