Professional Documents

Culture Documents

Why Taguchi Method Is Used

Why Taguchi Method Is Used

Uploaded by

Prashanth GurramOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Why Taguchi Method Is Used

Why Taguchi Method Is Used

Uploaded by

Prashanth GurramCopyright:

Available Formats

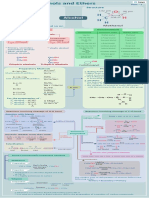

Why Taguchi method is used?

Taguchi method is robust design techniques widely used in industries as it can improve the processing quality, reduce the

number of experiments, minimize the processing variation and maintenance and promote the quality stability.

What is the Taguchi method?

The Taguchi method optimizes design parameters to minimize variation before optimizing design to hit mean target values

for output parameters. The Taguchi method uses special orthogonal arrays to study all the design factors with minimum of

experiments.

thermoplastic

1. denoting substances (especially synthetic resins) that become plastic on heating and harden on cooling, and are able to repeat these

processes.

Thermoplastics are polymers which soften when they are heated and solidify as they cool.

Polyethylene terephthalate glycol material (PETG)

ASTM D790 is a testing method to determine the flexural (bending) properties of reinforced and unreinforced plastics,

high-modulus composites, and electrical insulation materials.

the American Society for Testing and Materials(ASTM)

Additive manufacturing

3D printing (sometimes referred to as Additive Manufacturing (AM)) is the computer-controlled sequential layering of

materials to create three-dimensional shapes. It is particularly useful for prototyping and for the manufacture of

geometrically complex

durability

1. the ability to withstand wear, pressure, or damage.

Formability

Formability is the ability of a given metal workpiece to undergo plastic deformation without being damaged.

STL= standard tessellation language file

CIM = computer integrated manufacturing

Ultem® (polyetherimide) is a semi-transparent high strength plastic material that can operate in high service temperature

environments. Ultem® is resistant to hot water and steam and can withstand repeated cycles in a steam autoclave. FDA

compliant grades of Ultem® are available.

Electronic UTE-10 machine Universal testing machine model 10

the three-point bending flexural test provides values for the modulus of elasticity in bending , flexural stress , flexural strain and the flexural

stress–strain response of the material. This test is performed on a universal testing machine (tensile testing machine or tensile tester) with a

three-point or four-point bend fixture.The main advantage of a three-point flexural test is the ease of the specimen preparation and testing.

However, this method has also some disadvantages: the results of the testing method are sensitive to specimen and loading geometry and strain

rate.

The Taguchi method is a statistical tool developed by Genier Taguchi (1940) a Japanese engineer, proposed a model for

experiment design. ... The Taguchi's orthogonal array L9 (3^4) is used in order to estimate the factors that influence the

performance criteria and also which factors are more important than others

Responsible to Ask TO signel to voice ratio and means

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Solução Exercícios Carey - Parte B PDFDocument260 pagesSolução Exercícios Carey - Parte B PDFFelipe Antunes CalilNo ratings yet

- Material Grade Comparison TableDocument6 pagesMaterial Grade Comparison TableGhazali Zuberi100% (3)

- Calender-Holidays 2024Document1 pageCalender-Holidays 2024Prashanth GurramNo ratings yet

- New and ImportantDocument10 pagesNew and ImportantPrashanth GurramNo ratings yet

- Sreenidhi Institute of Science and TechnologyDocument15 pagesSreenidhi Institute of Science and TechnologyPrashanth GurramNo ratings yet

- Submission For PublicationDocument6 pagesSubmission For PublicationPrashanth GurramNo ratings yet

- Project Report On Fabric AdhesiveDocument5 pagesProject Report On Fabric AdhesiveEIRI Board of Consultants and PublishersNo ratings yet

- Vol IV Spare Part IllustrationDocument6 pagesVol IV Spare Part IllustrationgiangNo ratings yet

