Professional Documents

Culture Documents

At Pro 33 Ind

At Pro 33 Ind

Uploaded by

Jorge Adalberto Lugo Quintero0 ratings0% found this document useful (0 votes)

4 views4 pagesOriginal Title

at pro 33 ind

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

4 views4 pagesAt Pro 33 Ind

At Pro 33 Ind

Uploaded by

Jorge Adalberto Lugo QuinteroCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 4

AT33 IND

ALL-TEST PRO®33 INDUSTRIAL

EASY TO USE INSTRUMENT WITH IMMEDIATE INFORMATION

ABOUT THE COMPLETE CONDITION OF YOUR STATOR,

ROTOR AND CONNECTIONS!

The AT33IND instrument is the PERFECT TOOL for trouble

shooting, inspection of incoming or stored motors before installation or

repair and shows the complete condition of the Stator Windings,

TOA EMR Cha ene keene ee

Copyright ALL-TEST Fro, LLC 2011 All Rights Reserved.

EASY AND QUICK TEST TO CHECK YOUR ELECTRIC MOTORS

This instrument presents an exciting break-through in off-line (de-energized) testing.

Within minutes the operator can get a complete picture of the condition of a motor without

having to stress-test the windings or use other more expensive or elaborate instruments,

which can be difficult to operate and analyze captured data with.

Connect BLUE clin,

NO NEED TO CARRY ALONG HARD TO READ USER MANUALS €o7eang,

ito FrameGHD

How to proceed is shown step by step on the screen and virtually

anybody who can read can do the testing and understand the results.

The unit can be used stand-alone or with software, which enables you to

see all the underlying data from the test. For accuracy see our specifications.

TWO TESTS IN ONE

The instrument can be used in two modes: Static and Dynamic. Both quickly

collect data in auto mode and there is no need to operate a lot of difficult to.

understand buttons.

Woynanic Test?

THE STATIC TEST gives you the inform:

in Stator or Rotor has occurred between pri

and the present test.

n whether any change

test (baseline)

No ast

It measures Resistance, Inductance, Impedance,

The fault indicator is not dependent on Rotor posi

‘apacitance and Phase Angle.

n.

a

Meg-ohm-test with 500 and 1000 V reading up to 999 Mohm is standard. >500

(Special test-voltage requirements available by request and special quote).

The Static test is compared to a base-line test that can be retrieved from

“Reference Value Static” records in the instrument, or from the optional software.

DYNAMIC TEST BY ROTATING SHAFT

oK The AT33IND Dynamic Test analyzes the results for you by showing Bad,

&80 [i Warning or OK for Resistance, Stator, Rotor and Contamination. Itis

Tee imation UE" ff developed for testing induction motors with squirrel cage rotor.

lation Nor

If the Static test needs to be further evaluated, or if no baseline is available

a Dynamic test should be done. The DYNAMIC TEST is done with the

rotor shaft disconnected to the machinery.

It measures in real time, during the manual rotation of the shaft, several

measurements. Any problem is easily recognized by even inexperienced

operators.

It also collects data used for a “signature” of the Stator and Rotor and these

signatures allow for a more in-depth evaluation by an experienced user and

supports data of other faults showing in the report.

Additionally, a “Test Value Dynamic” is automatically calculated which can

be compared to a “Reference Test Value Dynamic” using the optional

computer software. A deviation between tests indicate a change in condition

has occurred.

Copyright ALL-TEST Pro, LLC 2011 All Rights Reserved.

ACCURACY and EASY TESTING

‘The AT33 IND comes with high quality, special made

test-leads and 4 wire Kelvin Clips for very accurate data

collection. Please see specifications.

The lithium batteries supports more than 8 hours of continuous use.

A spare battery pack, which is easy and quick to install ble

with a special charger.

No need to carry along a manual when testing, all instructions are shown step-by-step on the

instrument's large screen. The result is then automatically shown on the screen as well.

By calling up a prior test of the same motor you can easily see if a change has occurred.

The AT33IND is made for safe operation and for harsh environments incorporating CE Certification

and a casing rated CAT Ill. The tester has a large memory storage capacity for reference and

test-data and can be used as a stand-alone tester without software.

If our software is used, the instrument quickly up-loads its test-data and the report can be

printed. The data can also be further analyzed by a technician and compared to prior data

of the same motor; or motor of the same model to create a history of any problems

and solutions.

