Professional Documents

Culture Documents

Instrument Cable Specification

Uploaded by

Hassan Ejaz0 ratings0% found this document useful (0 votes)

11 views1 pagespecifications

Original Title

instrument cable specification

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentspecifications

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

11 views1 pageInstrument Cable Specification

Uploaded by

Hassan Ejazspecifications

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 1

JOB NO. 0.0800

GENERAL SPECIFICATION FOR INSTRUMENTATION JGC DOC. NO. §-000-1379-001

SHEET 30 OF 36

3.10.2 Selection

3.10.3

3.10.4

3.10.5

ay

@

@)

Safety relief valve capacity shall usually be determined on the basis of a superimposed

back pressure at the value no greater than

«10% of the valve set pressure for a conventional (non-balanced) :ype valve or,

«30% of the valve set pressure for a balance bellows type valve.

also, built-up back pressure up to 50% of the valve set pressure is allowed for a

balance bellows type valve.

Thermal relief valve shall be provided for liquid nes that can be blocked on and the

resultant increase in hydraulic pressure can occur due to heat inlet from external

sources such zs ambient temperature,

Sizing.

Q

The sizing of safety relief valves shall be in accordance with API-RP 520 far liquid

service and ASME Section VIII for gas service.

Size for thermal relief valves where the required flow capacity is not given shall be

aa" x 1"

Materials and Construction

w

Q

@Q)

Safety relief valves shall be of carbon steel with stainless steel disc and guides, as a

minimum.

Spring shall be carbon steel with rust proofing, unless the service requires other

materials.

‘The design of pressure parts shall be based on the allowable stress of ANSI or

equivalent.

Bolting shall conform to ASTM specitication A193 Grade B7 for bonnet studs and

A194 Grade 2H for bonnet studs nuts or equal

Accessories

()__ Plain lifting levers shall be furnished for all safety valves in air or steam services. No

Q

lifting levers are required for process valves, unless otherwise specified.

‘Test gags are required for safety relief valves, when specified on each data sheet.

‘Manufacturer's standard screwed caps shall be furnished.

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- UCH Compression Project Instrument Installation SpecificationDocument29 pagesUCH Compression Project Instrument Installation SpecificationHassan Ejaz100% (1)

- UCH Compression Project Instrumentation SpecificationDocument46 pagesUCH Compression Project Instrumentation SpecificationHassan Ejaz100% (1)

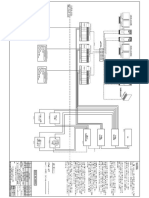

- 0221-IMF-6000-0 (Control System Architecture)Document1 page0221-IMF-6000-0 (Control System Architecture)Hassan Ejaz100% (1)

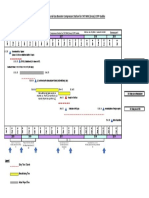

- 4985-ILT-6390-5 (Instrument Junction Box Location and Cable Layout)Document1 page4985-ILT-6390-5 (Instrument Junction Box Location and Cable Layout)Hassan EjazNo ratings yet

- Title Page Vol IID InstrumentationDocument1 pageTitle Page Vol IID InstrumentationHassan EjazNo ratings yet

- 0221-LT-6000-0 (Instrument List)Document19 pages0221-LT-6000-0 (Instrument List)Hassan EjazNo ratings yet

- Master Document Index (Instrument)Document1 pageMaster Document Index (Instrument)Hassan EjazNo ratings yet

- Assistant 25 G 2017Document3 pagesAssistant 25 G 2017Hassan EjazNo ratings yet

- ClarificationDocument1 pageClarificationHassan EjazNo ratings yet

- Current Affairs Quiz with AnswersDocument32 pagesCurrent Affairs Quiz with AnswersIkramNo ratings yet

- Operation Manual For Air CompressorDocument51 pagesOperation Manual For Air CompressorHassan Ejaz100% (1)

- Type MV Directional Spray Nozzles, Open Medium Velocity General DescriptionDocument14 pagesType MV Directional Spray Nozzles, Open Medium Velocity General Descriptionrusli bahtiarNo ratings yet

- GKDocument7 pagesGKHassan EjazNo ratings yet

- Design, Supply, Installation, Testing Commissioning of Natural Gas Booster Compressor Station For 747 MW (Gross) CCPP GudduDocument1 pageDesign, Supply, Installation, Testing Commissioning of Natural Gas Booster Compressor Station For 747 MW (Gross) CCPP GudduHassan EjazNo ratings yet

- GeneralDocument3 pagesGeneralHassan EjazNo ratings yet

- OtsDocument2 pagesOtsHassan EjazNo ratings yet

- Wapda Hydel ElectronicsDocument13 pagesWapda Hydel ElectronicsHassan EjazNo ratings yet

- Asj PPSC PaperDocument1 pageAsj PPSC PaperHassan EjazNo ratings yet

- Hazrat Usman Bin Affan Radhi Allah AnhuDocument7 pagesHazrat Usman Bin Affan Radhi Allah AnhuHassan EjazNo ratings yet

- OtsDocument2 pagesOtsHassan EjazNo ratings yet

- World Famous StreetsDocument12 pagesWorld Famous StreetsHassan EjazNo ratings yet

- Revenue Assistant Document SentDocument1 pageRevenue Assistant Document SentHassan EjazNo ratings yet

- Hazrat Usman Bin Affan Radhi Allah AnhuDocument7 pagesHazrat Usman Bin Affan Radhi Allah AnhuHassan EjazNo ratings yet

- 134-2 calibration procedureDocument4 pages134-2 calibration procedureHassan EjazNo ratings yet

- My NotesDocument8 pagesMy NotesHassan EjazNo ratings yet

- Migrate To Aus and Canada PDFDocument1 pageMigrate To Aus and Canada PDFHassan EjazNo ratings yet

- Time Table - Spring 2012 Updated 01-02-12Document2 pagesTime Table - Spring 2012 Updated 01-02-12Hassan EjazNo ratings yet

- Kepco KPSDocument1 pageKepco KPSHassan EjazNo ratings yet

- Job AdvertisementDocument1 pageJob AdvertisementHassan EjazNo ratings yet