- Constantes CríticasDocument30 pagesConstantes CríticaspaulaNo ratings yet

- A Review of Natural Fiber Composites PropertiesDocument65 pagesA Review of Natural Fiber Composites Propertieschatgpt51023No ratings yet

- AB Emflon PFRDocument2 pagesAB Emflon PFRsaulookNo ratings yet

- Boston Eaton Industrial Hose CatalogDocument152 pagesBoston Eaton Industrial Hose Catalogoguzhan turanNo ratings yet

- Central Lab D-53: Siddiqsons LimitedDocument2 pagesCentral Lab D-53: Siddiqsons LimitedTahir NizamNo ratings yet

- Principles of Microbial BiotechnologyDocument21 pagesPrinciples of Microbial BiotechnologyPS SuryaNo ratings yet

- Types of Dyeing ProcessesDocument5 pagesTypes of Dyeing ProcessesSyed Inamullah ShahNo ratings yet

- 04 - The - Logic - of - SynthesisDocument31 pages04 - The - Logic - of - SynthesisamelNo ratings yet

- Lecture 4 - 15 End Replication and Genetic Code - Transcription PDFDocument78 pagesLecture 4 - 15 End Replication and Genetic Code - Transcription PDFFafa MusNo ratings yet

- Phosphate EstersDocument2 pagesPhosphate EstersNikola TasićNo ratings yet

- Extraction OF Essential OIL Using Steam DistillationDocument39 pagesExtraction OF Essential OIL Using Steam Distillationmontiayman1No ratings yet

- Glycerol Propylene. Reaction Scheme: EpichlorohydrinDocument3 pagesGlycerol Propylene. Reaction Scheme: EpichlorohydrinMUHAMMED BAQA ANWER100% (1)

- Anaerobic Azo Dye ReductionDocument154 pagesAnaerobic Azo Dye ReductionrajdewaanNo ratings yet

- Introduction To Petroleum Petrochemical TechnologyDocument2 pagesIntroduction To Petroleum Petrochemical TechnologyrajachinthadaNo ratings yet

- General Rubber Compounds: By: Jim Ward, BRP ManufacturingDocument4 pagesGeneral Rubber Compounds: By: Jim Ward, BRP Manufacturing최승원No ratings yet

- Making Tie and DyeDocument3 pagesMaking Tie and DyeVera Wosu - ObiechefuNo ratings yet

- Alcohols Phenols and EthersDocument3 pagesAlcohols Phenols and EthersSubath KumarNo ratings yet

- Reverse Engineering Project ReportDocument5 pagesReverse Engineering Project Reportapi-352699138No ratings yet

- Cosmetic Hair Dyeing Agents: Yick-Vic Chemicals & Pharmaceuticals (HK) LTDDocument11 pagesCosmetic Hair Dyeing Agents: Yick-Vic Chemicals & Pharmaceuticals (HK) LTDolabi abdullahNo ratings yet

- Unit - 2 Theory of Dilute Solutions: NB M VDocument11 pagesUnit - 2 Theory of Dilute Solutions: NB M VPROJECT IEMNo ratings yet

- Chemistry Project: Synthesis and Property AnalysisDocument19 pagesChemistry Project: Synthesis and Property AnalysisUtkarsh PatelNo ratings yet

- History of PlasticDocument3 pagesHistory of PlasticVikneshwaran BalakrishnanNo ratings yet

- Carboxylic Acids - DerivativesDocument24 pagesCarboxylic Acids - DerivativesRit WickNo ratings yet

- DNA Translation J Muqaddas MukhtarDocument33 pagesDNA Translation J Muqaddas MukhtarSafia DurraniNo ratings yet

- RefrimasterplusDocument1 pageRefrimasterplusboldogguibor0202No ratings yet

- Synthesis of Nano Crystalline Zeolite Y From BentoniteDocument5 pagesSynthesis of Nano Crystalline Zeolite Y From BentonitegoaliefieldNo ratings yet