0% found this document useful (0 votes)

1K views5 pagesManagement Trainee Job Overview

The document describes a management trainee job and training program. Management trainees complete rotations in various departments to gain operational knowledge and skills needed to become future executives. They assist department heads with tasks and projects, and receive training over the course of a week in areas like production, quality control, planning and process engineering. Trainees are evaluated periodically and require a bachelor's degree plus technical and soft skills. The 12-month training schedule provides two months of experience in each operational function.

Uploaded by

Sangeeth BhoopaalanCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

1K views5 pagesManagement Trainee Job Overview

The document describes a management trainee job and training program. Management trainees complete rotations in various departments to gain operational knowledge and skills needed to become future executives. They assist department heads with tasks and projects, and receive training over the course of a week in areas like production, quality control, planning and process engineering. Trainees are evaluated periodically and require a bachelor's degree plus technical and soft skills. The 12-month training schedule provides two months of experience in each operational function.

Uploaded by

Sangeeth BhoopaalanCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd

- Management Trainee Job Description

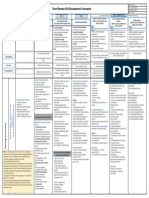

- Training Schedule

- Operations Management Trainee