WD hg

A

an

Pn es

ee el

Specifications AT33 IND

Test Frequencies

25, 50, 100, 200, 400, 800 Hz

Test Value Static / Reference Value Static

0.01 ~ 10000 #1%, (Dimensionless calculated value)

Test Value Dynamic / Reference Value Dynamic

0.01 ~ 10000 #2%, (Dimensionless calculated value)

Stator Test Dynamic

Repeatability +1%, (of measured data

and calculated deviations)

Rotor Test Dynamic

Repeatability +2%, (of measured data

and calculated deviations)

Resistance

0.01 - 999 0 +1%, Max Resolution: 0.01 mO

Relative Accuracy “Phase to Phase” + 0.1%

True 4-wire Kelvin measurement.

(Includes automatic compensation for

thermoelectric offset voltages)

Dissipation factor - DF (expressed as a percentage)

0- 100% measurement range

110% 40.5 (C = 10— 1000 nF)

10-30% #1.0

(This specification is based on battery operation and

USB not connected to PC)

(Measured dielectric phase angle displayed as @)

Capacitance (frame — stator)

22000 nF measurement range

10-1000 nF 43%, all other values 5%

(This specification is based on battery operation and

USB not connected to PC)

Insulation Resistance

0-999 MQ @1000v, 0~500Ma

@S00V 1-100 MO 43%,

all other values +5%

Enclosure

Material - Polycarbonate, UL94-V2

Safety

According to IEC 61010-1 cat.ill 1000V'

Approvals

cE

Keyboard

Sealed tactile touch, XL size keys

Tean see inside

cans

Connections

3 x Motor input/output - Lemo/Redel

e

1P series professional push-pull

nm nse

connectors 4-pole High Voltage output -

4mm safety jack PC communication - USB type B

connector

Charger input - 2.6mm diameter center pin DC-jack,

Universal input type 85-260VAC, output SVDC @ 1.7

Display

Graphic LCD, monochrome 128 x 64 pixels (3.1”)

Viewing Area=69 x 36.5mm, white LED backlight.

Batteries

2x LION cells with > 2100 mAH capacity

Temperature range storage

-20°C to #60 °C (-4 °F to +140 °F)

Temperature range operating

“10 °C to +50 °C (+14 °F to +122 °F)

Humidity

0-80% relative humidity, non-condensing

Ec

+ EN61000-6-4 (Emission)

+ EN61000-6-2 (Susceptibility)

Instrument Specifications

Size: 126 x 218 x 51 mm (3.2"x8.6"x2") (WxLxH)

(basic enclosure size without minor protrusions)

Weight: 0.7 kg (1.55 Ib)

Shipping Specifications

Gross Size: 45.7x40.6x15.2 cm (18°x16"x6") (WxLxH)

Gross Weight: 5.0 kg ( Slb )

AT33 IND Comes With

3x Test Leads with custom Kelvin Clips

1x Test Lead with 4mm safety plug and MC “Dolphin”

lip

Charging adapter,

Hard Case

Accessories NOT Included

Windows based software for test reporting and

trending (Windows XP/7 compatible).

USB Cable 1m

‘Soft Carrying Pouch for instrument and test leads

Patent Pending

ALL-TEST Pro, LLC Represented by

P.O. Box 1139

(Old Saybrook, CT 06475

Tel 860-399-4222

Fax 860-399-3180

Email sales@alltestpro.com

Web — wwwwaltestpro.com

‘AT39-0811 _Speciicaons are subject to change without note, Copyright ALL-TEST Pro, LLG 2011 AIRghts Reserved. August 2011-2

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- DW402 - Pulidor DewaltDocument3 pagesDW402 - Pulidor DewaltJorge Adalberto Lugo QuinteroNo ratings yet

- Operating, Maintenance & Parts Manual: Rated LoadsDocument29 pagesOperating, Maintenance & Parts Manual: Rated LoadsJorge Adalberto Lugo QuinteroNo ratings yet

- Varistor Datasheet LittelfuseDocument8 pagesVaristor Datasheet LittelfuseJorge Adalberto Lugo QuinteroNo ratings yet

- Varistores Uxell DatasheetDocument4 pagesVaristores Uxell DatasheetJorge Adalberto Lugo QuinteroNo ratings yet

- Revolvedora Hobart L-800Document88 pagesRevolvedora Hobart L-800Jorge Adalberto Lugo QuinteroNo ratings yet

- Adonai Li Salmo 118..6Document1 pageAdonai Li Salmo 118..6Jorge Adalberto Lugo QuinteroNo ratings yet

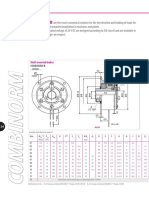

- Frenos Keb brakesCOMBINORM - B - enDocument2 pagesFrenos Keb brakesCOMBINORM - B - enJorge Adalberto Lugo QuinteroNo ratings yet

- The Ancient Hebrew Lexicon of The BibleDocument616 pagesThe Ancient Hebrew Lexicon of The BibleA. Herald100% (5)